Abstract

Ionic thermoelectric polymers are a new class of materials with great potential for use in low-grade waste heat harvesting and the field has seen much progress during the recent years. In this work, we briefly review the working mechanism of such materials, the main advances in the field and the main criteria for performance comparison. We examine two types of polymer-based ionic thermoelectric materials: ionic conductive polymer and ionogels. Moreover, as a comparison, we also examine the more conventional ionic liquid electrolytes. Their performance, possible directions of improvements and potential applications have been evaluated.

Similar content being viewed by others

Introduction

According to research by Forman et al. [1] in 2015, 72% of the global primary energy consumption was lost as waste heat, totalling about 68.254 TWh. Considering the worsening climate crisis and the finite nature of the fossil fuel supply, recovery and recycling of some of this wasted energy can increase the energy efficiency of our society and contribute to the effort of building a sustainable economy. Thermoelectric materials play a key role in the recovery of waste heat energy. When a heat gradient is applied, they can create a voltage gradient and thus generate an electrical current. This is caused by the thermo-diffusion of charge carriers, also known as the Seebeck effect. The strength of this effect is measured by the Seebeck coefficient (Se, unit: V/K). This is not the only parameter affecting the efficiency of energy harvesting; however, when applied in a thermoelectric generator (TEG), other material properties contribute too.

For example, the material thermal conductivity κ (unit: W/m*K) should be small to minimise heat flow from one side of the device to the other and maintain the temperature difference between the two sides of the thermoelectric device. [2] On the other hand, the electrical conductivity σ (unit: S/m) should be large to reduce energy loss through Joule heating. With these considerations in mind, researchers devised a figure of merit in the form of:

which allows the comparison of thermoelectric efficacy between different materials (T = absolute temperature).

Sometimes another value is used to compare the performance of the material, which is called the power factor (PF); this is defined as \( {\mathrm{S}}_e^2\sigma \)and has the unit of (mW/m*K2). The charge carriers in such materials can be electrons, as is the case in the inorganic, semiconductor-based thermoelectric materials, which have been very well researched. For example, the commercially available thermoelectric semiconductor material Bi2Te3 typically has a figure of merit (ZT) approximately equal to 1 [3] and is often used as a benchmark with which to measure the performance of other materials. Through the use of nanostructuring, its ZT has been boosted to 1.35 [3]. Other studies have made use of materials such as, among many others, skutterudite (ZT = 1.5) [4], SrTe (ZT = 2.2) [5] and SnSe (ZT = 2.6) [6]. A study published in 2019 [7] achieved a stunning ZT above 5 using a Heusler metal alloy and currently represents the cutting edge in this field.

Alternatively, the charge can also be transported by the diffusion of ions and ionic thermoelectric materials have come under attention in recent years, due to their larger Seebeck coefficient. Whereas the inorganic electronic thermoelectric materials typically have ideal operational temperatures well above 200 °C [8], ionic thermoelectric materials have the potential to fill the niche of low-grade heat harvesting [9,10,11].

In this review, we focus on recent progress in polymeric materials for ionic thermoelectric applications, specifically in the field of ionic conducting polymers and polymer gel electrolytes. Moreover, considering the importance of liquid electrolytes in this field of research, this class of materials is reviewed here as well.

Thermoelectric effect

Seebeck effect

Seebeck effect describes the generation of a voltage difference in the material following a temperature difference between the cold and hot sides of the material. This voltage difference appears due to the thermal diffusion of charge carriers, which can be electrons or, in the case of this study, ions (charged particles) [12]. The general equation describing the current density in a thermoelectric device has the form:

The first term in the equation is the contribution from any externally applied bias and the second is the thermoelectric contribution. Here σ is the conductivity tensor, ∇V is the applied voltage gradient, β is the thermoelectric tensor and ∇T is the temperature gradient [12].

The Seebeck coefficient represents the strength of the Seebeck effect and is a property intrinsic to the material. To measure its value, one can adjust the applied voltage gradient to reach the steady-state where J=0, i.e. no current flows. This means the two contributions have exactly cancelled each other out and the Seebeck coefficient is simply:

Equation 3 shows that the bigger Seebeck coefficient leads to a larger thermal voltage for a given temperature gradient and with it, a current can be generated to provide useful energy. The unit of the Seebeck coefficient is V/K, although it is often converted to mV/K or μV/K for easier handling.

Soret effect

The Soret effect describes the thermo-diffusion of particles in a mixture. This phenomenon is named after Swiss physicist Charles Soret who first studied it in great detail in 1879 [13]. He placed a tube with a salt solution inside with one end at room temperature and the other end at 80 °C and after some time he noticed that the concentration of the salt in the tube is higher at the cold end; therefore it was demonstrated that a thermal gradient can cause a migration of mobile particles in a mixture. Different types of particles show a different response to thermal gradients. When the particle moves from hot to cold, it is called “positive”; when the opposite is true, it is called “negative”. Much progress has been made to provide a theoretical description of this phenomenon [13], but as of now, there is no universal model which applies in every situation and the response of the system is material specific. When positive and negative ions diffuse in opposite directions under this influence, a voltage gradient can be created. Its contribution to the Seebeck coefficient [14] is expressed as:

where z is the ionic charge (unitless), F is the Faraday constant, c is the ionic concentration (unit: mol/m3), σ is the electrical conductivity (unit: S/m) and DT is the Soret thermal diffusion coefficient of the ions (unit: m2/s*K).

Ionic thermoelectric systems

Non-redox electrolytes and transient output

Unlike electronic thermoelectric materials, the charge transfer here is mediated by the thermophoresis of ions due to the Soret effect. In the absence of electrochemical reaction at the electrodes, ions cannot pass directly into the electrodes to complete the circuit and generate a continuous current. They rather work as a thermally chargeable (super)capacitor [15]. This can be seen more clearly in Fig. 1. An electrolyte is contained between two capacitor plates. At Stage I, a temperature gradient is applied to the system and the Soret effect causes positive and negative ion species to diffuse in opposite directions. At Stage II, the ions reach the electrode/electrolyte interface and accumulate there. When a connection is established between the two plates, an electric current is drawn across by the charge imbalance. This current decays with time and stops once the voltage caused by the accumulated ions at the two electrodes has been equalised. At Stage III, the connection between plates is removed, then the temperature gradient is also removed, causing the ions to diffuse back to their initial random distribution, but the plates stay charged up because the electrons and holes are isolated on the capacitor plates. At Stage IV, when the energy stored on the capacitor is needed, one connects the two plates to a load and the capacitor discharges.

Operation cycle of ionic thermoelectric supercapacitor (adapted from [16], with permission from John Wiley and Sons)

This kind of device is suitable for use with an intermittent heat source such as the sun, where the capacitors can charge up during the day and discharge during the night.

Electrochemically driven systems and steady output

The picture changes if an electrochemical reaction can occur at the electrodes. A common solution is to use a redox-active electrolyte, which is able to pass electrons to and from the electrodes via redox reaction and thus achieves continuous operation. A device of this kind is also called a thermogalvanic cell [17]. Ionic transport in these systems is due to several different mechanisms, the most important one being convection. Another important contribution comes from diffusion caused by the concentration gradient of ionic species. When there is no thermal gradient, the reaction rates (both forward and backward) are uniform at the two electrodes. But when the two electrodes are at different temperatures, the equilibrium constant and hence the concentration of both species in the redox couple will be different at the hot and cold electrode sides. This creates a concentration gradient of the redox couple across the device and these ions will diffuse across the device to approach equilibrium. It should be noted that the Soret effect still occurs in these systems, but its influence is relatively minor compared to the aforementioned transport mechanisms [18]. An example is the redox couple [Fe(CN)6]3−/[Fe(CN)6]4− as an example (Fig. 2):

Example of a thermogalvanic cell operating under a temperature gradient (adapted with permission (open access) by Nature Research from [17])

At the cold cathode, the [Fe(CN)6]3– is reduced into [Fe(CN)6]4– by accepting an electron; it then diffuses to the anode and become oxidised and transport the electron it picked up from the cathode into the anode. The cycle would then repeat and a steady current is created. This is a key difference when compared to the transient, non-steady output electrolytes discussed in the previous section and will be indicated in Tables 1 and 2.The magnitude of the Seebeck coefficient is determined by the difference between the partial molar entropies of the redox pair [33] and is expressed as:

where SB and SA are the partial molar entropies of the redox pair, ∆V is the open-circuit voltage, ∆T is the temperature difference between the hot and cold sides, F is the Faraday constant and n is the number of electrons transferred in each reaction [17]. The electrical conduction is dominated by the diffusion of the redox ions [9] and is related by the following Nernst-Einstein equation:

where the D is the diffusion coefficient of the ions, z is the ionic charge, R is the gas constant and T is the temperature. Substituting this into Eq. 1, one can find the alternative form of ZT, with mass transport taken into account, expressed as [9]:

In the case of one of the redox species being limiting, the sum of diffusion coefficients in Eq. 7 should be replaced with Dlim, the diffusion coefficient of the limiting redox species.

Different types of ionic thermoelectric materials

Ionic conductive polymers

We begin with conductive polymers. These materials have been known for many years, but research into their ionic thermoelectric properties was started only recently. In this subsection, we review the recent progress in this field over the past 5 years and the thermoelectric properties of the materials are listed in Table 1; the numbers in the italic format are not directly given in the original article, but calculated based on the other values provided in the same article and may serve for comparison purpose not necessarily reflecting the real performances of the material.

PEDOT:PSS is one of the most intensively studied conductive polymer due to its excellent electrical conductivity, solution processability, mechanical flexibility, low cost and environmental stability [34]. It is a mixed ionic-electronic conductor, meaning both electrons and mobile ions can serve as charge carriers in this material [35]. The electronic aspects of its conductance have been well researched and there is a large body of literature published on its many uses such as capacitors [36], solar cells [37], electrodes [38] and transistors [39]. But the ionic aspect of its conductivity is also very interesting and often overlooked. In pristine PEDOT:PSS, the conduction is dominated by electrons [35], but the ionic conductivity can be enhanced by various methods such as increasing the relative humidity (RH) [22], mixing with additives and ethylene glycol treatment [40]. Therefore PEDOT:PSS is the basis of many novel ionic thermoelectric materials in this review.

The first study on the ionic thermoelectric properties of PEDOT:PSS derivatives was carried out by Crispin et al [19]. Various PEDOT (poly(3,4-ethylene dioxythiophene) derivatives were synthesised, two of which were found to have both electronic and ionic conduction: PEDOT:PSS (PEDOT-polystyrene sulphonate) and PEDOT:PSS:PSSNa (PSSNa = poly(sodium-4-styrene sulphonate)). It was shown that the ionic conductive properties only appeared at above 40% relative humidity (RH) and increasing RH from 10 to 80% increased the total Seebeck coefficient by one order of magnitude due to the increase in ionic conductivity. This effect was the strongest in PEDOT:PSS:PSSNa because the electrical conduction was dominated by the transport of Na+ ions, which was one order of magnitude larger than the electronic conduction. Due to these improvements, when incorporated into a TEG device, the initial output voltage and power factor were both significantly enhanced, compared to other electronic conductors. However, the output voltage decayed rapidly with time due to the ion accumulation at the electrodes. This is an example of a redox-free electrolyte as described in “Soret effect” section.

Segalman et al. [14] explored this further by adding silver ions (at 12w/w%) into PEDOT:PSS (PEDOT:Ag:PSS), making silver the charge carrying mobile ion in this material instead of sodium ions in the previous example. Furthermore, the electrodes in this system were also made out of silver, thus making possible electrochemical reaction with the electrolyte. Its Seebeck coefficient was measured as a function of relative humidity and it increased exponentially above a critical humidity level of 60%. This increase is because the uptake of water enhances ion diffusion by creating a solvation shell around the mobile cations, which decreases its electrostatic interaction with the potential traps caused by the counter-ions (anions) it leaves behind in the polymer structure [19]. Water also creates more percolation paths in the PSS domains which primarily facilitate ion transport. But most interestingly, it was observed that while TEG devices made from PEDOT:PSS still showed output voltages that decayed exponentially with time, the incorporation of silver ions in conjunction with silver electrodes removed this effect and a steady output was obtained. Here silver ions are generated at one electrode, moved across the device and consumed at the other; evidently, ion accumulation was removed by the electrochemical reaction at the electrolyte-electrode interface. However it was noted that this reaction is non-reciprocal, so the transport of silver ions is one way only; eventually, one electrode will be depleted and the device must be flipped to continue its operation. Under ideal conditions, (suppression of needle-like growth of silver deposit which can short circuit the 2 electrodes), the lifetime of the device can be over 800 days.

There are more ways to improve the performance of PEDOT:PSS-based materials apart from adding electrochemically active ion and electrodes. Instead of mixing additives into the PEDOT:PSS, Ouyang et al. [24] coated polyelectrolytes onto the surface of PEDOT:PSS as a separate layer. Their motivation was that PEDOT:PSS had high conductivity but low Seebeck coefficient, while polyelectrolytes have low conductivity but high Seebeck coefficients and mixing the two would decrease the overall conductivity of the mixture and outweigh the gains made in the Seebeck coefficient, resulting in a decreased power factor(see the results of [19] in Table 1). They first treated the PEDOT:PSS with sulphuric acid to increase its electrical conductivity (A-PEDOT:PSS) and then coated a layer of PSSH (poly(4-styrene sulphonic acid)) on top to make a PSSH/A-PEDOT:PSS bilayer (see Fig. 3b). Compared to the mixture PEDOT:PSS:PSSH, the bilayer has a much higher power factor of 401 mW/m*K2. The difference in mechanism is shown in Fig. 3; in the mixture (Fig. 3a), the holes (from PEDOT:PSS, denoted as h+) and protons (from the polyelectrolyte PSSH, denoted as H+) both diffuse to the cold side, but the diffusion of holes is impeded by the decreased conductivity due to the addition of the polyelectrolyte, while the ions accumulate at the electrode. In the bilayer (Fig. 3b), the holes and protons diffuse in separate layers and the accumulated protons form an energy barrier at the cold electrode; while still not able to pass into the electrode, they can act as a filter to reflect the low-energy holes (as shown in the right side of Fig. 3c). Because the Seebeck coefficient in electronic TE materials can be expressed as Se = (EF – ET)T, where EF is the Fermi level and ET is the mean energy of the charge carriers, now if the low-energy holes are filtered out, their mean energy ET will be increased, thus the Seebeck coefficient of the PEDOT:PSS is enhanced, while the hole conductivity in the PEDOT:PSS is not affected. A similar effect was also found in PSSNa/BA-PEDOT:PSS (butylamine-doped PEDOT:PSS). It should be noted that the charge carriers, in this case are electrons, but the thermophoresis of ions due to the Soret effect plays an indispensable role in the enhanced thermoelectric performance.

(a) Proton and hole diffuse in the same mixture. (b) Protons and holes in separate layers. (c) Potential barrier of accumulated protons filters out low-energy holes. (Reproduced from [24] with permission from The Royal Society of Chemistry)

Devices made from this method vastly outperforms mixtures of PEDOT:PSS and polyelectrolytes in terms of power factor, electrical conductivity and the ability to operate continuously (see Table 1) and present a new direction for the optimisation of PEDOT:PSS-based materials.

While there had been encouraging developments with PEDOT-based mixed-electronic-ionic conductors, much effort was also spent to find a purely ionic solid polymer thermoelectric material. This was achieved by Segalman et al. in 2016 [20]. In keeping with their previous work [14], silver ions were once again the charge carriers and these were incorporated into Nafion and PSS membranes. The conductivity in these materials is purely of ionic origin, with no electronic contribution.

As can be seen from Fig. 4, the electrodes in the devices were made from silver, the same element as the charge carrying silver ions in the thermoelectric layer, to facilitate electrochemical reaction and thus continuous current generation. Like their previous work, the ion conduction in this device was also one way only and faces the same problem of electrode depletion. In Fig. 4b, the chemical structures of the materials are shown.

(A) TEG device structure. (B) Left, Ag-PSS; right, Ag-Nafion (adapted from [20] with permission by American Chemical Society)

The PSS and the Nafion polymers give a solid structure to the material, while the silver ions can dissociate from their polymer frameworks and facilitate charge conduction. It was noted again that electrical conductivity was positively correlated with the relative humidity; however, an unexpected and curious discovery was that above certain RH thresholds, the Seebeck coefficient of Ag-Nafion changed sign and became increasingly negative, while the same effect was not observed in Ag-PSS. A negative Seebeck coefficient means that the silver ions now migrate from the cold to the hot electrode and was explained by the opposite direction of water diffusion in Nafion compared to PSS [20]. In short, the water carries the silver ions despite the silver’s own tendency to diffuse in the other direction. This is a useful property because, in conventional electronic thermoelectric materials, the magnitude of the Seebeck coefficient and the electrical conductivity are often inversely correlated [41], which impede the optimisation of ZT as shown in Eq. 1. But if the Seebeck coefficient becomes negative and can be made increasingly negative with humidity, as with Ag-Nafion, because only the square of Seebeck coefficient matters in ZT, then both terms in the numerator in Eq. 1 are positively related to RH, thus overcoming this dilemma.

While ion accumulation presents a significant challenge to their application for waste heat harvesting, all hope is not lost for non-redox materials. As shown in “Non-redox electrolytes and transient output” section, they can be used to charge super-capacitors. Crispin et al. [21] presented one of such a device in 2016. The key material is composed of liquid polyethylene oxide as the electrolyte, to which NaOH was added. The reaction turned the alcohol end groups (–C–OH) into anionic alkoxide end groups (–C–O–Na+). The Na+ cations are very mobile and can dissociate from the polymeric anions, which are only weakly mobile. The mobile Na+ cations served as the charge carrier in this system. When a thermal gradient is applied, they diffuse and accumulate at the cold side under the influence of the Soret effect. Because the polymer anions are not very mobile, the degree of separation between the anion and cations is large, leading to a very high ionic Seebeck coefficient of 10 mV/K. This was the first demonstration of an “ionic thermoelectric supercapacitor” (ITESC).

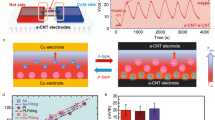

This was quickly followed up by Yu et al. [22] with an improved design. PSSH electrolyte was placed in between PANI-coated capacitor plates, with added graphene and carbon nanotubes for improved capacitance. When a thermal gradient is applied, H+ ions dissociate from the immobile PSS– and diffuse towards the cold side, charging up the capacitor plates. Compared to the ITESC system mentioned previously [21], this has the advantage of being a solid-state device. It also had a very high optimal ZT of 0.4 when tested at a humidity level of 70%, which outclassed all of the previously mentioned materials in this section. This device was very stable and had little decay in performance after 5000 charge-discharge cycles.

Apart from thermoelectric performances, the mechanical properties and the cost of manufacture are also important concerns. Those are the highlights of the 2017 work by the Crispin group [23]. A mixture of PSSNa and nanofibrillar cellulose (NFC) was cast from DMSO. Once again the charge carriers in this system were the dissociated Na+ ions, while some DMSO remained in the solid film to create ion percolation pathways. The material showed high Seebeck coefficient of 8 mV/K and had a moderate ZT of 0.025. The advantage of using cellulose is that it can mitigate the brittle nature of pure PSSNa, making this new material robust and flexible. While not being the highest performing material on the list, its mechanical properties make it suitable for wearable devices and, coupled with the low cost of cellulose, make large-scale roll-to-roll production a possibility.

Easy to manufacture graphene oxide films intercalated by sulphate ions (SGO) were also introduced [26]. The graphene oxide films (GO) have functional groups that contain H+ ions which can dissociate in the presence of moisture and serve as the charge carrier under Soret effect. In this way, one order of magnitude increase in the electric conductivity was achieved. SGO serves as the solid electrolyte, while reduced SGO (rSGO) acts as the capacitor for energy storage. Its ease of manufacture stems from the solution processability of SGO films. Furthermore, the rSGO capacitors can be “written” into the SGO films directly by laser irradiation. This significantly simplifies the manufacturing workflow and gives the possibility of roll-to-roll production. A single device was able to generate a charged voltage of 58 mV at a temperature difference of 10.5 K between electrodes and a voltage of 2.1 V was generated when eight of such devices were connected in series, at a temperature difference of 30 K. This shows the scalability of such systems, while also not having the largest ZT or the ability to operate continuously. Low cost and the ability to be deployed en masse is often more important than raw performance in terms of commercial applications.

Incorporation of carbon nanotubes (CNT) in PEDOT was also explored [27]. The addition of CNT promoted ionic and electronic conduction while keeping thermal conductivity low. The material has an excellent figure of merit of 0.7 and a Seebeck coefficient of 14 mV/K. This system shows the largest ZT and PF found in this category so far. Polyelectrolytes different than PSS were also explored [25]. Among them, Nafion and S-PEEK (sulphonated polyether ether ketone) had H+ ions as charge carriers, which can dissociate in water from the immobile, negatively charged polymer backbone. These displayed high Seebeck coefficients of 4.2 and 5.5 mV/K; however, increasing the RH greatly improved the Seebeck coefficient of S-PEEK while slightly decreased it for Nafion. This can be explained by water diffusing in the opposite direction of H+ in Nafion, an interesting phenomenon previously observed by Segalman et al [20]. Increased water uptake leads to increased percolated water channels and suppresses ion transport from hot to cold. On the other hand, water and H+ diffuse in the same direction in S-PEEK, so increasing RH enhances ion conductivity. In polyelectrolytes where both cations and anions are mobile, as with PVA-NaOH and PVA-H3PO4, they found that Seebeck coefficient is unaffected by RH. In poly(diallyldimethylammonium chloride) (abbreviated as PDDAC), where only Cl− anions are mobile, a very large Seebeck coefficient of 19 mV/K was reported. This study provided valuable data on the transport mechanisms and TE characteristics of polyelectrolytes, but unfortunately, no measurement was taken on the thermal conductivity of these materials and thus no figures of merits can be derived.

Most recently, Hallinan et al. [28] demonstrated another polymer electrolyte, which sets itself apart from all others in this section by being operational under completely dry conditions (0% RH). The material is a mixture of poly(ethylene oxide), abbreviated as PEO and lithium bis-trifluoromethane-sulphonyl imide (LiTFSI). The PEO provides a solid structure while also having functional groups which can coordinate the Li ions from the LiTFSI salt and the thermoelectricity in this material is purely ionic, driven by the Soret effect. A thermoelectric cell was fabricated, using Li as the electrode material to facilitate electrochemical reaction. This material was tested at several salt concentrations and was demonstrated to be capable of generating power, with the highest being 0.038 mW/m2 and its Seebeck coefficient ranged between 0.1 and 0.2 mV/K. While not being the most impressive in terms of raw power output, its ability to work in dry state and at low ambient humidity gives it a wider range of possible applications.

Polymer gel electrolytes

The properties of conducting polymers can also be efficiently combined with that of liquid electrolytes when the gel phase is considered. A gel is defined as a dispersion of liquid molecules within a solid medium; the whole system does not flow like a liquid, but is soft and stretchable and is often referred to as a “quasi-solid” [29]. The crosslinked polymer chains provide the material with structure, while the liquid electrolyte dispersed inside, which comprise most of the material by weight, can participate in ion transport and electrochemical reactions. Compared to solid polyelectrolytes, gels are usually more flexible and can be easily conformed into different shapes for wearable devices or wrapping around pipes and boilers, etc. Moreover, the use of mechanically robust gel systems can reduce the sealing problems and bulkiness of liquid electrolyte TEG systems.

In this section, we review the recent progress in these materials over the last 5 years and the relevant data are listed in Table 2, where the italic number is calculated based on other values in the article.

Zhou et al. [29] took wearable applications into consideration from the outset; they incorporated two different liquid electrolytes: ferric/ferrous chloride and potassium ferricyanide/ferrocyanide into a polymer network of poly(vinyl alcohol) and created two gel electrolytes: PVA/ferric/ferrous chloride (PFC) and PVA/potassium ferricyanide/ferrocyanide (PPF). These gel systems were found to withstand tensile stress up to 0.1 MPa and can stretch up to 2–4 times of their original length. Fifty-nine units of each gel were connected to Au/Cr electrodes being able to produce an output voltage of 0.7 V, current of 2 μA and power of 0.3 μW when wrapped around a human arm. The redox couple responsible for charge transfer in these systems are Fe2+/Fe3+ in the former and Fe(CN)64–/Fe(CN)63– in the latter, similar to the example given in Fig. 2, albeit in a gel rather than a liquid.

The ZT of these materials are 1.7 × 10–4 and 1.57 × 10–4 respectively, although the values are quite small; safe wearable application of these materials to body heat recovery was successfully demonstrated.

Pringle et al. [30] on the other hand made a gel electrolyte by combining cellulose and aqueous potassium ferri-/ferrocyanide. The choice of using cellulose is once again for its mechanical properties; it addresses problems such as brittleness, water loss and shrinkage of PVA-based gels. Increased weight of cellulose in the gel was found to decrease the Seebeck coefficient because having a more dense solid structure would impede the diffusion of ions. A 5% weight of cellulose was found to give the optimal combination of mechanical strength and TE characteristics. A device made from this gel was able to generate a power density of 14 mW/m2. Unfortunately, thermal and electrical conductivity was not measured and thus ZT and power factor cannot be reported here for comparison.

Researchers also investigated more exotic gel compositions. Pringle et al. [31] used cobalt bipyridyl (Co(bpy)32+/3+) as the redox couple, which was dissolved in 3-methoxypropionitrile (MPN), an ionic liquid. This combination was chosen for its large Seebeck coefficient and high boiling point. Polyvinylidene difluoride (PVDF) and poly(vinylidene fluoride-co-hexafluoro-propene) (PVDF-HFP) were two candidates for the gelation agent and after comparison, PVDF was found to be the superior choice due to the higher power density of the resulting TEG device. Once again it was found that the addition of gelling agents would decrease the Seebeck coefficient so a trade-off between mechanical and TE properties had to be made. The best weight percentage of PVDF was 5%. They found that the concentration of the redox couple can also be optimised, as too low a concentration causes a deficiency in charge carriers, while a concentration too large makes the electrolyte too viscous and impede ion transport. With a redox couple concentration of 1 M and electrode distance of 1 mm, the device had an output power density of 23 mW/m2 at a temperature gradient of 40 K. In a later article [11], the group replaced the MPN with the non-volatile 1-ethyl-3-methylimidazolium bis(trifluoro-methyl-sulphonyl)imide ([EMIM][TFSI]). The resulting TE gels had similar Seebeck coefficients and ion diffusion coefficients one order of magnitude larger, but strangely, the final device could only generate a power density of 0.8 mW/m2. It should also be noted that [EMIM][TFSI] is a toxic substance.

While the previously mentioned materials all contained a redox pair to ensure continuous operation, Hasan et al. [32] reported another novel ionic gel, which used 1-butyl-3-methyl imidazolium tetrafluoroborate ([EMIM][BF4]) as the ionic liquid; it can dissociate into [EMIM]+ and [BF4]− ions that thermodiffuse due to Soret effect, but it cannot engage in electrochemical reaction with the electrodes; thus it cannot operate continuously. The ionic liquid is locked in a polymer matrix of polyethene glycol dimethacrylate (PEGDMA). They tested the effect on the TE properties by changing the weight occupied by the [EMIM][BF4] from 60 to 90%. The maximum power density was achieved by 90% ionic liquid content at 0.107 mW/m2; while this is not too impressive, this material does have a remarkable feature, as the gel’s ionic conductivity (4.491 S/m) is ten times higher than that of the pure [EMIM][BF4] ionic liquid (0.45 S/m), unlike all of the previous cases examined, and it represents a new possible direction of improvement for ionic gels. This phenomenon can be explained by the “Breathing Polymeric Chain Model” [42], where the constant folding and unfolding of the polymer chains in the gel creates motion which helps the ion pairs in the ionic liquid to dissociate and create more mobile charge carriers. It is worth noting that [EMIM][BF4] is a toxic substance.

Another ionic liquid based on EMIM was tried by Ouyang et al. [16]: 1-ethyl-3-methylimidazolium dicyanamide ([EMIM][DCA]) and PVDF-HFP were the gelation agents. When compared with ionogels made from [EMIM][TFSI] and [EMIM][BF4], this ionogel had both higher conductivity and Seebeck coefficient and is also non-toxic. Whereas the previous study showed an increase in ionic conductivity after gelation, this ionogel showed increased Seebeck coefficient. They explained this by another expression of the Seebeck coefficient:

where Q∗ is the heat of transport and is related to the energy of ion-ion interaction and ion-dipole interaction between the ionic liquid and polymer matrix in the gel, F is the Faraday constant and T is the absolute temperature. Fourier-transform infrared spectroscopy (FTIR) was used to characterise the effect of adding ionic liquids into the polymer and the spectrum is shown in Fig. 5.

(a) FTIR spectra of different ionogels. (b) FTIR spectra of [EMIM][DCA] ionogels at different loading percentage (adapted from [16]), with permission from John Wiley and Sons

It can be seen that the addition of ionic liquids to the polymer causes an absorption peak (dip in Fig. 5a) at 831 cm–1, representing the presence of a high dipole-moment (β) phase in the polymer, which is not seen in the pure PVDF-HFP polymer (purple line on the top of Fig. 5a). This β phase is also visible in Fig. 5b, where the FTIR spectra of ionogels made from mixing [EMIM][DCA] and PVDF-HFP are shown, with an increasing percentage of [EMIM][DCA] from top to bottom. The dip is present for all combinations except the cases where there are only one of the two ingredients. This indicates a strong ion-dipole interaction, which is the origin of the increase in Seebeck coefficient [16]. The optimal ionic liquid to polymer weight ratio is 80% for this material and its Seebeck coefficient is 26.1 mV/K, its electrical conductivity is 0.67 S/m and its thermal conductivity is particularly low at 0.176 Wm–1K–1 which all contribute towards an impressive ZT of 0.75.

Liquid electrolyte

Thermoelectric cells using liquid electrolyte is one of the most well-researched types of TEG devices. Many of the past research was centred around aqueous electrolytes; however, in recent years, non-aqueous ionic liquids (molten salts) have come under attention because of their thermal and electrochemical stability, non-volatility and higher boiling points allowing them to operate at temperatures above 100 °C [43]. A selection of the most recent works in this field is presented here for comparison with the polymer-based thermoelectric materials reviewed above. All of the electrolytes reviewed here are redox-active; thus, they are all capable of continuous operation. Starting in 2013, Pringle et al. investigated the thermoelectric characteristics of various ionic liquids with 0.4 M of I3–/I– redox couple dissolved in them. The ionic liquids used were [EMIM][BF4], [EMIM][TSFI], [C4mpyr][TSFI], [EMIM][B(CN)4] and [EMIM][DCA]. They all have significantly lower thermal conductivity than water, which can help maintain a thermal gradient and improve ZT. It was discovered that the diffusion coefficients of the ions are inversely related to the viscosity of the electrolyte and thus the least viscous, among these, is [EMIM][BF4] + I3–/I– which has the highest ZT (as can be seen in Eq. 7) of 1.3 × 10–4.

At the same time, it also has the highest Seebeck coefficient of 0.23 mV/K because the entropy difference between the redox couple is the largest at 44 J/(K*mol). When operated at a thermal difference of 100 K, a TEG device made from this electrolyte is capable of generating a steady output power density of 29 mW/m2.

In another study [43], the same group synthesised and tested the TE performance of a novel redox couple: cobalt(II/III) tris(bipyridyl) (CoII/III(bpy)3). It was expected to have a higher Seebeck coefficient than the more conventional I or Fe-based redox pairs, because of the large entropy difference between its redox states, caused by a low to high spin transition upon reduction. It was tested in various concentrations with the following ionic liquids:[EMIM][B(CN)4], [EMIM][TFSI], [EMIM][eFAP] and high boiling point organic solvent: MPN (3-methoxypropionitrile) and the results can be found in Table 3.

In all these electrolytes, the entropy difference in the cobalt-based redox couple is 2 to 3 times larger than what was seen in their previous work using I3–/I– and gave rise to much larger Seebeck coefficients. The top-performing combination of redox couple and solvent is with 0.1 M of CoII/III(bpy)3 in MPN and, with smooth platinum electrodes, gave a power density of 499 mW/m2. This was further improved to 522 mW/m2 by increasing the electrode surface area by coating it with platinum black. The top-performing ionic liquid had a power density of 240 mW/m2, which is lower than that of MPN due to its high viscosity. This is a very impressive improvement in performance for ionic liquid electrolyte-based TEG within a very short time when compared to the meagre 29 mW/m2 obtained about 1 year earlier [9]. This shows the importance of maximising the entropy difference in the redox couple but also tackling the viscosity problem.

Ionic liquids, as they pointed out [47], have viscosity typically around 25 times that of water, which hinders significantly ionic transport. Thus maximising the ion flux is vital to the enhancement of TEG performance. A significant increase in the power density of TEG was achieved by mixing high boiling point molecular solvents with ionic liquid-redox couple electrolytes [44]. This is the result of a decrease in viscosity and higher ion diffusion coefficients. The best performance was achieved with 0.1 M concentration of CoII/III(bpy)3 in a 3:1 mixture of MPN and [EMIM][B(CN)4], operated with a temperature difference of 70 K; the power density is a record-breaking 880 mW/m2. The optimal redox couple concentration was found to be 0.1 M. For lower concentrations there is a deficiency in ion concentration, while for higher concentrations the viscosity of the electrolyte becomes too large.

The effect of diluting various ionic liquid + CoII/III(bpy)3 electrolytes with propylene carbonate at a 1:1 ratio was also investigated [48], showing the wide applicability of this dilution method. The resulting decrease in viscosity and increase in ion diffusion coefficients significantly boosted the performance of the TEGs, in some cases by almost tenfold. For example, the power density of a TEG operated at TH=60°C and TC=30 °C, with 0.01 M cobalt redox couple concentration and [BMIM][BF4] as the ionic liquid, was boosted from 0.34 mW/m2 before dilution to 3.91 mW/m2 after dilution.

Other ways to improve performance were tried; for instance, mixing multi-walled carbon nanotubes (MWCNTs) into the electrolyte was explored [47]. The addition of MWCNTs can facilitate ion-pair dissociation and interfacial polarisation at the surface of the MWCNTs, increasing total ion concentration and reducing the mass transport resistance, thus increasing ion conductivity and the power of the TEG. For a device based on [EMIM][TFSI]-cobalt electrolyte, the output power was increased by 25%, while for another device based on [PMIM][I] electrolyte, the increase was 30%.

In the meantime, advances were also being made in the field of aqueous electrolyte TEG. Baughman et al. [45] presented an electrochemical TEG that had an astonishing 12 W/m2 power density. The electrodes were made from an activated carbon cloth for increased contact surface area with the electrolyte, which even outperformed the very expensive platinum electrode. A cotton membrane was placed between the electrodes of each cell to minimise convection and thus keep a high thermal gradient. The electrolyte used was an aqueous solution of K3Fe(CN)6/(NH4)4Fe(CN)6 and has very high ionic conductivity.

The article also demonstrated a new device architecture with many individual thermocells with n- and p-type electrolytes connected in series. An n-type thermocell means the electrons flow from the hot to the cold electrode (negative Seebeck coefficient), while a p-type thermocell means the electrons flow from cold to hot (positive Seebeck coefficient). In this article, the n-type uses the Fe2+/Fe3+ redox couple and the p-type uses the [Fe(CN)6]3–/[Fe(CN)6]4– redox pair. It is worth noting that when one tries to stack multiple power cells together to obtain a higher voltage, one should connect the positive electrode of one cell to the negative electrode of the next, like using simple AA batteries. But when thermocells are used, if one has the same type of thermocell throughout, then one would have to connect the hot side of one cell to the cold side of the next via wires, because the polarity of the cell is tied to the orientation of the temperature gradient. This causes unwanted heat transfer between hot and cold which do not generate power, as can be seen in Fig. 6a. Therefore having both n- and p-types (Fig. 6b) allows the current to flow through the system without needing to connect the hot electrode of one cell to the cold electrode of another because the polarity of the cells can be alternated by using alternating n- and p-type thermocells. This not only minimises the unwanted heat transfer but also makes manufacturing much simpler. By convention, each of these thermocells is called a “leg” and this device has twenty-eight legs as shown in Fig. 7:

(a) Only p-type (b) n- and p-type in series (adapted from [45] with permission from John Wiley and Sons)

The alternating n- and p-type thermocell grid (adapted from [45] with permission from John Wiley and Sons)

The most recent advance in this field involves a liquid-gas two-phase thermo-electric cell. In their 2019 article, Ma et al. [46] reported about a thermoelectric cell that uses aqueous H2SO4 solution as the electrolyte. The dissociated protons in the solution can be reduced to H2 gas at the hot side and be transported to the cold side to be oxidised back into ions (see Fig. 8). The change of phase of hydrogen gives additional entropy difference larger than those found in liquid electrolytes and the ion transport H+ is faster than any other ion species. As shown in Fig. 8, the electrodes are separated by many alternating gas and liquid channels; this reduces the heat conduction because it limits convection and also because gas is a much better thermal insulator than liquid. This is also why the separation between hot and cold sides of this system can be smaller than 0.5 mm. The phase change when water vaporises into a gas also adds to the entropy difference and further boosts the Seebeck coefficient. The achieved power density is an impressive 4 W/m2.

The protons are reduced to hydrogen gas at the hot electrode and then move to the cold electrode to be oxidised back to protons. The separator between the electrodes consists of many parallel gas and liquid micro-channels to facilitate the gas and liquid transfer. The gas channels reduce thermal conductivity by reducing liquid convection. Entropy difference is also enhanced by the water vaporisation in the gas phase (adapted from [46] with permission from ACS, this is an “Editor’s Choice” and further permissions related to this image should be obtained from ACS. Link: https://pubs.acs.org/doi/10.1021/acsenergylett.9b00944)

Conclusion and perspective

The latest progress in the field of ionic thermoelectric materials has been examined in this review. The advances in the solid-state polyelectrolytes have been impressive, as the power factor went from the single digits to 1200 mW/m*K2 in just 3 years; high Seebeck coefficients up to 19 mV/K have been achieved and the figure of merit rose to 0.7, approaching the ZT = 1 of the typical thermoelectric semiconductors. One advantage of these materials is the absence of any risks associated with electrolyte leakage, but since most of them need to operate with a rather large ambient relative humidity of over 50% to achieve maximum efficiency, this adds the problem of humidity control and limits widespread application. Fortunately, recent progress with dry polyelectrolytes [28] shows that this problem can be solved. It should also be noted that many polymers degrade at high temperatures (e.g. PEDOT:PSS chemically degrades quickly when placed at 190 °C [49]).

Ionogels hold the biggest potential in the field of wearable technology due to their flexibility, stretchability and no risk of leakage. Within 3 years, the ZT rose from the 1.5 × 10–4 to 0.75, rivalling that of the traditional inorganic semiconductor materials. The Seebeck coefficient can also be as high as 26.1 mV/K.

Some require the use of a supercapacitor, which is quite suitable considering the frequent equipping/unequipping nature of wearable devices and can be used to recycle body heat. Ionogels can also be applied for energy harvesting at higher temperatures, for example, PVDF-HPF-based ionogels are stable up to 400 °C [50]. However, one should be cautious when choosing the chemical/ionic liquids to be loaded into the polymer matrix. For example, [EMIM][BF4] is toxic while [EMIM][DCA] is relatively harmless.

The advances in aqueous electrolytes are also impressive, with power density as high as 12 W/m2; the future looks promising for their application in industrial-scale waste heat harvesting, particularly because devices can be custom designed to fit whatever shape that is needed and portability is not a concern (e.g. fitting around a water boiler or pipe, where the temperature is below the aqueous electrolyte’s boiling point (below 100 °C).

Ionic liquids are relatively new, but their progress is just as rapid, with power density jumping from 29 to 880 mW/m2 in just 3 years; from what has been presented, the main direction of improvement in this area is to reduce viscosity and promote ion transport. Their main advantage is the low thermal conductivity and good stability at high temperatures; for example, [BMIM][BF4] is stable up to 280 °C [51]. Given time there will likely be new breakthroughs, they have the potential to fill in the gap for waste heat harvesting between 100 °C and 200 °C [43]. As mentioned at the beginning of this review, the amount of waste heat generated globally each year is enormous, giving rise to many potential applications for ionic thermoelectric materials. In order to push towards large-scale application, efforts should be made to continue improving the mechanical robustness, the ion conductivity and the Seebeck coefficient, while reducing the cost of manufacture.

Data availability

Not applicable.

References

Forman C, Muritala IK, Pardemann R, Meyer B (2016) Estimating the global waste heat potential. Renew Sust Energ Rev 57:1568–1579

Hofmann AI, Kroon R, Müller C (2019) Doping and processing of organic semiconductors for plastic thermoelectrics. In: Ostroverkhova O (ed) Handbook of organic materials for electronic and photonic devices, 2nd edn. Woodhead Publishing, Cambridge, pp 429–449

Lan Y, Minnich AJ, Chen G, Ren Z (2010) Enhancement of thermoelectric figure-of-merit by a bulk nanostructuring approach. Adv Funct Mater 20(3):357–376

Rull-Bravo M, Moure A, Fernández JF, Martín-González M (2015) Skutterudites as thermoelectric materials: revisited. RSC Adv 5(52):41653–41667

Biswas K, He J, Blum ID, Wu CI, Hogan TP, Seidman DN, Dravid VP, Kanatzidis MG (2012) High-performance bulk thermoelectrics with all-scale hierarchical architectures. Nature 489(7416):414–418

Zhao LD, Lo SH, Zhang Y, Sun H, Tan G, Uher C, Wolverton C, Dravid VP, Kanatzidis MG (2014) Ultralow thermal conductivity and high thermoelectric figure of merit in SnSe crystals. Nature 508(7496):373–377

Hinterleitner B, Knapp I, Poneder M, Shi Y, Müller H, Eguchi G, Eisenmenger-Sittner C, Stöger-Pollach M, Kakefuda Y, Kawamoto N, Guo Q, Baba T, Mori T, Ullah S, Chen XQ, Bauer E (2019) Thermoelectric performance of a metastable thin-film Heusler alloy. Nature 576(7785):85–90

Yao CJ, Zhang HL, Zhang Q (2019) Recent progress in thermoelectric materials based on conjugated polymers. Polymers 11(1):1–19

Abraham TJ, Macfarlane DR, Baughman RH, Jin L, Li N, Pringle JM (2013) Towards ionic liquid-based thermoelectrochemical cells for the harvesting of thermal energy. Electrochim Acta 113:87–93

Li T, Zhang X, Lacey SD, Mi R, Zhao X, Jiang F, Song J, Liu Z, Chen G, Dai J, Yao Y, Das S, Yang R, Briber RM, Hu L (2019) Cellulose ionic conductors with high differential thermal voltage for low-grade heat harvesting. Nat Mater 18(6):608–613

Taheri A, Macfarlane DR, Pozo-Gonzalo C, Pringle JM (2018) Flexible and non-volatile redox active quasi-solid state ionic liquid based electrolytes for thermal energy harvesting. Sustain Energy Fuels 2(8):1806–1812

Chikina I, Shikin V, Varlamov AA (2012) Seebeck effect in electrolytes. Phys Rev E 86(1):11505

Rahman MA, Saghir MZ (2014) Thermodiffusion or Soret effect: historical review. Int J Heat Mass Transf 73:693–705

Chang WB, Fang H, Liu J, Evans CM, Russ B, Popere BC, Patel SN, Chabinyc ML, Segalman RA (2016) Electrochemical effects in thermoelectric polymers. ACS Macro Lett 5(4):455–459

Wang H, Zhao D, Khan ZU, Puzinas S, Jonsson MP, Berggren M, Crispin X (2017) Ionic thermoelectric figure of merit for charging of supercapacitors. Adv Electron Mater 3(4):1700013

Cheng H, Xu H, Fan Z, Ouyang J (2019) Flexible quasi-solid state ionogels with remarkable Seebeck coefficient and high thermoelectric properties. Adv Energy Mater 9(32):1901085. https://doi.org/10.1002/aenm.201901085

Duan J, Feng G, Yu B, Li J, Chen M, Yang P, Feng J, Liu K, Zhou J (2018) Aqueous thermogalvanic cells with a high Seebeck coefficient for low-grade heat harvest. Nat Commun 9(1):1–8

Dupont MF, MacFarlane DR, Pringle JM (2017) Thermo-electrochemical cells for waste heat harvesting-progress and perspectives. Chem Commun 53(47):6288–6302

Wang H, Ail U, Gabrielsson R, Berggren M, Crispin X (2015) Ionic Seebeck effect in conducting polymers. Adv Energy Mater 5(11):1–6

Chang WB, Evans CM, Popere BC, Russ BM, Liu J, Newman J, Segalman RA (2016) Harvesting waste heat in unipolar ion conducting polymers. ACS Macro Lett 5(1):94–98

Zhao D, Wang H, Khan ZU, Chen JC, Gabrielsson R, Jonsson MP, Berggren M, Crispin X (2016) Ionic thermoelectric supercapacitors. Energy Environ Sci 9(4):1450–1457

Kim SL, Lin HT, Yu C (2016) Thermally chargeable solid-state supercapacitor. Adv Energy Mater 6(18):1–7

Jiao F, Naderi A, Zhao D, Schlueter J, Shahi M, Sundström J, Granberg H, Edberg J, Ail U, Brill J, Lindström T, Berggren M, Crispin X (2017) Ionic thermoelectric paper. J Mater Chem A 5(32):16883–16888

Guan X, Cheng H, Ouyang J (2018) Significant enhancement in the Seebeck coefficient and power factor of thermoelectric polymers by the Soret effect of polyelectrolytes. J Mater Chem A 6(40):19347–19352

Kim SL, Hsu J-H, Yu C (2018) Thermoelectric effects in solid state polyelectrolytes. Org Electron 54(September 2017):231–236

Kim SL, Hsu JH, Yu C (2018) Intercalated graphene oxide for flexible and practically large thermoelectric voltage generation and simultaneous energy storage. Nano Energy 48(March):582–589

Choi K, Kim SL, In Yi S, Hsu JH, Yu C (2018) Promoting dual electronic and ionic transport in PEDOT by embedding carbon nanotubes for large thermoelectric responses. ACS Appl Mater Interfaces 10(28):23891–23899

Mentor JJ, Torres R, Hallinan DT (2020) The Soret effect in dry polymer electrolyte. Mol Syst Des Eng 5(4):856–863

Yang P, Liu K, Chen Q, Mo X, Zhou Y, Li S, Feng G, Zhou J (2016) Wearable thermocells based on gel electrolytes for the utilization of body heat. Angew Chem 128(39):12229–12232

Jin L, Greene GW, MacFarlane DR, Pringle JM (2016) Redox-active quasi-solid-state electrolytes for thermal energy harvesting. ACS Energy Lett 1(4):654–658

Taheri A, MacFarlane DR, Pozo-Gonzalo C, Pringle JM (2018) Quasi-solid-state electrolytes for low-grade thermal energy harvesting using a cobalt redox couple. ChemSusChem 11(16):2788–2796

Sajid IH, Aslfattahi N, Sabri MFM, Said SM, Saidur R, Salleh MFM, Ghazali NNN, Hasan SW (2019) Synthesis and characterization of novel p-type chemically cross-linked ionogels with high ionic Seebeck coefficient for low-grade heat harvesting. Electrochim Acta 320:134575

Mua Y (1995) A review of power generation in aqueous thermogalvanic cells. J Electrochem Soc 142(11):3985–3994

Liu J, Wang X, Li D, Coates NE, Segalman RA, Cahill DG (2015) Thermal conductivity and elastic constants of PEDOT:PSS with high electrical conductivity. Macromolecules 48(3):585–591

Ail U, Jafari MJ, Wang H, Ederth T, Berggren M, Crispin X (2016) Thermoelectric properties of polymeric mixed conductors. Adv Funct Mater 26(34):6288–6296

Song J, Ma G, Qin F, Hu L, Luo B, Liu T, Yin X, Zhen S, Zeng Z, Jiang Y, Wang G, Li Z (2020) High-conductivity, flexible and transparent PEDOT: PSS electrodes for high performance semi-transparent supercapacitors. Polymers 12(2):450. https://doi.org/10.3390/polym12020450

Guo B, Yin Q, Zhou J, Li W, Zhang K, Li Y (2019) Semiconductive polymer-doped PEDOT with high work function, conductivity, reversible dispersion, and application in organic solar cells. ACS Sustain Chem Eng 7(9):8206–8214

Neves MFFD, Damasceno JPV, Holakoei S, Rocco MLM, Zarbin AJG, De Oliveira CKBQM, Roman LS (2019) Enhancement of conductivity and transmittance of graphene oxide/PEDOT:PSS electrodes and the evaluation of charge transfer dynamics. J Appl Phys 126(21):215107. https://doi.org/10.1063/1.5124619

Fan J, Rezaie SS, Facchini-Rakovich M, Gudi D, Montemagno C, Gupta M (2019) Tuning PEDOT:PSS conductivity to obtain complementary organic electrochemical transistor. Org Electron 66(December 2018):148–155

Abdullayeva N, Sankir M (2017) Influence of electrical and ionic conductivities of organic electronic ion pump on acetylcholine exchange performance. Materials 10(6):586. https://doi.org/10.3390/ma10060586

Jeffrey G (2008) Snyder and Eric S Toberer. Snyder_complexTEmeterials. Nat Mater 7(February):105–114

Chandra S, Sekhon SS, Arora N (2000) PMMA based protonic polymer gel electrolytes. Ionics 6(1–2):112–118

Abraham TJ, Macfarlane DR, Pringle JM (2013) High Seebeck coefficient redox ionic liquid electrolytes for thermal energy harvesting. Energy Environ Sci 6(9):2639–2645

Lazar MA, Al-Masri D, Macfarlane DR, Pringle JM (2016) Enhanced thermal energy harvesting performance of a cobalt redox couple in ionic liquid-solvent mixtures. Phys Chem Chem Phys 18(3):1404–1410

Zhang L, Kim T, Li N, Kang TJ, Chen J, Pringle JM, Zhang M, Kazim AH, Fang S, Haines C, Al-Masri D, Cola BA, Razal JM, Di J, Beirne S, MacFarlane DR, Gonzalez-Martin A, Mathew S, Kim YH, Wallace G, Baughman RH (2017) High power density electrochemical thermocells for inexpensively harvesting low-grade thermal energy. Adv Mater 29(12):1–7

Ma H, Wang X, Peng Y, Peng H, Hu M, Xiao L, Wang G, Lu J, Lin Z (2019) Powerful thermogalvanic cells based on a reversible hydrogen electrode and gas-containing electrolytes. ACS Energy Lett 4(8):1810–1815

Salazar PF, Stephens ST, Kazim AH, Pringle JM, Cola BA (2014) Enhanced thermo-electrochemical power using carbon nanotube additives in ionic liquid redox electrolytes. J Mater Chem A 2(48):20676–20682

He J, Al-Masri D, MacFarlane DR, Pringle JM (2016) Temperature dependence of the electrode potential of a cobalt-based redox couple in ionic liquid electrolytes for thermal energy harvesting. Faraday Discuss 190:205–218

Stepien L, Roch A, Tkachov R, Leupolt B, Han L, van Ngo N, Leyens C (2017) Thermal operating window for PEDOT:PSS films and its related thermoelectric properties. Synth Met 225:49–54

Shalu, Singh VK, Singh RK (2015) Development of ion conducting polymer gel electrolyte membranes based on polymer PVdF-HFP, BMIMTFSI ionic liquid and the Li-salt with improved electrical, thermal and structural properties. J Mater Chem C 3(28):7305–7318

Laux E, Uhl S, Gauthier N, Jeandupeux L, Keppner H, López PP, Pauline S, Vanoli E, Marti R (2018) Development of thermoelectric generator based on ionic liquids for high temperature applications. Mater Today: Proc 5(4):10195–10202

Acknowledgements

This review was conceived under the Top Master Nanoscience program. We acknowledge Jingjin Dong for interesting discussions.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Code availability

Not applicable.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Yang, B., Portale, G. Ionic thermoelectric materials for waste heat harvesting. Colloid Polym Sci 299, 465–479 (2021). https://doi.org/10.1007/s00396-020-04792-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00396-020-04792-4