Abstract

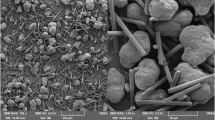

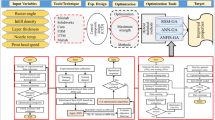

Recently, the adaptive network-based fuzzy inference system (ANFIS) has been used extensively in modeling of manufacturing processes to save both optimization time and manufacturing costs. ANFIS is a powerful iterative tool for optimizing non-linear and multivariable manufacturing operations. In the present study, ANFIS is used to predict the optimum manufacturing parameters in selective laser sintering (SLS) of cement-filled polyamide 12 (PA12) composite. For this purpose, a set of cement-filled PA12 test specimens is manufactured by SLS technique with 8 different values of laser power (4.5–8 Watt) and 8 different weight fractions of white cement (5 %–40 %). Mechanical characterization of cement-filled PA12 is carried out to evaluate the ultimate tensile strength (UTS), compressive strength, and flexural properties. The experimental data are then divided into two groups; one group for training the ANFIS model and the other group for checking the validity of the identified model. The built ANFIS model was validated experimentally and comparison with experimental results revealed mean relative errors of 2.92 %, 3.84 %, 4.75 %, and 3.31 % in the predictions of UTS, compressive strength, flexural modulus, and flexural yield strength, respectively.

Similar content being viewed by others

References

R. D. Goodridge, C. J. Tuck and R. J. Hague, Laser sintering of polyamides and other polymers, Prog. Mater. Sci., 57, (2012) 229–267.

T. L. Starr, T. J. Gornet and J. S. Usher, The effect of process conditions on mechanical properties of laser-sintered nylon, Rapid Prototyping J., 17, (2011) 418–423.

S. A. Aldahash, Optimum manufacturing parameters in selective laser sintering of PA12 with white cement additives, Int. J. Adv. Manuf. Technol., 96, (2018) 257–270.

A. M. Gadelmoula and S. A. Aldahash, Effects of fabrication parameters on the properties of parts manufactured with selective laser sintering: application on cement-filled PA12, Adv. Mater. Sci. Eng. (2019) 8404857.

I. Gibson and D. P. Shi, Material properties and fabrication parameters in selective laser sintering process, Rapid Prototyping J., 3, (1997) 129–136.

G. Casalino, Computational intelligence for smart laser materials processing, Optics and Laser Technology, 100, (2018) 165–175.

S. Siverao, P. Brevern, N. S. M. El-Tayeb and V. C. Vengkatesh, Modelling of laser processing cut quality by an adaptive network-based fuzzy inference system, Proc. Inst. Mech. Eng. C, 223(10), (2009) 2369–2381.

S. Siverao, P. Brevern, N. S. M. El-Tayeb and V. C. Vengkatesh, ANFIS modeling of laser machining responses by specially developed graphical user interface, International Journal of Mechanical and Mechatronics Engineering, 9(9), (2009) 181–189.

M. F. Zaharuddin, D. H. Kim and S. Rhee, An ANFIS based approach for predicting the weld strength of resistance spot welding in artificial intelligence development, Journal of Mechanical Science and Technology, 31(11), (2017) 5467–5476.

R. G. Baldovino, I. C. Valenzuela, A. A. Bandala and E. P. Dadios, Optimization of CO2 laser cutting parameters using adaptive neuro-fuzzy inference system (ANFIS), Journal of Telecommunication, Electronic and Computer Engineering, 10(9), (2018) 103–107.

H. Sohrabpoor, Analysis of laser powder deposition parameters: ANFIS modeling and ICA optimization, Optik, 127, (2016) 4031–4038.

H. Sohrabpoor, R. T. Mousavian, M. Obeidi, I. U. Ahad and D. Brabazon, Improving precision in the prediction of laser texturing and surface interference of 316L assessed by neural network and adaptive neuro-fuzzy inference models, Int. J. Adv. Manuf. Technol., 104, (2019) 4571–4580.

S. Chatterjee, S. S. Mahapatra, V. Bharadwaj, A. Choubey, B. N. Upadhyay and K. S. Bindra, Drilling of micro-holes on titanium alloy using pulsed Nd: YAG laser: parametric appraisal and prediction of performance characteristics, Proc. Inst. Mech. Eng. B., 233(8), (2019) 1872–1889.

S. Chatterjee, S. S. Mahapatra, V. Bharadwaj, B. N. Upadhyay and K. S. Bindra, Prediction of quality characteristics of laser drilled holes using artificial intelligence techniques, Engineering with Computers (2019) 1–24.

S. Chatterjee, S. S. Mahapatra, V. Bharadwaj, B. N. Upadhyay, K. S. Bindra and J. Thomas, Parametric appraisal of mechanical and metallurgical behavior of butt welded joints using pulsed Nd:YAG laser on thin sheets of AISI 316, Optics and Laser Technology, 117, (2019) 186–199.

E. Boillat et al., Finite element and neural network models for process optimization in selective laser sintering, Proc. Inst. Mech. Eng. B, 218(6), (2004) 607–614.

B. Hamid and B. O. Moosa, A novel hybrid ICA-ANFIS model for prediction of manufacturing processes performance, Proc. Inst. Mech. Eng. E, 231(2), (2015) 181–190.

H. Sohrabpoor et al., Optimizing selective laser sintering process by grey relational analysis and soft computing techniques, Optik, 174, (2018) 185–194.

B. Caulfield, P. E. McHugh and S. Lohfeld, Dependence of mechanical properties of polyamide components on build parameters in the SLS process, J. Mater. Process. Technol., 182, (2007) 477–488.

E. H. Mamdani and S. Assilian, An experiment in linguistic synthesis with a fuzzy logic controller, Int. J. Man-Machine Stud., 7(1), (1975) 1–13.

A. Abraham, Adaptation of Fuzzy Inference System Using Neural Learning: Fuzzy Systems Engineering, Springer Berlin Heidelberg (2005).

J. S. R. Jang, ANFIS: adaptive-network-based fuzzy inference system, IEEE Transactions on Systems, Man, and Cybernetics, 23(3), (1993) 665–85.

D. He and B. Jiang, The elastic modulus of filled polymer composites, J. Appl. Polym. Sci., 49, (1993) 617–621.

T. J. Gill and K. B. Hon, Experimental investigation into the selective laser sintering of silicon carbide polyamide composites, Proc. Inst. Mech. Eng. B, 218, (2004) 1249–1256.

Acknowledgments

Manufacturing of test specimens and mechanical characterization were carried out at the Manufacturing Engineering Centre in Cardiff University (UK); the authors are grateful to the sincere efforts of Professor Duc Pham throughout this research work. And the authors would like to thank the Deanship of Scientific Research at Majmaah University for supporting this research under Project No. R-1441-145.

Author information

Authors and Affiliations

Corresponding author

Additional information

Conflict of interests

The authors declare that they have no conflict of interest.

Saleh Aldahash is an Assistant Professor in the Department of Mechanical and Industrial Engineering, Majmaah University, Saudi Arabia. He received his Ph.D. in Manufacturing Engineering from University of Cardiff, UK. His research interests include modern manufacturing, computer-integrated manufacturing, 3D printing and rapid prototyping, prosthetic rehabilitation. He has published couple of research articles related to these topics.

Shaaban Ali has completed his Ph.D. from the Australian Defense Force Academy, UNSW@ADFA, Australia. He worked as an Assistant Professor at the Mechanical Engineering Department, Assiut University. Currently he is a faculty member in Electromechanical Department, Abu Dhabi Polytechnic. His research involved intelligent adaptive control, UAV, identification, and control.

Abdelrasoul Gadelmoula is an Associate Professor at the Department of Mechanical and Industrial Engineering, Majmaah University, Saudi Arabia. He received his Ph.D. in Mechanical Engineering from Yonsei University, South Korea. Also, he received the JSPS fellowship at the University of Tokyo. His research interests include additive manufacturing, numerical simulations in fluid-structure interaction, flow-induced vibrations, and tribology. Dr. Gadelmoula has published many research articles in reputable journals related to these subjects.

Rights and permissions

About this article

Cite this article

Aldahash, S.A., Salman, S.A. & Gadelmoula, A.M. Towards selective laser sintering of objects with customized mechanical properties based on ANFIS predictions. J Mech Sci Technol 34, 5075–5084 (2020). https://doi.org/10.1007/s12206-020-1111-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-020-1111-6