Abstract

In this study cassava starch modified by ozone technology and cellulose nanofibres were used to produce films. These nanocomposites were produced by casting technique using non-modified and ozonated cassava starches, glycerol and, water reinforced with cellulose nanofibres (NCF) at 1%, 2%, and 5%. Films were characterized in terms of mechanical, barrier and functional properties, morphology, opacity and the sealing ability. In general, ozonated cassava films result in increased mechanical properties, water vapour permeability, and hydrophilicity. The addition of cellulose nanofibres, in certain conditions, improved these properties due to the NCF dispersion in the polymeric matrix. However, the formation of agglomerates in higher concentrations (2% and 5%) was visible by SEM images. In specific, the addition of 1% of NCF to the 60 min ozonated film increased the Tensile Strength and the Young Modulus in ~ 117% and ~ 137%, respectively, and decreased the water vapour permeability in ~ 47%, in comparison to the non-modified film without NCF. In conclusion, the addition of NCF to ozonated cassava films improved their properties aiming specific application showing to be an interesting alternative for packaging industries in different areas.

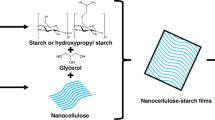

Graphic Abstract

Similar content being viewed by others

Abbreviations

- A :

-

Area (m2)

- E :

-

Young’s Modulus (MPa)

- m :

-

Mass (g)

- NCF:

-

Cellulose nanofibres

- p :

-

Pressure (kPa)

- t :

-

Time (h)

- TS :

-

Tensile strength (MPa)

- WVP :

-

Water vapour permeability (g mm/m2 day kPa)

- x :

-

Thickness (µm or mm)

- Y:

-

Opacity (%)

- b :

-

Black standard

- w:

-

White standard

- Δ:

-

Delta

- ε:

-

Strain (%)

References

Khan A, Huq T, Khan RA, Riedl B, Lacroix M (2014) Nanocellulose-based composites and bioactive agents for food packaging. Crit Rev Food Sci Nutr 54(2):163–174. https://doi.org/10.1080/10408398.2011.578765

Röper H (2002) Renewable raw materials in Europe—industrial utilisation of starch and sugar. Starch/Staerke 54(3–4):89

La Fuente CIA, de Souza AT, Tadini CC, Augusto PED (2019) Ozonation of cassava starch to produce biodegradable films. Int J Biol Macromol 141:713–720. https://doi.org/10.1016/j.ijbiomac.2019.09.028

La Fuente CIA, Castanha N, Maniglia BC, Tadini CC, Augusto PED (2020) Biodegradable films produced from ozone-modified potato starch. J Packag Technol Resdoi. https://doi.org/10.1007/s41783-020-00082-0

Carvalho BKCC, Pereira PHF, Cioffi MOH (2017) Effect of acid hydrolysis conditions on the degradation properties of cellulose from Imperata brasiliensis fibers. Procedia Eng. https://doi.org/10.1016/j.proeng.2017.07.035

Ghanbari A, Tabarsa T, Ashori A, Shakeri A, Mashkour M (2018) Preparation and characterization of thermoplastic starch and cellulose nanofibers as green nanocomposites: extrusion processing. Int J Biol Macromol 112:442–447. https://doi.org/10.1016/j.ijbiomac.2018.02.007

Mok CF, Ching YC, Muhamad F, Abu Osman NA, Singh R (2017) Poly(vinyl alcohol)-α-chitin composites reinforced by oil palm empty fruit bunch fiber-derived nanocellulose. Int J Polym Anal Charact 22(4):294–304. https://doi.org/10.1080/1023666X.2017.1288345

Siró I, Plackett D (2010) Microfibrillated cellulose and new nanocomposite materials: a review. Cellulose 17(3):459–494. https://doi.org/10.1007/s10570-010-9405-y

Hietala M, Mathew AP, Oksman K (2012) Bionanocomposites of thermoplastic starch and cellulose nanofibers manufactured using twin-screw extrusion. Eur Polym J 49(4):950–956. https://doi.org/10.1016/j.eurpolymj.2012.10.016

Da Silva JBA et al (2015) Effect of source and interaction with nanocellulose cassava starch, glycerol and the properties of films bionanocomposites. Mater Today Proc 2(1):200–207. https://doi.org/10.1016/j.matpr.2015.04.022

Da Silva JBA, Pereira FV, Druzian JI (2012) Cassava starch-based films plasticized with sucrose and inverted sugar and reinforced with cellulose nanocrystals. J Food Sci 77(6):14–19. https://doi.org/10.1111/j.1750-3841.2012.02710.x

Kampangkaew S, Thongpin C, Santawtee O (2014) The synthesis of cellulose nanofibers from Sesbania Javanica for filler in thermoplastic starch. Energy Procedia 56:318–325. https://doi.org/10.1016/j.egypro.2014.07.163

Meneguin AB, Ferreira Cury BS, dos Santos AM, Franco DF, Barud HS, Da Silva Filho EC (2017) Resistant starch/pectin free-standing films reinforced with nanocellulose intended for colonic methotrexate release. Carbohydr Polym 157:1013–1023. https://doi.org/10.1016/j.carbpol.2016.10.062

Yang Z, Peng H, Wang W, Liu T (2010) Crystallization behavior of poly(ε-caprolactone)/layered double hydroxide nanocomposites. J Appl Polym Sci 116(5):2658–2667. https://doi.org/10.1002/app

Lima DC, Castanha N, Maniglia BC, Matta MD Jr., La Fuente CIA, Augusto PED (2020) Ozone processing of cassava starch. Ozone Sci Eng 9512:1–18. https://doi.org/10.1080/01919512.2020.1756218

Llanos JHR, Tadini CC (2017) Preparation and characterization of bio-nanocomposite films based on cassava starch or chitosan, reinforced with montmorillonite or bamboo nanofibers. Int J Biol Macromol 107:371–382. https://doi.org/10.1016/j.ijbiomac.2017.09.001

ASTM International 2012 ASTM Standard D 882-12 Standard test method for tensile properties of thin plastic sheeting. ASTM Stand 1–11

ASTM (2013) StandardTest methods for water vapor transmission of materials E96/E96M. Annu B ASTM Stand. https://doi.org/10.1520/E0096

ASTM International 2013 ASTM D7334-08: Standard practice for surface wettability of coatings, substrates and pigments by advancing contact angle measurement: active standard. Am Soc Test Mater 8:1–3. https://doi.org/10.1520/D7334-08R13.2

Savaderkar NR, Mhaske ST (2012) Synthesis of nano cellulose fibers and effect on thermoplastics starch based films. Carbohydr Polym 89:145–151. https://doi.org/10.1016/j.carbpol.2012.02.063

Börjesson M, and Westman G (2016) Crystalline nanocellulose—preparation, modification, and properties chap. 7

Robles E, Labidi J, Halász K, Csóka L (2017) Key issues in reinforcement involving nanocellulose. Cell Nanofibre Compos Prod Prop Appl. https://doi.org/10.1016/B978-0-08-100957-4.00018-8

Souza AC, Goto GEO, Mainardi JA, Coelho ACV, Tadini CC (2013) Cassava starch composite films incorporated with cinnamon essential oil: antimicrobial activity, microstructure, mechanical and barrier properties. LWT-Food Sci Technol 54(2):346–352. https://doi.org/10.1016/j.lwt.2013.06.017

Nair SS, Zhu J, Deng Y, Ragauskas AR (2014) High performance green barriers based on nanocellulose. Sustain Chem Process 2(1):1–7. https://doi.org/10.1186/s40508-014-0023-0

Slavutsky AM, Bertuzzi M (2014) Water barrier properties of starch films reinforced with cellulose nanocrystals obtained from sugarcane bagasse. Carbohydr Polym 110:53–61. https://doi.org/10.1016/j.carbpol.2014.03.049

Chen Y, Changhua L, Chang PR, Cao X, Anderson D (2009) Bionanocomposites based on pea starch and cellulose nanowhiskers hydrolyzed from pea hull fibre: effect of hydrolysis time. Carbohydr Polym 76:607–615. https://doi.org/10.1016/j.carbpol.2008.11.030

Li Y et al (2015) Nanocellulose as green dispersantfor two-dimensional energy materials. Nano Energy 13:346–354. https://doi.org/10.1016/j.nanoen.2015.02.015

Phanthong S, Reubroycharoen P, Kongparakul P, Samart C, Wang Z, Hao X (2018) Fabrication and evaluation of nanocellulose sponge for oil/water separation. Carbohydr Polym. https://doi.org/10.1016/j.carbpol.2018.02.066

Visakh PM, Thomas S, Oksman K, Mathew AP (2011) Crosslinked natural rubber nanocomposites reinforced with cellulose whiskers isolated from bamboo waste: processing and mechanical/thermal properties. Composites Part A 43(4):735–741. https://doi.org/10.1016/j.compositesa.2011.12.015

Shayan E, Fathi M, Kadiva M (2019) Production and characterization of chitosan-gelatin nanofibers by nozzle-less electrospinning and their application to enhance edible film’s properties. Food Packag Shelf Life 22:1100387. https://doi.org/10.1016/j.fpsl.2019.100387

Santacruz S, Rivadeneira C, Castro M (2015) Edible films based on starch and chitosan. Effect of starch source andconcentration, plasticizer, surfactant’s hydrophobic tail andmechanical treatment. Food Hydrocoll 49:89–94. https://doi.org/10.1016/j.foodhyd.2015.03.019

Khoo RZ, Ismal H, Chow WS (2016) Thermal and morphological properties of poly (lactic acid)/nanocellulose nanocomposites. Procedia Chem. https://doi.org/10.1016/j.proche.2016.03.086

Trifol J, Plackett D, Sillard C, Szabo P, Bras J, Daugaard AE (2016) Hybrid poly(lactic acid)/nanocellulose/nanoclay composites with synergistically enhanced barrier properties and improved thermomechanical resistance. Polym Int 65(8):988–995. https://doi.org/10.1002/pi.5154

Funding

The authors are grateful to the National Council for Scientific and Technological Development (CNPq, Brazil) the productivity grants of Tadini (306414/2017-1) and Augusto (306557/2017-7), and for funding the project of La Fuente (429043/2018-0). Moreover, the São Paulo Research Foundation (FAPESP, Brazil) for the B.Sc. scholarship of Souza (2018/24291-8); and for the post-doctoral fellowship of La Fuente (2017/05307-8).

Author information

Authors and Affiliations

Contributions

Conceptualization: CIALF, PEDA; Methodology: CIALF, ATS; Validation: CIALF; ATS; Formal analysis and investigation: CIALF, ATS; Resources: CCT, PEDA; Data Curation and writing—original draft preparation: CIALF; Writing—review and editing: PEDA, CCT; Visualization: CIALF; ATS; Supervision: CCT, PEDA; Project administration: CIALF, PEDA; Funding acquisition: CIALF, CCT, PEDA.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

A patent related with this work was filed (BR1020190112166).

Rights and permissions

About this article

Cite this article

La Fuente, C.I.A., de Souza, A.T., Tadini, C.C. et al. A New Ozonated Cassava Film with the Addition of Cellulose Nanofibres: Production and Characterization of Mechanical, Barrier and Functional Properties. J Polym Environ 29, 1908–1920 (2021). https://doi.org/10.1007/s10924-020-02013-1

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-020-02013-1