Abstract

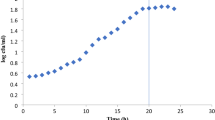

The high sensitivity of probiotic bacteria (PB) to many environmental factors limits the number of food products where they can be incorporated. This study aimed to examine the capability of a unique three-layered microcapsule structure to protect PB against extremely elevated temperatures and low pHs to allow their incorporation into bakery goods. The microcapsules were prepared first by granulation of a Bifidobacterium lactis (BL) strain, as a model PB, to form a core, and then coating the core with three consecutive protective layers. The physical features and the shape of the microcapsules obtained from three sequential preparations were characterized using various methods. A viable cell count was utilized to evaluate the efficiency of the microcapsule structure to protect the bacteria during a bread-baking process carried out at 180 °C for 40 min and also during the exposure to simulated gastric fluid (pH 1.2) for up to 1 h. The results showed that whereas the free bacteria (unprotected BL) encountered a significant viability loss under these conditions, the microencapsulated BL presented superior resistance.

Similar content being viewed by others

References

Hasler CM (2002) Functional foods benefits, concerns and challenges-a position paper from the american council on science and health. J Nutr 132:3772–3781. https://doi.org/10.1093/jn/132.12.3772

Syngai GG, Gopi R, Bharali R, Dey S, Lakshmanan GMA, Ahmed G (2016) Probiotics -the versatile functional food ingredients. J Food Sci Technol 53:921–933. https://doi.org/10.1007/s13197-015-2011-0

Stanton C, Gardiner G, Meehan H, Collins K, Fitzgerald G, Lynch PB, Ross RP (2001) Market potential for probiotics. Am J Clin Nutr 73:476S-483S. https://doi.org/10.1093/ajcn/73.2.476s

Araya M, Morelli L, Reid G, Sanders ME, Stanton C, Pineiro M, Ben Embarek P (2002) Joint FAO/WHO working group report on drafting guidelines for the evaluation of probiotics in food. World Health Organization, Food and Agriculture Organization of the United Nations: London Ontario, Canada. Available via DIALOG. https://www.who.int/foodsafety/fs_management/en/probiotic_guidelines.pdf. Accessed 03 July 2019.

World Health Organization (WHO) and Food and Agriculture Organization (FAO) of the United Nations (2006) Probiotics in food: health and nutritional properties and guidelines for evaluation. FAO, Food and Nutrition Paper 85, Rome, Italy. Available via DIALOG. http://www.fao.org/3/a-a0512e.pdf. Accessed 03 July 2019.

Hill C, Guarner F, Reid G, Gibson GR, Merenstein DJ, Pot B, Morelli L, Canani RB, Flint HJ, Salminen S, Calder PC, Sanders ME (2014) The International Scientific Association for Probiotics and Prebiotics consensus statement on the scope and appropriate use of the term probiotic. Nature Rev Gastroenterol Hepatol 11:506–514

Rivera-Espinoza Y, Gallardo-Navarro Y (2010) Non-dairy probiotic products. Food Microbiol 27:1–11. https://doi.org/10.1016/j.fm.2008.06.008

Fenster K, Freeburg B, Hollard C, Wong C, Laursen RR, Ouwehand AC (2019) The production and delivery of probiotics: A review of a practical approach. Microorganisms 7(83):1–16. https://doi.org/10.3390/microorganisms7030083

Braegger C, Chmielewska A, Decsi T, Kolacek S, Mihatsch W, Moreno L, Pieścik M, Puntis J, Shamir R, Szajewska H, Turck D, Van Goudoever J (2011) Supplementation of infant formula with probiotics and/or prebiotics: A systematic review and comment by the ESPGHAN committee on nutrition. J Pediatr Gastroenterol Nutr 52:238–250. https://doi.org/10.1097/MPG.0b013e3181fb9e80

Corona-Hernandez RI, Alvarez-Parrilla E, Lizardi-Mendoza J, Islas-Rubio AR, De La Rosa LA, Wall-Medrano A (2013) Structural stability and viability of microencapsulated probiotic bacteria: A review. Comprehensive Reviews in Food Science and Food Safety 12:614–628. https://doi.org/10.1111/1541-4337.12030

Mortazavian A, Razavi SH, Ehsani MR, Sohrabvandi S (2007) Principles and methods of microencapsulation of probiotic microorganisms. Iranian Journal of Biotechnology 5:1–18

Anal AK, Singh H (2007) Recent advances in microencapsulation of probiotics for industrial applications and targeted delivery. Trends Food Sci Technol 18:240–251. https://doi.org/10.1016/j.tifs.2007.01.004

Penhasi A (2014) Microencapsulation of probiotic bacteria using thermo-sensitive sol-gel polymers for powdered infant formula. J Microencapsul 32:372–380. https://doi.org/10.3109/02652048.2015.1028497

Martína MJ, Lara-Villoslada F, Ruiz MA, Morales ME (2015) Microencapsulation of bacteria: A review of different technologies and their impact on the probiotic effects. Innovative Food Science & Emerging Technologies 27:15–25. https://doi.org/10.1016/j.ifset.2014.09.010

Burgain J, Gaiani C, Linder M, Scher J (2011) Encapsulation of probiotic living cells: From laboratory scale to industrial applications. J Food Eng 104:467–483. https://doi.org/10.1016/j.jfoodeng.2010.12.031

Burgain J, Corgneau M, Scher J, Gaiani C (2015) Encapsulation of probiotics in milk protein microcapsules. In: Sagis LMC (ed) Microencapsulation and microspheres for food applications. Academic Press, CA USA, pp 391–406

Islam MA, Yun CH, Choi YJ, Cho CS (2010) Microencapsulation of live probiotic bacteria. J Microbiol Biotechnol 20:1367–1377. https://doi.org/10.4014/jmb.1003.03020

Gbassi GK, Vandamme T (2012) Probiotic encapsulation technology: From microencapsulation to release into the gut. Pharmaceutics 4:149–163. https://doi.org/10.3390/pharmaceutics4010149

Zhang L, Huang S, Ananingsih VK, Zhou W, Chen XD (2014) A study on Bifidobacterium lactis Bb12 viability in bread during baking. J Food Eng 122:33–37. https://doi.org/10.1016/j.jfoodeng.2013.08.029

Anselmo AC, McHugh KJ, Webster J, Langer R, Jaklenec A (2016) Layer-by-layer encapsulation of probiotics for delivery to the microbiome. Adv Mater 28:9486–9490. https://doi.org/10.1002/adma.201603270

Govender M, Choonara YE, Kumar P, du Toit LC, vanVuuren S, Pillay V (2014) A review of the advancements in probiotic delivery: Conventional vs. non-conventional formulations for intestinal flora supplementation. AAPS PharmSciTech 15:29–43. https://doi.org/10.1208/s12249-013-0027-1

Jao CL, Huangba SL, Wua SC, Kuo-Chiang H (2011) The study on SFLAB GanedenBC30 viability on baking products during storage. Procedia Food Science 1:1601–1609

Côté JP, Dion J, Burguière P, Casavant L, Eijk JV (2013) Probiotics in Bread and Baked Products: A New Product Category. Cereal Foods World 58:293–296. https://doi.org/10.1094/CFW-58-6-0293

Soukoulis C, Yonekura L, Gan HH, Behboudi-Jobbehdar S, Parmenter C, Fisk I (2014) Probiotic edible films as a new strategy for developing functional bakery products: The case of pan bread. Food Hydrocoll 39:231–242. https://doi.org/10.1016/j.foodhyd

Altamirano-Fortoulab R, Moreno-Terrazas R, Quezada-Gallo A, Rosell CM (2012) Viability of some probiotic coatings in bread and its effect on the crust mechanical properties. Food Hydrocoll 29:166–174. https://doi.org/10.1016/j.foodhyd.2012.02.015

Seyedain-Ardabili M, Sharifan A, Ghiassi Tarzi B (2016) The production of synbiotic bread by microencapsulation. Food Technol Biotechnol 54:52–59. https://doi.org/10.17113/ftb.54.01.16.4234

Süle J, Kõrösi T, Hucker A, Varga L (2014) Evaluation of culture media for selective enumeration of bifidobacteria and lactic acid bacteria. Braz J Microbiol 45:1023–1030. https://doi.org/10.1590/s1517-83822014000300035

ISO/TS 19036:2006 (2006) Microbiology of food and animal feeding stuffs — Guidelines for the estimation of measurement uncertainty for quantitative determinations

The United States Pharmacopeia (2002) Particle size distribution estimation by analytical sieving. USP 27, 2335 and page 1581 of PF 28(5). Available via DIALOG. https://www.usp.org/sites/default/files/usp/document/harmonization/gen-chapter/g01_pf_30_6_2004.pdf. Accessed 15 August 2019.

Pordesimo LO, Onwulata CI, Carvalho CWP (2009) Food powder delivery through a feeder system: effect of physicochemical properties. Int J Food Prop 12:556–570. https://doi.org/10.1080/10942910801947748

U.S. Food and Drug Administration (1997) Guidance for Industry: Dissolution testing of immediate release solid oral dosage forms. U.S. Department of Health and Human Services Food and Drug Administration Center for Drug Evaluation and Research (CDER). Available via DIALOG. http://www.fda.gov/downloads/drugs/guidancecomplianceregulatoryinformation/guidances/ucm070237.pdf. Accessed 07 February 2020.

Nejati R, Gheisari H, Hosseinzadeh S, Amin H (2011) Viability of encapsulated bifidobacterium lactis (BB-12) in synbiotic UF cheese and it’s survival under in vitro simulated gastrointestinal conditions. Int J Probiotics Prebiotics 6:197–204

Haack D, Koeberle M (2014) Hot melt coating for controlling the stability, release properties and taste of solid oral dosage forms. TechnoPharm 4:258–263

Xu Q, Li M, Zhang J, Li Z (2017) Hot-melt fluidized bed encapsulation of citric acid with lipid. Int J Food Eng 13:8–9. https://doi.org/10.1515/ijfe-2016-0247

Pole S, Maurya S, Hasnale P, Rathod N, Bendale S, Khutle NM (2016) A detail understanding of enteric coated tablet: manufacturing and evaluation. Eur J Pharm Med Res 3:135–144

Tønnesen HH, Karlsen J (2002) Alginate in drug delivery systems. Drug Dev Ind Pharm 28:621–630. https://doi.org/10.1081/ddc-120003853

Smith AM, Ingham A, Grover LM, Perrie Y (2010) Polymer film formulations for the preparation of enteric pharmaceutical capsules. J Pharm Pharmacol 62:167–172. https://doi.org/10.1211/jpp.62.02.0003

Muthamizhi K, Kalaichelvi P, Powar ST, Jaishree R (2014) Investigation and modelling of surface tension of power-law fluids. RSC Advances 4:9771–9776. https://doi.org/10.1039/c3ra46555a

Penhasi A, Elias M, Eshtauber F, Naiman-Nissenboim H, Reuveni A, Baluashvili I (2017) A novel hybrid solid dispersion film coat as a moisture barrier for pharmaceutical applications. J Drug Delivery Sci Technol 40:105–115. https://doi.org/10.1016/j.jddst.2017.05.024

Jones D, Brischke C (2017) Performance of the bio-based materials. In: Jones D, Brischke C (eds) Performance of Bio-based building materials. Woodhead Publishing, Cambridge, pp 249–333

Azubuike CP, Okhamafe AO (2012) Physicochemical, spectroscopic and thermal properties of microcrystalline cellulose derived from corn cobs. Int J Recycl Org Waste Agricult 1:1–7. https://doi.org/10.1186/2251-7715-1-9

Maronga S (1998) On the optimization of the fluidized bed particulate coating process. Thesis (PhD). Department of Chemical Engineering and Technology, Royal Institute of Technology, Stockholm, Sweden.

Vesterlund S, Salminen K, Salminen S (2012) Water activity in dry foods containing live probiotic bacteria should be carefully considered: A case study with Lactobacillus rhamnosus GG in flaxseed. Int J Food Microbiol 157:319–321. https://doi.org/10.1016/j.ijfoodmicro.2012.05.016

Abe F, Miyauchi H, Uchijima A, Yaeshima T, Iwatsuki K (2009) Effects of storage temperature and water activity on the survival of bifidobacteria in powder form. Int J Dairy Technol 62:234–239. https://doi.org/10.1111/j.1471-0307.2009.00464.x

Czuchajowska Z, Pomeranz Y (1989) Differential scanning calorimetry, water activity, and moisture contents in crumb center and near-crust zones of bread during storage. Cereal Chem 66:305–309

Shenoy PP, Viau M, Tammel K, Innings F, Fitzpatrick JJ, Ahrné LM, LM, (2015) Effect of powder densities, particle size and shape on mixture quality of binary food powder mixtures. Powder Technol 272:165–172. https://doi.org/10.1016/j.powtec.2014.11.023

Musha H, Chandratilleke GR, Chan SLI, Bridgwater J, Aibing YuA (2013) Effects of size and density differences on mixing of binary mixtures of particles. AIP Conf Proc 1542:739–742. https://doi.org/10.1063/1.4812037

Density of Flour, wheat (material). Available via DIALOG. https://www.aqua-calc.com/page/density-table/substance/flour-coma-and-blank-wheat. Accessed 4 October 2019.

Shah NP, Ali JF, Ravula RK (2000) Populations of. acidophilus, Bifidobacterium spp., and Lactobacillus casei in commercial fermented milk products. Biosci Microflora 19:35–39. https://doi.org/10.12938/bifidus1996.19.35

Kosin B, Rakshit SK (2006) Microbial and processing criteria for production of probiotics: a review. Food Technol Biotechnol 44:371–379

Kailasapathy K (2002) Microencapsulation of probiotic bacteria: Technology and potential applications. Curr Issues Intest Microbiol 3:39–48

Nunes GL, Motta MH, Cichoski AJ, Wagner R, Muller EI, Codevilla CF, Da Silva CB, De Menezes CR (2018) Encapsulation of Lactobacillus acidophilus La-5 and Bifidobacterium Bb-12 by spray drying and evaluation of its resistance in simulated gastrointestinal conditions, thermal treatments and storage conditions. Cienc Rural 48:1–10. https://doi.org/10.1590/0103-8478cr20180035

Ayub M, Wahab S, Durrani Y (2003) Effect of water activity (Aw) moisture content and total microbial count on the overall quality of bread. Int J Agric Biol 5:274–278

Simsek S (2018) Wheat Quality & Carbohydrate Research [online]. NDSU, North Dakota State University. Available via DIALOG. https://www.ndsu.edu/faculty/simsek/. Accessed 12 October 2019.

Simpson PJ, Stanton C, Fitzgerald GF, Ross RP (2005) Intrinsic tolerance of Bifidobacterium species to heat and oxygen and survival following spray drying and storage. J Appl Microbiol 99:493–501. https://doi.org/10.1111/j.1365-2672.2005.02648.x

Eglite A, Kunkulberga D (2017) Bread choice and consumption trends, Foodbalt 178–182. Available via DIALOG. https://pdfs.semanticscholar.org/0e5c/a05ca768ff69a1a8102cf88371452394271e.pdf. Accessed 19 December 2019.

Vernazza CL, Gibson GR, Rastall RA (2006) Carbohydrate preference, acid tolerance and bile tolerance in five strains of Bifidobacterium. J Appl Microbiol 100:846–853. https://doi.org/10.1111/j.1365-2672.2006.02832.x

Ritter P, Kohler C, Ah U (2009) Evaluation of the passage of Lactobacillus gasseri K7 and bifidobacteria from the stomach to intestines using a single reactor model. BMC Microbiol 9:1–9. https://doi.org/10.1186/1471-2180-9-87

Funding

This study was part of the research and development department’s activities of PolyCaps Holdings Ltd.

Author information

Authors and Affiliations

Contributions

AP is the inventor of the idea and was responsible for the design and development of the microcapsule structure and also for the design of the experiments in this study. AR was responsible for the development of the production process and production of the experimental and validation batches. IB contributed to the development and performance of the microbiological tests including the methods for releasing the bacteria from the microcapsules and performance of the validation of the methods.

Corresponding author

Ethics declarations

Conflict of interest

All authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Penhasi, A., Reuveni, A. & Baluashvili, I. Microencapsulation May Preserve the Viability of Probiotic Bacteria During a Baking Process and Digestion: A Case Study with Bifidobacterium animalis Subsp. lactis in Bread. Curr Microbiol 78, 576–589 (2021). https://doi.org/10.1007/s00284-020-02292-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00284-020-02292-w