Abstract

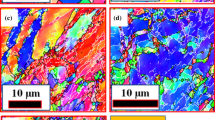

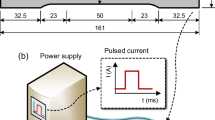

The effects of pre-strain and subsequent electrically assisted annealing on the mechanical behaviors of two different (Al–Mg and Al–Si–Mg) aluminum alloys during electrically assisted dual stage forming are experimentally investigated. First, a specimen is deformed to a specific pre-strain by uniaxial tension and then automatically unloaded. After that, the pre-strained specimen is subjected to electrically assisted annealing by electric current with a fixed subsecond duration. Finally, the specimen is reloaded until fracture. Experimental results show that application of electric current with a subsecond duration induces electrically assisted annealing to both pre-strained aluminum alloys. The electric current also increases total achievable elongation until fracture during electrically assisted dual stage forming for both aluminum alloys. However, analysis of the stress–strain behavior during reloading and microstructural observations suggest that the quantitative effects of electric current on the post-electrically assisted annealing mechanical behavior and resultant microstructure are strongly dependent on the type of aluminum alloy. With the electric current density of 140 A/mm2, a full recrystallization followed by grain growth occurs in the pre-strained Al–Mg alloy specimens. For the pre-strained Al–Mg–Si alloy specimens, the electric current density of 140 A/mm2 induces both annealing and solid solutioning. Together, our findings indicate that while electrically assisted annealing is effective at improving the productivity of dual stage forming of an aluminum alloy, the composition of the aluminum alloy should be carefully considered in the design of forming process utilizing the concept of electrically assisted annealing since the beneficial effect was limited for the precipitation hardening 6061-T6 aluminum alloy.

Similar content being viewed by others

Data Availability

The raw/processed data required to reproduce these findings cannot be shared at this time as the data also forms part of an ongoing study.

References

Cole, G. S., & Sherman, A. M. (1995). Light weight materials for automotive applications. Materials Characterization, 35(1), 3–9.

Miller, W. S., Zhuang, L., Bottema, J., Wittebrood, A., De Smet, P., Haszler, A., et al. (2000). Recent development in aluminium alloys for the automotive industry. Materials Science and Engineering A, 280(1), 37–49.

Dursun, T., & Soutis, C. (2014). Recent developments in advanced aircraft aluminium alloys. Materials and Design, 1980–2015(56), 862–871.

Campbell, F. C. (Ed.). (2008). Elements of metallurgy and engineering alloys. ASM International.

Krajewski, P. E. (2007). U.S. Patent No. 7,260,972. Washington, DC: U.S. Patent and Trademark Office.

Li, J., Carsley, J. E., Stoughton, T. B., Hector, L. G., Jr., & Hu, S. J. (2013). Forming limit analysis for two-stage forming of 5182-O aluminum sheet with intermediate annealing. International Journal of Plasticity, 45, 21–43.

Wang, K., Li, J., Stoughton, T. B., Carsley, J. E., & Carlson, B. E. (2018). Effect of preform annealing on plastic anisotropy of an age-hardenable Al–Mg–Si alloy. Journal of Materials Processing Technology, 252, 381–388.

Li, J., Kim, S., Lee, T. M., Krajewski, P. E., Wang, H., & Hu, S. J. (2011). The effect of prestrain and subsequent annealing on the mechanical behavior of AA5182-O. Materials Science and Engineering A, 528(10–11), 3905–3914.

Wang, K., He, B., Carsley, J. E., Raghavan, R. S., Li, J., Hartfield-Wünsch, S. E., et al. (2014). Structure–property characterization of an age hardenable Al–Mg–Si alloy after straining and flash annealing. Materials Science and Engineering A, 595, 25–33.

Fang, X. W., Xiao, H., Marthinsen, K., Belyakov, A., Fang, X. Y., & Huang, K. (2020). Tailoring microstructure and texture of annealed Al–Mn alloy through the variation of homogenization and prior cold deformation strain. Materials Characterization, 110438.

Harris, P. (1972). Electromechanical effects in metals. Physical Review B, 5(6), 2107.

Roh, J. H., Seo, J. J., Hong, S.-T., Kim, M. J., Han, H. N., & Roth, J. T. (2014). The mechanical behavior of 5052-H32 aluminum alloys under a pulsed electric current. International Journal of Plasticity, 58, 84–99.

Kim, S. J., Kim, S. D., Yoo, D., Lee, J., Rhyim, Y., & Kim, D. (2016). Evaluation of the athermal effect of electric pulsing on the recovery behavior of magnesium alloy. Metallurgical and Materials Transactions A, 47(12), 6368–6373.

Nguyen-Tran, H. D., Oh, H. S., Hong, S. T., Han, H. N., Cao, J., Ahn, S. H., et al. (2015). A review of electrically-assisted manufacturing. International Journal of Precision Engineering and Manufacturing-Green Technology, 2(4), 365–376.

Jeong, H. J., Kim, M. J., Choi, S. J., Park, J. W., Choi, H., Luu, V. T., et al. (2020). Microstructure reset-based self-healing method using sub-second electric pulsing for metallic materials. Applied Materials Today, 20, 100755.

Li, Y. F., Hong, S. T., Choi, H., & Han, H. N. (2019). Solid-state dissimilar joining of stainless steel 316L and Inconel 718 alloys by electrically assisted pressure joining. Materials Characterization, 154, 161–168.

Kim, M. J., Lee, K., Oh, K. H., Choi, I. S., Yu, H. H., Hong, S.-T., et al. (2014). Electric current-induced annealing during uniaxial tension of aluminum alloy. Scripta Materialia, 75, 58–61.

Kim, M. J., Lee, M. G., Hariharan, K., Hong, S.-T., Choi, I. S., Kim, D., et al. (2017). Electric current–assisted deformation behavior of Al–Mg–Si alloy under uniaxial tension. International Journal of Plasticity, 94, 148–170.

Fan, R., Magargee, J., Hu, P., & Cao, J. (2013). Influence of grain size and grain boundaries on the thermal and mechanical behavior of 70/30 brass under electrically-assisted deformation. Materials Science and Engineering A, 574, 218–225.

ASTM, E. 9. (2001). Standard test methods for tension testing of metallic materials. Annual book of ASTM standards. ASTM.

Engler, O., Schäfer, C., & Myhr, O. R. (2015). Effect of natural ageing and pre-straining on strength and anisotropy in aluminium alloy AA 6016. Materials Science and Engineering A, 639, 65–74.

Stribeck, N. (2007). X-ray scattering of soft matter. Springer.

Park, J. W., Jeong, H. J., Jin, S. W., Kim, M. J., Lee, K., Kim, J. J., et al. (2017). Effect of electric current on recrystallization kinetics in interstitial free steel and AZ31 magnesium alloy. Materials Characterization, 133, 70–76.

Luu, V. T., Dinh, T. K. A., Das, H., Kim, J. R., Hong, S.-T., Sung, H. M., et al. (2018). Diffusion enhancement during electrically assisted brazing of ferritic stainless steel alloys. International Journal of Precision Engineering and Manufacturing-Green Technology, 5(5), 613–621.

Humphreys, F. J., & Hatherly, M. (2012). Recrystallization and related annealing phenomena. Elsevier.

Acknowledgements

This research was supported by the 2020 research fund of the University of Ulsan.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Dinh, KA., Hong, ST., Choi, SJ. et al. The Effect of Pre-strain and Subsequent Electrically Assisted Annealing on the Mechanical Behaviors of Two Different Aluminum Alloys. Int. J. Precis. Eng. Manuf. 21, 2345–2358 (2020). https://doi.org/10.1007/s12541-020-00424-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-020-00424-7