Abstract

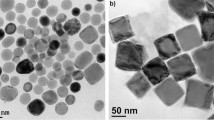

The morphology and composition of metal–oxide coronaparticles after the thermal oxidation of iron particles within the temperature range of 25–600°C under atmospheric conditions were investigated by in situ Raman-scattering spectroscopy. Thermal treatment at 100–300°C results in the predominant formation of a Fe3O4 and γ-Fe2O3 mixture, with a small amount of α-Fe2O3, on the surface of the iron particles, while annealing at higher temperatures results in further oxidation of iron, as well as phase transformation of Fe3O4 and γ-Fe2O3 phase transformation to the most thermodynamically stable form of iron oxide α-Fe2O3. At thermal treatment at 300°C and higher, localization of the reaction of hematite formation is observed: one-dimensional nanofilaments of the hematite-forming corona start to grow radially from spherical iron microparticles that are accompanied by depassivation and acceleration of growth of the oxide layer. With an increase of temperature and time of oxidation, the microparticles transform into multilayer metal–oxide coronaparticles consisting of a metal–oxide core and corona of the elongated crystalline α-Fe2O3 nanowhiskers growing transversely to the surface of the particles. Growth of the hematite nanowhiskers lasts until complete oxidation of the metal core has taken place. It has been hypothesized that the reason for the growth of hematite nanowhiskers at iron oxidation is associated with autolocalization of the topochemical reaction of maghemite formation in the magnetite–hematite interface phase boundary, as well as acceleration of transport of metal into the growing hematite whiskers by the effect of internal stresses in the growing oxide layer.

Similar content being viewed by others

Notes

Typically, solid-phase reactions taking place on interphase boundary are usually related to topochemical reactions [1–5]. In such reactions, the formation of a solid reaction product is not fraught with destruction or thoroughgoing rearrangement of structure of the parent phase. Specific character of the topochemical reactions is inspired by their localization in the region of solid–solid interphase of the initial substance and product of reaction, and inspired by increased reaction capacity of the solid reactive chemical in the region of this interphase. The reasons of this phenomenon are connected with various factors: anisotropy of properties of the transition layer, catalytic action of the solid product, etc. The reasons for localization of the process at topochemical reactions in the metal–oxide systems are usually associated with occurrence of defects in the metal and metal–oxide crystals and low mobility of the ions, atoms, or molecules forming the lattice.

Ion exchange, intercalation, some of the redox processes, and pillaring are representative examples of the topochemical reactions [2].

As opposed to high-temperature “ceramic” reactions, the low-temperature topochemical reaction schemes make it possible to form the metastable phases, realizing the kinetic and not thermodynamic control over selection of the phases of the product by use the differences in the rates of diffusion in the solid state of various particles, because they correspond to differences in reaction capacity [2–4]. Typically, in many complex oxides, one class of ions, whether cations or anions, is often much more mobile at that specific temperature. As a consequence, these mobile particles (cations or anions) can be incorporated into, or removed from, the parent phase at low temperature under the conditions in which surrounding lattice is actually changeless, with the formation of metastable phases that are usually unobtainable at high-temperature synthesis. Chemical transformations of this sort are described as “topochemical”; i.e., as opposed to the majority of high-temperature reactions, they preserve the main structural topology of the parent phase.

In this particular case, the author has in mind the structure of a metal-oxide crown-nanoparticle, which includes nanoobjects of various dimensions (one-dimensional whiskers and three-dimensional spherical nuclei of particles [11]).

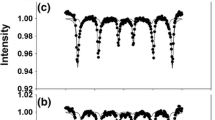

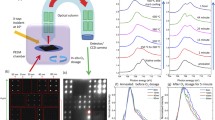

Registration of Raman spectra at maximum focusing of probing radiation on single particles required limiting the intensity of the excitation laser (to prevent laser–thermal effects). It resulted in a significant increase in the noise component of registered Raman spectra. For this reason, to process the obtained spectra, noise limitation by signal accumulation and resultant equalization of the registered spectra over time of registration was used. Because the process of oxidation did not cease, optimized equalization was reached with resulting broadening of the Raman bands.

The broad band at 840 cm–1 can be associated both with magnon excitation in hematite [59], and Raman scattering from the glass substrate [60]. The sharp decrease of intensity of the band with temperature (Fig. 3) appears to evidence in favor of the second reason—“overgrowth” of the illuminated surface of the glass by the oxide layer—and resultant sharp decrease of Raman scattering from the glass.

Indeed, oxidation of magnetite to maghemite can run with low rate and at room temperature. However, below 150–200°C, the kinetic inhibition of oxidizing reaction in consequence of rearrangement of the lattice of γ-Fe2O3 to the lattice of α-Fe2O3 has been noted. Because of this, the first noticeable signs of oxidation of the magnetite are observed at 150–200°С, when the mobility of particles is enough for their displacement in the lattice. However, noticeable oxidation starts only at 300–400°C. Above 500–600°C, the oxidation rate of magnetite is sufficiently high for pure hematite can already forms.

At the present time, the possibility of direct formation, at the specified temperature, of thin γ-Fe2O3 sublayer in the interface between the magnetite and α-Fe2O3 is experimentally proven. The debate on this issue was started a long while ago [41]. Electrochemical corroboration of existence of the γ-Fe2O3 layer between the magnetite and α-Fe2O3 was proposed already in [42]. In [43], the formation of a thin γ-Fe2O3 interlayer between the magnetite and α-Fe2O3 (350C, 20 Torr, 2 h) was registered. In addition the main component of the oxide layer was α‑Fe2O3. By reference to our earlier data of IR spectroscopy [44], it also can be inferred about thin layer of the γ-Fe2O3 phase at atmospheric low-temperature oxidation of iron.

In comparison with the reference peaks, some of the peaks of our samples demonstrated small red shift at increase of temperature of the thermal treatment, which is probably connected with the smaller size of 1D hematite crystallites (nanowhiskers) in our samples [47, 48]. It is known that nanomaterials and nanostructures of less than 20 nm in size demonstrate red shifts of the optical phonon modes. This phenomenon can be explained by the phonon confinement model (PCM), according to which the magnitude of the red shift increases with decrease of the size of an object [49]. It is visible in Fig. 3 that, upon an increase in the temperature of oxidation from 300 to 500°C, peaks at 221 cm–1 (A1g) and 290 cm–1 (Eg) have a very small, but distinctive, red shift. It is clear that this is connected with the fact that an increase of unit content of the hematite whiskers in the oxidized coronaparticle in comparison with initial hematite shell of iron particles takes place at an increase in the temperature of thermal treatment (Fig. 6), which, as a result, leads to an insignificant red shift of the peaks.

Surface effects, strictly speaking, should also be taken into account in consideration of internal stresses, especially for the case of quantum-dimensional metal nanoparticles [58].

When iron is oxidized, a transition layer with the lattice of magnetite enriched with oxygen by the effect of the vacant sites contained in the iron arises in the interface between magnetite (Fe304) and hematite (α-Fe203). The quantity of vacant sites in one unit cell changes. When it increases, a defect lattice determining interconversions of magnetite to γ-Fe203 and then to α-Fe203 forms. A decrease in the number of vacant sites, i.e., their occupation by iron ions, makes this phase similar to magnetite in composition. Because of this, taking into account the similar structures of the lattices of Fe304 and γ-Fe203, a small change takes place in the relationships between the iron cations and the oxygen anions, between magnetite and hematite, and a number of metastable solid solutions distinguished by lattice constants and degree of oxidation.

REFERENCES

Rozovskii, A.Ya., Kinetika topokhimicheskikh reaktsii (Kinetic of Topochemical Reactions), Moscow: Khimiya, 1974.

Gopalakrishnan, J., Chem. Mater., 1995, vol. 7, no. 7, pp. 1265–1275.

Hayward, M.A., Semicond. Sci. Technol., 2014, vol. 29, p. 064010. https://doi.org/10.1088/0268-1242/29/6/064010

Testa-Anta, M., Rodríguez-González, B., and Salgueiriño, V., Part. Part. Syst. Charact., 2019, vol. 36, no. 11, p. 1900283. https://doi.org/10.1002/ppsc.201900283

Prodan, E.A., Pavlyuchenko, M.M., and Prodan, S.L., Zakonomernosti topokhimicheskikh reaktsii (Regularities of Topochemical Reactions), Minsk: Nauka i Tekhnika, 1976.

Kotenev, V.A. and Vysotskii, V.V., Prot. Met. Phys. Chem. Surf., 2019, vol. 55, pp. 880–887.

Revina, A.A., Suvorova, O.V., Pavlov, Yu.S., et al., Prot. Met. Phys. Chem. Surf., 2019, vol. 55, pp. 888–894.

Hsu, L.C., Yu, H.C., Chang, T.H., and Li, Y.Y., ACS Appl. Mater. Interfaces, 2011, vol. 3, p. 3084.

Petrunin, M.A., Maksaeva, L.B., Yurasova, T.A., et al., Prot. Met. Phys. Chem. Surf., 2015, vol. 51, pp. 1010–1017.

Srivastava, M., Ojha, A.K., Chaubey, S., Singh, J., Sharma, P.K., and Pandey, A.C., J. Alloys Compd., 2010, vol. 500, p. 206.

Lee, J.-H., Sens. Actuators, B, 2009, vol. 140, pp. 319–336.

Aslamazova, T.R., Vysotskii, V.V., Zolotarevskii, V.I., et al., Prot. Met. Phys. Chem. Surf., 2019, vol. 55, pp. 1091–1096.

Otero-Lorenzo, R., Ramos-Docampo, M.A., Rodriguez-Gonzalez, B., Comesana-Hermo, M., and Salgueirino, V., Chem. Mater., 2017, vol. 29, p. 8729.

Qiao, L., Fu, Z., Ghosen, J., Zeng, M., Stebbins, J., Prasad, P.N., and Swihart, M.T., ACS Nano, 2017, vol. 11, no. 2017, p. 6370.

Gilbert, G., Huang, F., Zhang, H., Waychunas, G.A., and Banfield, J.F., Science, 2004, vol. 305, p. 651.

Li, Z.A., Fontaina-Troitino, F., Kovács, A., et al., Sci. Rep., 2015, vol. 5, p. 7997.

Pratt, A., Lari, L., Hovorka, O., et al., Nat. Mater., 2014, vol. 13, p. 26.

Pichon, B.P., Gerber, O., Lefevre, C., et al., Chem. Mater., 2011, vol. 23, p. 2886.

Gilbert, D.A., Olamit, J., Dumas, R.K., et al., Nat. Commun., 2016, vol. 7, p. 11050.

Maier, J., Chem. Mater., 2014, vol. 26, p. 348.

Jansons, A.W., Plummer, L.K., and Hutchison, J.E., Chem. Mater., 2017, vol. 29, p. 5415.

Kotenev, V.A., Kiselev, M.R., Vysotskii, V.V., Averin, A.A., and Tsivadze, A.Yu., Prot. Met. Phys. Chem. Surf., 2016, vol. 52, no. 5, pp. 825–831.

Golgoon, A., Aliofkhazrae, M., and Toorani, M., Prot. Met. Phys. Chem. Surf., 2018, vol. 54, pp.192–221.

Raynaud, G. and Rapp, R., Oxid. Met., 1984, vol. 21, p. 89.

Fu, Y., Chen, J., and Zhang, J., Chem. Phys. Lett., 2001, vol. 350, p. 491.

Kotenev, V.A., Kiselev, M.R., Zolotarevskii, V.I., and Tsivadze, A.Yu., Prot. Met. Phys. Chem. Surf., 2014, vol. 50, no. 4, pp. 488–492.

Raman Spectroscopy for Nanomaterials Characterization, Kumar, Challa S.S.R., Ed., Berlin, Heidelberg: Springer, 2012, p. 379.

Jubb, A.M. and Allen, H.C., ACS Appl. Mater. Interfaces, 2010, vol. 2, no. 10, pp. 2804–2812. https://doi.org/10.1021/am1004943

Cornell, R.M. and Schwertmann, U., The Iron Oxides. Structure, Properties, Reactions, Occurrences and Uses, Weinheim: Wiley-VCH, 2003.

Bersani, D., Lotticil, P.P., and Montenero, A., J. Raman Spectrosc., 1999, vol. 30, pp. 355–360.

de Faria, D.L.A., Venancio, S.S., and De Oliveira, M.T., J. Raman Spectrosc., 1997, vol. 28, pp. 873–878.

Xu, Y.Y., Zhao, D., Zhang, X.J., Jin, W.T., Kashkarov, P., and Zhang, H., Phys. E (Amsterdam, Neth.), 2009, vol. 41, p. 806.

McCarty, K.F., Solid State Commun.,1988, vol. 68, p. 799.

Wang, C.M., Baer, D.R., Amonette, J.E., Engelhard, M.H., Antony, J., and Qiang, Y., J. Am. Chem. Soc., 2009, vol. 131, pp. 8824–8832. https://doi.org/10.1021/ja900353f

Zhorin, V.A., Kiselev, M.R., and Kotenev, V.A., Prot. Met. Phys. Chem. Surf., 2020, vol. 56, no. 4.

Stoia, M., Istratie, R., and Pacurariu, C., J. Therm. Anal. Calorim., 2016, vol. 125, no. 3, pp. 1185–1198. https://doi.org/10.1007/s10973-016-5393-y

Khan, U.S., Amanullah, Manan, A., Khan, N., Mahmood, A., and Rahim, A., Mater. Sci.-Pol., 2015, vol. 3, pp. 278–285.

Mürbe, J., Rechtenbach, A., and Töpfer, J., Mater. Chem. Phys., 2008, vol. 110, nos. 2–3, pp. 426–433.

Kotenev, V.A., Prot. Met. Phys. Chem. Surf., 2018, vol. 54, pp. 969–975.

Hsu, L.C., Yu, H.C., Chang, T.H., and Li, Y.Y., ACS Appl. Mater. Interfaces, 2011, vol. 3, p. 3084.

L’Oxydation des Metaux, Bénard, J., Ed., Paris: Gauthier-Villars, 1962, vol. 2.

Sewell, P.B. and Cohen, M., J. Electrochem. Soc., 1964, vol. 111, p. 508.

Ramasubramainan, N., Sewell, P.B., and Cohen, M., J. Electrochem. Soc., 1968, vol. 115, no. 1, p. 12.

Kotenev, V.A., Sokolova, N.P., Gorbunov, A.M., and Tsivadze, A.Yu., Prot. Met. Phys. Chem. Surf., 2007, vol. 43, no. 6, pp. 567–571.

Yu, H.C., Hsu, L.C., Chang, T.H., and Li, Y.Y., Dalton Trans., 2012, vol. 41, pp. 723–726.

Zhao, Y.M., Li, Y.H., Ma, R.Z., Roe, M.J., McCartney, D.G., and Zhu, Y.Q., Small, 2006, vol. 2, no. 3, pp. 422–427.

de Faria, D.L.A. and Lopes, F.N., Vib. Spectrosc., 2007, vol. 45, p. 117.

Chernyshova, I.V., Hochella, M.F., and Madden, A.S., Phys. Chem. Chem. Phys., 2007, vol. 9, p. 1736.

Adu, K.W., Xiong, Q., Gutierrez, H.R., Chen, G., and Eklund, P.C., Appl. Phys. A: Mater. Sci. Process., 2006, vol. 85, pp. 287–297.

Kotenev, V.A., Kiselev, M.R., Vysotskii, V.V., Ave-rin, A.A., and Tsivadze, A.Yu., Prot. Met. Phys. Chem. Surf., 2016, vol. 52, no. 5, pp. 825–831.

Tohmyoh, H. and Watanabe, A., J. Phys. Soc. Jpn., 2013, vol. 82, p. 044804.

Zhorin, V.A., Kiselev, M.R. and Kotenev, V.A., Prot. Met. Phys. Chem. Surf., 2019, vol. 55, pp. 460–467.

Kotenev, V.A., Petrunin, M.A., Maksaeva, L.B., et al., Prot. Met. Phys. Chem. Surf., 2013, vol. 49, pp. 479–484.

Bardyshev, I.I., Gol’danskii, A.V., Kotenev, V.A., et al., Prot. Met. Phys. Chem. Surf., 2018, vol. 54, pp. 648–651.

Kotenev, V.A., Zhorin, V.A., Kiselev, M.R., Vysotskii, V.V., Averin, A.A., Roldugin, V.I., and Tsivadze, A.Yu., Prot. Met. Phys. Chem. Surf., 2014, vol. 50, no. 6, pp. 792–796.

Herring, C., J. Appl. Phys., 1950, vol. 21, p. 437.

Korhonen, M.A., Borgesen, P., Tu, K.N., and Li, C.-Y., J. Appl. Phys., 1993, vol. 73, p. 3790.

Gräfe, W.A., Prot. Met. Phys. Chem. Surf., 2019, vol. 55, pp. 872–879.

Martin, T., Merlin, R., Huffman, D., and Cardona, M., Solid State Commun., 1977, vol. 22, pp. 565–567.

Velde, B. and Couty, R., J. Non-Cryst. Solids, 1987, vol. 94, pp. 238–250.

Hanesch, M., Int. J. Geophys., 2009, vol. 177, pp. 941–948.

ACKNOWLEDGMENTS

The author thanks A.A. Averin, V.V. Vysotsky and M.R. Kiselev for assistance.

Funding

This work was supported by a state order to the Institute of Physical Chemistry and Electrochemistry of the Russian Academy of Sciences on the theme “Physicochemistry of Functional Materials on the Basis of Architectural Ensembles of Metal–Oxide Particles, Multilayer Nanoparticles, and Film-Type Nanocomposite Materials.” Registration no. AAAA-A19-119031490082-6.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by G. Levina

Rights and permissions

About this article

Cite this article

Kotenev, V.A. Raman Spectroscopy of Iron-Oxide Core-Corona Nanoparticles: Effect of Synthesis Temperature. Prot Met Phys Chem Surf 56, 1159–1167 (2020). https://doi.org/10.1134/S2070205120060167

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S2070205120060167