Abstract

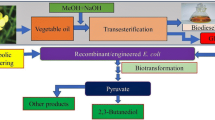

In the pursuit of sustainable development, there is a rapid increase in the generation of biodiesel, which eventually results in the synthesis of glycerol as a major by-product. The surplus amount of glycerol from biodiesel industries is one of the rising environmental concerns. Alternatively, glycerol can serve as an attractive raw material for synthesizing value-added products that offer simultaneous management and valorization of this waste. 1,3-propanediol is a vital value-added material having extensive applications in the industrial domain. Microbial biosynthesis of 1,3-propanediol from glycerol has proven to be an economic and eco-friendly approach. However, biosynthesis of this bio-product is often affected by some environmental stresses, such as glycerol and 1,3-propanediol concentrations, accumulation of 3-hydroxypropionaldehyde, and by-product synthesis. To overcome the influences of these factors as well as to improve 1,3-propanediol yield, efforts have been devoted over the past years, which mostly included the application of metabolic engineering strategies to transform microbial strains into robust cell factories. This review focuses on the environmental stresses restricting 1,3-propanediol biosynthesis, and how these restrictions could be overcome using the metabolic engineering strategies. In this context, some technological and strategical aspects, including rechanneling metabolic flux in co-producing strains, rebalancing of co-factors and gene expression, co-culture and co-substrate fermentation, and application of untranslated region engineering. It also discusses the role of key enzymes involved in 1,3-propanediol biosynthesis and the influence of polyhydroxyalkanoate granule-associated protein on the tolerance to high concentration of this bio-product.

Graphic abstract

Similar content being viewed by others

References

Alibaba (2020a) Acrolein. https://www.alibaba.com/countrysearch/CN/acrolein.html, accessed on September 23, 2020

Alibaba (2020b) 1,3-Propanediol. https://www.alibaba.com/showroom/1-3-propanediol.html, accessed on September 23, 2020

Amaral PFF, Ferreira TF, Fontes GC, Coelho MAZ (2009) Glycerol valorization: new biotechnological routes. Food Bioprod Process 87(3):179–186

Amaretti A, di Nunzio M, Pompei A, Raimondi S, Rossi M, Bordoni A (2013) Antioxidant properties of potentially probiotic bacteria: in vitro and in vivo activities. Appl Microbiol Biotechnol 97:809–817

An H, Zhou H, Huang Y, Wang G, Luan C, Mou J, Luo Y, Hao Y (2010) High-level expression of heme-dependent catalase gene kata from Lactobacillus sakei protects Lactobacillus rhamnosus from oxidative stress. Mol Biotechnol 45(2):155–160

Apiwatanapiwat W, Vaithanomsat P, Tachaapaikoon C, Ratanakhanokchai K, Kosugi A (2016) Effect of cassava pulp supplement on 1,3-propanediol production by Clostridium butyricum. J Biotechnol 230:44–46

Apiwatanapiwat W, Vaithanomsat P, Thanapase W, Ratanakhanokchai K, Kosugi A (2018) Xylan supplement improves 1,3-propanediol fermentation by Clostridium butyricum. J Biosci Bioeng 125(6):662–668

Ashok S, Raj SM, Rathnasingh C, Park S (2011) Development of recombinant Klebsiella pneumoniae ∆dhaT strain for the co-production of 3-hydroxypropionic acid and 1,3-propanediol from glycerol. Appl Microbiol Biotechnol 90(4):1253–1265

Ayoub M, Abdullah AZ (2012) Critical review on the current scenario and significance of crude glycerol resulting from biodiesel industry towards more sustainable renewable energy industry. Renew Sust Energy Rev 16(5):2671–2686

Baeza-Jiménez R, Lopez-Martinez L, De la Cruz-Medina J, Espinosa-De-Los-Monteros J, Garcia-Galindo H (2011) Effect of glucose on 1, 3-propanediol production by Lactobacillus reuteri. Rev Mex Ing Quím 10(1):39–46

Biebl H, Menzel K, Zeng AP, Deckwer WD (1999) Microbial production of 1,3-propanediol. Appl Microbial Biotechnol 52:289–297

Celińska E (2010) Debottlenecking the 1, 3-propanediol pathway by metabolic engineering. Biotechnol Adv 28(4):519–530

Celińska E, Drożdżyńska A, Jankowska M, Białas W, Czaczyk K, Grajek W (2015) Genetic engineering to improve 1, 3-propanediol production in an isolated Citrobacter freundii strain. Process Biochem 50(1):48–60

Chatzifragkou A, Dietz D, Komaitis M, Zeng AP, Papanikolaou S (2010) Effect of biodiesel-derived waste glycerol impurities on biomass and 1,3-propanediol production of Clostridium butyricum VPI 1718. Biotechnol Bioeng 107(1):76–84

Chatzifragkou A, Makri A, Belka A, Bellou S, Mavrou M, Mastoridou M, Mystrioti P, Onjaro G, Aggelis G, Papanikolaou S (2011) Biotechnological conversions of biodiesel derived waste glycerol by yeast and fungal species. Energy 36:1097–108

Chen Z, Liu D (2016) Toward glycerol biorefinery: metabolic engineering for the production of biofuels and chemicals from glycerol. Biotechnol Biofuels 9(1):205

Chen Z, Liu H, Liu D (2009) Regulation of 3-hydroxypropionaldehyde accumulation in Klebsiella pneumoniae by overexpression of dhaT and dhaD genes. Enzyme Microb Technol 45(4):305–309

Chen Z, Bommareddy RR, Frank D, Rappert S, Zeng AP (2014) Deregulation of feedback inhibition of phosphoenolpyruvate carboxylase for improved lysine production in Corynebacterium glutamicum. Appl Environ Microbiol 80(4):1388–1393

Chen Z, Geng F, Zeng AP (2015) Protein design and engineering of a de novo pathway for microbial production of 1, 3-propanediol from glucose. Biotechnol J 10(2):284–289

Chen L, Ma C, Wang R, Yang J, Zheng H (2016) Deletion of ldha and aldh genes in Klebsiella pneumoniae to enhance 1, 3-propanediol production. Biotechnol Lett 38(10):1769–1774

Cho C, Choi SY, Luo ZW, Lee SY (2015) Recent advances in microbial production of fuels and chemicals using tools and strategies of systems metabolic engineering. Biotechnol Adv 33(7):1455–1466

Choudhary E, Thakur P, Pareek M, Agarwal N (2015) Gene silencing by CRISPR interference in mycobacteria. Nat Comm 6(1):6267

Colin T, Bories A, Moulin G (2000) Inhibition of Clostridium butyricum by 1,3-propanediol and diols during glycerol fermentation. Appl Microbiol Biotechnol 54(2):201–205

Da Silva GP, De Lima CJB, Contiero J (2014) Production and productivity of 1,3-propanediol from glycerol by Klebsiella pneumoniae GLC29. Catal Today 257(2):259–266

De Almeida A, Catone MV, Rhodius VA, Gross CA, Pettinari MJ (2011) Unexpected stress-reducing effect of phap, a poly (3-hydroxybutyrate) granule-associated protein. Escherichia coli Appl Environ Microbiol 77(18):6622–6629

De Souza EA, Rossi DM, Ayub MAZ (2014) Bioconversion of residual glycerol from biodiesel synthesis into 1, 3-propanediol using immobilized cells of Klebsiella pneumoniae blh-1. Renew energy 72(1):253–257

Dishisha T, Pereyra LP, Pyo SH, Britton RA, Hatti-Kaul R (2014) Flux analysis of the Lactobacillus reuteri propanediol-utilization pathway for production of 3-hydroxypropionaldehyde, 3-hydroxypropionic acid and 1, 3-propanediol from glycerol. Microb Cell Fact 13(1):76

Dishisha T, Sabet-Azad R, Arieta V, Hatti-Kaul R (2019) Lactobacillus reuteri NAD(P)H oxidase: properties and coexpression with propanediol-utilization enzymes for enhancing 3-hydroxypropionic acid production from 3-hydroxypropionaldehyde. J Biotechnol 289:135–143

Drozdzynska A, Pawlicka J, Kubiak P, Kosmider A, Pranke D, Olejnik-Schmidt A, Czaczyk K (2014) Conversion of glycerol to 1,3-propanediol by Citrobacter freundii and Hafnia alvei – newly isolated strains from enterobacteriaceae. N Biotechnol 31(5):402–410

Elshobary ME, Abo-Shady AM, Khairy HM, Essa D, Zabed HM, Qi X, Abomohra AEF (2019) Influence of nutrient supplementation and starvation conditions on the biomass and lipid productivities of Micractinium reisseri grown in wastewater for biodiesel production. J Environ Manage 250: Article ID 109529

Fokum E, Zabed HM, Guo Q, Yun J, Pang H, An Y, Li W, Qi X (2019) Metabolic engineering of bacterial strains using crispr/cas9 systems for biosynthesis of value-added products. Food Biosci 28(1):125–132

Furusawa H, Koyoma N (2004) Effect of fatty acids on the membrane potential of an alkaliphilic bacillus. Curr Microbiol 48:196–198

González-Pajuelo M, Andrade J, Vasconcelos I (2005a) Production of 1, 3-propanediol by Clostridium butyricum vpi 3266 in continuous cultures with high yield and productivity. J Ind Microbiol Biotechnol 32(9):391–396

González-Pajuelo M, Meynial-Salles I, Mendes F, Andrade JC, Vasconcelos I, Soucaille P (2005b) Metabolic engineering of Clostridium acetobutylicum for the industrial production of 1, 3-propanediol from glycerol. Metab Eng 7(5–6):329–336

Guo Y, Dai L, Xin B, Tao F, Tang H, Shen Y, Xu P (2017) 1,3-Propanediol production by a newly isolated strain, Clostridium perfringens GYL. Bioresour Technol 233:406–412

Guo J, Cao Y, Liu H, Zhang R, Xian M, Liu H (2019a) Improving the production of isoprene and 1, 3-propanediol by metabolically engineered Escherichia coli through recycling redox cofactor between the dual pathways. Appl Microbiol Biotechnol 103(6):2597–2608

Guo Q, Zabed H, Zhang H, Wang X, Yun J, Zhang G, Yang M, Sun W, Qi X (2019b) Optimization of fermentation medium for a newly isolated yeast strain (Zygosaccharomyces rouxii JM-C46) and evaluation of factors affecting biosynthesis of D-arabitol. LWT 99:319–327

Gupta A, Murarka A, Campbell P, Gonzales R (2009) Anaerobic fermentation of glycerol in Paenibacillus macerans metabolic pathway and environmental determinants. Appl Envir Microbiol 75:5871–5883

Gupta SC, Sharma A, Mishra M, Mishra RK, Chowdhuri DK (2010) Heat shock proteins in toxicology: how close and how far? Life Sci 86(11–12):377–384

Hao J, Lin R, Zheng Z, Sun Y, Liu D (2008) 3-hydroxypropionaldehyde guided glycerol feeding strategy in aerobic 1, 3-propanediol production by Klebsiella pneumoniae. J Ind Microbiol Biotechnol 35(12):1615–1624

Hennequin C, Porcheray F, Waligora-Dupriet AJ, Collignon A, Barc MC, Bourlioux P, Karjalainen T (2001) Groel (hsp60) of Clostridium difficile is involved in cell adherence. Microbiol 147(1):87–96

Heo MJ, Jung HM, Um J, Lee SW, Oh MK (2016) Controlling citrate synthase expression by crispr/cas9 genome editing for n-butanol production in Escherichia coli. ACS Synth Biol 6(2):182–189

Hermann BG, Blok K, Patel MK (2007) Producing bio-based bulk chemicals using industrial biotechnology saves energy and combats climate change. Environ Sci Technol 41(22):7915–7921

Hirokawa Y, Dempo Y, Fukusaki E, Hanai T (2017) Metabolic engineering for isopropanol production by an engineered cyanobacterium, Synechococcus elongatus pcc 7942, under photosynthetic conditions. J Biosci Bioeng 123(1):39–45

Hong E, Kim J, Ha SJ, Ryu Y (2015) Improved 1,3-propanediol production by Escherichia coli from glycerol due to co-expression of glycerol dehydratase reactivation factors and succinate addition. Biotechnol Bioprocess Eng 20:849–855

Horng YT, Chang KC, Chou TC, Yu CJ, Chien CC, Wei YH, Soo PC (2010) Inactivation of dhaD and dhaK abolishes by-product accumulation during 1,3-propanediol production in Klebsiella pneumoniae. J Industrial Microbiol Biotechnol 37(7):707–716

Huang Y, Li Z, Shimizu K, Ye Q (2012) Simultaneous production of 3-hydroxypropionic acid and 1,3-propanediol from glycerol by recombinant strain of Klebsiella pneumoniae. Bioresour Technol 103(1):351–359

Huang J, Wu Y, Wu W, Zhang Y, Liu D, Chen Z (2017) Cofactor recycling for co-production of 1,3-propanediol and glutamate by metabolically engineered Corynebacterium glutamicum. Sci Rep 7:42246

Imlay JA (2003) Pathways of oxidative damage. Annu Rev Microbiol 57:395–418

Jang YS, Kim B, Shin JH, Choi YJ, Choi S, Song CW, Lee J, Park HG, Lee SY (2012) Bio-based production of c2–c6 platform chemicals. Biotechnol Bioeng 109(10):2437–2459

Jänsch A, Freiding S, Behr J, Vogel RF (2011) Contribution of the nadh-oxidase (nox) to the aerobic life of Lactobacillus sanfranciscensis dsm 20451t. Food Microbiol 28(1):29–37

Jiang W, Zhao J, Wang Z, Yang ST (2014) Stable high-titer n-butanol production from sucrose and sugarcane juice by Clostridium acetobutylicum JB200 in repeated batch fermentations. Bioresour Technol 163:172–179

Jiang W, Wang S, Wang Y, Fang B (2016) Key enzymes catalyzing glycerol to 1,3-propanediol. Biotechnol Biofuels 9(1): Article ID 57

Jin P, Li S, Lu S, Zhu J, Huang H (2011) Improved 1,3-propanediol production with hemicellulosic hydrolysates (corn straw) as cosubstrate: impact of degradation products on Klebsiella pneumoniae growth and 1,3-propanediol fermentation. Bioresour Technol 102(2):1815–1821

Jolly J, Hitzmann B, Ramalingam S, Ramachandran KB (2014) Biosynthesis of 1,3-propanediol from glycerol with Lactobacillus reuteri: effect of operating variables. J Biosci Bioeng 118(2):188–194

Ju JH, Wang D, Heo SY, Kim MS, Seo JW, Kim YM, Kim DH, Kang SA, Kim CH, Oh BR (2020) Enhancement of 1,3-propanediol production from industrial by-product by Lactobacillus reuteri CH53. Microb Cell Fact 19(1):6

Jung WS, Kang JH, Chu HS, Choi IS, Cho KM (2014) Elevated production of 3-hydroxypropionic acid by metabolic engineering of the glycerol metabolism in Escherichia coli. Metab Eng 23:116–122

Kang TS, Korber DR, Tanaka T (2013) Influence of oxygen on nadh recycling and oxidative stress resistance systems in Lactobacillus panis pm1. AMB Express 3(1):10

Kaur G, Srivastava AK, Chand S (2012) Advances in biotechnological production of 1,3-propanediol. Biochem Eng J 64(19):106–118

Keading T, Daluz J, Kube J, Zeng AP (2014) Integrated study of fermentation and downstream processing in a miniplant significantly improved the microbial 1,3-propanediol production from raw glycerol. Bioproc Biosys Eng 38:575–586

Kim SC, Min BE, Hwang HG, Seo SW, Jung GY (2015) Pathway optimization by re-design of untranslated regions for l-tyrosine production in Escherichia coli. Sci Rep 5:13853

Ko Y, Seol E, Sekar BS, Kwon S, Lee J, Park S (2017) Metabolic engineering of Klebsiella pneumoniae j2b for co-production of 3-hydroxypropionic acid and 1, 3-propanediol from glycerol: reduction of acetate and other by-products. Bioresour Technol 244(1):1096–1103

Koganti S, Kuo TM, Kurtzman CP, Smith N, Ju LK (2011) Production of arabitol from glycerol: strain screening and study of factors affecting production yield. Appl Microbiol Biotechnol 90(1):257–267

Kong PS, Aroua MK, Daud WMAW (2016) Conversion of crude and pure glycerol into derivatives: a feasibility evaluation. Renew Sust Energ Rev 63:533–555

Kongjao S, Damronglerd S, Hunsom M (2011) Electrochemical reforming of an acidic aqueous glycerol solution on pt electrodes. J Appl Electrochem 41(2):215–222

Kośmider A, Leja K, Czaczyk K (2011) Improved utilization of crude glycerol by-product from biodiesel production. Biodiesel–Quality, Emissions and by-Products 19:341–365

Kumar V, Park S (2017) Potential and limitations of Klebsiella pneumoniae as a microbial cell factory utilizing glycerol as the carbon source. J Biotechnol Adv 36(1):150–167

Kumar V, Sankaranarayanan M, Jae K, Durgapal M, Ashok S, Ko Y, Sarkar R, Park S (2012) Co-production of 3-hydroxypropionic acid and 1,3-propanediol from glycerol using resting cells of recombinant Klebsiella pneumoniae J2B strain overexpressing aldehyde dehydrogenase. Appl Microbiol Biotechnol 96(2):373–383

Kumar V, Sankaranarayanan M, Durgapal M, Zhou S, Ko Y, Ashok S, Sarkar R, Park S (2013) Simultaaneous production of 3-hydroxypropionic acid and 1,3-propanediol from glycerol using resting cells of the lactate dehydrogenase-deficient recombinant Klebsiella pneumoniae overexpressing an aldehyde dehydrogenase. Bioresour Technol 135:555–563

Kumar GS, Wee Y, Lee I, Sun HJ, Zhao X, Xia S, Kim S, Lee J, Ping W, Kim J (2015) Stabilized glycerol dehydrogenase for the conversion of glycerol to dihydroxyacetone. Chem Eng J 276(1):283–288

Kwak DH, Lim HG, Yang J, Seo SW, Jung GY (2017) Synthetic redesign of Escherichia coli for cadaverine production from galactose. Biotechnol Biofuels 10(1):2

Lee JH, Jung MY, Oh MK (2018) High-yield production of 1,3-propanediol from glycerol by metabolically engineered Klebsiella pneumoniae. Biotechnol Biofuels 11(1):104

Leja K, Czaczyk K, Myszka K (2011) The use of microorganisms in 1, 3-propanediol production. Afri J Microbiol Res 5(26):4652–4658

Li L, Li K, Wang Y, Chen C, Xu Y, Zhang L, Han B, Gao C, Tao F, Ma C, Xu P (2015) Metabolic engineering of Enterobacter cloacae for high yield production of enantiopure (2R, 3R)-2,3-butanediol from lignocellulose-derived sugars. Metab Eng 28:19–27

Lim HG, Noh MH, Jeong JH, Park S, Jung GY (2016) Optimum rebalancing of the 3-hydroxypropionic acid production pathway from glycerol in Escherichia coli. ACS Synthetic Biology 5(11):1247–1255

Lin J, Zhang Y, Xu D, Xiang G, Jia Z, Fu S, Gong H (2016) Deletion of poxb, pta, and acka improves 1, 3-propanediol production by Klebsiella pneumoniae. Appl Microbiol Biotechnol 100(6):2775–2784

Lu XY, Ren SL, Lu JZ, Zong H, Song J, Zhuge B (2018) Enhanced 1,3-propanediol production in Klebsiella pneumoniae by a combined strategy of strengthening the TCA cycle and weakening the glucose effect. J Appl Microbiol 124(3):682–690

Ma J, Jiang H, Hector SB, Xiao Z, Li J, Liu R, Li C, Zeng B, Liu G, Zhu Y (2019) Adaptability of Klebsiella pneumoniae 2e, a newly isolated 1,3-propanediol producing strain, to crude glycerol as revealed by genomic profiling. Appl Environ Microbiol 10:e00254–19

Maervoet VE, De Mey M, Beauprez J, De Maeseneire S, Soetaert WK (2011) Enhancing the microbial conversion of glycerol to 1, 3-propanediol using metabolic engineering. Org Process Res Dev 15(1):189–202

Maervoet VE, De Maeseneire SL, Avci FG, Beauprez J, Soetaert WK, De Mey M (2014) 1, 3-propanediol production with Citrobacter werkmanii dsm17579: effect of a dhad knock-out. Microb Cell Factories 13(1):70

Maervoet VE, De Maeseneire SL, Avci FG, Beauprez J, Soetaert WK, De Mey M (2016) High yield 1, 3-propanediol production by rational engineering of the 3-hydroxypropionaldehyde bottleneck in Citrobacter werkmanii. Microb Cell Factories 15(1): Article ID 23

Malaoui H, Marczak R (2000) Purification and characterization of the 1-3-propanediol dehydrogenase of Clostridium butyricum e5. Enzyme Microb Technol 27(6):399–405

Mangayil R, Efimova E, Kontinen J, Santala V (2019) Co-production of 1,3-propanediol and long-chain alkyl esters from crude glycerol. N Biotechnol 53:81–89

Marçal D, Rêgo AT, Carrondo MA, Enguita FJ (2009) 1, 3-propanediol dehydrogenase from Klebsiella pneumoniae: decameric quaternary structure and possible subunit cooperativity. J Bacteriol 191(4):1143–1151

Maru B, Bielen A, Constanti M, Medina F, Kengen S (2013) Glycerol fermentation to hydrogen by thermotoga maritima: proposed pathway and bioenergetic considerations. Int J Hydrogen Energy 38(14):5563–5572

Meiswinkel TM, Rittmann D, Lindner SN, Wendisch VF (2013) Crude glycerol-based production of amino acids and putrescine by Corynebacterium glutamicum. Bioresour Technol 145(1):254–258

Metsoviti M, Paraskevaidi K, Koutinas A, Zeng AP, Papanikolaou S (2012) Production of 1, 3-propanediol, 2, 3-butanediol and ethanol by a newly isolated Klebsiella oxytoca strain growing on biodiesel-derived glycerol based media. Process Biochem 47(12):1872–1882

Metsoviti M, Zeng AP, Koutinas AA, Papanikolaou S (2013) Enhanced 1, 3-propanediol production by a newly isolated Citrobacter freundii strain cultivated on biodiesel-derived waste glycerol through sterile and non-sterile bioprocesses. J Biotechnol 163(4):408–418

Mezzina MP, Wetzler DE, Catone MV, Bucci H, Di Paola M, Pettinari MJ (2014) A phasin with many faces: structural insights on phap from Azotobacter sp. Fa8. PLoS ONE 9(7):e103012

Mezzina MP, Wetzler DE, de Almeida A, Dinjaski N, Prieto MA, Pettinari MJ (2015) A phasin with extra talents: a polyhydroxyalkanoate granule-associated protein has chaperone activity. Environ Microbiol 17(5):1765–1776

Mezzina MP, Álvarez D, Egoburo D, Peña RD, Nikel PI, Pettinari MJ (2017) A new player in the biorefineries field: Phasin phap enhances tolerance to solvents and boosts ethanol and 1, 3-propanediol synthesis in Escherichia coli. Appl Environ Microbiol AEM 00662-00617

Monteiro MR, Kugelmeier CL, Pinheiro RS, Batalha MO, Cesar ADS (2018) Glycerol from biodiesel production: technological paths for sustainability. Renew Sust Energ Rev. 88:109–122

Nicolaou SA, Gaida SM, Papoutsakis ET (2010) A comparative view of metabolite and substrate stress and tolerance in microbial bioprocessing: from biofuels and chemicals, to biocatalysis and bioremediation. Metab Eng 12(4):307–331

Nikel PI, Pettinari MJ, Galvagno MA, Méndez BS (2010) Metabolic selective pressure stabilizes plasmids carrying biosynthetic genes for reduced biochemicals in Escherichia coli redox mutants. Appl Microbiol Biotechnol 88(2):563–573

Oh BR, Seo JW, Heo SY, Hong WK, Luo LH, Kim S, Park DH, Kim CH (2012) Optimization of culture conditions for 1, 3-propanediol production from glycerol using a mutant strain of Klebsiella pneumoniae. Appl Biochem Biotechnol 166(1):127–137

Oh BR, Hong WK, Heo SY, Luo LH, Kondo A, Seo JW, Kim CH (2013) The production of 1, 3-propanediol from mixtures of glycerol and glucose by a Klebsiella pneumoniae mutant deficient in carbon catabolite repression. Bioresour Technol 130:719–724

Oh BR, Lee SM, Heo SY, Seo JW, Kim CH (2018) Efficient production of 1,3-propanediol from crude glycerol by repeated fed-batch fermentation strategy of a lactate and 2,3-butanediol deficient mutant of Klebsiella pneumoniae. Microb Cell Fact 17(1): Article ID 92

Park JM, Rathnasingh C, Song H (2017) Metabolic engineering of Klebsiella pneumoniae based on in silico analysis and its pilot-scale application for 1,3-propanediol and 2,3-butanediol co-production. J Ind Microbiol Biotechnol 44:431–441

Petrache HI, Stephanie TN, Daniel H, Norbert K, Nagle JF, Adrian PV (2006) Swelling of phospholipids by monovalent salt. J Lipid Res 47(2):302–309

Pflugl S, Marx H, Mattanovich D, Sauer M (2012) 1,3-Propanediol production from glycerol with Lactobacillus diolivorans. Bioresour Technol 119:133–140

Pflugl S, Marx H, Mattanovich D, Sauer M (2014) Heading for an economic industrial upgrading of crude glycerol from biodiesel production to 1,3-propanediol by Lactobacillus diolivorans. Bioresour Technol 152:499–504

Pflügl S, Marx H, Mattanovich D, Sauer M (2013) Genetic engineering of Lactobacillus diolivorans. FEMS Microbiol Lett 344(2):152–158

Przystałowska H, Zeyland J, Szymanowska-Powałowska D, Szalata M, Słomski R, Lipiński D (2015) 1, 3-propanediol production by new recombinant Escherichia coli containing genes from pathogenic bacteria. Microbiol Res 171(1):1–7

Qi X, Chen Y, Jiang K, Zuo W, Luo Z, Wei Y, Du L, Wei H, Huang R, Du Q (2009) Saturation-mutagenesis in two positions distant from active site of a Klebsiella pneumoniae glycerol dehydratase identifies some highly active mutants. J Biotechnol 144(1):43–50

Qi X, Guo Q, Wei Y, Xu H, Huang R (2012) Enhancement of pH stability and activity of glycerol dehydratase from Klebsiella pneumoniae by rational design. Biotechnol Lett 34(2):339–346

Qi X, Deng W, Wang F, Guo Q, Chen H, Wang L, He X, Huang R (2013) Molecular cloning, co-expression, and characterization of glycerol dehydratase and 1,3-propanediol dehydrogenase from Citrobacter freundii. Mol Biotechnol 54(2):469–474

Qi X, Qi Y, Yuan J, Zhang H (2015) Research progress on the microbial fermentation of 1, 3-propandiol from crude glycerol. J Food Saf Quality 6(10):3923–3927

Qi X, Yun J, Qi Y, Zhang H, Wang F, Guo Q, Cao Z (2016) Expression and characterization of a novel 1,3-propanedioldehydrogenase from Lactobacillus brevis. Appl Biochem Biotech 179(6):959–972

Ramos JL, Sol Cuenca M, Molina-Santiago C, Segura A, Duque E, Gómez-García MR, Udaondo Z, Roca A (2015) Mechanisms of solvent resistance mediated by interplay of cellular factors in pseudomonas putida. FEMS Microbiol Rev 39(4):555–566

Rochat T, Gratadoux JJ, Gruss A, Corthier G, Maguin E, Langella P, van de Guchte M (2006) Production of a heterologous nonheme catalase by Lactobacillus casei: an efficient tool for removal of H2O2 and protection of Lactobacillus bulgaricus from oxidative stress in milk. Appl Environ Microbiol 72:5143–5149

Rodriguez A, Wojtusik M, Ripoll V, Santos VE, Garcia-Ochoa F (2016) 1,3-propanediol production from glycerol with a novel biocatalyst Shimwellia blattae ATCC 33430: operational conditions and kinetics in batch cultivations. Bioresour Technol 200:830–837

Sabapathy PC, Devaraj S, Meixner K, Anburajan P, Kathirvel P, Ravikumar Y, Zabed HM, Qi X (2020) Recent developments in polyhydroxyalkanoates (PHAs) production–A review. Bioresour Technol 306: Article ID 123132

Sahu JN, Karri RR, Zabed HM, Shams S, Qi X (2019) Current perspectives and future prospects of nano-biotechnology in wastewater treatment. Sep Purif Rev. https://doi.org/10.1080/15422119.2019.1630430

Sattayasamitsathit S, Prasertsan P, Methacanon P (2011) Statistical optimization for simultaneous production of 1, 3-propanediol and 2, 3-butanediol using crude glycerol by newly bacterial isolate. Process Biochem 46(2):608–614

Saxena R, Anand P, Saran S, Isar J (2009) Microbial production of 1, 3-propanediol: recent developments and emerging opportunities. Biotechnol Adv 27(6):895–913

Skraly FA, Lytle BL, Cameron DC (1998) Construction and characterization of a 1,3-propanediol operon. Appl Environ Microbiol 64(1):98–105

Stasha ERA, Loh SK (2018) Bio-based 1,3-propanediol production from crude glycerol. Palm Oil Eng Bull 123:27–30

Sun JB, Heuvel JVD, Qu YB, Soucaille P, Zeng AP (2010) Comparative genomic analysis of dha regulon and related genes for anaerobic glycerol metabolism in bacteria. Biotechnol Prog 19(2):263–272

Sun Y, Shen J, Yan L, Zhou J, Jiang L, Chen Y, Yuan J, Feng E, Xiu Z (2018) Advances in bioconversion of glycerol to 1,3-propanediol: prospects and challenges. Proc Biochem 71:134–146

Suppuram P, Ramakrishnan GG, Subramanian R (2018) An integrated process for the production of 1, 3-propanediol, lactate and 3-hydroxypropionic acid by an engineered Lactobacillus reuteri. Biosci Biotechnol Biochem 83(4):755–762

Szymanowska-Powałowska D (2015) The effect of high concentrations of glycerol on the growth, metabolism and adaptation capacity of Clostridium butyricum dsp1. Electron J Biotechnol 18(2):128–133

Szymanowska-Powałowska D, Białas W (2014) Scale-up of anaerobic 1, 3-propanediol production by Clostridium butyricum dsp1 from crude glycerol. BMC Microbiol 14(1): Article ID 45

Szymanowska-Powałowska D, Kubiak P (2015) Effect of 1, 3-propanediol, organic acids, and ethanol on growth and metabolism of Clostridium butyricum dsp1. Appl Microbiol Biotechnol 99(7):3179–3189

Tang X, Tan Y, Zhu H, Zhao K, Shen W (2009) Microbial conversion of glycerol to 1, 3-propanediol by an engineered strain of Escherichia coli. Appl Environ Microbiol 75(6):1628–1634

Tanielyan SK, Marin N, Alvez G, Ramesh Bhagat, Miryala B, Augustine RL, Schmidt SR (2014) An efficient, selective process for the conversion of glycerol to propylene glycol using fixed bed raney copper catalysts. Org Process Res Dev 18(11):1419–1426

Tian P, Wang J, Shen X, Rey JF, Yuan Q, Yan Y (2017) Fundamental crispr-cas9 tools and current applications in microbial systems. Synth Syst Biotechnol 2(3):219–225

TRIDGE (2020) Real-time market prices of cassava. https://www.tridge.com/intelligences/mandioca/price, accessed on September 23, 2020

Venkataramanan KP, Boatman JJ, Kurniawan Y, Taconi KA, Bothun GD, Scholz C (2012) Impact of impurities in biodiesel-derived crude glycerol on the fermentation by Clostridium pasteurianum atcc 6013. Appl Microbiol Biotechnol 93(3):1325–1335

Veras STS, Rojas P, Florencio L, Kato MT, Sanz JL (2019) Production of 1,3-propanediol from pure and crude glycerol using UASB reactor with attached biomass in silicone support. Bioresour Technol 279:140–148

Vivek N, Pandey A, Binod P (2016) Biological valorization of pure and crude glycerol into 1,3-propanediol using a novel isolate Lactobacillus brevis N1E9.3.3

Vivek N, Christopher M, Kumar MK, Castro E, Binod P, Pandey A (2018) Pentose rich acid pretreated liquor as co-substrate for 1,3-propanediol production. Renew Energy 129:794–799

Wang W, Sun J, Hartlep M, Deckwer WD, Zeng AP (2003) Combined use of proteomic analysis and enzyme activity assays for metabolic pathway analysis of glycerol fermentation by Klebsiella pneumoniae. Biotechnol Bioeng 83(5):525–536

Wang F, Qu H, Zhang D, Tian P, Tan T (2007) Production of 1, 3-propanediol from glycerol by recombinant Escherichia coli using incompatible plasmids system. Mol Biotechnol 37(2):112–119

Wang M, Wang G, Zhang T, Fan L, Tan T (2017) Multi-modular engineering of 1, 3-propanediol biosynthesis system in Klebsiella pneumoniae from co-substrate. Appl Microbiol Biotechnol 101(2):647–657

Wang X, Zhou J, Sun Y, Xiu Z (2019) Bioconversion of raw glycerol from waste cooking-oil-based biodiesel production to 1,3-propanediol and lactate by a microbial consortium. Front Bioeng Biotechnol 7(1): Article ID 14

Werkman CH, Gillen GF (1932) Bacteria producing trimethylene glycol. J Bacteriol 23(2):167–182

Westbrook AW, Miscevic D, Kilpatrick S, Bruder MR, Moo-Young M, Chou CP (2019) Strain engineering for microbial production of value-added chemicals and fuels from glycerol. Biotechnol Adv 37:538–568

Wilkens E, Ringel AK, Hortig D, Willke T, Vorlop KD (2012) High-level production of 1, 3-propanediol from crude glycerol by Clostridium butyricum akr102a. Appl Microbiol Biotechnol 93(3):1057–1063

Wischral D, Zhang J, Cheng C, Lin M, De Souza LMG, Pessoa FLP, Pereira N Jr, Yang ST (2016) Production of 1, 3-propanediol by Clostridium beijerinckii dsm 791 from crude glycerol and corn steep liquor: process optimization and metabolic engineering. Bioresour Technol 212:100–110

Xin B, Wang Y, Tao F, Li L, Ma C, Xu P (2016) Co-utilization of glycerol and lignocellulosic hydrolysates enhances anaerobic 1, 3-propanediol production by Clostridium diolis. Sci Rep 6: Article ID 19044

Xin B, Tao F, Wang Y, Liu H, Ma C, Xu P (2017) Coordination of metabolic pathways: enhanced carbon conservation in 1, 3-propanediol production by coupling with optically pure lactate biosynthesis. Metab Eng 41:102–114

Xiu ZL, Zeng AP (2008) Present state and perspective of downstream processing of biologically produced 1,3-propanediol and 2,3-butanediol. Appl Microbiol Biotechnol 78(6):917–926

Yang B, Liang S, Liu H, Liu J, Cui Z, Wen J (2018a) Metabolic engineering of Escherichia coli for 1, 3-propanediol biosynthesis from glycerol. Bioresour Technol 267:599–607

Yang M, Yun J, Zhang H, Magocha TA, Zabed H, Xue Y, Fokum E, Sun W, Qi X (2018b) Genetically engineered strains: application and advances for 1, 3-propanediol production from glycerol. Food Technol Biotechnol 56(1):3–15

Yang X, Choi HS, Lee JH, Lee SK, Han SO, Park C, Kim SW (2018c) Improved production of 1,3-propanediol from biodiesel-derived crude glycerol by Klebsiella pneumoniae in fed-batch fermentation. Chem Eng J 349:25–36

Yang M, An Y, Zabed HM, Guo Q, Yun J, Zhang G, Awad FN, Sun W, Qi X (2019) Random mutagenesis of Clostridium butyricum strain and optimization of biosynthesis process for enhanced production of 1,3-propanediol. Bioresour Technol 284:188–196

Yang M, Zabed HM, Yun J, Zhang G, Qi X (2020) The Draft Genome Sequence of Clostridium butyricum QXYZ514, a potent bacterium for converting glycerol into fuels and bioproducts in the waste-based biorefinery. Curr Microbiol. https://doi.org/10.1007/s00284-020-02182-1

YCHARTS (2020) Sugar price. https://ycharts.com/indicators/world_sugar_price, accessed on September 23, 2020

Yoko A, Eiichiro K, Yoshihiro U, Yoshio K, Kazuhiko M, Tsuyoshi O, Tsuyoshi N (2007) Altered metabolic flux due to deletion of odha causes l-glutamate overproduction in Corynebacterium glutamicum. Appl Environ Microbiol 73(4):1308–1319

Yun J, Yang M, Magocha TA, Zhang H, Xue Y, Zhang G, Qi X, Sun W (2018) Production of 1, 3-propanediol using a novel 1, 3-propanediol dehydrogenase from isolated Clostridium butyricum and co-biotransformation of whole cells. Bioresour Technol 247(1):838–843

Zabed H, Boyce AN, Faruq G, Sahu JN (2016) A comparative evaluation of agronomic performance and kernel composition of normal and high sugary corn genotypes (Zea mays L.) grown for dry-grind ethanol production. Ind Crop Prod 94:9–19

Zabed HM, Zhang Y, Guo Q, Yun J, Yang M, Zhang G, Qi X (2019) Co-biosynthesis of 3-hydroxypropionic acid and 1, 3-propanediol by a newly isolated Lactobacillus reuteri strain during whole cell biotransformation of glycerol. J Clean Prod 226(1):432–442

Zaushitsyna O, Dishisha T, Hatti-Kaul R, Mattiasson B (2017) Crosslinked, cryostructured Lactobacillus reuteri monoliths for production of 3-hydroxypropionaldehyde, 3-hydroxypropionic acid and 1,3-propanediol from glycerol. J Biotechnol 241:22–32

Zeng AP, Biebl H (2002) Bulk chemicals from biotechnology: the case of 1,3-propanediol production and the new trends. Adv Biochem Eng Biotechnol 74:239–259

Zeng AP, Sabra W (2011) Microbial production of diols as platform chemicals: recent progresses. Curr Opin Biotechnol 22(6):749–757

Zhao L, Zheng Y, Ma X, Wei D (2009) Effects of over-expression of glycerol dehydrogenase and 1, 3-propanediol oxidoreductase on bioconversion of glycerol into 1, 3-propandediol by Klebsiella pneumoniae under micro-aerobic conditions. Bioprocess Biosyst Eng 32(3):313–320

Zhou S, Li L, Perseke M, Huang Y, Wei J, Qin Q (2015) Isolation and characterization of a Klebsiella pneumoniae strain from mangrove sediment for efficient biosynthesis of 1,3-propanediol. Sci Bull 60(5):511–521

Zhou S, Lama S, Sankaranarayanan M, Park S (2019) Metabolic engineering of Pseudomonas denitrificans for the 1,3-propanediol production from glycerol. Bioresour Technol 292:121933

Zhu C, Fang B, Wang S (2016) Effects of culture conditions on the kinetic behavior of 1,3-propanediol fermentation by Clostridium butyricum with a kinetic model. Bioresour Technol 212(1):130–137

Zhuge B, Zhang C, Fang H, Zhuge J, Permaul K (2010) Expression of 1,3-propanediol oxidoreductase and its isoenzyme in Klebsiella pneumoniae for bioconversion of glycerol into 1,3-propanediol. Appl Genet Mol Biotechnol 87(6):2177–2184

Zingaro KA, Papoutsakis ET (2012) Toward a semisynthetic stress response system to engineer microbial solvent tolerance. mBio 3(5):e00308–e00312

Acknowledgements

This work was supported by the National Natural Science Foundation of China [Grant Nos. 31972042, 31950410550, and 31571806] and High-Level Talents Project of Six Talent Peaks in Jiangsu Province [Grant No. SWYY-018].

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Editorial responsibility: Parveen Fatemeh Rupani.

Rights and permissions

About this article

Cite this article

Fokum, E., Zabed, H.M., Yun, J. et al. Recent technological and strategical developments in the biomanufacturing of 1,3-propanediol from glycerol. Int. J. Environ. Sci. Technol. 18, 2467–2490 (2021). https://doi.org/10.1007/s13762-020-03036-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13762-020-03036-w