Abstract

The effects of process parameters and aging treatment on the microstructure and mechanical properties of selective laser melting (SLM) fabricated high Mg-content Al-Mg-Sc-Zr aluminum alloy were systematically studied. Our experiment results show that the samples exhibit good processability with porosity less than 1%. The increase of Mg content in Al-Mg-Sc-Zr is beneficial to reduce the texture of the alloy. The laser scanning speed has a large influence on the Vickers hardness of as-fabricated samples. The maximum microhardness of as-fabricated sample reaches 148 ± 2 HV with a compression yield strength of 342 ± 7 MPa. After aging treatment, the distinction in microhardness of the samples obtained under different laser scanning speed is obviously reduced, and the mechanical properties of the samples are further improved with a maximum microhardness of 175 ± 5 HV and a maximum compressive yield strength of 476 ± 10 MPa, which are superior to the known Al-Mg-Sc-Zr alloy with same Sc and Zr content fabricated by SLM. In this study, a novel high Mg-content Al-Mg-Sc-Zr aluminum alloy specifically for SLM with good processability and mechanical properties was reported.

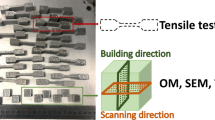

Graphic Abstract

Similar content being viewed by others

References

K.N. Amato, S.M. Gaytan, L.E. Murr, E. Martinez, P.W. Shindo, J. Hernandez, S. Collins, F. Medina, Acta Mater. 60, 2229–2239 (2012)

C.Y. Yap, C.K. Chua, Z.L. Dong, Z.H. Liu, D.Q. Zhang, L.E. Loh, S.L. Sing, Appl. Phys. Rev. 2, 041101 (2015)

K.G. Prashanth, S. Scudino, A.K. Chaubey, L. Löber, P. Wnag, H. Attar, F.P. Schimansky, F. Pyczak, J. Eckert, J. Mater. Res. 31, 55–65 (2016)

L.C. Zhang, H. Attar, M. Calin, J. Eckert, Mater. Technol. 31, 66–76 (2015)

D. Jafari, W.W. Wits, Renew. Sust. Energy Rev. 91, 420–442 (2018)

E.O.T. Olakanmi, R.F. Cochrane, K.W. Dalgarno, Prog. Mater. Sci. 74, 401–477 (2015)

J.R. Croteau, S. Griffithsb, M.D. Rossell, C. Leinenbach, C. Kenel, V. Jansen, D.N. Seidman, D.C. Dunand, N.Q. Vo, Acta Mater. 153, 35–44 (2018)

J.L. Zhang, B. Song, Q.S. Wei, D. Bourell, Y.S. Shi, J. Mater. Sci. Technol. 35, 270–284 (2019)

X.J. Wang, L.C. Zhang, M.H. Fang, T.B. Sercombe, Mater. Sci. Eng. A 597, 370–375 (2014)

I. Rosenthal, R. Shneck, A. Stern, Mater. Sci. Eng. A 729, 310–322 (2018)

X.P. Li, G. Ji, Z. Chen, A. Addad, Y. Wu, H.W. Wang, J. Vleugels, Acta Mater. 129, 183–193 (2017)

A.B. Spierings, K. Dawson, P. Dumitraschkewitz, S. Pogatscher, K. Wegener, Addit. Manuf. 20, 173–181 (2018)

H. Zhang, H.H. Zhu, T. Qi, Z.H. Hu, X.Y. Zeng, Mater. Sci. Eng. A 656, 47–54 (2016)

E. Louvis, P. Fox, C.J. Sutcliffe, J. Mater. Process. Technol. 211, 275–284 (2011)

W. Reschetnik, J.P. Brüggemann, M.E. Aydinöz, O. Grydin, K.P. Hoyer, G. Kullmer, H.A. Richard, Procedia Struct. Integr. 2, 3040–3048 (2016)

Y.K. Xiao, Z.Y. Bian, Y. Wu, G. Ji, Y.Q. Li, M.J. Li, Q. Lian, Z. Chen, A. Addad, H.W. Wang, J. Alloy. Compd. 798, 644–655 (2019)

J. Suryawanshi, K.G. Prashanth, S. Scudino, J. Eckert, O. Prakash, Acta Mater. 115, 285–294 (2016)

W. Li, S. Li, J. Liu, A. Zhang, Y. Zhou, Q.S. Wei, C.Z. Yan, Y.S. Shi, Mater. Sci. Eng. A 663, 116–125 (2016)

T. Qi, H.H. Zhu, H. Zhang, J. Yin, L. Ke, X.Y. Zeng, Mater. Design 135, 257–266 (2017)

K. Schmidtke, F. Palm, A. Hawkins, C. Emmelmann, Physics Proc. 12, 369–374 (2011)

Y.J. Shi, K. Yang, S.K. Kairy, F. Palm, X.H. Wu, P.A. Rometsch, Mater. Sci. Eng. A 732, 41–52 (2018)

A.B. Spierings, K. Dawson, P.J. Uggowitzer, K. Wegener, Mater. Design 140, 134–143 (2018)

R.L. Ma, C.Q. Peng, Z.Y. Cai, R.C. Wang, Z.H. Zhou, X.G. Li, X.Y. Cao, J. Alloy. Compd. 815, 152422 (2020)

P.A. Rometsch, H. Zhong, K.M. Nairn, T. Jarvis, X.H. Wu, Scripta Mater. 87, 13–16 (2014)

Q.B. Jia, P. Rometsch, P. Kürnsteiner, Q. Chao, A.J. Huang, M. Weyland, L. Bourgeois, X.H. Wu, Acta Mater. 171, 108–118 (2019)

S.L. Sing, J. An, W.Y. Yeong, F.E. Wiria, J. Orthop. Res. 34, 369–385 (2016)

R.D. Li, M.B. Wang, T.C. Yuan, B. Song, C. Chen, K.H. Zhou, P. Cao, Powder Technol. 319, 117–128 (2017)

N.T. Aboulkhair, M. Simonelli, L. Parry, I. Ashcroft, C. Tuck, R. Hague, Prog. Mater. Sci. 106, 100578 (2019)

K.V. Yang, Y. Shi, F. Palm, X. Wu, P. Rometsch, Scripta Mater. 145, 113–117 (2018)

E.A. Marquis, D.N. Seidman, Acta Mater. 49, 1909–1919 (2001)

J. Bi, Z.L. Lei, X. Chen, P. Li, N.N. Lu, Y.B. Chen, Ceram. Int. 45, 5680–5692 (2019)

A. Aversa, M. Lorusso, G. Cattano, D. Manfredi, F. Calignano, E.P. Ambrosio, S. Biamino, P. Fino, M. Lombardi, M. Pavese, J. Alloy. Compd. 695, 1470–1478 (2017)

J. Bi, Z.L. Lei, Y.B. Chen, X. Chen, Z. Tian, J.W. Liang, X.K. Qin, X.R. Zhang, Mater. Sci. Eng. A 774, 138931 (2020)

J.A. Lyndon, R.K. Gupta, M.A. Gibson, N. Birbilis, Corros. Sci. 70, 290–293 (2013)

J.Y. Zhang, Y.H. Gao, C. Yang, P. Zhang, J. Kuang, Rare Metals 39, 636–650 (2020)

A.B. Spierings, K. Dawson, K. Kern, F. Palm, K. Wegener, Mater. Sci. Eng. A 701, 264–273 (2017)

A.B. Spierings, K. Dawson, M. Voegtlin, F. Palm, P.J. Uggowitzer, CIRP Ann. Manuf. Techn. 65, 213–216 (2016)

A.B. Spierings, K. Dawson, T. Heeling, P.J. Uggowitzer, R. Schäublin, F. Palm, K. Wegener, Mater. Design 115, 52–63 (2017)

C. Varvenne, G.P.M. Leyson, M. Ghazisaeidi, W.A. Curtin, Acta Mater. 124, 660–683 (2017)

Acknowledgements

This work was supported by the National Key R&D Program of China (No. 2016YFB1100103), the Natural Science Foundation of China (No. 52001140), the Natural Science Foundation for Young Scientists of Jiangsu, China (No. BK20180985), the Natural Science Foundation in Higher Education of Jiangsu (No. 18KJB430011) and the Open Foundation of Zhenjiang Key Laboratory for high technology research on marine functional films (No. ZHZ2019001).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Tang, H., Geng, Y., Luo, J. et al. Mechanical Properties of High Mg-Content Al-Mg-Sc-Zr Alloy Fabricated by Selective Laser Melting. Met. Mater. Int. 27, 2592–2599 (2021). https://doi.org/10.1007/s12540-020-00907-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-020-00907-2