Abstract

The effects of the heating rate during solid solution heat treatment on the mechanical properties and microstructure of the 7055 aluminum alloy were investigated. The dissolution and formation kinetics of the precipitates in the sample before the solid solution treatment vary depending on the heating rate. This is because the dissolution and formation of precipitate particles are diffusion-controlled. Therefore, dilatometric tests were carried out to control the heating rates during the solid solution treatment. Then, the mechanical properties were evaluated using hardness and compressive tests, while the microstructural features were observed using X-ray diffraction, optical microscopy, and scanning transmission electron microscopy. The characteristics of the precipitate for each heating rate were calculated using thermodynamic simulation, and a model to predict the mechanical properties was proposed based on the results.

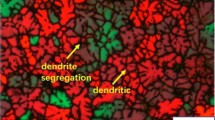

Graphic Abstract

Similar content being viewed by others

References

J.C. Williams, E.A. Starke Jr., Acta Mater. 51, 5775 (2003)

M. Nakai, T. Eto, Mater. Sci. Eng. A 285, 62 (2000)

J. Lee, H.J. Bong, D. Kim, Y.S. Lee, Y. Choi, M.G. Lee, Met. Mater. Int. 26, 682 (2020)

J.G. Kaufman, Properties of Aluminum Alloys-Tensile, Creep, and Fatigue Data at High and Low Temperature (ASM International, Materials Park, OH, ASM, 1999), p. 207

J.R. Davis, ASM Speciality Handbook, (ASM International, Materials Park, OH, 1993), pp. 65–67.

J. Buha, R.N. Lumley, A.G. Crosky, Mater. Sci. Eng. A 492, 1 (2008)

S.H. Kayani, J.G. Jung, M.S. Kim, K. Euh, Met. Mater. Int. 26, 1079 (2020)

M. Dixit, R.S. Mishra, K.K. Sankaran, Mater. Sci. Eng. A 478, 163 (2008)

H. Puga, V.H. Carneiro, Light–alloy melt ultrasonication: shorter T6 with higher precipitation strengthening. Met. Mater. Int. (2020). https://doi.org/10.1007/s12540-020-00798-3

K.S. Ghosh, N. Gao, Trans. Nonferrous Metal. Soc. 21, 1199 (2011)

A. Karaaslan, I. Kaya, H. Atapek, Met. Sci. Heat treat. 49, 443 (2007)

Y. Liu, D. Jiang, B. Li, T. Ying, J. Hu, Mater. Des. 60, 116 (2014)

T. Furuhara, K. Kobayashi, T. Maki, ISIJ Int. 44, 1937 (2004)

O.N. Senkov, M.R. Shagiev, S.V. Senkova, D.B. Miracle, Acta Mater. 56, 3723 (2008)

Z. Zhang, J. Yu, D. He, Mater. Sci. Eng. A 743, 500 (2019)

X. Xu, Y. Zhao, X. Wang, Y. Zhang, Y. Ning, Mater. Sci. Eng. A 654, 278 (2016)

S.D. Liu, X.M. Zhang, M.A. Chen, J.H. You, Mater. Charact. 59, 53 (2008)

G. Sha, A. Cerezo, Acta Mater. 52, 4503 (2004)

W. Yang, S. Ji, M. Wang, Z. Li, J. Alloy. Compd. 610, 623 (2014)

V. Hanen, O.B. Karlsen, Y. Langsrud, J. Gjønnes, Mater. Sci. Tech. 20, 185 (2004)

Y.L. Chang, F.Y. Hung, T.S. Lui, Mater. Sci. Eng. A 702, 438 (2017)

C. Mondal, A.K. Mukhopadhyay, Mater. Sci. Eng. A 391, 367 (2005)

B. Milkereit, N. Wanderka, C. Schick, O. Kessler, Mater. Sci. Eng. A 550, 87 (2012)

Y.C. Lin, J.L. Zhang, M.S. Chen, J. Alloy. Compd. 684, 177 (2016)

M. Mihara, C.D. Marioara, S.J. Andersen, R. Holmenstad, E. Kobayashi, T. Sato, Mater. Sci. Eng. A 658, 91 (2016)

O.R. Myhr, Ø. Grong, S.J. Andersen, Acta Mater. 49, 65 (2001)

G.E. Totten, D.S. MacKenzie, Handbook of Aluminum-Physical Metallurgy and Processes (Marcel Dekker Inc., New York, 2003), p. 89

G.E. Dieter, Mechanical Metallurgy (McGraw-Hill Book, New York, 1986), pp. 77–80

P.M. Kelly, Scr. Metall. 6, 647 (1972)

S.D. Harkness, J.J. Hren, Metall. Trans. 1, 43 (1970)

E. Hornbogen, E.A. Starke, Acta Metall. Mater. 41, 1 (1993)

N.M. Han, X.M. Zhang, S.D. Liu, D.G. He, R. Zhang, J. Alloy. Compd. 509, 4138 (2011)

M. Esmailian, M. Shakouri, A. Mottahedi, S.G. Shabestari, Int. J. Chem. Mol. Nucl. Mater. Metall. Eng. 9, 1303 (2015)

Acknowledgements

This work was supported by a Korea Institute for Advancement of Technology grant, funded by the Korea Government (MOTIE) (P0002019), as part of the Competency Development Program for Industry Specialists. This paper was supported by research funds of Jeonbuk National University in 2020.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Choi, S., Jeon, J., Seo, N. et al. Effect of Heating Rate on Microstructure and Mechanical Properties in Al 7055. Met. Mater. Int. 27, 449–455 (2021). https://doi.org/10.1007/s12540-020-00910-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-020-00910-7