Abstract

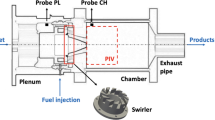

Experimental investigations have been carried out for impingement heat transfer characteristics of an enclosed dual swirling flame for various enclosure configurations. Effects of the size of the enclosure (DE = 70 mm, 90 mm, 90 mm, 110 mm and 150 mm) and the level of gap between the top of the enclosure and the target surface (G = 12, 16, 20, 24 and 28 mm) have been examined at fixed other operating conditions (Re(o), H/Dh and S). In addition to this, the effects of variation in outer swirling flame Reynolds numbers (Re(o) = 7000–13,000), dimensionless separation distances (H/Dh = 2–5) and the swirl number (S = 0.86, 1.54 and 2.4) have also been examined. Impingement heat transfer characteristics strongly depend on the size of the enclosure (DE) and the level of gap (G). Larger sized enclosures (DE of 110 and 150 mm) with smaller gap levels (G of 12 and 16 mm) perform much better than small sized enclosures (DE of 70 and 80 mm) with larger gap levels (G of 24 and 28 mm). Heat transfer performance continuously increases with an increase in Re(o) in presence of an enclosure in contrast to unenclosed flames where performance deteriorates at high Re(o). The heat transfer enhancement effect in presence of enclosure is more pronounced at larger separation distances (H/Dh of 4 and 5) because of the formation of the outer recirculation zone (ORZ). The effect of the presence of enclosure on impingement heat transfer enhancement becomes more significant at higher levels of swirl.

Similar content being viewed by others

Abbreviations

- A/F:

-

air to fuel ratio

- Re:

-

Reynolds number

- Re(i):

-

Reynolds number of inner premixed flame

- Re(o):

-

Reynolds number of outer swirling flame

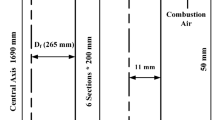

- Dh :

-

hydraulic diameter at burner exit (m)

- d:

-

inner premixed pipe diameter (m)

- H/Dh :

-

dimensionless separation distance

- T:

-

percentage proportion of tangential flow rate

- A:

-

percentage proportion of axial flow rate

- S:

-

Swirl number

- r/Dh :

-

dimensionless radial distance

- CRZ:

-

Central Recirculation Zone

- ORZ:

-

Outer Recirculation Zone

- \( \overset{.}{q^{{\prime\prime} }} \) :

-

heat flux (in kW/m2)

- DB :

-

diameter at the burner exit (mm)

- DE :

-

diameter of the enclosure (mm)

- \( \overset{.}{q_f} \) :

-

total firing rate (kW)

- ρ:

-

density (kg/m3)

- ϕ(i):

-

the inner conical flame equivalence ratio

- ϕ(o):

-

the outer swirling flame equivalence ratio

- μ:

-

dynamic viscosity (kg/m-s)

- i:

-

inner

- o:

-

outer

- stoic-:

-

stoichiometric

- mix:

-

mixture

- p:

-

tangential port

- r:

-

radial distance (in m)

References

Malikov GK, Lobanov DL, Malikov KY et al (2001) Direct flame impingement heating for rapid thermal materials processing. Int J Heat Mass Transf 44:1751–1758

Baukal CE, Gebhart B (1995) A review of flame impingement heat transfer – part I: experimental conditions. Combust Sci Technol 104:339–357

Shao Z, Jiang J, Lin J (2018) Feasibility study on direct flame impingement heating applied for the solution heat treatment, forming and cold die quenching technique. J Manuf Process 36:398–404

Viskanta R (1993) Heat transfer to impinging isothermal gas and flame jets. Exp Thermal Fluid Sci 6:111–134

Singh G, Chander S, Ray A (2012) Heat transfer characteristics of natural gas/air swirling flame impinging on a flat surface. Exp Thermal Fluid Sci 41:165–176

Zhen HS, Leung CW, Cheung CS (2011) A comparison of the thermal , emission and heat transfer characteristics of swirl-stabilized premixed and inverse diffusion flames. Energy Convers Manag 52:1263–1271

Luo DD, Zhen HS, Leung CW, Cheung CS (2010) Premixed flame impingement heat transfer with induced swirl. Int J Heat Mass Transf 53:4333–4336

Singh S, Chander S (2014) Heat transfer characteristics of dual flame with outer swirling and inner non-swirling flame impinging on a flat surface. Int J Heat Mass Transf 77:995–1007

Singh S, Chander S (2015) Heat transfer characteristics of dual swirling flame impinging on a flat surface. Int J Therm Sci 89:1–12

Singh P, Chander S (2018) Heat transfer and fluid flow characteristics of a pair of interacting dual swirling flame jets impinging on a flat surface. Int J Heat Mass Transf 124:90–108

Singh P, Chander S (2020) Effect of interactions on flow field and heat transfer characteristics for three Corotating dual swirling flames impinging on a flat surface. Combust Sci Technology 192(4):701–727

Colucci DW, Viskanta R (1996) Effect of nozzle geometry on local convective heat transfer to a confined impinging air jet. Exp Thermal Fluid Sci 13:71–80

Delichatsios MA, Orloff L (1985, January) Entrainment measurements in turbulent buoyant jet flames and implications for modeling. In symposium (international) on combustion. (Vol. 20, no. 1), Elsevier, pp 367–375

Hill BJ (1972) Measurement of local entrainment rate in the initial region of axisymmetric turbulent air jets. J Fluid Mech 51:773–779

Park SH, Shin HD (1993) Measurements of entrainment characteristics of swirling jets. Int J Heat Mass Transf 36:4009–4018

Sheen HJ, Chen WJ, Jeng SY (1996) Recirculation zones of unconfined and confined annular swirling jets. AIAA J 34(3):572–579

Ahmad NT, Andrews GE, Kowkabi M, Sharif SF (1985, January) Centrifugal mixing forces in enclosed swirl flames. In Symposium (International) on Combustion (Vol. 20, no. 1). Elsevier, pp 259–267

Archer S, Gupta AK (2004) The role of confinement on flow dynamics under fuel lean combustion conditions. In 2nd international energy conversion engineering conference, p 5617

Cai J, Elkady A, Fu Y (2003) Swirl cup modeling part IV: effect of confinement on flow characteristics. AIAA

Nogenmyr KJ, Cao HJ, Chan CK, Cheng RK (2013) Effects of confinement on premixed turbulent swirling flame using large Eddy simulation. Combust Theor Model 17:1003–1019

Nogenmyr K, Fureby C, Bai XS et al (2009) Large eddy simulation and laser diagnostic studies on a low swirl stratified premixed flame. Combust Flame 156:25–36

Syred N, Dahman DR (1978) Effect of high levels of confinement upon the aerodynamics of swirl burners. J Energy 2:8–15

Kline SJ, McClintock FA (1953) Describing uncertainties in single sample experiments, mechanical engineering. Mech Eng 75:3–8

Archer S, Gupta AK (2004) The role of confinement on flow dynamics under fuel lean combustion conditions. In: 2nd international energy conversion engineering conference. Pp 1–10

Sapra G, Chander S (2020) Effect of operating and geometrical parameters of tangential entry type dual swirling flame burner on impingement heat transfer. Appl Therm Eng 181:115936

Claypole TC, Syred N (1981) The effect of swirl burner aerodynamics on NOx formation. Symp Combust 18:81–89

Chander S, Ray A (2008) An experimental and numerical study of stagnation point heat transfer for methane / air laminar flame impinging on a flat surface. Int J Heat Mass Transf 51:3595–3607

Hargrave GK, Fairweather M, Kilham JK (1987) Forced convective heat transfer from premixed flames - - P a r t 1 : Flame structure. Int J Heat Fluid Flow 8:55–63

Tuttle SG, Webb BW, Mcquay MQ (2005) Convective heat transfer from a partially premixed impinging flame jet . Part I : Time-averaged results. Int J Heat Mass Transf 48:1236–1251

Zhen HS, Cheung CS, Leung CW, Li HB (2013) Thermal and heat transfer behaviors of an inverse diffusion flame with induced swirl. Fuel 103:212–219

Coghe ALDO, Solero GAG, & Terragni C (2000) Experimental analysis on turbulent mixing in a swirl burner. In: in open meeting on combustion, 23rd event of the Italian section of the combustion institute. Pp 1–4

Chander S, Ray A (2007) Heat transfer characteristics of three interacting methane / air flame jets impinging on a flat surface. Int J Heat Mass Transf 50:640–653

Coghe AS, Solero GA, Terragni C (2000) Experimental analysis on turbulent mixing in a swirl burner. In open meeting on combustion, 23rd event of the Italian section of the combustion institute. pp 1–4

Syred N, Chigier NA, Beer JM (1971) Flame stabilization in recirculation zones of jets with swirl. Symp Combust 13:617–624

Coghe A, Solero G, Scribano G (2004) Recirculation phenomena in a natural gas swirl combustor. Exp Thermal Fluid Sci 28:709–714

Tamir A, Elperin I, Yotzer S (1989) Performance characteristics of a gas burner with a swirling central flame. Energy 14:373–382

Schmittel P, Gunther B, Lenze B, et al (2000) Turbulent swirling flames : experimental investigation of the flow field and formation of nitrogen oxide. In: Proceedings of the Combustion Institute. pp. 303–309

Zhen HS, Leung CW, Cheung CS (2010) Thermal and emission characteristics of a turbulent swirling inverse diffusion flame. Int J Heat Mass Transf 53:902–909

Acknowledgements

The authors convey their sincere gratitude to Dr. BR Ambedkar National Institute of Technology for their financial support in executing the experimental study.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sapra, G., Chander, S. Effect of enclosure on heat transfer characteristics of dual swirling flame impinging on a flat surface. Heat Mass Transfer 57, 1011–1023 (2021). https://doi.org/10.1007/s00231-020-03006-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-020-03006-5