Abstract

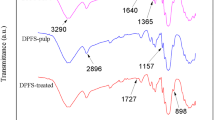

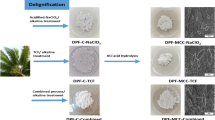

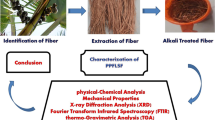

The aim of present study is to extract microcrystalline cellulose (MCC) from fruit bunch branches fibers of Algerian date palm trees (phoenix dactylifera L) as biofiber for reinforcing green composite and thus replace synthetic fibers in various applications. The extraction of MCC from date palm fibers passed via serial chemical treatments, including alkali, bleaching and acid hydrolysis process. Subsequently, several analyses were implemented to determine the characteristics of each sample prepared at different stages of treatment. Fourier transform infrared spectroscopy (FTIR) analysis revealed the effectiveness in removing substantial amorphous components of lignin and hemicellulose from date palm fibers. Altered and irregular shaped morphology of microfibrils with slightly rougher surface was observed for microcrystalline date palm fibers (MCC-DP) through scanning electron microscope (SEM) examination. Furthermore, X-ray diffraction (XRD) presents the increasing of the crystallinity from 55% in raw date palm (R-DP) to 76.26% in MCC-DP. Also, the results of TGA and DSC indicate the MCC-DP has greater thermal stability than that of R-DP, A-DP and B-DP fibers. These results demonstrate the feasibility of using date palm waste (fruit bunch branches fibers) to extract a good reinforcing material (MCC) with high properties and low cost, which qualifies its use in composite materials. Also, it can be transformed into nano-scale for isolating nanocrystalline cellulose with the aim of using it, in the future to produce ecofriendly bionanocomposites in different fields of applications, biomedical, pharmaceutical and packaging.

Similar content being viewed by others

References

Amroune S, Bezazi A, Belaadi A, Zhu C, Scarpa F, Rahatekar S, Imad A (2015) Appl Sci Manuf 71:95–106

Abdal-Hay A, Suardana NPG, Choi KS, Lim JK (2012) Int J Precis Eng Manuf 13:1199–1206

Alothman OY, Alrashed MM, Anis A, Naveen J, Jawaid M (2020) Polymers 12:1–18

S Amroune S, Bezazi A, Dufresne A, Scarpa F, Imad A (2019) J Nat Fibers 0478: 1–18

Alotaibi MD, Alshammari BA, Saba N, Alothman OY, Sanjay MR, Almutairi Z, Jawaid M (2019) Int J Biol Macromol 135:69–76

AL-Oqla F M, Alothman O Y, Jawaid M, Sapuan S M, Es-Saheb M H, (2014) In Biomass and bioenergy. Springer, Cham, pp 1–25

Bolio-López GI, Cadenas-Madrigal G, Veleva L, Falconi R, de la Cruz-Burelo P, Hernández-Villegas MM, Pelayo-Muñoz L (2015) Int J Innov Sci Eng Technol 2:977–981

Kian LK, Jawaid M, Ariffin H, Alothman OY (2017) Int J Biol Macromol 103:931–940

Fardioui M, Stambouli A, Gueddira T, Dahrouch A, Bouhfid R (2016) J Polym Environ 24:356–362

Kale RD, Bansal PS, Gorade VG (2018) J Polym Environ 26:355–364

Haafiz MM, Eichhorn SJ, Hassan A, Jawaid M (2013) Carbohydr Polym 93:628–634

Rasheed M, Jawaid M, Karim Z, Abdullah LC (2020) Molecules 25:2824

Tarchoun AF, Trache D, Klapötke TM, Derradji M, Bessa W (2019) Cellulose 26(2019):13–14

Hussin MH, Pohan NA, Garba ZN, Kassim MJ, Rahim AA, Brosse N, Haafiz MM (2016) Int J Biol Macromol 92:11–19

Shanmugam N, Nagarkar RD, Kurhade M (2015) Indian J Nat Prod Resou 6:42–50

Prosvirnikov DB, Safin RG, Zakirov SR (2018) Solid State Phenom 284:773–778

Tarchoun AF, Trache D, Klapötke TM (2019) Int J Biol Macromol 138:837–845

Collazo-Bigliardi S, Ortega-Toro R, Boix AC (2018) Carbohydr Polym 191:205–215

Peng BL, Dhar N, Liu HL, Tam KC (2011) Can J Chem Eng 89:1191–1206

Abdullah N A, Sainorudin M H, Asim N, Mohammad M, Abd Kadir N H, Yaakob Z (2020) IOP Conf Ser Mater Sci Eng: 739

Hermawan D, Lai TK, Jafarzadeh S, Gopakumar DA, Hasan M, Owolabi FT, Khalil HA (2019) Bio Resources 14:3389–3410

Alotabi MD, Alshammari BA, Saba N, Alothman OY, Kian LK, Khan A, Jawaid M (2020) J Polym Environ 28:1766–1775

Chen H, Yu Y, Zhong T, Wu Y, Li Y, Wu Z, Fei B (2017) Cellulose 24:333–347

Zhou C, Wu Q (2012) Synth Charact Appl :103–120

Xiang LY, Mohammed MAP, Baharuddin AS (2016) Carbohydr Polym 148:11–20

Rosa SM, Rehman N, de Miranda MIG, Nachtigall SM, Bica CI (2012) Carbohydr Polym 87:1131–1138

Abu-Thabit NY, Judeh AA, Hakeem AS, Ul-Hamid A, Umar Y, Ahmad A (2020) Int J Biol Macromol 155:730–739

Owolabi AF, Haafiz MM, Hossain MS, Hussin MH, Fazita MN (2017) Int J Biol Macromol 95:1228–1234

Trache D, Donnot A, Khimeche K, Benelmir R, Brosse N (2014) Carbohydr Polym 104:223–230

Kian LK, Saba N, Jawaid M, Fouad H (2020) Int J Biol Macromol 156:347–353

Trache D, Hussin MH, Chuin CTH, Sabar S, Fazita MN, Taiwo OF, Haafiz MM (2016) Int J Biol Macromol 93:789–804

Jahan MS, Saeed A, He Z, Ni Y (2011) Cellulose 18:451–459

Ferrer A, Salas C, Rojas OJ (2016) Ind Crops Prod 84:337–343

Merci A, Urbano A, Grossmann MVE, Tischer CA, Mali S (2015) Food Res Int 73:38–43

Kumar A, Negi YS, Choudhary V, Bhardwaj NK (2014) J Mater Phys Chem 2:1–8

Trache D, Hussin MH, Haafiz MM, Thakur VK (2017) Nanoscale 9:1763–1786

Kim U J, Eom S H, Wada M (2010) olym Degrad Stab 95 :778–781

Sonia A, Dasan KP (2013) Carbohydr Polym 92:668–674

Acknowledgements

This work supported by Mesrs of Algeria, under the research project, PRFU (A16N01UN350120180002), the author would like to acknowledges, Biocomposite Technology Laboratory, INTROP, Universiti Putra Malaysia, for providing the necessary facilities and encouragement for the accomplishment of this research.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hachaichi, A., Kouini, B., Kian, L.K. et al. Extraction and Characterization of Microcrystalline Cellulose from Date Palm Fibers using Successive Chemical Treatments. J Polym Environ 29, 1990–1999 (2021). https://doi.org/10.1007/s10924-020-02012-2

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-020-02012-2