Abstract

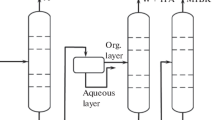

Optimization criteria are proposed for processes of separating ethylene and propylene from a mixture of low-boiling gases. These criteria are based on the physicochemical properties of substances and take into account special techniques used for separating such mixtures. Unlike the existing criteria based on considering the heat input to the reboiler and the heat output from the condenser of a distillation column, these optimality criteria more accurately evaluate the economic performance of the process, because they include the refrigerant preparation cost, which plays a decisive role in separating low-boiling gases. Four known methods of separating mixtures of low-boiling gases are considered: (A) separation in a column with steam as the heat-transfer medium in the column reboiler and with a refrigerant in the condenser, (B) separation in a column with the condensation of the vapor of a refrigerant in the column reboiler and with the same refrigerant in the condenser, (C) separation in a column with the condensation of the vapor of the ith refrigerant in the column reboiler and with the jth refrigerant in the condenser, and (D) separation in a column with steam as a heat-transfer medium in the column reboiler and with recirculating water in the condenser. Parameters that are expediently used as optimality criteria are identified. New approaches to creating the optimal processes of separating low-boiling gases are developed and theoretically justified for further implementation.

Similar content being viewed by others

REFERENCES

L’vov, S.V., On the distillation of multicomponent mixtures, Khim. Prom-st., 1947, no. 6, p. 15.

Westerberg, A.W., A retrospective on design and process synthesis, Comput. Chem. Eng., 2004, vol. 28, no. 4, pp. 447–458. https://doi.org/10.1016/j.compchemeng.2003.09.029

Nishida, N., Stephanopoulos, G., and Westerberg, A.W., A review of process synthesis, AIChE J., 1981, vol. 27, no. 3, pp. 321–351. https://doi.org/10.1002/aic.690270302

Rod, V. and Marek, J., Separation sequences in multicomponent rectification, Collect. Czech. Chem. Commun., 1959, vol. 24, p. 3240.

Nadgir, V.M. and Liu, Y.A., Studies in chemical process design and synthesis: Part V: A simple heuristic method for systematic synthesis of initial sequences for multicomponent separations, AIChE J., 1983, vol. 29, no. 6, pp. 926–934. https://doi.org/10.1002/aic.690290609

Beregovykh, V.V., Korabel’nikov, M.M., Ermak, N.V., Rudakovskaya, T.S., Serafimov, L.A., and L’vov, S.V., Specific features of the distillation of the benzene–toluene–ethylbenzene– α-methylstyrene four-component system, Prom-st. Sint. Kauch., 1977, no. 5, p. 4.

Petlyuk, F.B. and Isaev, B.A., Computational study of various process flow diagrams of installations for gas fractionation, Neftepererab. Neftekhim. (Moscow, Russ. Fed.), 1978, no. 1, p. 22.

Abdel’-Aal, Kh.K., Study of technological innovations for ethylene production plants, Neftegazov. Tekhnol. Anal., October 2017, p. 49.

Kuzina, O.D., Development of energy-saving process flow diagrams for the distillation of multicomponent zeotropic mixtures of organic products, Cand. Sci. (Eng.) Dissertation, Moscow: Lomonosov Moscow State Academy of Fine Chemical Technology, 2000.

Golovanov, M.L., Vostoplyatova, S.A., and Timoshenko, A.V., The possibility of reducing energy expenditure on gas fractionation in petroleum processing plants, Khim. Prom-st. Segodnya, 2007, no. 6, p. 49.

Kocharyan, S.O., Rudakov, D.G., and Timoshenko, A.V., Dependence of the energy efficiency of a complex column on the feed composition in the separation of pyrolysis products, Tonkie Khim. Tekhnol., 2017, vol. 12, no. 3, p. 33.

Aleksandrov, I.A., Serafimov, L.A., Petlyuk, F.B., and Groisman, S.A., On the choice of the region of optimal parameters for precision fractional distillation of close-boiling mixtures of hydrocarbons, Izv. Vyssh. Uchebn. Zaved., 1975, no. 6, p. 45.

Szabó, L., Németh, S., and Szeifert, F., Separation of multicomponent mixtures, Hung. J. Ind. Chem., 2011, vol. 39, no. 2, pp. 295–300.

Churilin, A.S., Frolkova, A.K., and Zelentsova, N.I., Decreasing the energy consumption of production by using an open refrigeration cycle, Khim. Prom-st. Segodnya, 2011, no. 12, p. 42.

Ul’ev, L.M., Zebeshev, T.Z., Ryabova, I.B., Vasil’ev, M.A., and Maatouk, A., Integration of a heat pump into the separation of light hydrocarbons, Nauchn. Tr. Odess. Nats. Akad. Pishch. Tekhnol., 2016, vol. 80, no. 1, p. 8.

Alcántara-Avila, J.R., Gómez-Castro, F.I., Segovia-Hernández, J.G., Sotowa, K.-I., and Horikawa, T., Optimal design of cryogenic distillation columns with side heat pumps for the propylene/propane separation, Chem. Eng. Process., 2014, vol. 82, pp. 112–122. https://doi.org/10.1016/j.cep.2014.06.006

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by V. Glyanchenko

Rights and permissions

About this article

Cite this article

Absattarov, A.I., Pisarenko, Y.A. & Semenov, I.P. Developing Optimization Criteria for Processes of Separating Low-Boiling Gases. Theor Found Chem Eng 54, 1111–1119 (2020). https://doi.org/10.1134/S0040579520050024

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0040579520050024