Abstract

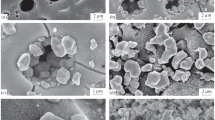

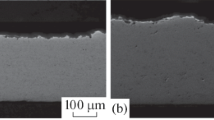

It has been confirmed in the present work that the components of an electrolyte and impregnating solution accumulated in pores can serve as a material for the microcrystal formation on the surface of oxide layers at high-temperature oxidative annealing. WO3 microcrystals were formed in the pores and along the pore perimeter of coatings formed by the method of plasma-electrolytic oxidation (PEO) in aqueous solutions with Na2WO4. Hemispheres containing NiWO4 nanogranules occluded the coating pores after their additional impregnation with an aqueous solution Ni(NO3)2 and annealing. The pore content has been analyzed, and possible mechanisms for its transformation into microcrystals and hemispheres have been considered. The obtained results were important for determination of the methods of targeted change in the composition and architecture of the complex oxide coatings' surface and, consequently, for controlling their functional properties.

Similar content being viewed by others

REFERENCES

Petrovic, S., Stojadinovic, S., Rozic, L., Radic, N., Grbic, B., and Vasilic, R., Surf. Coat. Technol., 2015, vol. 269, pp. 250–257. https://doi.org/10.1016/j.surfcoat.2014.12.026

Chen, L., Qu, Y., Yang, X., Liao, B., Xue, W.B., and Cheng, W., Mater. Chem. Phys., 2017, vol. 201, pp. 311–322. https://doi.org/10.1016/j.matchemphys.2017.08.013

Vasilyeva, M.S., Rudnev, V.S., Tulush, A.I., Nedozorov, P.M., and Ustinov, A.Y., Russ. J. Phys. Chem. A, 2015, vol. 89, no. 6, pp. 968–973. https://doi.org/10.1134/S0036024415060321

Rudnev, V.S., Lukiyanchuk, I.V., Vasilyeva, M.S., Morozova, V.P., Zelikman, V.M., and Tarkhanova, I.G., Appl. Surf. Sci., 2017, vol. 422, pp. 1007–1014. https://doi.org/10.1016/j.apsusc.2017.06.071

Yerokhin, A.L., Nie, X., Leyland, A., Matthews, A., and Dowey, S.J., Surf. Coat. Technol., 1999, vol. 122, pp. 73–93. https://doi.org/10.1016/S0257-8972(99)00441-7

Lukiyanchuk, I.V. and Rudnev, V.S., Inorg. Mater., 2007, vol. 43, no. 3, pp. 264–267. https://doi.org/10.1134/S0020168507030107

Rudnev, V.S., Vasilyeva, M.S., and Lukiyanchuk, I.V., Inorg. Mater., 2019, vol. 55, no. 7, pp. 681–686. https://doi.org/10.1134/S0020168519070148

Luo, Q., Cai, Q.Z., He, J., Li, X.W., Chen, X.D., Pan, Z.H., and Li, Y.J., Int. J. Appl. Ceram. Technol., 2014, vol. 11, no. 2, pp. 254–262. https://doi.org/10.1111/ijac.12062

Jiang, Y.N., Liu, B., Zhai, Z.F., Liu, X.Y., Yang, B., Liu, L.S., and Jiang, X., Appl. Surf. Sci., 2015, vol. 356, pp. 273–281. https://doi.org/10.1016/j.apsusc.2015.08.080

Jiang, Y.N., Liu, B.D., Yang, W.J., Yang, B., Liu, X.Y., Zhang, X.L., Mohsin, M.A., and Jiang, X., CrystEngComm, 2016, vol. 18, no. 10, pp. 1832–1841. https://doi.org/10.1039/c5ce02445e

Grilikhes, S.Ya., Obezzhirivanie, travlenie i polirovanie metallov (Degreasing, Etching and Polishing of Metals), Leningrad: Mashinostroenie, 1977.

Launay, J.P., Boyer, M., and Chauveau, F., J. Inorg. Nucl. Chem., 1976, vol. 38, no. 2, pp. 243–247. https://doi.org/10.1016/0022-1902(76)80402-2

Morlige, J.R., Skeldon, P., Thompson, G.E., Habazaki, H., Shimizu, K., and Wood, G.S., Electrochim. Acta, 1999, vol. 44, no. 14, pp. 2423–2435. https://doi.org/10.1016/S0013-4686(98)00363-6

Lur'e, Yu.Yu., Spravochnik po analiticheskoi khimii (Handbook on Analytical Chemistry), Moscow: Khimiya, 1989.

Lassner, E. and Schubert, W.D., Tungsten - Properties, Chemistry, Technology of the Element, Alloys, and Chemical Compounds, New York: Springer, 1999.

Gillet, M., Delamare, R., and Gillet, E., J. Cryst. Growth, 2005, vol. 279, nos. 1–2, pp. 93–99. https://doi.org/10.1016/j.jcrysgro.2005.01.089

Vasilyeva, M.S., Rudnev, V.S., Wiedenmann, F., Wybomov, S., Yarovaya, T.P., and Jiang, X., Appl. Surf. Sci., 2011, vol. 258, no. 2, pp. 719–726.

Rudnev, V.S., Malyshev, I.V., Lukiyanchuk, I.V., and Kuryavyi, V.G., Prot. Met. Phys. Chem. Surf., 2012, vol. 48, no. 4, pp. 455–461.

Viktorov, V.V., Belaya, E.A., and Serikov, A.S., Inorg. Mater., 2012, vol. 48, no. 5, pp. 488–493. https://doi.org/10.1134/S0020168512050202

Rudnev, V.S., Morozova, V.P., Lukiyanchuk, I.V., Tkachenko, I.A. Adigamova, M.V., Ustinov, A.Yu., Kharitonskii, P.V., Frolov, A.M., and Boev, S.A., Prot. Met. Phys. Chem. Surf., 2013, vol. 49, no. 3, pp. 309–318. https://doi.org/10.1134/S2070205113030143

Rogov, A.B., Mater. Chem. Phys., 2015, vol. 167, pp. 136–144. https://doi.org/10.1016/j.matchemphys.2015.10.020

Hakimizad, A., Raeissi, K., Santamaria, M., and Asghari, M., Electrochim. Acta, 2018, vol. 284, pp. 618–629. https://doi.org/10.1016/j.electacta.2018.07.200

Tu, W.B., Cheng, Y.L., Wang, X.Y., Zhan, T.Y., Han, J.X., and Cheng, Y.L., J. Alloys Compd., 2017, vol. 725, pp. 199–216. https://doi.org/10.1016/j.jallcom.2017.07.117

Funding

This work was supported by grant 18-03-00418 of the Russian Foundation for Basic Research.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by D. Marinin

Rights and permissions

About this article

Cite this article

Rudnev, V.S., Lukiyanchuk, I.V., Chernykh, I.V. et al. On the Effect of an Electrolyte and Impregnating Solution on Microcrystal Growth on the Surface of W-Containing PEO Coatings on Titanium at Oxidative Annealing. Prot Met Phys Chem Surf 56, 1201–1209 (2020). https://doi.org/10.1134/S207020512005024X

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S207020512005024X