Abstract

Bioremediation systems represent an environmentally sustainable approach to degrading industrially generated thiocyanate (SCN−), with low energy demand and operational costs and high efficiency and substrate specificity. However, heavy metals present in mine tailings effluent may hamper process efficiency by poisoning thiocyanate-degrading microbial consortia. Here, we experimentally tested the tolerance of an autotrophic SCN−-degrading bacterial consortium enriched from gold mine tailings for Zn, Cu, Ni, Cr, and As. All of the selected metals inhibited SCN− biodegradation to different extents, depending on concentration. At pH of 7.8 and 30 °C, complete inhibition of SCN− biodegradation by Zn, Cu, Ni, and Cr occurred at 20, 5, 10, and 6 mg L−1, respectively. Lower concentrations of these metals decreased the rate of SCN− biodegradation, with relatively long lag times. Interestingly, the microbial consortium tolerated As even at 500 mg L−1, although both the rate and extent of SCN− biodegradation were affected. Potentially, the observed As tolerance could be explained by the origin of our microbial consortium in tailings derived from As-enriched gold ore (arsenopyrite). This study highlights the importance of considering metal co-contamination in bioreactor design and operation for SCN− bioremediation at mine sites.

Key points

• Both the efficiency and rate of SCN− biodegradation were inhibited by heavy metals, to different degrees depending on type and concentration of metal.

• The autotrophic microbial consortium was capable of tolerating high concentrations of As, potential having adapted to higher As levels derived from the tailings source.

Similar content being viewed by others

Introduction

For higher organisms, thiocyanate (SCN−) is a known goitrogen, i.e., a chemical with deleterious anti-thyroid effects with prolonged exposure (Ermans and Bourdoux 1989); acute SCN− poisoning can also occur (Gould et al. 2012). The toxicity of this compound occurs at blood serum concentrations greater than 1 mg per 100 mL (Lage et al. 1994). Both chronic and acute toxicity of SCN− to aquatic organisms, including Daphnia magna (Parkhurst et al. 1979) and various fish species (Bhunia et al. 2000; Kevan and Dixon 1991; Lanno and Dixon 1996), has also been demonstrated.

Gold processing commonly involves mixing finely ground ores with the lixiviant sodium cyanide (Woffenden et al. 2008). Gold-bearing ores also naturally contain sulfide minerals that release reduced sulfur species during ore processing, which react with cyanide (CN−) to generate SCN− (Mudder et al. 2001). This process can elevate SCN− concentrations to higher than 1000 mg L−1 in tailings wastewaters (Given and Meyer 1998). Finely ground and chemically processed ore materials and associated wastewaters are typically stored in tailings storage facilities (TSFs) intended to limit the environmental impact and facilitate water reuse by mining companies (ERR 2007). However, tailings water seepage from TSFs can potentially contaminate the underlying groundwater with pollutants such as SCN− that exist in tailings (Kossoff et al. 2014) and sometimes results in elevated concentrations of these contaminants in groundwater near mine sites (Bakatula et al. 2012).

Although SCN− is almost seven times less toxic than CN− (Woffenden et al. 2008; Kuyucak and Akcil 2013), the greater chemical stability of SCN− compared to its parent compound (Akcil 2003) leads to its accumulation in mining waste streams (Woffenden et al. 2008), as well as its environmental persistence (Mediavilla et al. 2019). Therefore, although not explicitly addressed in regulatory guidelines for discharge of CN−-bearing mine effluents, SCN− is still considered by regulatory agencies to be a threat to aquatic wildlife (Bhunia et al. 2000; Gould et al. 2012).

Comprehensive reviews have summarized current chemical and biological treatment methods for either CN− degradation (Gould et al. 2012) or concomitant degradation of CN− and SCN− (Akcil 2003; Botz et al. 2016; Mudder et al. 2001). Compared to physical or chemical approaches, bioremediation systems are considered to be more environmentally friendly, efficient (Akcil 2003), cost-effective (Akcil and Mudder 2003; Nelson et al. 1998), and substrate specific (Das and Dash 2014). Accordingly, they constitute a preferred treatment approach in the mining industry, especially when cleaner effluents are targeted (Akcil 2003). Pilot scale bioreactors such as trickling filter (Evangelho et al. 2001) and biofilm reactors (Watts and Moreau 2018) and commercialized systems like ASTER™ technology (van Buuren et al. 2011; Huddy et al. 2015) are examples of bioremediation systems that have been used for thiocyanate degradation.

In bioremediation systems for SCN−, growth of specific microorganisms is promoted (Watts and Moreau 2018), particularly bacteria that can utilize SCN− as a source of electrons. These sulfur oxidizing autotrophs encode SCN− hydrolase (SCNase) and were revealed as strains of Thiobacillus. Non-SCN−-degrading autotrophic and heterotrophic microorganisms also exist in SCN-degrading communities, and they rely only on nitrogen and/or sulfur obtained from SCN− as growth nutrients (Kantor et al. 2015, 2017; Watts et al. 2019; Wang et al. 2020). However, tailings effluents typically contain a range of contaminants, including cyanide, cyanate (CNO−), ammonia, nitrate, sulfate, chloride, and heavy metals (Given and Meyer 1998; Woffenden et al. 2008) that may inhibit the efficiency of SCN− biodegradation (Gould et al. 2012).

Like most other organisms, microorganisms are susceptible to high concentrations of heavy metals (Giller et al. 1998; Mattila et al. 2007). The effects of heavy metals on biodegradation of environmental pollutants have been studied, mostly for separate hydrocarbons (Ma et al. 2018), mixtures of hydrocarbons (Amatya et al. 2006), diesel oil (Sprocati et al. 2012), polychlorinated biphenyls (PCBs), perchloroethene (PCE) (Lu et al. 2020), and phenanthrene (Wong et al. 2005). The effects of operational conditions such as pH, temperature, loading, phosphate amendment, and light, on SCN− biodegradation, have also been investigated (Kantor et al. 2015, 2017; Lay-Son and Drakides 2008; van Zyl et al. 2017; Watts et al. 2017a, 2019). Furthermore, the inhibitory effect of NH4+, another co-contaminant from gold cyanidation (Given and Meyer 1998), on SCN− biodegradation has been studied for pure cultures and microbial consortia in shake flask experiments and laboratory-scale activated sludge bioreactors (Lay-Son and Drakides 2008). However, a lack of knowledge exists on the effects of toxic heavy metals on microorganisms actively degrading SCN−.

The present study aimed to evaluate the heavy metal tolerance of a previously characterized autotrophic SCN−-degrading consortium enriched from surface tailings of a gold mine in Western Victoria, Australia (Watts et al. 2017b). Here, we hypothesized that heavy metals at varying concentrations, associated with tailings effluent, would differentially inhibit the performance of this SCN−-biodegrading consortium in shake flask experiments.

Materials and methods

Consortium growth conditions

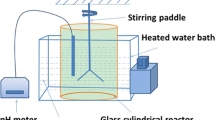

A previously characterized natural autotrophic SCN−-degrading consortium (Watts et al. 2017a, b, 2019) was used for this study. Prior to the start of experiments, at least five transfers were performed aseptically with 10% (v/v) of early stationary phase culture to a 500 mL Erlenmeyer flask containing 180 mL of fresh medium. All cultures were incubated at 30 °C and 120 rpm continuous rotation. The medium (1 L) was comprised of Na2SO4 (2.25 g), NaHCO3 (0.25 g), MgSO4 (0.51 g), CaCl2·2H2O (1.25 g), KCl (0.1 g), NaCl (1.5 g), Na2HPO4·7H2O (0.05 g), KSCN (1 g), and 4-(2-hydroxyethyl)-1-piperazineethanesulfonic acid (HEPES) (3.5 g) in ultrapure water (Milli-Q®). Micronutrients were supplied through addition of 0.05% (v/v) of Mineral Elixir solution to the medium. The composition of this solution per liter was nitrilotriacetic acid (NTA; free acid non-trisodium salt, 2.14 g), MnCl2·4H2O (0.1 g), FeSO4·7H2O (0.3 g), CoCl2·6H2O (0.17 g), ZnSO4·7H2O (0.2 g), CuCl2·2H2O (0.03 g), AlK(SO4)2·12H2O (0.005 g), H3BO3 (0.005 g), Na2MoO4·2H2O (0.09 g), NiSO4·6H2O (0.11 g), and Na2WO4·2H2O (0.02 g). After pH adjustment at 7.5 ± 0.02 using 1 N NaOH and 1 N HCl, the medium was autoclaved at 121 °C for 15 min.

Inoculum preparation

For all experiments, a 36-h culture was centrifuged (Eppendorf Centrifuge 5810) at 5000 rcf for 10 min at room temperature. Cells were washed twice with a half volume of sterile saline solution (pH 7.0 ± 0.6), and pellets were resuspended in fresh medium before inoculation. Optical density at 600 nm wavelength (OD600) was measured to monitor cell growth.

Metal solutions

Stock solutions of zinc (as ZnII), copper (as CuII), chromium (as CrVI), nickel (as NiII), and arsenic (as AsV) were prepared immediately before use by dissolving ZnCl2, CuCl2·2H2O, K2CrO4, NiCl2·6H2O, and Na2HAsO4·7H2O in ultrapure water (Milli-Q®), respectively. Stock solutions were further diluted and filtered via 0.22 μm syringe filters (Millex® Express PES Membrane). These metals and their concentrations were selected based on previous studies of soils, tailings, and effluent at an operating Victorian gold mine (Ebbs et al. 2010; Fashola et al. 2016; Noble et al. 2010; proprietary data from the mine), published metal tolerance experiments with various microorganisms (Alexandrino et al. 2011; Chiboub et al. 2016; Ma et al. 2019; Takeuchi et al. 2007), and an aim to find metal tolerance limits for our experimental consortium. Background Ni, Zn, and Cu concentrations derived from medium reagents were all < 1 mg L−1 (data not shown); As and Cr levels were below detection limits.

Metal tolerance experiment

Prior to each experiment, all glassware was soaked in nitric acid (2.5% for 24 h) and rinsed with ultrapure water to remove any trace metals. Four concentrations were used for each heavy metal: 10, 20, 40, and 60 mg L−1 for Zn2+; 0.5, 1.5, 2.5, and 5 mg L−1 for Cu2+; 5, 7.5, 10, and 15 mg L−1 for Ni2+; 1.5, 3, 6, and 30 mg L−1 for Cr6+; and 10, 30, 300, and 500 mg L−1 for As5+. For each metal, 5% (v/v) pre-prepared metal solution was added to 250 mL of sterile culture medium. Filtered ultrapure water (no metals) was used for metal-free (i.e., positive) controls. All flasks were inoculated with 10% (v/v) of cell suspension. For negative controls, the inoculum was replaced with the same volume of cell-free culture medium. Furthermore, killed-cell controls were used for metal-free trials to ensure that the observed SCN− degradation is a result of cell metabolism. Cu experiments, however, included killed-cell controls for all metal amendment concentrations as well. These extra controls were used to investigate whether the drop in dissolved Cu throughout the experiments was due to cell adsorption or metabolic activity. To prepare killed-cell controls, washed cells were resuspended in fresh culture medium followed by autoclaving. All cultures were incubated in triplicate simultaneously for one type of metal at a time. Statistical analyses were performed using Minitab® 18.1 (Minitab 18 Statistical Software 2017).

Initial and final experimental SCN− concentrations (mg L−1) were used in Eq. (1) to calculate SCN− biodegradation efficiency (%). Lag time was defined as hours with insignificant change to SCN− concentration, as determined by dependent t test (P ≤ 0.05). Equation (2) was used to calculate SCN− biodegradation rate. The duration of biodegradation was defined as either 5 days (i.e., time from beginning to end of the experiment) or the time until SCN− concentration remained constant.

Thiocyanate measurement

Shake flasks were sampled at regular intervals over the 5 days of incubation. For SCN− measurements, less than 0.8 mL of medium was centrifuged at 16,000 rcf for 10 min at room temperature to pellet cells. The supernatant was removed and stored at − 20 °C until quantification. A colorimetric method was adapted to determine SCN− concentration (Baird et al. 2017). For this analysis, each sample was diluted with ultrapure water, acidified using nitric acid, and mixed with ferric nitrate reagent (20:1 ratio). The absorbance of the mixture was then measured within 5 min at 460 nm wavelength.

Metal analyses

Sampling for dissolved metals was performed in the same way as SCN− analyses, except that the supernatant was stored at 4 °C prior to analysis. Furthermore, at sampling intervals, less than 2.5 mL of the medium was centrifuged at 5000 rcf for 10 min, and the pH of the supernatant was measured.

Sample aliquots of between 10 and 60 μl were diluted with 0.4 N double-distilled nitric acid solution containing 10 ppb Rh as an internal standard. Single element standards spiked with 10 ppb Rh were used for calibration. Sample dilution factors varied from 50 to 300, depending on the original analyte concentration. Sample solutions were then vortexed briefly, prior to analysis on an Agilent 7700x ICP-MS in collision cell mode using 3 ml per minute He as the carrier gas.

Geochemical modeling

Metal speciation under experimental conditions was calculated using PHREEQC (Parkhurst and Appelo 2013). A modified Minteq (version 4) database (US Environmental Protection Agency 1998) was used for all simulations, with pH 7.7 and a temperature of 30 °C as input parameters.

Results

Measured dissolved metal concentrations by ICP-MS

Dissolved Zn and Cu concentrations over time for Zn- and Cu-amended experiments are shown in Fig. S1. These metals were the only ones observed to change in concentration over time, e.g., dissolved Zn concentrations decreased significantly over the first 40 h of incubation. In Cu-amended experiments, aqueous Cu concentrations generally decreased in inoculated cultures over the 120-h incubation period, with the exception of an apparent increase from an initially lower-than-added value (by nearly half) for the highest Cu concentration (added as 5 mg L−1). All other metal amendments showed no significant changes over the incubation period for any initial concentration (Fig. S2).

pH monitoring

Previous studies have reported the effect of pH on metal toxicity to microorganisms (Moberly et al. 2010; Van Nostrand et al. 2005). Therefore, the pH of cultures was monitored across sampling timepoints. The initial addition of filtered heavy metal solutions to the culture medium did not change pH significantly neither was any difference observed between initial pH values for any experimental conditions. Average pH values were 7.75 ± 0.03 and 7.73 ± 0.06 for the start and end, respectively, of all experiments for all trials and controls.

Metal speciation calculations

Generally, increasing concentrations of metals in culture amendments produced increasing dissolved metal concentrations, as well as higher saturation indices (SI) with respect to respective mineral phases. PHREEQC modeling predicted that almost all Zn in the culture medium was present as dissolved sulfide species (Table S1), with positive or close to zero SI values with respect to sphalerite, wurtzite, and amorphous ZnS (Table S2). Likewise, with aqueous Cu(HS)3− as the predominant dissolved Cu species (Table S3), Cu was predicted to be near or at saturation with respect to copper sulfides (Table S4).

In metal-free experiments (i.e., positive controls), approximately 99.6% of Ni (from medium ingredients) was present as Ni(NTA)− (Table S5). The next most prevalent Ni species in these experiments were Ni(NTA)24−, Ni2+, and NiOH(NTA)2−, each accounting for only about 0.1% of total Ni. Total Ni at amendment concentrations of 5, 7.5, 10, and 15 mg L−1 was comprised of about 64%, 43%, 32%, and 22% Ni(NTA)− and about 24%, 38%, 45%, and 53% Ni2+, respectively. Relatively large positive SI values were calculated for nickel sulfide phases (Table S6), as well as for Ni-molybdate (at 7.5, 10, and 15 mg L−1 Ni) and Ni-phosphate (at 15 mg L−1 Ni).

Modeling of Cr-amended experiments predicted that most added Cr was present as chromate (Table S7). None of the predicted Cr phases showed negative or close to zero SI values (Table S8). Four arsenate species were predicted in As-amended experiments (Table S9), including HAsO42− as 94–95% of total As. Like Cr, As was largely undersaturated with respect to any phase (Table S10).

Heavy metal influences on SCN− biodegradation

The influence of heavy metals on SCN− biodegradation is summarized in Table 1 in terms of SCN− biodegradation efficiency (%), rate, and lag time for all inoculated experiments. None of the negative and killed-cell controls showed SCN− biodegradation.

Zinc

The effect of Zn additions on SCN− biodegradation is presented in Fig. 1. At Zn concentrations of 20, 40, and 60 g L−1, SCN− biodegradation was completely inhibited. At 10 mg L−1 Zn, SCN− was completely degraded within 4.5 days, after a lag period of roughly 48 h. Furthermore, a slower biodegradation rate (143.0 mg L−1 day−1) was observed for 10 mg L−1 Zn, compared to Zn-free cultures (377.1 mg L−1 day−1).

Copper

At 5 mg L−1 Cu, SCN− biodegradation was completely inhibited (Fig. 2). With 2.5 mg L−1 Cu, ~ 30% SCN− was degraded, with a ~ 85-h lag time. Complete SCN− biodegradation was observed at 1.5 and 0.5 mg L−1 Cu, with lag times of ~ 48 and ~ 32 h and biodegradation rates of 158.8 and 183.4 mg L−1 day−1, respectively.

Nickel

At 15 and 10 mg L−1, nickel completely inhibited SCN− biodegradation (Fig. 3). Only 6% degradation was observed at 7.5 mg L−1 Ni, with a ~ 56-h lag period. At 5 mg L−1 Ni, 23% of initial SCN− was degraded after a 48-h lag period.

Chromium

The effect of Cr amendment on SCN− biodegradation is presented in Fig. 4. At concentrations of 30 and 6 mg L−1 Cr, no SCN− was degraded. With 3 mg L−1 Cr, only 16% SCN− was degraded over the last 35 h of the experiment. Amending the culture medium with 1.5 mg L−1 Cr did not inhibit complete SCN− biodegradation; however, this concentration of Cr decreased the degradation rate to 160.6 mg L−1 day−1, compared to 319.4 mg L−1 day−1 in Cr-free cultures.

Arsenic

The experimental consortium seemed relatively more tolerant to arsenic even at higher concentrations of this metalloid. Figure 5 presents how SCN− biodegradation was affected by varying concentrations of As. Complete SCN− degradation was observed at As concentrations of 10 and 30 mg L−1 within 40 and 72 h of incubation, respectively. These concentrations of As influenced neither biodegradation extent nor lag time, compared to As-free experiments. A slightly faster biodegradation rate (392.1 mg L−1 day−1) was calculated for experiments with 10 mg L−1 As than for As-free trials (380.4 mg L−1 day−1), which probably resulted from a slightly higher SCN− concentration in As-amended flasks. Adding 30 mg L−1 As to the culture medium led to a biodegradation rate of 206.2 mg L−1 day−1. The SCN− biodegradation rate in cultures amended with a relatively high concentration of 300 mg L−1 As was 113.1 mg L−1 day−1. At this As concentration, 34% of SCN− was degraded over the first 48 h. The same pattern was observed for experiments amended with 500 mg L−1 As, with slightly lower biodegradation efficiency (31%) and rate (101.6 mg L−1 day−1).

Discussion

Each of the metal(loid)s tested here inhibited SCN− biodegradation to an extent and duration that depended on both type and concentration. Biodegradation of SCN− was fully inhibited at concentrations > 20, 5, 10, and 6 mg L−1 for Zn, Cu, Ni, and Cr, respectively, consistent with previous reports for metal toxicity to non-thiocyanate degrading microorganisms (Alexandrino et al. 2011). However, these values represent controlled laboratory experiments, and other experimental or environmental metal toxicity thresholds may differ, depending on geochemical conditions (Alexandrino et al. 2011; Cabrera et al. 2006; Sani et al. 2001; Utgikar et al. 2003). Furthermore, we note that our experiments used (autotrophically growing) planktonic cells, whereas protection afforded by microenvironments within biofilms typically growing inside (heterotrophic) activated sludge bioreactors (e.g., the ASTER™ system) (Huddy et al. 2015) may also have affected relative inhibition by metals.

Lag time for the onset of SCN− biodegradation was a useful measure for comparing metal toxicity effects. For example, while similar biodegradation rates were measured for 1.5 mg L−1 each of Cu and Cr, an eightfold longer lag phase was observed for Cr, indicative of greater toxicity to the SCN− degraders of this microbial consortium from hexavalent Cr. In contrast, these SCN− degraders seemed more tolerant to As, with regard to lag time, over the range of 10 to 500 mg L−1; none of the As concentrations tested in this study extended the lag time for SCN− biodegradation, compared to As-free trials.

The ordering of microbial metal tolerance in this study was As > Zn > Ni > Cu > Cr, in terms of the ability of the consortium to degrade SCN− at similar metal concentrations. The consortium that was used here is dominated by thiobacilli. However, only some strains of this genus that possess SCN− hydrolase are considered as SCN− degraders, while the other autotrophs such as non-SCN-degrading thiobacilli and heterotrophic microorganisms rely on the metabolic products of SCN degradation. The proportions of each group greatly depend upon the experimental conditions (Watts et al. 2017b, 2019). Overall, higher tolerance to Zn when compared with Cu was observed in studies using sulfate-reducing bacteria for either single strains (Poulson et al. 1997; Sani et al. 2001) or mixed cultures (Hao et al. 1994; Utgikar et al. 2001, 2003). Presumably, this observed difference in Zn and Cu toxicity reflected to some degree the relative solubilities of Zn and Cu sulfides, which our modeling predicted to be a factor controlling the speciation of these metals in our experiment with SCN− as well.

Lower threshold concentrations for toxicity were previously observed for Ni when compared with Zn under the same experimental conditions (Hao et al. 1994; Poulson et al. 1997), again potentially due to the tendency for Zn to form Zn sulfides over Ni in mixed metal solutions, as predicted by PHREEQC. Divalent Ni competes catabolically and allosterically with Zn and Fe and therefore interferes with metalloenzyme activities, as well as generates reactive oxygen (Macomber and Hausinger 2016). Therefore, the observed inhibition of SCN− biodegradation in Ni-amended experiments may be attributed to Ni2+ species that comprised a larger proportion of total Ni at higher amendment concentrations, as modeled.

Almost all added Cr in our experiments was predicted to be speciated as chromate, with known adverse effects on bacterial cells (Ramírez-Díaz et al. 2008). We can speculate therefore that the relatively low tolerance of this consortium to Cr is due to the lack or inefficiency of mechanisms required for microbial resistance to chromate (e.g., efflux systems and chromate reductases) (Ramírez-Díaz et al. 2008).

Interestingly, both Cu and Zn concentrations decreased to some degree at the start of incubation periods for inoculated cultures, except for the highest Cu amendment concentration (Fig. S1). Contrary to Zn, we hypothesize that Cu partially adsorbed to microbial cells during the course of our experiments. Alternatively, it is possible that Zn and Cu were incorporated into nanophase Zn and Cu sulfides, some of which aggregated to be removed by filtration before ICP-MS analysis. Zn concentrations decreased asymptotically to a limited extent of removal from solution, while Cu displayed a less systematic trend, decreasing faster than Zn to near complete removal from solution from ~ 40 h of incubation for all but the highest Cu concentration (5 mg L−1). In any case, we acknowledge that such processes as just described may have impacted on SCN− biodegradation efficiency by effectively reducing metal bioavailability and therefore also metal toxicity. Further work beyond the scope and aim of this study is needed to elucidate such levels of detail and test the above hypotheses. Utgikar et al. (2004) described microbial tolerance for Zn and Cu as a function of metal concentration and exposure time, and we add here the possibility of speciation-driven vital effects. The total concentrations of heavy metals were measured throughout the experiments as filtered (i.e., dissolved) metal concentrations, and for all the experiments, pH remained constant at 7.7–7.8. PHREEQC modeling predicted conditions exceeding or near to saturation with respect to the precipitation of certain Zn and Cu sulfide phases, as opposed to undersaturated conditions for Ni, Cr, and As. Thus, the results of our incubation experiments are consistent with our hypotheses and exemplify to a degree the links between metal speciation and toxicity. Speculatively, it is also possible, where dissolved Cu concentrations were observed to increase slightly towards the end of our experiments, that release of Cu from SCN−-degrading bacterial cells, in stationary and/or death phases, could explain this observation. Previous findings of the incorporation of Cu in one of the main enzymes involved in autotrophic SCN− biodegradation (Tikhonova et al. 2020), along with the inhibitory effect of cell-associated Cu (De Schamphelaere et al. 2005), would support this speculation.

Arsenic tolerance as observed in the present study was higher than that reported for an endophytic Citrobacter strain (400 mg L−1) (Selvankumar et al. 2017) or for Bacillus isolates (225 and 90 mg L−1) (Taran et al. 2019). Complete inhibition of SCN− biodegradation did not occur even at the highest As concentration (500 mg L−1), at which approximately 33% of initial SCN− was degraded within the first 48 h of incubation. However, no further SCN− degradation was observed in As-amended trials beyond this timepoint, highlighting both As concentration and exposure time as a possible consideration for evaluating As toxicity. It is noteworthy that in abovementioned studies in this regard, growth inhibition was the primary indicator of As toxicity, rather than the effect of As on a specific phenotypic function, e.g., thiocyanate biodegradation.

The observed tolerance of our experimental consortium for As may indicate an in situ selective pressure from the source material used to enrich the experimental microbial consortium. This consortium originated from a gold mine (Watts et al. 2017b) where sulfide ores on average contain significant amounts of As (e.g., 225 mg kg−1) (Noble et al. 2010). In fact, arsenopyrite is a main source of As in the mine tailings (0.2–0.4%) (King et al. 2008) and can incorporate As up to 10% w/w (Abraitis et al. 2004). Analysis of soil samples near the mine site from which cultures used for this study were enriched revealed 16–946 mg As (background values: 1–16 mg), 18–740 mg Cr (background: 26–143), and 12–430 mg Pb (background: 9–23 mg) per kg soil (Noble et al. 2010). Chemical monitoring of decant water from the mine site showed concentration (mg L−1) ranges of about 0.03–3.33 for Cu, 0.08–0.61 for As, 0.02–0.26 for Ni, and 0.01–0.17 for Zn (personal communication). We note that high levels of As tolerance have been reported previously, e.g., isolates of Bacillus sp. and Aneurinibacillus sp. that were able to grow in over 1 g L−1 As. These isolates were similarly cultivated from As-contaminated (ground)water samples (Dey et al. 2016).

Metal toxicity is determined by both biotic effects and abiotic factors, i.e., physicochemical characteristics of the environment (Babich et al. 1980; Gadd and Griffiths 1977). Microbial inhibition by metals varies with respect to type of microorganism and metal (Babich et al. 1980; Sadler and Trudinger 1967), metal speciation and bioavailability (Wang et al. 2007), and presence of other chemicals such as chelating agents (Sadler and Trudinger 1967) and environmental solutes (Babich et al. 1980). For instance, under anoxic conditions, arsenite is the predominant species of arsenic, while arsenate prevails in aerated systems. Lower sorption capacity of As(III) results in its greater immobilization in aqueous systems and consequently its higher level of bioavailability and greater toxicity when compared to As(V) (Oremland and Stolz 2005; Rosen 2002). The other example is Cr(VI) which is much more toxic to living organisms when compared to the relatively less reactive Cr(III) (Barnhart 1997). Therefore, higher concentrations of metals do not necessarily imply greater toxicity (Sadler and Trudinger 1967). Also, higher toxicity has been reported in multi-metal experiments than for single metal assays (Li and Ke 2001a, b; Utgikar et al. 2004), and previous studies have demonstrated greater degrees of metal tolerance of microbial consortia and co-cultures, when compared to isolates (Lu et al. 2020; Ma et al. 2018). This study provides a first step in evaluating the sensitivity of microbial consortia in SCN− bioremediation systems towards potential heavy metal co-contaminants in tailings waste streams. As actual influent to SCN− bioremediation systems likely contains multiple metal co-contaminants, synergistic effects of these metals should also be considered in future research.

Data availability

Not applicable.

References

Abraitis PK, Pattrick RAD, Vaughan DJ (2004) Variations in the compositional, textural and electrical properties of natural pyrite: a review. Int J Miner Process 74(1):41–59. https://doi.org/10.1016/j.minpro.2003.09.002

Akcil A (2003) Destruction of cyanide in gold mill effluents: biological versus chemical treatments. Biotechnol Adv 21(6):501–511. https://doi.org/10.1016/S0734-9750(03)00099-5

Akcil A, Mudder T (2003) Microbial destruction of cyanide wastes in gold mining: process review. Biotechnol Lett 25(6):445–450. https://doi.org/10.1023/A:1022608213814

Alexandrino M, Macías F, Costa R, Gomes NCM, Canário AVM, Costa MC (2011) A bacterial consortium isolated from an Icelandic fumarole displays exceptionally high levels of sulfate reduction and metals resistance. J Hazard Mater 187(1):362–370. https://doi.org/10.1016/j.jhazmat.2011.01.035

Amatya PL, Hettiaratchi JP, Joshi RC (2006) Interaction effects of metals and salinity on biodegradation of a complex hydrocarbon waste. J Air Waste Manage Assoc 56(2):197–205. https://doi.org/10.1080/10473289.2006.10464442

Babich H, Stotzky G, Ehrlich HL (1980) Environmental factors that influence the toxicity of heavy metal and gaseous pollutants to microorganisms. CRC Crit Rev Microbiol 8(2):99–145. https://doi.org/10.3109/10408418009081123

Baird RB, Eaton AD, Rice EW (2017) Standard methods for the examination of water and wastewater, 23rd edn. American Water Works Association, Washington D.C

Bakatula EN, Cukrowska EM, Chimuka L, Tutu H (2012) Characterization of cyanide in a natural stream impacted by gold mining activities in the Witwatersrand Basin, South Africa. Toxicol Environ Chem 94(1):7–19. https://doi.org/10.1080/02772248.2011.638637

Barnhart J (1997) Chromium chemistry and implications for environmental fate and toxicity. J Soil Contam 6(6):561–568. https://doi.org/10.1080/15320389709383589

Bhunia F, Saha NC, Kaviraj A (2000) Toxicity of thiocyanate to fish, plankton, worm, and aquatic ecosystem. Bull Environ Contam Toxicol 64(2):197–204. https://doi.org/10.1007/s001289910030

Botz MM, Mudder TI, Akcil AU (2016) Cyanide treatment: physical, chemical, and biological processes. In: Adams MD (ed) Gold ore processing, 2nd edn. Elsevier, pp 619–645. https://doi.org/10.1016/B978-0-444-63658-4.00035-9

Cabrera G, Pérez R, Gómez JM, Ábalos A, Cantero D (2006) Toxic effects of dissolved heavy metals on Desulfovibrio vulgaris and Desulfovibrio sp. strains. J Hazard Mater 135(1):40–46. https://doi.org/10.1016/j.jhazmat.2005.11.058

Chiboub M, Saadani O, Fatnassi IC, Abdelkrim S, Abid G, Jebara M, Jebara SH (2016) Characterization of efficient plant-growth-promoting bacteria isolated from Sulla coronaria resistant to cadmium and to other heavy metals. C R Biol 339(9–10):391–398. https://doi.org/10.1016/j.crvi.2016.04.015

Das S, Dash HR (2014) Microbial bioremediation: a potential tool for restoration of contaminated areas. In: Das S (ed) Microbial biodegradation and bioremediation. Elsevier, Oxford, pp 1–21

De Schamphelaere KAC, Stauber JL, Wilde KL, Markich SJ, Brown PL, Franklin NM, Creighton NM, Janssen CR (2005) Toward a biotic ligand model for freshwater green algae: surface-bound and internal copper are better predictors of toxicity than free Cu2+-ion activity when pH is varied. Environ Sci Technol 39(7):2067–2072. https://doi.org/10.1021/es049256l

Dey U, Chatterjee S, Mondal NK (2016) Isolation and characterization of arsenic-resistant bacteria and possible application in bioremediation. Biotechnol Rep (Amst) 10:1–7. https://doi.org/10.1016/j.btre.2016.02.002

Ebbs SD, Kolev SD, Piccinin RCR, Woodrow IE, Baker AJM (2010) Solubilization of heavy metals from gold ore by adjuvants used during gold phytomining. Miner Eng 23(10):819–822. https://doi.org/10.1016/j.mineng.2010.06.002

ERR (2007) Technical guideline - design and management of tailings storage facilities. Victoria State Government, Earth Resources Regulation (ERR), Australia

Ermans AM, Bourdoux P (1989) Antithyroid sulfurated compounds. In: Gaitan E (ed) Environmental goitrogenesis, chap 2. CRC Press, Boca Raton, Florida, pp 15–33

Evangelho MR, Gonçalves MMM, Sant'Anna GL, Bôas RCV (2001) A trickling filter application for the treatment of a gold milling effluent. Int J Miner Process 62(1–4):279–292. https://doi.org/10.1016/s0301-7516(00)00059-4

Fashola MO, Ngole-Jeme VM, Babalola OO (2016) Heavy metal pollution from gold mines: environmental effects and bacterial strategies for resistance. Int J Environ Res Public Health 13(11):1047. https://doi.org/10.3390/ijerph13111047

Gadd GM, Griffiths AJ (1977) Microorganisms and heavy metal toxicity. Microb Ecol 4(4):303–317. https://doi.org/10.1007/BF02013274

Giller KE, Witter E, McGrath SP (1998) Toxicity of heavy metals to microorganisms and microbial processes in agricultural soils: a review. Soil Biol Biochem 30(10):1389–1414. https://doi.org/10.1016/S0038-0717(97)00270-8

Given B, Meyer S (1998) Biological treatment of tailings solution at the Nickel Plate Mine. In: 22nd Annual British Columbia Mine Reclamation Symposium, Penticton, BC, Canada. The Technical and Research Committee on Reclamation, pp 157–151. https://doi.org/10.14288/1.0042330

Gould WD, King M, Mohapatra BR, Cameron RA, Kapoor A, Koren DW (2012) A critical review on destruction of thiocyanate in mining effluents. Miner Eng 34:38–47. https://doi.org/10.1016/j.mineng.2012.04.009

Hao OJ, Huang L, Chen JM, Buglass RL (1994) Effects of metal additions on sulfate reduction activity in wastewaters. Toxicol Environ Chem 46(4):197–212. https://doi.org/10.1080/02772249409358113

Huddy RJ, van Zyl AW, van Hille RP, Harrison STL (2015) Characterisation of the complex microbial community associated with the ASTER™ thiocyanate biodegradation system. Miner Eng 76:65–71. https://doi.org/10.1016/j.mineng.2014.12.011

Kantor RS, van Zyl AW, van Hille RP, Thomas BC, Harrison STL, Banfield JF (2015) Bioreactor microbial ecosystems for thiocyanate and cyanide degradation unravelled with genome-resolved metagenomics. Environ Microbiol 17(12):4929–4941. https://doi.org/10.1111/1462-2920.12936

Kantor RS, Huddy RJ, Iyer R, Thomas BC, Brown CT, Anantharaman K, Tringe S, Hettich RL, Harrison STL, Banfield JF (2017) Genome-resolved meta-omics ties microbial dynamics to process performance in biotechnology for thiocyanate degradation. Environ Sci Technol 51(5):2944–2953. https://doi.org/10.1021/acs.est.6b04477

Kevan SD, Dixon DG (1991) The acute toxicity of pulse-dosed thiocyanate (as KSCN and NaSCN) to rainbow trout (Oncorhynchus mykiss) eggs before and after water hardening. Aquat Toxicol 19(2):113–122. https://doi.org/10.1016/0166-445X(91)90031-4

King DJ, Doronila AI, Feenstra C, Baker AJM, Woodrow IE (2008) Phytostabilisation of arsenical gold mine tailings using four Eucalyptus species: growth, arsenic uptake and availability after five years. Sci Total Environ 406(1):35–42. https://doi.org/10.1016/j.scitotenv.2008.07.054

Kossoff D, Dubbin WE, Alfredsson M, Edwards SJ, Macklin MG, Hudson-Edwards KA (2014) Mine tailings dams: characteristics, failure, environmental impacts, and remediation. Appl Geochem 51:229–245. https://doi.org/10.1016/j.apgeochem.2014.09.010

Kuyucak N, Akcil A (2013) Cyanide and removal options from effluents in gold mining and metallurgical processes. Miner Eng 50–51:13–29. https://doi.org/10.1016/j.mineng.2013.05.027

Lage SG, Carvalho RT, Kopel L, Monachini MC, Bellotti G, Pileggi F (1994) Thiocyanate toxicity arising from prolonged use of sodium nitroprusside in severe heart failure. Arq Bras Cardiol 62(3):155–157

Lanno RP, Dixon DG (1996) The comparative chronic toxicity of thiocyanate and cyanide to rainbow trout. Aquat Toxicol 36(3):177–187. https://doi.org/10.1016/S0166-445X(96)00815-6

Lay-Son M, Drakides C (2008) New approach to optimize operational conditions for the biological treatment of a high-strength thiocyanate and ammonium waste: pH as key factor. Water Res 42(3):774–780. https://doi.org/10.1016/j.watres.2007.08.009

Li H-M, Ke J-J (2001a) Influence of Cu2+ and Mg2+ on the growth and activity of Ni2+ adapted Thiobacillus ferrooxidans. Miner Eng 14(1):113–116. https://doi.org/10.1016/S0892-6875(00)00165-5

Li H-M, Ke J-J (2001b) Influence of Ni2+ and Mg2+ on the growth and activity of Cu2+-adapted Thiobacillus ferrooxidans. Hydrometallurgy 61(3):151–156. https://doi.org/10.1016/S0304-386X(01)00167-0

Lu Q, Zou X, Liua J, Liang Z, Shim H, Qiu R, Wang S (2020) Inhibitory effects of metal ions on reductive dechlorination of polychlorinated biphenyls and perchloroethene in distinct organohaliderespiring bacteria. Environ Int 135:1–9. https://doi.org/10.1016/j.envint.2019.105373

Ma XK, Li TT, Fam H, Peterson EC, Zhao WW, Guo W, Zhou B (2018) The influence of heavy metals on the bioremediation of polycyclic aromatic hydrocarbons in aquatic system by a bacterial–fungal consortium. Environ Technol 39(16):2128–2137. https://doi.org/10.1080/09593330.2017.1351492

Ma L, Xu J, Chen N, Li M, Feng C (2019) Microbial reduction fate of chromium (Cr) in aqueous solution by mixed bacterial consortium. Ecotoxicol Environ Saf 170:763–770. https://doi.org/10.1016/j.ecoenv.2018.12.041

Macomber L, Hausinger RP (2016) Nickel toxicity, regulation, and resistance in bacteria. In: de Bruijn FJ (ed) Stress and environmental regulation of gene expression and adaptation in bacteria, pp 1131–1144. https://doi.org/10.1002/9781119004813.ch110

Mattila K, Zaitsev G, Langwaldt J (2007) Biological removal of nutrients from mine waters. Biologinen ravinteiden poisto kaivosvedestä Final report - loppuraportti. Finnish Forest Research Institute, Rovaniemi, p 99

Mediavilla JJV, Perez BF, de Cordoba MCF, Espina JA, Ania CO (2019) Photochemical degradation of cyanides and thiocyanates from an industrial wastewater. Molecules 24(7):1373. https://doi.org/10.3390/molecules24071373

Minitab 18 Statistical Software (2017) [Computer software] 18.1 edn. Minitab, Inc., State College, PA. www.minitab.com. Accessed April 2020

Moberly JG, Staven A, Sani RK, Peyton BM (2010) Influence of pH and inorganic phosphate on toxicity of zinc to Arthrobacter sp. isolated from heavy-metal-contaminated sediments. Environ Sci Technol 44(19):7302–7308. https://doi.org/10.1021/es100117f

Mudder TI, Botz MM, Smith A (2001) The chemistry and treatment of cyanidation wastes. Mining Journal Books Ltd, London

Nelson MG, Kroegef EB, Arps PJ (1998) Chemical and biological destruction of cyanide: comparative costs in a cold climate. Miner Process Extr Metall Rev 19(1):217–226. https://doi.org/10.1080/08827509608962441

Noble RRP, Hough RM, Watkins RT (2010) Enrichment and exposure assessment of As, Cr and Pb of the soils in the vicinity of Stawell, Victoria, Australia. Environ Geochem Health 32(3):193–205. https://doi.org/10.1007/s10653-009-9275-0

Oremland RS, Stolz JF (2005) Arsenic, microbes and contaminated aquifers. Trends Microbiol 13(2):45–49. https://doi.org/10.1016/j.tim.2004.12.002

Parkhurst DL, Appelo CAJ (2013) Description of input and examples for PHREEQC version 3—a computer program for speciation, batch-reaction, one-dimensional transport, and inverse geochemical calculations. U.S. Geological Survey Techniques and Methods 6(A43):497. Available at https://pubs.usgs.gov/tm/06/a43

Parkhurst BR, Bradshaw AS, Forte JL, Wright GP (1979) An evaluation of the acute toxicity to aquatic biota of a coal conversion effluent and its major components. Bull Environ Contam Toxicol 23(1):349–356. https://doi.org/10.1007/BF01769968

Poulson SR, Colberg PJS, Drever JI (1997) Toxicity of heavy metals (Ni, Zn) to Desulfovibrio desulfuricans. Geomicrobiol J 14(1):41–49. https://doi.org/10.1080/01490459709378032

Ramírez-Díaz MI, Díaz-Pérez C, Vargas E, Riveros-Rosas H, Campos-García J, Cervantes C (2008) Mechanisms of bacterial resistance to chromium compounds. BioMetals 21(3):321–332. https://doi.org/10.1007/s10534-007-9121-8

Rosen BP (2002) Biochemistry of arsenic detoxification. FEBS Lett 529(1):86–92. https://doi.org/10.1016/S0014-5793(02)03186-1

Sadler WR, Trudinger PA (1967) The inhibition of microorganisms by heavy metals. Mineral Deposita 2(3):158–168. https://doi.org/10.1007/BF00201912

Sani RK, Peyton BM, Brown LT (2001) Copper-induced inhibition of growth of Desulfovibrio desulfuricans G20: assessment of its toxicity and correlation with those of zinc and lead. Appl Environ Microbiol 67(10):4765–4772. https://doi.org/10.1128/AEM.67.10.4765-4772.2001

Selvankumar T, Radhika R, Mythili R, Arunprakash S, Srinivasan P, Govarthanan M, Kim H (2017) Isolation, identification and characterization of arsenic transforming exogenous endophytic Citrobacter sp. RPT from roots of Pteris vittata. 3 Biotech 7(4):264. https://doi.org/10.1007/s13205-017-0901-8

Sprocati AR, Alisi C, Tasso F, Marconi P, Sciullo A, Pinto V, Chiavarini S, Ubaldi C, Cremisini C (2012) Effectiveness of a microbial formula, as a bioaugmentation agent, tailored for bioremediation of diesel oil and heavy metal co-contaminated soil. Process Biochem 47(11):1649–1655. https://doi.org/10.1016/j.procbio.2011.10.001

Takeuchi M, Kawahata H, Gupta LP, Kita N, Morishita Y, Ono Y, Komai T (2007) Arsenic resistance and removal by marine and non-marine bacteria. J Biotechnol 127(3):434–442. https://doi.org/10.1016/j.jbiotec.2006.07.018

Taran M, Fateh R, Rezaei S, Gholi MK (2019) Isolation of arsenic accumulating bacteria from garbage leachates for possible application in bioremediation. Iran J Microbiol 11(1):60–66

Tikhonova TV, Sorokin DY, Hagen WR, Khrenova MG, Muyzer G, Rakitina TV, Shabalin IG, Trofimov AA, Tsallagov SI, Popov VO (2020) Trinuclear copper biocatalytic center forms an active site of thiocyanate dehydrogenase. PNAS 117(10):5280–5290. https://doi.org/10.1073/pnas.1922133117

U.S. Environmental Protection Agency (1998) MINTEQA2/PRODEFA2, A geochemical assessment model for environmental systems—User manual supplement for version 40. National Exposure Research Laboratory, Ecosystems Research Division, Athens, p 76. Revised September 1999

Utgikar VP, Chen BY, Chaudhary N, Tabak HH, Haines JR, Govind R (2001) Acute toxicity of heavy metals to acetate-utilizing mixed cultures of sulfate-reducing bacteria: EC100 and EC50. Environ Toxicol Chem 20(12):2662–2669. https://doi.org/10.1002/etc.5620201202

Utgikar VP, Tabak HH, Haines JR, Govind R (2003) Quantification of toxic and inhibitory impact of copper and zinc on mixed cultures of sulfate-reducing bacteria. Biotechnol Bioeng 82(3):306–312. https://doi.org/10.1002/bit.10575

Utgikar VP, Chaudhary N, Koeniger A, Tabak HH, Haines JR, Govind R (2004) Toxicity of metals and metal mixtures: analysis of concentration and time dependence for zinc and copper. Water Res 38(17):3651–3658. https://doi.org/10.1016/j.watres.2004.05.022

van Buuren C, Makhotla N, Olivier JW (2011) The ASTER process: technology development through to piloting, demonstration and commercialization. Paper presented at the Proceedings of the ALTA 2011 Nickel–cobalt–copper, Uranium and Gold Conference, Perth, Australia

Van Nostrand JD, Sowder AG, Bertsch PM, Morris PJ (2005) Effect of pH on the toxicity of nickel and other divalent metals to Burkholderia cepacia PR1(301). Environ Toxicol Chem 24(11):2742–2750. https://doi.org/10.1897/04-335R.1

van Zyl AW, Harrison STL, van Hille RP (2017) Determining an effective operating window for a thiocyanate-degrading mixed microbial community. J Environ Chem Eng 5(1):660–666. https://doi.org/10.1016/j.jece.2016.12.046

Wang Y, Shi J, Lin Q, Chen X, Chen Y (2007) Heavy metal availability and impact on activity of soil microorganisms along a Cu/Zn contamination gradient. J Environ Sci 19(7):848–853. https://doi.org/10.1016/S1001-0742(07)60141-7

Wang X, Liu L, Lin W, Luo J (2020) Development and characterization of an aerobic bacterial consortium for autotrophic biodegradation of thiocyanate. Chem Eng J 398:125461. https://doi.org/10.1016/j.cej.2020.125461

Watts MP, Moreau JW (2018) Thiocyanate biodegradation: harnessing microbial metabolism for mine remediation. Microbiol Aust 39(3):157–161. https://doi.org/10.1071/MA18047

Watts MP, Gan HM, Peng LY, Le Cao KA, Moreau JW (2017a) In situ stimulation of thiocyanate biodegradation through phosphate amendment in gold mine tailings water. Environ Sci Technol 51(22):13353–13362. https://doi.org/10.1021/acs.est.7b04152

Watts MP, Spurr LP, Gan HM, Moreau JW (2017b) Characterization of an autotrophic bioreactor microbial consortium degrading thiocyanate. Appl Microbiol Biotechnol 101(14):5889–5901. https://doi.org/10.1007/s00253-017-8313-6

Watts MP, Spurr LP, Lê Cao KA, Wick R, Banfield JF, Moreau JW (2019) Genome-resolved metagenomics of an autotrophic thiocyanate-remediating microbial bioreactor consortium. Water Res 158:106–117. https://doi.org/10.1016/j.watres.2019.02.058

Woffenden M, Noller B, Noonan K, Breuer P, Cooper P, Donato D (2008) Cyanide management: leading practice sustainable development program for the mining industry. Deptartment of Industry, Tourism and Resources, Commonwealth of Australia, Canberra, A.C.T., Australia

Wong KW, Toh BA, Ting YP, Obbard JP (2005) Biodegradation of phenanthrene by the indigenous microbial biomass in a zinc amended soil. Lett Appl Microbiol 40(1):50–55. https://doi.org/10.1111/j.1472-765X.2004.01623.x

Acknowledgments

The authors wish to acknowledge David Coe, Peter Wemyss, and Cameron Hope of Stawell Gold Mine for providing access to mine tailings for enrichment culturing and historical geochemical data. Also, we are grateful to Alan Greig for help with ICP-MS analyses, Christopher Aitken for initial observations that helped to guide experiments, and Angus Keillar for assistance with geochemical modeling.

Funding

This work was funded by a University of Melbourne Research Training Program Scholarship to FS and ARC Linkage Grant LP160100866 to JWM.

Author information

Authors and Affiliations

Contributions

FS and JWM devised the research and wrote the manuscript with critical contributions from MPW. FS conducted all experiments and analyses, with assistance for some tests from LP.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethics approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Consent to participate

Not applicable.

Consent for publication

The authors approved the manuscript and gave their consent for its submission to Applied Microbiology and Biotechnology.

Code availability

Not applicable.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

ESM 1

(PDF 285 kb).

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Shafiei, F., Watts, M.P., Pajank, L. et al. The effect of heavy metals on thiocyanate biodegradation by an autotrophic microbial consortium enriched from mine tailings. Appl Microbiol Biotechnol 105, 417–427 (2021). https://doi.org/10.1007/s00253-020-10983-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-020-10983-4