Abstract

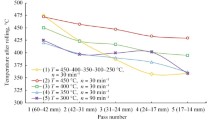

The analysis of the influence exerted by the deformation techniques on the conditions of radial-shear rolling (RSR) of commercial purity aluminum A1050 is carried out. Based on finite-element modeling (FEM), the temperature change at various feed angles and elongation in the first and last passes is obtained. The increase in feed angle slightly raises the temperature variations in the surface layer due to the increase in reduction per pass but does not significantly influence total deformation heating during the RSR process. The finishing deformation temperature can be controlled by varying a reduction ratio. In this case, it is necessary to take into account the initial temperature of heating, dimensions of rolled products obtained, and elongation per pass. The dimensions of a workpiece have a significant effect on thermal changes in the RSR process. In the last pass, when the diameters are 20–14 mm, deformation heating is almost completely compensated for by rod cooling upon contact between the environment and the tool and begins to prevail, with an increase in elongation ratio of more than 1.2. An analysis of effective strain (εeff) at various deformation modes shows that the difference in εeff values over the cross section of the rod decreases with an increasing feed angle. A comparison of the data with the hardness and microstructure of the rolled A1050 samples shows that εeff has a significant impact on the change in the structure and properties to a certain value, which is confirmed by the distribution of the microhardness over the cross section of the rods. The mechanical properties of the rods correspond to the properties of commercial purity aluminum in the work-hardened state (σeff ~ 115 MPa, σ0.2 ~ 110 MPa, δ ~ 1%, HV ~ 40–43).

Similar content being viewed by others

REFERENCES

Totten, G.E. and MacKenzie, D.S., Handbook of Aluminium, vol. 1: Physical Metallurgy and Processes, New York: Marcel Dekker, 2003.

Beletskii, V.M. and Krivov, G.A., Alyuminievye splavy (Sostav, svoistva, tekhnologiya, primenenie). Spravochnik (Aluminum Alloys (Composition, Properties, Technology, Application). Handbook), Kyiv: KOMINTEKh, 2005.

Williams, J.C. and Starke, E.A., Progress in structural materials for aerospace systems, Acta Mater., 2003, vol. 51, no. 19, pp. 5775–5799. https://doi.org/10.1016/j.actamat.2003.08.023

Alieva, S.G., Al’tman, M.B., Ambartsumyan, S.M., Anan’in, S.N., Aristova, N.A., Archakova, Z.N., Bazurina, E.Ya., Batrakov, V.P., Belousov, N.N., Borovskikh, S.N., Bubenshchikov, A.S., Bykov, V.M., Val’kov, V.D., Valyaeva, V.I., Vinogradova, N.M., Vlasova, T.A., Gol’dbukht, G.E., Gordeeva, G.D., Drozdovskii, B.A., Elagin, V.I., Zabolotskii, A.A., Zaitseva, N.I., Zolotorevskii, Yu.S., Ivanova, T.V., Kvasov, F.I., Kishkina, S.I., Klyagina, N.S., Kovalev, A.I., Kolobnev, N.I., Kolobnev, I.F., Komissarova, V.S., Kondrat’eva, N.B., Krivenko, R.A., Kuznetsova, E.A., Kutaitseva, E.I., Leshchiner, L.N., Livanov, V.A., Malysheva, E.N., Matveev, B.I., Mikheeva, E.N., Nepomnyashchaya, E.Z., Novoselova, A.V., Novosil’tseva, N.I., Polishchuk, T.V., Postnikov, N.S., Romanova, O.A., Salibekov, S.E., Sandler, V.S., Senatorova, O.G., Sinyavskii, V.S., Soin, V.Yu., Sokolov, A.S., Stepanova, M.G., Stroganova, V.F., Tkachenko, E.A., Fedorov, V.M., Fridlyander, I.N., Khatsinskaya, I.M., Khokhlatova, L.B., Chubarov, V.M., Shilova, E.I., Shiryaeva, N.V., and Yatsenko, K.P., Promyshlennye alyuminievye splavy. Spravochnik (Industrial Aluminum Alloys. Handbook), Moscow: Metallurgiya, 1984.

Archakova, Z.N., Balakhontsev, G.A., Basova, I.G., Bobovnikov, V.N., Butusova, I.V., Vainblat, Yu.M., Vasil’eva, E.N., Vinogradova, N.M., Galatskaya, I.K., Gorokhov, V.P., Grishkovets, Ya.G., Dobatkin, V.I., Drits, A.M., Elagin, V.I., Ermanok, M.Z., Zakharov, V.V., Ivanova, T.V., Kleimenov, V.F., Kozlovskaya, V.P., Kolobnev, N.I., Kondrat’eva, N.B., Kutaitseva, E.I., Lovtsov, V.M., Lokshin, M.Z., Medvedeva, G.I., Mel’nikova, M.G., Miklyaev, P.G., Molodchinina, S.P., Molodchinin, E.V., Nikitaeva, O.G., Ponagaibo, Yu.N., Raitbarg, L.Kh., Romanova, O.A., Rubin, Yu.L., Samarina, M.V., Senatorova, O.G., Sinyavskii, V.S., Starostina, Z.I., Teleshov, V.V., Tertyshnik, R.S., Tulyankin, F.V., Filippova, Z.G., Tskhondiya, A.G., Sheenkov, V.A., Shelkov, V.G., Shilova, E.I., Shiryaeva, N.V., and Shneerov, I.S., Struktura i svoistva polufabrikatov iz alyuminievykh splavov. Spravochnik (Structure and Properties of Semi-Finished Aluminum Alloys Products. Handbook), Moscow: Metallurgiya, 1984.

Kliauga, A.M., Sordi, V.L., De Vincentis, N.S., Bolmaro, R.E., Schell, N., and Brokmeier, H.-G., Severe plastic deformation by equal channel angular pressing and rolling: the influence of the deformation path on strain distribution, Adv. Eng. Mater., 2018, vol. 20, no. 4, p. 1700055. https://doi.org/10.1002/adem.201700055

Verlinden, B., Chen, E., Duchêne, L., and Habraken, A.M., Transient yielding during compression tests on ECAP’ed AA1050 aluminium, Mater. Sci. Forum, 2011, vols. 667–669, pp. 955–960. https://doi.org/10.4028/www.scientific.net/MSF.667-669.955

Saito, Y., Utsunomiya, H., Tsuji, N., and Sakai, T., Novel ultra-high straining process for bulk materials–development of the accumulative roll-bonding (ARB) process, Acta Mater., 1999, vol. 47, no. 2, pp. 579–583. https://doi.org/10.1016/S1359-6454(98)00365-6

Lanjewar, H., Naghdy, S., Vercruysse, F., Kestens, L.A.I., and Verleysen, P., Severe plastically deformed commercially pure aluminum: Substructure, micro-texture and associated mechanical response during uniaxial tension, Mater. Sci. Eng., A, 2019, vol. 764, p. 138195. https://doi.org/10.1016/j.msea.2019.138195

Verleysen, P. and Lanjewar, H., Dynamic high pressure torsion: A novel technique for dynamic severe plastic deformation, J. Mater. Process. Technol., 2020, vol. 276, p. 116393. https://doi.org/10.1016/j.jmatprotec.2019.116393

Vu, V.Q., Prokof’eva, O., Toth, L.S., Usov, V., Shkatulyak, N., Estrin, Y., Kulagin, R., Varyukhin, V., and Beygelzimer, Y., Obtaining hexagon-shaped billets of copper with gradient structure by twist extrusion, Mater. Charact., 2019, vol. 153, pp. 215–223. https://doi.org/10.1016/j.matchar.2019.04.042

Faregh, S.S.H. and Hassani, A., Stress and strain distribution in twist extrusion of AA6063 aluminum alloy, Int. J. Mater. Form., 2018, vol. 11, no. 2, pp. 175–184. https://doi.org/10.1007/s12289-017-1340-0

Zhu, Q.F., Zhao, Z.H., Zuo, Y.B., Li, L., and Cui, J.Z., The structure evolution of a 99.995 percent high purity aluminum during multi-forging process in room temperature, Mater. Sci. Forum, 2014, vols. 794–796, pp. 876–881. https://doi.org/10.4028/www.scientific.net/MSF.794-796.876

Galkin, S.P., Romantsev, B.A., and Kharitonov, E.A., Putting into practice innovative potential in the universal radial-shear rolling process, CIS Iron Steel Rev., 2014, no. 9, pp. 35–39.

Galkin, S.P., Kharitonov, E.A., and Romanenko, V.P., Screw rolling for pipe-blank production, Steel Transl., 2009, vol. 39, no. 8, pp. 700–703. https://doi.org/10.3103/S096709120908018X

Valeev, I.S., Valeeva, A.K., Fazlyakhmetov, R.F., and Khalikova, G.R., Effect of radial-shear rolling on structure of aluminum alloy D16 (Al–4.4Cu–1.6Mg), Inorg. Mater.: Appl. Res., 2015, vol. 6, no. 1, pp. 45–48. https://doi.org/10.1134/S2075113315010153

Shurkin, P.K., Akopyan, T.K., Galkin, S.P., and Aleshchenko, A.S., Effect of radial shear rolling on the structure and mechanical properties of a new-generation high-strength aluminum alloy based on the Al-Zn-Mg–Ni–Fe system, Met. Sci. Heat Treat., 2019, vol. 60, nos. 11–12, pp. 764–769. https://doi.org/10.1007/s11041-019-00353-x

Stefanik, A., Szota, P., Mróz, S., Bajor, T., and Dyja, H., Properties of the AZ31 magnesium alloy round bars obtained in different rolling processes, Arch. Metall. Mater., 2015, vol. 60, no. 4, pp. 3002–3005. https://doi.org/10.1515/amm-2015-0479

Galkin, S.P., Romantsev, B.A., Ta, D.X., and Gamin, Yu.V., Resource-saving technology for production of round bars from used shaft of rolling railroad stock, Chern. Met., 2018, no. 4, pp. 20–27.

Skripalenko, M.M., Romantsev, B.A., Kaputkina, L.M., Galkin, S.P., Skripalenko, M.N., and Cheverikin, V.V., Study of transient and steady-state stages during two-high and three-high screw rolling of a 12Kh18N10T steel workpiece, Metallurgist, 2019, vol. 63, nos. 3–4, pp. 366–375. https://doi.org/10.1007/s11015-019-00832-9

Karpov, B.V., Patrin, P.V., Galkin, S.P., Kharitonov, E.A., and Karpov, I.B., Radial-shear rolling of titanium alloy VT-8 bars with controlled structure for small diameter ingots (≤ 200 mm), Metallurgist, 2018, vol. 61, nos. 9–10, pp. 884–890. https://doi.org/10.1007/s11015-018-0581-6

Sheremetyev, V., Kudryashova, A., Cheverikin, V., Korotitskiy, A., Galkin, S., Prokoshkin, S., and Brailovski, V., Hot radial shear rolling and rotary forging of metastable beta Ti–18Zr–14Nb (at %) alloy for bone implants: Microstructure, texture and functional properties, J. Alloys Compd., 2019, vol. 800, pp. 320–326. https://doi.org/10.1016/j.jallcom.2019.06.041

Sheremet’ev, V.A., Kudryashova, A.A., Dinh, X.T., Galkin, S.P., Prokoshkin, S.D., and Brailovskii, V., Advanced technology for preparing bar from medical grade Ti–Zr–Nb superelastic alloy based on combination of radial-shear rolling and rotary forging, Metallurgist, 2019, vol. 63, nos. 1–2, pp. 51–61. https://doi.org/10.1007/s11015-019-00793-z

Lopatin, N.V., Salishchev, G.A., and Galkin, S.P., Mathematical modeling of radial-shear rolling of the VT6 titanium alloy under conditions of formation of a globular structure, Russ. J. Non-Ferrous Met., 2011, vol. 52, no. 5, pp. 442–447. https://doi.org/10.3103/S1067821211050075

Romancev, B.A., Goncharuk, A.V., Aleshchenko, A.S., and Gamin, Y.V., Production of hollow thick-walled profiles and pipes made of titanium alloys by screw rolling, Russ. J. Non-Ferrous Met., 2015, vol. 56, no. 5, pp. 522–526. https://doi.org/10.3103/S1067821215050132

Diez, M., Kim, H.-E., Serebryany, V., Dobatkin, S., and Estrin, Y., Improving the mechanical properties of pure magnesium by three-roll planetary milling, Mater. Sci. Eng., A, 2014, vol. 612, pp. 287–292. https://doi.org/10.1016/j.msea.2014.06.061

Dobatkin, S., Galkin, S., Estrin, Y., Serebryany, V., Diez, M., Martynenko, N., Lukyanova, E., and Perezhogin, V., Grain refinement, texture, and mechanical properties of a magnesium alloy after radial-shear rolling, J. Alloys Compd., 2019, vol. 774, pp. 969–979. https://doi.org/10.1016/j.jallcom.2018.09.065

Ding, X.-F., Shuang, Y.-H., Liu, Q.-Z., and Zhao, C.-J., New rotary piercing process for an AZ31 magnesium alloy seamless tube, Mater. Sci. Technol., 2018, vol. 34, no. 4, pp. 408–418. https://doi.org/10.1080/02670836.2017.1393998

Akopyan, T.K., Belov, N.A., Aleshchenko, A.S., Galkin, S.P., Gamin, Y.V., Gorshenkov, M.V., Cheverikin, V.V., and Shurkin, P.K., Formation of the gradient microstructure of a new Al alloy based on the Al‒Zn–Mg–Fe–Ni system processed by radial-shear rolling, Mater. Sci. Eng., A, 2019, vol. 746, pp. 134–144. https://doi.org/10.1016/j.msea.2019.01.029

Akopyan, T.K., Aleshchenko, A.S., Belov, N.A., and Galkin, S.P., Effect of radial-shear rolling on the formation of structure and mechanical properties of Al‒Ni and Al–Ca aluminum-matrix composite alloys of eutectic type, Phys. Met. Metallogr., 2018, vol. 119, no. 3, pp. 241–250. https://doi.org/10.1134/S0031918X18010039

Gorelik, S.S., Dobatkin, S.V., and Kaputkina, L.M., Rekristallizatsiya metallov i splavov (Recrystallization of Metals and Alloys), Moscow: National Univ. of Science and Technology MISiS, 2005.

Fomin, A.V., Aleshchenko, A.S., Maslennikov, I.M., Galkin, S.P., and Nikulin, A.N., Structural and analytical evaluation of the strain intensity and its components during cross-roll piercing at different feed angles, Metallurgist, 2019, vol. 63, nos. 5–6, pp. 477–486. https://doi.org/10.1007/s11015-019-00848-1

Kazuyuki, N., Kouichi, K., and Chihiro, H., Development and features of rotary reduction mill, ISIJ Int., 1991, vol. 31, no. 6, pp. 620–627. https://doi.org/10.2355/isijinternational.31.620

Skripalenko, M.M., Galkin, S.P., Sung, H.J., Romantsev, B.A., Huy, T.B., Skripalenko, M.N., Kaputkina, L.M., and Sidorow, A.A., Prediction of potential fracturing during radial-shear rolling of continuously cast copper billets by means of computer simulation, Metallurgist, 2019, vol. 62, nos. 9–10, pp. 849–856. https://doi.org/10.1007/s11015-019-00728-8

Deng, G.Y., Zhu, Q., Tieu, K., Zhu, H.T., Reid, M., Saleh, A.A., Su, L.H., Ta, T.D., Zhang, J., Lu, C., Wu, Q., and Sun, D.L., Evolution of microstructure, temperature and stress in a high speed steel work roll during hot rolling: Experiment and modeling, J. Mater. Process. Technol., 2017, vol. 240, pp. 200–208. https://doi.org/10.1016/j.jmatprotec.2016.09.025

Zhang, Z., Liu, D., Yang, Y., Zheng, Y., Pang, Y., Wang, J., and Wang, H., Explorative study of rotary tube piercing process for producing titanium alloy thick-walled tubes with bi-modal microstructure, Arch. Civ. Mech. Eng., 2018, vol. 18, no. 4, pp. 1451–1463. https://doi.org/10.1016/j.acme.2018.05.005

QuantorForm2019. https://qform3d.com. Accessed November 11, 2019.

Zhang, Z., Liu, D., Yang, Y., Wang, J., Zheng, Y., and Zhang, F., Microstructure evolution of nickel-based superalloy with periodic thermal parameters during rotary tube piercing process, Int. J. Adv. Manuf. Technol., 2019, vol. 104, nos. 9–12, pp. 3991–4006. https://doi.org/10.1007/s00170-019-04126-x

Hallberg, H., Wallin, M., and Ristinmaa, M., Modeling of continuous dynamic recrystallization in commercial-purity aluminum, Mater. Sci. Eng., A, 2010, vol. 527, nos. 4–5, pp. 1126–1134. https://doi.org/10.1016/j.msea.2009.09.043

Hallberg, H., Influence of process parameters on grain refinement in AA1050 aluminum during cold rolling, Int. J. Mech. Sci., 2013, vol. 66, pp. 260–272. https://doi.org/10.1016/j.ijmecsci.2012.11.016

Wang, Y.L., Molotnikov, A., Diez, M., Lapovok, R., Kim, H.-E., Wang, J.T., and Estrin, Y., Gradient structure produced by three roll planetary milling: Numerical simulation and microstructural observations, Mater. Sci. Eng., A, 2015, vol. 639, pp. 165–172. https://doi.org/10.1016/j.msea.2015.04.078

ACKNOWLEDGMENTS

We are grateful to the personnel of Research and Production Facility of the Department of Metal Forming for assistance in performing the experimental studies. We also thank Cand. Sci. (Eng.) T.K. Akopyan, a researcher at the Department of Metal Forming, for help in processing the results of the metallographic study and the mechanical tests.

Funding

This work was supported by the Russian Science Foundation (project no. 19-79-00054).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

The authors declare no conflict of interest.

Additional information

Translated by L. Mukhortova

About this article

Cite this article

Gamin, Y.V., Koshmin, A.N., Dolbachev, A.P. et al. Studying the Influence of Radial-Shear Rolling on Thermal Deformation Conditions of A1050 Processing. Russ. J. Non-ferrous Metals 61, 646–657 (2020). https://doi.org/10.3103/S1067821220060085

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1067821220060085