Abstract

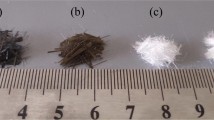

Animal fibers with α-keratin had obvious advantages of mechanical strength and durability on reinforced microbially induced carbonate precipitation (MICP)-cemented loose sands. Herein, wool fiber, α-keratin-rich animal fiber with high strength, was applied to reinforcement of MICP-cemented loose sands. The mechanical properties and underlying mechanism were experimentally explored. Results showed that adding 0.1 wt% wool fiber enhanced up to 3.34-fold the compressive strength and significantly improved the flexure resistance performance. The microstructural results revealed that wool fibers providing many nucleation sites for calcite precipitation not only significantly decreased the porosity of the specimen, but also effectively generated calcite and distributed fiber-bridging microstructure uniformly, resulting in a marked reinforcement of MICP performance. Further studies indicated that sand grains were cemented with calcite through the intermolecular hydrogen bonds HN–H…O–C(Si). This study first reports the potential and the underlying mechanism of animal fiber on improvement of MICP performance and provides new insight into enhancing mechanical behavior of MICP-cemented loose sands with fibrous proteins.

Graphic abstract

Similar content being viewed by others

References

Achal V, Mukherjee A (2015) A review of microbial precipitation for sustainable construction. Constr Build Mater 93:1224–1235

Aggarwal LK (1995) Bagasses-reinforced cement composites. Cement Concr Compos 17:107–112

Al-Salloum Y, Hadi S, Abbas H, Almusallam T, Moslem MA (2017) Bio-induction and bioremediation of cementitious composites using microbial mineral precipitation—a review. Constr Build Mater 154:857–876

ASTM C496 (2017) Standard test method for splitting tensile strength of cylindrical concrete specimens. ASTM International, West Conshohocken

Bai Y, Guo XJ, Li YZ, Huang T (2017) Experimental and visual research on the microbial induced carbonate precipitation by Pseudomonas aeruginosa. AMB Express 7:57–65

Banagan BL, Wertheim BM, Roth MJS, Caslake LF (2010) Microbial strengthening of loose sand. Lett Appl Microbiol 51:138–142

Banthia N, Nandakumar N (2003) Crack growth resistance of hybrid fiber reinforced cement composites. Cement Concr Compos 25:3–9

Bhavsar P, Zoccola M, Patrucco A, Montarsolo A, Mossotti R, Rovero G, Giansetti M, Tonin C (2016) Superheated water hydrolysis of waste wool in a semi-industrial reactor to obtain nitrogen fertilizers. ACS Sustain Chem Eng 4:6722–6731

Binici H, Aksogan O, Bodur MN, Akca E, Kapur S (2007) Thermal isolation and mechanical properties of fiber reinforced mud bricks as wall materials. Constr Build Mater 21:901–906

Bontognali TRR, Vasconcelos C, Warthmann RJ, Dupraz C, Bernasconi SM, McKenzie JA (2008) Microbes produce nanobacteria-like structures, avoiding cell entombment. Geology 36:663–666

Bundur ZB, Amiri A, Ersan YC, Boon N, Belie ND (2017) Impact of air entraining admixtures on biogenic calcium carbonate precipitation and bacterial viability. Cement Concrete Res 98:44–49

Cheng L, Shahin MA (2019) Microbially induced calcite precipitation (MICP) for soil stabilization: innovative approaches to socio-ecological sustainability. In: Achal V, Mukherjee A (eds) Ecological wisdom inspired restoration engineering. Springer, Singapore, pp 47–54

Cheng L, Shahin MA, Chu J (2019) Soil bio-cementation using a new one-phase low-pH injection method. Acta Geotech 14:615–626

Choi SG, Wang K, Chu J (2016) Properties of biocemented, fiber reinforced sand. Constr Build Mater 120:623–629

Chu J, Ivanov V, Naeimi M, Stabnikov V, Liu HL (2014) Optimization of calcium-based bioclogging and biocementation of sand. Acta Geotech 9:277–285

Clark S, Francis PS, Conlan XA, Barnett NW (2007) Determination of urea using high-performance liquid chromatography with fluorescence detection after automated derivatisation with xanthydrol. J Chromatogr A 1161:207–213

Corscadden KW, Biggs JN, Stiles DK (2014) Sheep’s wool insulation: a sustainable alternative use for a renewable resource? Resour Conserv Recycl 86:9–15

Cui MJ, Zheng JJ, Zhang RJ, Lai HJ, Zhang J (2017) Influence of cementation level on the strength behaviour of bio-cemented sand. Acta Geotech 12:971–986

Das O, Kim NK, Sarmah AK, Bhattacharyya D (2017) Development of waste based biochar/wool hybrid biocomposites: flammability characteristics and mechanical properties. J Clean Prod 144:79–89

Dhami NK, Reddy MS, Mukherjee A (2016) Significant indicators for biomineralisation in sand of varying grain sizes. Constr Build Mater 104:198–207

EN 196-1 (2016) Methods of testing cement-part 1: determination of strength. European Committee for Standardization

Fang X, Yang Y, Chen Z, Liu H, Xiao Y, Shen C (2020) Influence of fiber content and length on engineering properties of MICP-treated coral sand. Geomicrobiol J 37:582–594

Fantilli AP, Sicardi S, Dotti F (2016) The use of wool as fiber-reinforcement in cement-based mortar. Constr Build Mater 139:562–569

Gao Y, Hang L, He J, Chu J (2019) Mechanical behaviour of biocemented sands at various treatment levels and relative densities. Acta Geotech 14:697–707

Gashti MP, Ghehi ST, Arekhloo SV, Mirsmaeeli A, Kiumarsi A (2015) Electromagnetic shielding response of UV-induced polypyrrole/silver coated wool. Fiber Polym 16:585–592

Griffith AA (1924) Theory of rupture. In: Proceedings of the first international congress. Applied rock mechanics delft. pp 55–63

Hakamy A, Shaikh FUA, Low IM (2013) Microstructures and mechanical properties of hemp fabric reinforced organoclay-cement nanocomposites. Constr Build Mater 49:298–307

Hakamy A, Shaikh FUA, Low IM (2014) Characteristics of hemp fabric reinforced nanoclay-cement nanocomposites. Cement Concr Compos 50:27–35

Hamzaoui R, Guessasmam S, Mecheri B, Eshtiaghi AM, Bennabi A (2014) Microstructure and mechanical performance of modified mortar using hemp fibres and carbon nanotubes. Mater Des 56:60–68

Lauchnor EG, Schultz LN, Bugni S, Mitchell AC, Cunningham AB, Gerlach R (2013) Bacterially induced calcium carbonate precipitation and strontium coprecipitation in a porous media flow system. Environ Sci Technol 47:1557–1564

Li M, Li L, Ogbonnaya U, Wen K, Tian A, Amini F (2016) Influence of fiber addition on mechanical properties of MICP-treated sand. J Mater Civ Eng 28:04015166

Li M, Zhu X, Mukherjee A, Huang M, Achal V (2017) Biomineralization in metakaolin modified cement mortar to improve its strength with lowered cement content. J Hazard Mater 329:178–184

Marsmann H (1981) 29Si-NMR spectroscopic results. In: Diehl P, Fluck E, Kosfeld R (eds) Oxygen-17 and silicon-29. Springer, Berlin Heidelberg, pp 65–235

Merta I (2016) Hemp fibres—a promising reinforcement for cementitious materials. In: Fangueiro R, Rana S (eds) Natural fibres: advances in science and technology towards industrial applications. Springer, Dordrecht, pp 291–303

Minto JM, Qian T, Lunn RJ, Mountassir GE, Guo H, Cheng X (2018) ‘Microbial mortar’-restoration of degraded marble structures with microbially induced carbonate precipitation. Constr Build Mater 180:44–54

Mondal S, Ghosh AD (2019) Review on microbial induced calcite precipitation mechanisms leading to bacterial selection for microbial concrete. Constr Build Mater 225:67–75

Muynck WD, Debrouwer D, Belie ND, Verstraete W (2008) Bacterial carbonate precipitation improves the durability of cementitious materials. Cement Concr Res 38:1005–1014

Onuaguluchi O, Banthia N (2016) Plant-based natural fibre reinforced cement composites: a review. Cement Concr Compos 68:96–108

Pacheco-Torgal F, Jalali S (2011) Cementitious building materials reinforced with vegetable fibres: a review. Constr Build Mater 25:575–581

Phillips AJ, Cunningham AB, Gerlach R, Hiebert R, Hwang C, Lomans BP, Westrich J, Mantilla C, Kirksey J, Esposito R, Spangler L (2016) Fracture sealing with microbially-induced calcium carbonate precipitation: a field study. Environ Sci Technol 50:4111–41117

Phillips AJ, Gerlach R, Lauchnor E, Mitchell AC, Cunningham AB, Spangler L (2013) Engineered applications of ureolytic biomineralization: a review. Biofouling 29:715–733

Qiu R, Tong H, Fang X, Liao Y, Li Y (2019) Analysis of strength characteristics of carbon fiber-reinforced microbial solidified sand. Adv Mech Eng 11:1–7

Ramamoorthy SK, Skrifvars M, Persson A (2015) A review of natural fibers used in biocomposites: plant, animal and regenerated cellulose fibers. Polym Rev 55:107–162

Rong H, Qian CX (2015) Binding functions of microbe cement. Adv Eng Mater 17:334–340

Rong H, Qian CX, Li LZ (2012) Study on microstructure and properties of sandstone cemented by microbe cement. Constr Build Mater 36:687–694

Shavandi A, Silva TH, Bekhit AA, Bekhit AEA (2017) Keratin: dissolution, extraction and biomedical application. Biomater Sci 5:1699–1735

Tang C, Shi B, Gao W, Chen F, Cai Y (2007) Strength and mechanical behavior of short polypropylene fiber reinforced and cement stabilized clayey soil. Geotext Geomembr 25:194–202

Wang XF, Zhang JH, Zhao W, Han R, Han NX, Xing F (2018) Permeability and pore structure of microcapsule-based self-healing cementitious composite. Constr Build Mater 165:149–162

Wen K, Bu C, Liu S, Li Y, Li L (2018) Experimental investigation of flexure resistance performance of bio-beams reinforced with discrete randomly distributed fiber and bamboo. Constr Build Mater 176:241–249

Wu C, Chu J, Wu S, Cheng L, van Paassen LA (2018) Microbially induced calcite precipitation along a circular flow channel under a constant flow condition. Acta Geotech 14:673–683

Xu S, Liu J, Li Q (2015) Mechanical properties and microstructure of multi-walled carbon nanotube-reinforced cement paste. Constr Build Mater 76:16–23

Yu XN, Qian CX, Wang X (2015) Cementing mechanism of bio-phosphate cement. Sci China Technol Sci 58:1112–1117

Zhang Y, Guo HX, Cheng XH (2015) Role of calcium sources in the strength and microstructure of microbial mortar. Constr Build Mater 77:160–167

Zhang J, Zhao C, Zhou A, Yang C, Zhao L, Li Z (2019) Aragonite formation induced by open cultures of microbial consortia to heal cracks in concrete: insights into healing mechanisms and crystal polymorphs. Constr Build Mater 224:815–822

Zhao Y, Xiao Z, Fan C, Shen W, Wang Q, Liu P (2020) Comparative mechanical behaviors of four fiber-reinforced sand cemented by microbially induced carbonate precipitation. Bull Eng Geol Environ 79:3075–3086

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Grant Numbers 41902314, 41972319); the China Postdoctoral Science Foundation (Grant number 2019M652620); and the Fundamental Research Funds for HUST (Grant number 2017KFTSZZ001). The authors would like to acknowledge the Analytical and Testing Center of HUST and the Research Core Facilities for Life Science (HUST) for their valuable assistance in HPLC, IC, FE-SEM, FE-TEM, FTIR, XPS and CLSM analyses.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yao, D., Wu, J., Wang, G. et al. Effect of wool fiber addition on the reinforcement of loose sands by microbially induced carbonate precipitation (MICP): mechanical property and underlying mechanism. Acta Geotech. 16, 1401–1416 (2021). https://doi.org/10.1007/s11440-020-01112-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11440-020-01112-6