Abstract

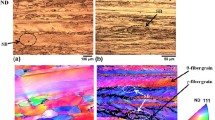

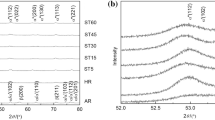

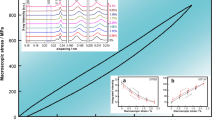

The mechanism of negative linear thermal expansion (NLTE) of Ti-34Nb (wt.%) alloy after 90% cold rolling is investigated by X-ray diffraction, thermal expansion and transmission electron microscopy. From the results, it is observed that 90% cold-rolled Ti-34Nb alloy is composed of β and α″ (Martensite) phases with the existence of < 110 > β and < 010 > α″ textures along rolling direction (RD). The cyclic thermal expansion, XRD and TEM studies show that when the thermal cycle temperature is at 100 °C, the RD of 90% cold-rolled Ti-34Nb alloy performs a reversible NLTE, which gradually weakens when thermal cycle temperature is at 300 °C, attributing to the gradual decomposition of α″-phase. When thermal cycle temperature rises to 380 °C, the reversible NLTE disappears and turns into positive linear thermal expansion, meanwhile, α″-phase decomposes completely. Based on the formation of β and α″ textures by cold rolling and α″\(\leftrightarrow\) β thermo-reversible transformation mechanism, the NLTE mechanism of 90% cold-rolled Ti-34Nb alloy is successfully explained. Moreover, according to the present results, a novel strategy is proposed to tailoring the negative coefficient of linear thermal expansion by changing α″ content, which improves the application potential of Ti alloys.

Similar content being viewed by others

References

Kittel C (2007) Introduction to Solid State Physics, eighth ed. Wiley

Arsenault RJ, Shi N (1986) Dislocation generation due to differences between the coefficients of thermal expansion. Mater Sci Eng 81:175–187

Fang W, Lo C-Y (2000) On the thermal expansion coefficients of thin films. Sens Actuators A 84(3):310–314

Qian G, Nakamura T, Berndt CC (1998) Effects of thermal gradient and residual stresses on thermal barrier coating fracture. Mech Mater 27(2):91–110

Chen J, Hu L, Deng JX, Xing XR (2015) Negative thermal expansion in functional materials: controllable thermal expansion by chemical modifications. Chem Soc Rev 44(11):3522–3567

Wang L, Wang C, Sun Y, Shi KW, Deng SH, Lu HQ, Hu PW, Zhang XY (2015) Metal fluorides, a new family of negative thermal expansion materials. J Mater 1(2):106–112

Lind C (2012) Two decades of negative thermal expansion Research. Where do we stand? Materials 5:1125–1154

Goodwin AL, Kepert CJ (2015) Negative thermal expansion and low-frequency modes in cyanide-bridged framework materials. Phys Rev B 71(14):1–4

Perottoni CA, Jornada JAHda, (1998) Pressure-induced amorphization and negative thermal expansion in ZrW2O8. Science 280(5365):886–889

Nakai M, Niinomi M, Akahori T, Tsutsumi H, Feng XL, Ogawa M (2009) Anomalous Thermal Expansion of Cold-Rolled Ti-Nb-Ta-Zr Alloy. Mater Trans 50(2):423–426

Hao YL, Wang HL, Li T, Cairney JM, Ceguerra AV, Wang YD, Wang Y, Wang D, Obbard EG, Li SJ, Yang R (2016) Superelasticity and Tunable Thermal Expansion across a Wide Temperature Range. J Mater Sci Technol 32:705–709

Ahadi A, Matsushita Y, Sawaguchi T, Sun QP, Tsuchiya K (2017) Origin of zero and negative thermal expansion in severely-deformed superelastic NiTi alloy. Acta Mater 124:79–92

Saito T, Furuta T, Hwang J-H, Kuramoto S, Nishino K, Suzuki N (2003) Multifunctional alloys obtained via a dislocation-free plastic deformation mechanism. Science 300:464–467

Kim HY, Wei L, Kobayashi S, Tahara M, Miyazaki S (2013) Nanodomain structure and its effect on abnormal thermal expansion behaviorof a Ti-23Nb-2Zr-0.7Ta-1.2O alloy. Acta Mater 61(13):4874–4886

Wang Y, Gao J, Wu H, Yang S, Ding X, Wang D, Ren X, Wang Y, Song X, Gao J (2014) Strain glass transition in a multifunctional β -type Ti alloy. Sci Rep 4:3995

Gepreel AH, Niinomi M, Nakai M, Morinaga M (2019) Invar Properties in Ti-Alloys Achieved Through Alloy Design and Thermomechanical Treatments. JOM 71(10):3631–3639

Monroe JA, Gehring D, Karaman I, Arroyave R, Brown DW, Clausen B (2016) Tailored thermal expansion alloys. Acta Mater 102:333–341

Gehring D, Monroe AJ, Karaman I (2020) Effects of composition on the mechanical properties and negative thermal expansion in martensitic TiNb alloys. Scripta Mater 178:351–355

Bönisc M, Panigrahi A, Stoica Mi, Calin M, Ahrens E, Zehetbauer M, Skrotzki W, Eckert J (2017) Giant thermal expansion and α-precipitation pathways in Ti-alloys. Nat Commun 8(1):1429

Hayama AOF, Lopes JFSC, Silva MJGD, Abreu HFG, Caram R (2014) Crystallographic texture evolution in Ti-35Nb alloy deformed by cold rolling. Mater Design 60:653–660

Kim HY, Satoru H, Kim JI, Hosoda H, Miyazaki S (2004) Mechanical properties and shape memory behavior of Ti-Nb alloys. Mater Trans 7:2443–2448

Wang Y, Zhao J, Dai SJ, Chen F, Yu XQ, Zhang YF (2013) Influence of cold rolling and ageing treatment on microstructure and mechanical properties of Ti-30Nb-5Ta-6Zr alloy. J Mech Behav Biomed 27:33–42

Dai SJ, Wang Y, Chen F, Yu XQ, Zhang YF (2013) Effects of annealing on the microstructures and mechanical properties of biomedical cold-rolled Ti-Nb-Zr-Mo-Sn alloy. Mater Sci Eng A 575:35–40

Wang LQ, Lu WJ, Qin JN, Zhang F, Zhang D (2008) Effect of precipitation phase on microstructure and superelasticity of cold-rolled beta titanium alloy during heat treatment. Mater Design 30(9):3873–3878

Pionnier D, Humbert M, Philippe MJ, Combres Y (1998) Study of the α″ phase texture obtained by martensitic β α″ phase transformation induced by tensile test in a sheet of Ti5Al2Sn4Zr4Mo2Cr1Fe. Acta Mater 46(16):5891–5898

Lieberman DS, Wechsler MS, Read TA (1955) Cubic to Orthorhombic Diffusionless Phase Change-Experimental and Theoretical Studies of AuCd. J Appl Phys 26(4):473–484

Khromova LP, Dyakonova NB, Rodionov Y, Yudin GV, Korms I (2003) Martensitic transformations, thermal expansion and mechanical properties of titanium-niobium alloys. J Phys IV Fr 112:1051–1054

Abdel-Hady M, Hinoshita K, Fuwa H, Murata Y, Morinaga M (2008) Change in anisotropy of mechanical properties with β-phase stability in high Zr-containing Ti-based alloys. Mat Sci Eng A 480(1–2):167–174

Abdel-Hady M (2013) Texturing Tendency in β-Type Ti-Alloys. In: Wilson P (ed) Recent Developments in the Study of Recrystallization. InTech, NewYork, pp 117–138

Mantani Y, Tajima M (2006) Phase transformation of quenched α″ martensite by aging in Ti-Nb alloys. Mat Sci Eng A 438–440:315–319

Barriobero-Vila P, Biancardi Oliveira V, Schwarz S, Buslaps T, Requena G (2017) Tracking the α″ martensite decomposition during continuous heating of a Ti-6Al-6V-2Sn alloy. Acta Mater 135:132–143

Kim HY, Ikehara Y, Kim JI, Hosoda H, Miyazaki S (2006) Martensitic transformation, shape memory effect and superelasticity of Ti-Nb binary alloys. Acta Mater 54(9):2419–2429

Furuta T, Kuramoto S, Hwang J, Nishino K, Saito T (2005) Elastic Deformation Behavior of Multi-Functional Ti-Nb-Ta-Zr-O Alloys. MateR Trans 46(12):3001–3007

Kim JI, Kim HY, Inamura T, Hosoda H, Miyazaki S (2005) Shape memory characteristics of Ti-22Nb-(2-8)Zr(at.%) biomedical alloys. Mat Sci Eng A 403(1–2):334–339

Kim HY, Hashimoto S, Kim JI, Inamura T, Hosoda H, Miyazaki S (2006) Effect of Ta addition on shape memory behavior of Ti-22Nb alloy. Mat Sci Eng A 417:120–128

Wang BL, Zheng YF, Zhao LC (2008) Effects of Sn content on the microstructure, phase constitution and shape memory effect of Ti-Nb-Sn alloys. Mat Sci Eng A 486:146–151

Li MJ, Min XH, Yao K, Ye F (2018) Novel insight into the formation of α"-martensite and ω-phase with cluster structure in metastable Ti-Mo alloys. Acta Mater 164:322–333

Hao YL, Li SJ, Sun SY, Yang R (2006) Effect of Zr and Sn on Young’s modulus and superelasticity of Ti-Nb-based alloys. Mat Sci Eng A 441:112–118

Acknowledgements

The authors gratefully acknowledge the financial supports from the National Aerospace Science Foundation of China (Grant No. 20133069014) and National Natural Science Foundation of China (Grant No. U1737103) and Open Foundation of Guangxi Key Laboratory of Processing for Non-Ferrous Metals and Featured Materials (Grant No. GXYSOF1802).

Author information

Authors and Affiliations

Corresponding author

Additional information

Handling Editor: David Balloy.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wu, X., Zou, W., Huang, J. et al. The mechanism of negative linear thermal expansion behavior of cold-rolled Ti-34Nb alloy. J Mater Sci 56, 5190–5200 (2021). https://doi.org/10.1007/s10853-020-05574-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-020-05574-7