Abstract

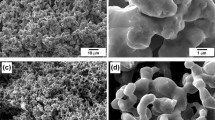

The processes of hydrogen production from various types of fossil and renewable fuels are energy-intensive multi-route chemical reactions, and for their efficient implementation it is necessary to use selective and high-performance catalysts that combine high activity, thermal conductivity, and corrosion and thermal resistance. A general strategy for the design of catalytic systems for hydrogen production is outlined; it consists in the use of composite catalysts of the “metal nanoparticles/active oxide nanoparticles/structural oxide component/structured metal support” type; an approach for their directed synthesis is described. The structured metal support provides efficient heat removal or supply for exo- or endothermic reactions, possesses good hydrodynamic characteristics, and facilitates scale transition. The structural oxide component (aluminum oxide) provides thermal and corrosion resistance and a high specific surface area of the catalytic coating, as well as performing a protective function for the metal support. The active oxide component (mainly cerium–zirconium oxides) increases resistance to carbonization due to oxygen mobility and maintains a high dispersion of the active component due to its strong metal–support interaction. Metal nanoparticles 1–2 nm in size are involved in the activation of substrate molecules. FeCrAl alloy wire meshes, formed into cylindrical blocks of specified sizes, to be used as a heat-conducting substrate. By controlled annealing with the formation of a micron α-Al2O3 layer and subsequent deposition of a η-Al2O3 layer according to the Bayer method (through aluminum hydroxide), a structural layer of η-Al2O3 with a “breathing” needle morphology was deposited onto the FeCrAl alloy surface; then the catalytic active component was deposited onto this layer by impregnation and/or deposition. The efficiency of the proposed strategy is shown for Rh/Ce0.75Zr0.25O2 – δ–η-Al2O3/FeCrAl catalysts for methane tri-reforming and Cu–CeO2 – δ/η-Al2O3/FeCrAl catalysts for dimethoxymethane steam reforming.

Similar content being viewed by others

REFERENCES

J. Ren, N. M. Musyoka, H. W. Langmi, et al., Int. J. Hydrogen Energy 42, 289 (2017). https://doi.org/10.1016/j.ijhydene.2016.11.195

F. Zhang, P. Zhao, M. Niu, and J. Maddy, Int. J. Hydrogen Energy 41, 14535 (2016). https://doi.org/10.1016/j.ijhydene.2016.05.293

J. G. Speight, “Fuels for fuel cells,” in Fuel Cells: Technologies for Fuel Processing, Ed. by D. Shekhawat et al. (Elsevier, Amsterdam, 2011), Chap. 3, p. 29. https://doi.org/10.1016/B978-0-444-53563-4.10003-3

C. Song, Catal. Today 77, 17 (2002). https://doi.org/10.1016/S0920-5861(02)00231-6

J. R. Rostrup-Nielsen, T. Christensen, and I. Dybkjaer, Recent Adv. Basic Appl. Asp. Ind. Catal. 113, 81 (1998).

A. V. Porsin, V. N. Rogozhnikov, A. V. Kulikov, et al., Cryst. Growth Des. 17, 4730 (2017). https://doi.org/10.1021/acs.cgd.7b00660

T. B. Shoynkhorova, P. A. Simonov, D. I. Potemkin, et al., Appl. Catal. B 237, 237 (2018). https://doi.org/10.1016/j.apcatb.2018.06.003.14

H. Zhang, X. Li, F. Zhu, et al., Chem. Eng. J. 310, 114 (2017). https://doi.org/10.1016/j.cej.2016.10.104

S. T. Wismann, J. S. Engb[oe]k, S. B. Vendelbo, et al., Science (Washington, DC, U. S.) 364, 756 (2019). https://doi.org/10.1126/science.aaw8775

G. Pauletto, A. Vaccari, G. Groppi, et al., Chem. Rev. 120, 7516 (2020). https://doi.org/10.1021/acs.chemrev.0c00149

T. B. Shoynkhorova, V. N. Rogozhnikov, N. V. Ruban, et al., Int. J. Hydrogen Energy 44, 9941 (2019). https://doi.org/10.1016/j.ijhydene.2018.12.148

W. Pan, Catal. Today 98, 463 (2004). https://doi.org/10.1016/j.cattod.2004.09.054

V. A. Kirillov, A. B. Shigarov, N. A. Kuzin, et al., Catal. Ind. 12, 66 (2020). https://doi.org/10.1134/S2070050420010080

A. Álvarez, A. Bansode, A. Urakawa, et al., Chem. Rev. 117, 9804 (2017). https://doi.org/10.1021/acs.chemrev.6b00816

S. Schemme, J. L. Breuer, M. Koller, et al., Int. J. Hydrogen Energy 45, 5395 (2020). https://doi.org/10.1016/j.ijhydene.2019.05.028

A. A. Pechenkin, S. D. Badmaev, V. D. Belyaev, and V. A. Sobyanin, Appl. Catal. B 166–167, 535 (2015). https://doi.org/10.1016/j.apcatb.2014.12.008

R. Thattarathody, S. Katheria, and M. Sheintuch, Ind. Eng. Chem. Res. 58, 21382 (2019). https://doi.org/10.1021/acs.iecr.9b04483

Funding

The work was financially supported by the Russian Foundation for Basic Research in the framework of project no. 19-33-60008 (D.I. Potemkin) for the study of the tri-reforming of methane.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Potemkin, D.I., Snytnikov, P.V., Badmaev, S.D. et al. Design of Catalytic Polyfunctional Nanomaterials for the Hydrogen Production Processes. Nanotechnol Russia 15, 308–313 (2020). https://doi.org/10.1134/S1995078020030106

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1995078020030106