Abstract

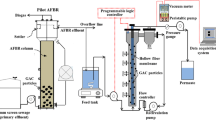

Membrane fouling behaviors were investigated to different biogas sparging flows such as 0.5, 1.0, and 1.5 L biogas/min for anaerobic submerged membrane bioreactor (AnSMBR) treating synthetic wastewater in a laboratory-scale. For each different biogas flow rate, the membrane module of the same feature was used in the system and the effect of biogas sparging flow on fouling control was examined in the process. Surface area of the used membrane module was selected as 162.6 cm2. The sprarging biogas was supplied from the gas formed in reactor system. Treatment parameters were analyzed in the process of reactor operation. Also, a series of analysis, including soluble microbial products (SMP), extracellular polymeric substances (EPSs), scanning electron microscopy, energy dispersive X-ray spectroscopy, particle size distribution, and filtration resistances were performed by considering the membrane module. The AnSMBR accomplished COD removal efficiencies between 95 and 98%. Total organic carbon and sulfate concentration in permeate were found in the range of 25–56 and 90–200 mg/L, and 96–98 and 38–65% in removal percentage; respectively. TSS and VSS concentrations in permeate were less than 10 mg/L that means removal efficiencies of 98%. Methane production rate in the system was determined of 0.35 ± 0.08 LCH4/g COD removed. The results showed that differences between COD and TOC removals were negligible at different biogas sparging flows. The priority of biogas sparging flows in terms of providing high permeate fluxes were found to be 1.5 L biogas/min > 1.0 L biogas/min > 0.5 L biogas/min. The same order was found with the fluxes in terms of both SMP and EPS within cake formed on the fibers in membrane module. Studying results showed that biogas sparging flow increasing was found to effective on membrane fouling controls. It has been determined that sparging gas at an optimum flow rate (1.0 L biogas/min) can be effective in controlling membrane fouling.

Similar content being viewed by others

REFERENCES

Lebrero, R., Gondim, A.C., Pérez, R., García-Encina, P.A., and Munoz, R., Comparative assessment of a biofilter, a biotrickling filter and a hollow fiber membrane bioreactor for odor treatment in wastewater treatment plants, Water Res., 2014, vol. 49, pp. 339–350.

Lin, H., Peng, W., Zhang, M., Chen, J., Hong, H., and Zhang, Y., A review on anaerobic membrane bioreactors: Applications, membrane fouling and future perspectives, Desalination, 2013, vol. 314, pp. 169–188.

Shin, C. and Bae, J., Current status of the pilot-scale anaerobic membrane bioreactor treatments of domestic wastewaters: A critical review, Bioresour. Technol., 2018, vol. 247, pp. 1038–1046.

Le-Clech, P., Membrane bioreactors and their uses in wastewater treatments, Appl. Microbiol Biotechnol., 2010, vol. 88, pp. 1253–1260.

Iorhemen, O.T., Hamza, R.A., and Tay, J.H., Membrane fouling control in membrane bioreactors (MBRs) using granular materials, Bioresour. Technol., 2017, vol. 240, pp. 9–24.

Chan, Y.J., Chong, M.F., Law, C.L., and Hasell, D.G., A review on anaerobic-aerobic treatment of industrial and municipal wastewater, Chem. Eng. J., 2009, vol. 155, pp. 1–18.

Yamamura, H., Kımura, K., and Watanabe, Y., Mechanism involved in the evolution of physically irreversible fouling in microfiltration and ultrafiltration membranes used for drinking water treatment, Environ. Sci. Technol., 2007, vol. 41, pp. 6789–6794.

Shen, L.-G., Lei, Q., Chen, J.R, Hong, H.C., He, Y.M., and Lin, H.J., Membrane fouling in a submerged membrane bioreactor: Impacts of floc size, Chem. Eng. J., 2015, vol. 269, pp. 328–334.

Jiang, T., Kennedy, M.D., van der Meer, W.G.J., Vanrolleghem, P.A., and Schippers, J.C., The role of blocking and cake filtration in MBR fouling, Desalination, 2003, vol. 157, pp. 335–434.

Frenkel, V.S., Planning and design of membrane systems for water treatment, in Advances in Membrane Technologies for Water Treatment, Amsterdam: Elsevier, 2015, pp. 329–347.

Tian, J.-Y., Xu, Y.-P., Chen, Z.-L., Nan, J., and Li, G.-B., Air bubbling for alleviating membrane fouling of immersed hollow-fiber membrane for ultrafiltration of river water, Desalination, 2010, vol. 260, pp. 225–230.

Meng, F., Zhang, S., Oh, Y., Zhou, Z., Shin, H.-S., and Chae, S.-R., Fouling in membrane bioreactors: An updated review, Water Res., 2017, vol. 114, pp. 151–180.

Hulse, C.A., Singh, K.S., and Grant, S.R., An innovative submerged anaerobic membrane bioreactor for treatment of potato solids and bioenergy production, Proc. 82nd Annual Water Environment Federation Technical Exposition and Conf., Orlando, Florida, October 11–14, 2009, Alexandria, VA: Water Environ. Fed., 2009, pp. 2216–2230.

Dvorak, L., Gomez, M., Dvorakova, M., Ruzickova, I., and Wanner, J., The impact of different operating conditions on membrane fouling and EPS production, Bioresour. Technol., 2011, vol. 102, pp. 6870–6875.

Wang, Z., Ma, J., Tang, C.Y., Kimura, K., Wang, Q., and Han, X., Membrane cleaning inmembrane bioreactors: A review, J. Membr. Sci., 2014, vol. 468, pp. 276–307.

Dereli, R.K., Ersahin, M.E., Ozgun, H., Ozturk, I., Jeison, D., van der Zee, F., and van Lier, J.B., Potentials of anaerobic membrane bioreactors to overcome treatment limitations induced by industrial wastewaters, Bioresour. Technol., 2012, vol. 122, pp. 160–170.

Ding, A., Liang, H., Li, G.B., Derlon, N., Szivak, I., Morgenroth, E., and Pronk, W., Impact of aeration shear stress on permeate flux and fouling layer properties in a low pressure membrane bioreactor for the treatment of grey water, J. Membr. Sci., 2016, vol. 510, pp. 382–390.

Standard Methods for the Examination of Water and Wastewater, Washington, DC: Am. Publ. Health Assoc., Am. Water Works Assoc., 2005, 21th ed.

Zhang, A.N., Liu, Z., Chen, Y.P., Kuschk, P., and Liu, Y.J., Effects of EPS on membrane fouling in a hybrid membrane bioreactor for municipal wastewater treatment, Membr. Water Treat., 2014, vol. 5, pp. 1–14.

Fouladitajar, A., Ashtiani, F.Z., Dabir, B., Rezaei, H., and Valizadeh, B., Response surface methodology for the modeling and optimization of oil-in-water emulsion separation using gas sparging assisted microfiltration, Environ. Sci. Pollut. Res., 2015, vol. 22, pp. 2311–2327.

Dagnew, M., Characterization of anaerobic membrane digesters for stabilization of waste activated sludge, PhD Thesis, Waterloo, ON, 2010.

ACKNOWLEDGMENTS

This study was supported by the Scientific and Technological Research Council of Turkey (TUBITAK) under grant projects no ÇAYDAG-110Y043.

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Mustafa Aslan Effect of Biogas Sparging Flow on Fouling Control in Anaerobic Membrane Bioreactors. J. Water Chem. Technol. 42, 373–380 (2020). https://doi.org/10.3103/S1063455X20050021

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1063455X20050021