Abstract

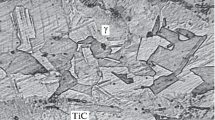

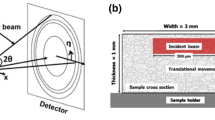

The effect of liquid carburizing at a temperature of 780°C on the micromechanical characteristics of the corrosion-resistant chromium–nickel austenitic steel (in wt %: Cr, 16.80; Ni, 8.44) has been studied in this work. According to instrumented microindentation data, it has been established that carburizing leads to the superficial hardening of the studied steel. An average increase in the indentation hardness HIT is nearly 500%. It has been demonstrated that carburizing also leads to an increase in the contact elasticity modulus of the steel E* that grew by 28% on average compared to E* in the quenched state. The carburized steel surface is characterized by an increased resistance to elastoplastic strain as evidenced by an increase in the parameters Re by 1.3–3.5 times, HIT/E* by 2.4–3.5 times, and \({{H_{{{\text{IT}}}}^{3}} \mathord{\left/ {\vphantom {{H_{{{\text{IT}}}}^{3}} {{{E}^{{*2}}}}}} \right. \kern-0em} {{{E}^{{*2}}}}}\) by 49–109 times. On the contrary, the plasticity index δA decreases by 20% on average from 0.92–0.93 to 0.70–0.74 after carburizing. It has been shown that the instrumented indentation of the steel in the quenched state and after carburizing at different maximum indentor loads provides the possibility to perform a more precise analysis of the micromechanical characteristics of the gradient layer formed by means of carburizing by comparing them with the characteristics of the quenched steel. Based on the results of indentation at different maximum indentor loads, the gradient of properties in the thin carburized layer of up to 4 µm in depth has also been established.

Similar content being viewed by others

REFERENCES

Surface Hardening of Steels: Understanding the Basics, Ed. by J. R. Davis (ASM International, 2002), p. 364.

R. A. Savrai, P. A. Skorynina, A. V. Makarov, and A. L. Osintseva, “Structure and surface properties of metastable austenitic steel subjected to liquid carburizing at a reduced temperature,” Phys. Met. Metallogr. 121, No. 1, 65–71 (2020).

A. V. Makarov, R. A. Savrai, E. S. Gorkunov, A. S. Yurovskikh, I. Yu. Malygina, and N. A. Davydova, “Structure, mechanical characteristics, and deformation and fracture features of quenched structural steel under static and cyclic loading after combined strain-heat nanostructuring treatment,” Phys. Mesomech. 18, 43–57 (2014).

A. V. Makarov, S. N. Luchko, V. A. Shabashov, E. G. Volkova, A. L. Osintseva, A. E. Zamatovskii, A. V. Litvinov, and V. V. Sagaradze, “Structural and phase transformations and micromechanical properties of the high-nitrogen austenitic steel deformed by shear under pressure,” Phys. Met. Metallogr. 118, No. 1, 52–64 (2017).

R. A. Savrai, A. V. Makarov, I. Yu. Malygina, S. A. Rogovaya, and A. L. Osintseva, “Improving the strength of the AISI 321 austenitic stainless steel by frictional treatment [Digital resource],” Diagnostics, Resource and Mechanics of Materials and Structures, issue 5, 43–62 (2017). URL: http://dream-journal.org/issues/2017-5/2017-5_149.html

R. A. Savrai, A. V. Makarov, I. Yu. Malygina, and E. G. Volkova, “Effect of nanostructuring frictional treatment on the properties of high-carbon pearlitic steel. Part I: microstructure and surface properties,” Mater. Sci. Eng., A 734, 506–512 (2018).

A. V. Makarov, P. A. Skorynina, E. G. Volkova, and A. L. Osintseva, “Effect of friction treatment on the structure, micromechanical and tribological properties of austenitic steel 03Kh16N14M3T,” Met. Sci. Heat Treat., Nos. 11–12, 764–768 (2020).

J. Qu, P. J. Blau, L. Zhang, and H. Xu, “Effects of multiple treatments of low-temperature colossal supersaturation on tribological characteristics of austenitic stainless steels,” Wear 265, 1909–1913 (2008).

M. C. S. Duarte, C. Godoya, and J. C. A. B. Wilson, “Analysis of sliding wear tests of plasma processed AISI 316L steel,” Surf. Coat. Technol. 260, 316–325 (2014).

Y. Jiang, Y. Li, Y. F. Jia, X. C. Zhang, and J. M. Gong, “Gradient elastic-plastic properties of expanded austenite layer in 316L stainless steel,” Acta Metall. Sin. 31, No. 8, 831–841 (2018).

A. V. Makarov, N. A. Pozdejeva, R. A. Savrai, I. Yu. Malygina, and A. S. Yurovskikh, “Improvement of wear resistance of quenched structural steel by nanostructuring frictional treatment,” J. Frict. Wear 33, No. 6, 433–442 (2012).

V. P. Kuznetsov, A. V. Makarov, S. G. Psakhie, R. A. Savrai, I. Y. Malygina, and N. A. Davydova, “Tribological aspects in nanostructuring burnishing of structural steels,” Phys. Mesomech. 17, No. 4, 250–264 (2014).

A. V. Makarov, N. N. Soboleva, R. A. Savrai, and I. Yu. Malygina, “Improving the micromechanical properties and wear resistance of chromium-nickel laser coating by finishing friction treatment,” Vector Nauki TGU, No. 4, 60–67 (2015).

N. B. Pugacheva, E. B. Trushina, and T. M. Bykova, “Research on the tribological properties of iron borides as diffusion coatings,” J. Frict. Wear 35, No. 6, 489–496 (2014).

R. A. Savrai and A. V. Makarov, “Effect of nanostructuring frictional treatment on the properties of high-carbon pearlitic steel. Part II: mechanical properties,” Mater. Sci. Eng., A 734, 513–518 (2018).

R. A. Savrai, A. V. Makarov, N. N. Soboleva, I. Yu. Malygina, and A. L. Osintseva, “The behavior of gas powder laser clad NiCrBSi coatings under contact loading,” J. Mater. Engineer. Perform. 25, No. 3, 1068–1075 (2016).

R. A. Savrai, “Resistance of laser-clad chromium–nickel coatings to failure under contact fatigue loading,” Phys. Met. Metallogr. 119, No. 10, 1013–1021 (2018).

R. A. Savrai, N. N. Soboleva, I. Yu. Malygina, and A. L. Osintseva, “The structural characteristics and contact loading behavior of gas powder laser clad CoNiCrW coating,” Opt. Laser Technol. 126, 106079, 1–8 (2020).

A. Yonezu, R. Kusano, T. Hiyoshi, and X. Chen, “A method to estimate residual stress in austenitic stainless steel using a microindentation test,” J. Mater. Eng. Perform. 24, 362–372 (2015).

GOST R 8.748-2011 (ISO 14577-1:2002) State system for ensuring the uniformity of measurements (GSI). Metals and alloys. Measurement of hardness and other characteristics of materials during instrumental indentation. Part 1. Method of testing.

Y. T. Cheng and C. M. Cheng, “Relationships between hardness, elastic modulus and the work of indentation,” Appl. Phys. Lett. 73, No. 5, 614–618 (1998).

T. F. Page and S. V. Hainsworth, “Using nanoindentation techniques for the characterization of coated systems: a critique,” Surf. Coat. Technol. 61, Nos. 1–3, 201–208 (1993).

M. I. Petrzhik and E. A. Levashov, “Modern methods for investigating functional surfaces of advanced materials by mechanical contact testing,” Crystallogr. Rep. 52, No. 6, 966–974 (2007).

P. H. Mayrhofer, C. Mitterer, and J. Musil, “Structure-property relationships in single- and dual-phase nanocrystalline hard coatings,” Surf. Coat. Technol. 174–175, 725–731 (2003).

Yu. V. Mil’man, S. I. Chugunova, and I. V. Goncharova, “Characteristic of plasticity determined by indentation,” Vopr. At. Nauki Tekh., No. 4, 182–187 (2011).

A. O. Zhigachev, Yu. I. Golovin, A. V. Umrikhin, A. V. Korenkov, A. I. Tyurin, V. V. Rodaev, and T. A. D’yachek, Ceramic Materials Based on Zirconium Dioxide, Ed. by Yu.I. Golovin (Tekhnosfer, Moscow, 2018), p. 358 [in Russian].

J. A. Benito, J. Jorba, J. M. Manero, and A. Roca, “Change of Young’s modulus of cold-deformed pure iron in a tensile test,” Metall. Mater. Trans. A 36, No. 12, 3317–3324 (2005).

A. V. Makarov, R. A. Savrai, V. M. Schastlivtsev, T. I. Tabatchikova, I. L. Yakovleva, and L. Yu. Egorova, “Structural features of the behavior of a high-carbon pearlitic steel upon cyclic loading,” Phys. Met. Metallogr. 111, No. 1, 95–109 (2011).

D. McLean, Mechanical Properties of Metals (Wiley, New York, 1965).

V. G. Gavrilyuk, Distribution of Carbon in Steel (Naukova dumka, Kiev, 1987) [in Russian].

ACKNOWLEDGMENTS

Scanning electron microscopy and instrumented microindentation were carried out in the Shared Facilities Center “Plastometry” of the Institute of Engineering Science of the Ural Branch of the Russian Academy of Sciences.

Funding

This work was performed within the state tasks for the Institute of Engineering Science of the Ural Branch of the Russian Academy of Sciences (project no. AAAA-A18-118020790148-1) and the Mikheev Institute of Metal Physics of the Ural Branch of the Russian Academy of Sciences (project no. AAAA-A18-118020190116-6) as part of the studied materials and methods of their treatment and within the complex program of the Ural Branch of the Russian Academy of Sciences (project no. 18-10-1-40) as part of the method of studying the micromechanical characteristics of modified surface layers.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by E. Glushachenkova

Rights and permissions

About this article

Cite this article

Savrai, R.A., Skorynina, P.A., Makarov, A.V. et al. Effect of Liquid Carburizing at Lowered Temperature on the Micromechanical Characteristics of Metastable Austenitic Steel. Phys. Metals Metallogr. 121, 1015–1020 (2020). https://doi.org/10.1134/S0031918X20100105

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X20100105