Abstract

Living organisms have evolved sophisticated cell-mediated biomineralization mechanisms to build structurally ordered, environmentally adaptive composite materials. Despite advances in biomimetic mineralization research, it remains difficult to produce mineralized composites that integrate the structural features and ‘living’ attributes of their natural counterparts. Here, inspired by natural graded materials, we developed living patterned and gradient composites by coupling light-inducible bacterial biofilm formation with biomimetic hydroxyapatite (HA) mineralization. We showed that both the location and the degree of mineralization could be regulated by tailoring functional biofilm growth with spatial and biomass density control. The cells in the composites remained viable and could sense and respond to environmental signals. Additionally, the composites exhibited a maximum 15-fold increase in Young’s modulus after mineralization and could be applied to repair damage in a spatially controlled manner. Beyond insights into the mechanism of formation of natural graded composites, our study provides a viable means of fabricating living composites with dynamic responsiveness and environmental adaptability.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The main data supporting the findings of this study are available within the article and its Supplementary Information. Additional data are available from the corresponding author upon reasonable request.

References

Dunlop, J. W. C. & Fratzl, P. Biological composites. Annu. Rev. Mater. Res. 40, 1–24 (2010).

Michaela Eder, S. A. & Fratzl, P. Biological composites—complex structures for functional diversity. Science 362, 543–547 (2018).

Liu, Z., Meyers, M. A., Zhang, Z. & Ritchie, R. O. Functional gradients and heterogeneities in biological materials: design principles, functions, and bioinspired applications. Prog. Mater. Sci. 88, 467–498 (2017).

Shaw, J. A. et al. Ultrastructure of the epithelial cells associated with tooth biomineralization in the chiton Acanthopleura hirtosa. Microsc. Microanal. 15, 154–165 (2009).

Meunier, F. J. Spatial organization and mineralization of the basal plate of elasmoid scales in osteichthyans. Am. Zool. 24, 953–964 (1984).

Bentov, S. et al. Enamel-like apatite crown covering amorphous mineral in a crayfish mandible. Nat. Commun. 3, 839 (2012).

Reznikov, N., Steele, J. A. M., Fratzl, P. & Stevens, M. M. A materials science vision of extracellular matrix mineralization. Nat. Rev. Mater. 1, 16041 (2016).

Meldrum, F. C. & Colfen, H. Controlling mineral morphologies and structures in biological and synthetic systems. Chem. Rev. 108, 4332–4432 (2008).

Boys, A. J. et al. Understanding the stiff-to-compliant transition of the meniscal attachments by spatial correlation of composition, structure, and mechanics. ACS Appl. Mater. Interfaces 11, 26559–26570 (2019).

Jeffrey, D., Hartgerink, E. B. & Stupp, S. I. Self-assembly and mineralization of peptide-amphiphile nanofibers. Science 294, 1684–1688 (2001).

Nils Kröger, S. L., Brunner, E. & Sumper, M. Self-assembly of highly phosphorylated silaffins and their function in biosilica morphogenesis. Science 298, 584–586 (2002).

Ha, Y. et al. Phase-transited lysozyme as a universal route to bioactive hydroxyapatite crystalline film. Adv. Funct. Mater. 28, 1704476 (2018).

Mao, L. B. et al. Synthetic nacre by predesigned matrix-directed mineralization. Science 354, 107–110 (2016).

Sean, A., Davis, S. L. B., Mendelson, N. H. & Mann, S. Bacterial templating of ordered macrostructures in silica and silica-surfactant mesophases. Nature 385, 420–423 (1997).

Wu, C. H., Park, A. & Joester, D. Bioengineering single crystal growth. J. Am. Chem. Soc. 133, 1658–1661 (2011).

Cameron, D. E., Bashor, C. J. & Collins, J. J. A brief history of synthetic biology. Nat. Rev. Microbiol. 12, 381–390 (2014).

Brophy, J. A. & Voigt, C. A. Principles of genetic circuit design. Nat. Methods 11, 508–520 (2014).

Chen, A. Y., Zhong, C. & Lu, T. K. Engineering living functional materials. ACS Synth. Biol. 4, 8–11 (2015).

Gilbert, C. & Ellis, T. Biological engineered living materials: growing functional materials with genetically programmable properties. ACS Synth. Biol. 8, 1–15 (2019).

Nguyen, P. Q., Courchesne, N. D., Duraj-Thatte, A., Praveschotinunt, P. & Joshi, N. S. Engineered living materials: prospects and challenges for using biological systems to direct the assembly of smart materials. Adv. Mater. 30, e1704847 (2018).

Chen, A. Y. et al. Synthesis and patterning of tunable multiscale materials with engineered cells. Nat. Mater. 13, 515–523 (2014).

Huang, J. et al. Programmable and printable Bacillus subtilis biofilms as engineered living materials. Nat. Chem. Biol. 15, 34–41 (2019).

Zhang, C. et al. Engineered Bacillus subtilis biofilms as living glues. Mater. Today 28, 40–48 (2019).

Heveran, C. M. et al. Biomineralization and successive regeneration of engineered living building materials. Matter 2, 481–494 (2020).

Gonzalez, L. M., Mukhitov, N. & Voigt, C. A. Resilient living materials built by printing bacterial spores. Nat. Chem. Biol. 16, 126–133 (2020).

Praveschotinunt, P. et al. Engineered E. coli Nissle 1917 for the delivery of matrix-tethered therapeutic domains to the gut. Nat. Commun. 10, 5580 (2019).

Wei, W. et al. An underwater surface-drying peptide inspired by a mussel adhesive protein. Adv. Funct. Mater. 26, 3496–3507 (2016).

Tavafoghi, M. & Cerruti, M. The role of amino acids in hydroxyapatite mineralization. J. R. Soc. Interface 13, 20160462 (2016).

Lee, B. P., Messersmith, P. B., Israelachvili, J. N. & Waite, J. H. Mussel-inspired adhesives and coatings. Annu. Rev. Mater. Res. 41, 99–132 (2011).

Wei, W. et al. A mussel-derived one-component adhesive coacervate. Acta Biomater. 10, 1663–1670 (2014).

Matthew, R. et al. Role of Escherichia coli curli operons in directing amyloid fiber formation. Science 295, 851–855 (2002).

Li, B. et al. Single-molecule force spectroscopy reveals self-assembly enhanced surface binding of hydrophobins. Chemistry 24, 9224–9228 (2018).

Wang, X. et al. Programming cells for dynamic assembly of inorganic nano-objects with spatiotemporal control. Adv. Mater. 30, e1705968 (2018).

Moser, F., Tham, E., González, L. M., Lu, T. K. & Voigt, C. A. Light-controlled, high-resolution patterning of living engineered bacteria onto textiles, ceramics, and plastic. Adv. Funct. Mater. 29, 1901788 (2019).

Mahamid, J. et al. Mapping amorphous calcium phosphate transformation into crystalline mineral from the cell to the bone in zebrafish fin rays. Proc. Natl Acad. Sci. USA 107, 6316–6321 (2010).

Lu, X., Al-Qadiri, H. M., Lin, M. & Rasco, B. A. Application of mid-infrared and Raman spectroscopy to the study of bacteria. Food Bioprocess Technol. 4, 919–935 (2011).

Koutsopoulos, S. Synthesis and characterization of hydroxyapatite crystals: a review study on the analytical methods. J. Biomed. Mater. Res. 62, 600–612 (2002).

Manteca, A., Fernandez, M. & Sanchez, J. A death round affecting a young compartmentalized mycelium precedes aerial mycelium dismantling in confluent surface cultures of Streptomyces antibioticus. Microbiology 151, 3689–3697 (2005).

Hale, L. V., Ma, Y. F. & Santerre, R. F. Semi-quantitative fluorescence analysis of calcein binding as a measurement of in vitro mineralization. Calcif. Tissue Int. 67, 80–84 (2000).

Liang, K. et al. Metal-organic framework coatings as cytoprotective exoskeletons for living cells. Adv. Mater. 28, 7910–7914 (2016).

Zhu, W. et al. SupraCells: living mammalian cells protected within functional modular nanoparticle-based exoskeletons. Adv. Mater. 31, e1900545 (2019).

Kroger, N. Prescribing diatom morphology: toward genetic engineering of biological nanomaterials. Curr. Opin. Chem. Biol. 11, 662–669 (2007).

Iannucci, L. E., Boys, A. J., McCorry, M. C., Estroff, L. A. & Bonassar, L. J. Cellular and chemical gradients to engineer the meniscus-to-bone insertion. Adv. Healthc. Mater. 8, e1800806 (2019).

Zhu, C., Qiu, J., Pongkitwitoon, S., Thomopoulos, S. & Xia, Y. Inverse opal scaffolds with gradations in mineral content for spatial control of osteogenesis. Adv. Mater. 30, e1706706 (2018).

Lee, C., Wei, X., Kysar, J. W. & Hone, J. Measurement of the elastic properties and intrinsic strength of monolayer graphene. Science 321, 385–388 (2008).

Waite, J. H. Mussel adhesion—essential footwork. J. Exp. Biol. 220, 517–530 (2017).

Cui, M. et al. Exploiting mammalian low-complexity domains for liquid–liquid phase separation-driven underwater adhesive coatings. Sci. Adv. 5, eaax3155 (2019).

Kaberniuk, A. A., Shemetov, A. A. & Verkhusha, V. V. A bacterial phytochrome-based optogenetic system controllable with near-infrared light. Nat. Methods 13, 591–597 (2016).

Nils Kröger, R. D. & Sumper, M. Polycationic peptides from diatom biosilica that direct silica nanosphere formation. Science 286, 1129–1132 (1999).

Komeili, A. Molecular mechanisms of compartmentalization and biomineralization in magnetotactic bacteria. FEMS Microbiol. Rev. 36, 232–255 (2012).

Fernandez-Rodriguez, J., Moser, F., Song, M. & Voigt, C. A. Engineering RGB color vision into Escherichia coli. Nat. Chem. Biol. 13, 706–708 (2017).

Ohlendorf, R., Vidavski, R. R., Eldar, A., Moffat, K. & Moglich, A. From dusk till dawn: one-plasmid systems for light-regulated gene expression. J. Mol. Biol. 416, 534–542 (2012).

Zhong, C. et al. Strong underwater adhesives made by self-assembling multi-protein nanofibres. Nat. Nanotechnol. 9, 858–866 (2014).

O’Toole, G. A. Microtiter dish biofilm formation assay. J. Vis. Exp. https://doi.org/10.3791%2F2437 (2011).

Kokubo, T. & Takadama, H. How useful is SBF in predicting in vivo bone bioactivity? Biomaterials 27, 2907–2915 (2006).

Chavan, D. et al. Ferrule-top nanoindenter: an optomechanical fiber sensor for nanoindentation. Rev. Sci. Instrum. 83, 115110 (2012).

Acknowledgements

We thank X. Wang for AFM training and W. Liu and Y. Jiang for TEM and SEM training, respectively. AFM characterization was executed at the Analytical Instrumentation Center (AIC); SEM and TEM experiments were supported by the Center for High-resolution Electron Microscopy (CћEM) at ShanghaiTech University. We also thank K. Kang and W. Xing from the animal core facility at the Shanghai Institute of Biochemistry and Cell Biology for helping with µCT experiments and image analysis. This work was partially sponsored by the National Science and Technology Major Project of the Ministry of Science and Technology of China (grant no. 2020YFA0908100 and grant no. 2018YFA0902804), the Joint Funds of the National Natural Science Foundation of China (key program no. U1932204), the Commission for Science and Technology of Shanghai Municipality (grant no. 17JC1403900) and the China Postdoctoral Science Foundation (grant no. 2019M661676). C.Z. also acknowledges start-up funding support from the 1000 Youth Talents Program, granted by the Chinese Central Government.

Author information

Authors and Affiliations

Contributions

C.Z. conceived the concept and directed the research. C.Z., Y.W. and B.A. designed and conducted the experiments and data analysis. Y.C. and B.X. participated in AFM nano-indentation and SMFS experiments and relevant data analysis. J.P. conducted the QCM experiments and analyzed the resulting data. Y.Y. and X.Z. contributed to acquiring selected-area electron diffraction patterns and relevant data analysis. Y.H. assisted with western blot experiments and the cell viability assay. C.Z., Y.W. and B.A. wrote the manuscript with help from all authors.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Extended data

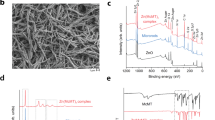

Extended Data Fig. 1 Comparison of biofilm formation for genetically engineered E.coli strains that express different CsgA-Mfp fusion proteins.

a, TEM characterization of biofilms formed by E.coli strains consisting of different CsgA-Mfp fusion proteins. Scale bars, 500 nm. b, Quantitative Congo Red (CR) binding assay and Crystal Violet (CV) staining revealed that few amounts of biofilm biomass were produced by aTcReceiver/CsgA-Mefp5, while aTcReceiver/CsgA-Mfp3S-pep yielded almost the same amount of biofilm biomass as that of the aTcReceiver/CsgA biofilms. c, Biofilm growth monitored by quantitative CR binding assay revealed that aTcReceiver/CsgA-Mfp3S exhibited a much slower growth rate and produced lower amounts of biofilm biomass compared with both the CsgA and CsgA-Mfp3S-pep biofilms. Results in b,c are presented as Mean ± s.d. Data are representative of n = 4 independent experiments.

Extended Data Fig. 2 Comparison of HA precipitation on CsgA and CsgA-Mfp3S-pep nanofibers.

TEM images of the precipitated minerals on different protein nanofibers after mineralization for 1, 3, 5, and 7 days. Scale bars, 500 nm.

Extended Data Fig. 3 Comparison of HA crystallization on CsgA and CsgA-Mfp3S-pep biofilms.

TEM images and corresponding SAED patterns of the precipitated minerals on different biofilms after 5-day mineralization.

Extended Data Fig. 4 Adsorption behavior comparison of CsgA and CsgA-Mfp3S-pep on HA surfaces measured by QCM.

a, Adsorption behavior of the CsgA and CsgA-Mfp3S-pep monomers (0.5 mg/mL) on HA-coated QCM chip. b, Adsorption behavior of the CsgA and CsgA-Mfp3S-pep nanofibers (initial monomer concentration at 0.5 mg/mL) on HA-coated QCM chip.

Extended Data Fig. 5 SMFS experiments for quantifying the interactions between the Mfp3S-pep proteins and hydroxyapatite.

a, Schematic of the AFM single-molecule spectroscopy experiments. The SNAP-Mfp3S-pep was connected to the cantilever tip via an O6−benzylguanine (BG)-terminated PEG linker. The substrate was hydroxyapatite-coated. b, Typical force-extension curves of Mfp3S-pep on HA-coated surfaces. Force-extension curves were fitted with WLC (green). All data are collected at the pulling speed of 1000 nm·s-1. c, Histograms (bars, N = 107) and Gaussian function (blue) fitting of the interaction strength between the Mfp3S-pep and HA. d, Histograms (bars, N = 107) and Gaussian function (black) fitting of the fracture length for the rupture of the Mfp3S-pep and HA interactions. e, Schematic of the AFM single-molecule spectroscopy experiments for the interaction between SNAP and HA. f, Typical force-extension curves for the interaction between the SNAP and HA. All data are collected at the pulling speed of 1000 nm·s-1.

Extended Data Fig. 6 TEM observation of morphology and phase evolution.

TEM images (Top) and corresponding SAED patterns (bottom) of the extracellularly self-assembled CsgA-Mfp3S-pep nanofibers (0 day) and the precipitated minerals on nanofibers after mineralization of the CsgA-Mfp3S-pep biofilm samples for 1, 3, 5, and 7 days. Scale bars, 500 nm.

Extended Data Fig. 7 Various illumination images (concentric circles, grids) are recapitulated as patterned biofilms (top) and patterned composites.

The grid pattern of the mineralized composite has a 1 mm spatial resolution. Scale bars, 1 cm.

Extended Data Fig. 8 Mineral contents of mineralized composites with different incubation time determined by TGA analyses.

a, Representative TGA measurements of the dried biofilm samples and living composite samples after mineralization for 1, 3, 5, and 7 days. b, Inorganic contents in the living composites with different mineralization time calculated based on TGA analyses. Results are presented as Mean ± s.d. Data are representative of n = 3 independent experiments.

Extended Data Fig. 9 Mechanical properties of biofilms and mineralized composites.

a, Young’s modulus of biofilms and mineralized living composites, measured using micro-indentation technique with a spherical probe (diameter = ~ 93 microns). The experiments were performed in an aqueous environment. Results are presented as Mean ± s.d. P = 0.00000027. *P < 0.05, **P < 0.01, ***P < 0.001. Statistics are derived using a two-sided t-test. Data are representative of n = 5 independent experiments. b, Representative indentation curves of the biofilms and living composites.

Extended Data Fig. 10 Local nanoscale mechanical properties of the dried gradient living composites measured by nano-indentation through atomic force microscopy (AFM).

a, Schematic model showing how AFM nano-indentation is used to measure the mechanical properties of composite microstructures. AFM nano-indentation is used to estimate Young’s modulus b, and stiffness c, of the different regions in the dried gradient composites. Results are presented as Mean ± s.d., at least 1200 counts were used for Young’s modulus, stiffness statistics.

Supplementary information

Supplementary Information

Supplementary Figs. 1−16 and Tables 1−4.

Rights and permissions

About this article

Cite this article

Wang, Y., An, B., Xue, B. et al. Living materials fabricated via gradient mineralization of light-inducible biofilms. Nat Chem Biol 17, 351–359 (2021). https://doi.org/10.1038/s41589-020-00697-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41589-020-00697-z

This article is cited by

-

Accelerating the design of pili-enabled living materials using an integrative technological workflow

Nature Chemical Biology (2024)

-

Structural engineered living materials

Nano Research (2024)

-

A soil-inspired dynamically responsive chemical system for microbial modulation

Nature Chemistry (2023)

-

Bioprinting microporous functional living materials from protein-based core-shell microgels

Nature Communications (2023)

-

Endowing textiles with self-repairing ability through the fabrication of composites with a bacterial biofilm

Scientific Reports (2023)