The paper examines the effect of high-energy grinding and post-treatment conditions on the structure and physical and mechanical properties of iron aluminide Fe–15 wt.% Al obtained by sintering and impulse hot pressing. It was shown that the grinding of a mixture of iron and aluminum powders in a planetary mill results in the formation of lamellar particles whose morphology is preserved in the alloy structure after sintering and impulse hot pressing. After grinding, sintered intermetallic compounds obtained from powder mixtures demonstrate low physical and mechanical properties due to the low quality of grain boundaries. The use of impulse hot pressing for compaction of samples from milled powders at temperatures of 850–1150°C significantly increases the density of intermetallic compounds compared to sintered materials of a similar composition—from 5 to 6.5 g/cm3. The increase in the temperature of impulse hot pressing contributes to an increase in mechanical characteristics, where the maximum values of bending strength and fracture toughness are 880 MPa and 21 MPa · m0.5, respectively. Subsequent hightemperature annealing (1350–1450°C) leads to an improvement of the quality of grain boundaries with the formation of a predominantly discontinuous grid, coagulation of impurity segregation, and, as a result, to a sharp increase in bending strength and fracture toughness, which are 1400 MPa and 27 MPa · m0.5, respectively. It was shown that the interparticle rupture observed in the samples after impulse hot pressing at relatively low temperatures changes to transcrystalline after hightemperature annealing.

Similar content being viewed by others

References

N.S. Stoloff, “Iron aluminides: present status and future prospects,” Mater. Sci. Eng.: A, 258, 1–14 (1998).

S.C. Deevi and V.K. Sikka, “Nickel and iron aluminides: an overview on properties, processing, and applications,” Intermetallics, 4, No. 5, 357–375 (1996).

M. Zamanzade, A. Barnoush, and C.A. Motz, “Review on the properties of iron aluminide intermetallics,” Crystals, 6, No. 10, 1–29 (2016).

E. Godlewska, S. Szczepanik, R. Mania, J. Krawiarz, and S. Kozinski, “FeAl materials from intermetallic powders,” Intermetallics, 11, No. 4, 307–312 (2003).

S. Gedevanishvili and S.C. Deevi, “Processing of iron aluminides by pressureless sintering through Fe+Al elemental route,” Mater. Sci. Eng.: A, A325, 163–176 (2002).

T. Talako, “On the combustion synthesis of B2 FeAl based powders for thermal spray coatings,” J. Mineral, Metal Mater. Eng., No. 3, 32–45 (2017).

T.C. Totemeier, R.N. Wright, and W.D. Swank, “Microstructure and stresses in HVOF sprayed iron aluminide coatings,” J. Thermal Spray Technol., 11, Issue 3, 400–408 (2002).

J.H. Schneibel and M.A. Crimp, Selected Properties of Iron Aluminides. Processing, Properties and Applications of Iron Aluminides, TMS, Warrendale, PA (1994), pp. 329–342.

X.Q. Yu and Y.S. Sun, “Hot working of Fe3Al based alloy, Mater. Sci. Technol., 20, 339–342 (2004).

C. Jia, Q. He, J. Meng, and L. Guo, “Influence of mechanical alloying time on the properties of Fe3AI intermetallics prepared by spark plasma sintering,” J. University Sci. Technol. Beijing, 14, No. 4, 331–334 (2007).

H. Song, Y. Wu, C. Tang, S. Yuan, Q. Gong, and J. Liang, “Microstructure and mechanical properties of FeAl intermetallics prepared by mechanical alloying and hot-pressing,” Tsinghua Sci. Technol., 14, No. 3, 300–306 (2009).

G.A. Baglyuk, A.I. Tolochin, A.V. Tolochina, R.V. Yakovenko, A.N. Gripachevckii, and M.E. Golovkova, “Effect of Process Conditions on the Structure and Properties of the Hot-Forged Fe3Al Intermetallic Alloy,” Powder Metall. Met. Ceram., 55, No. 5–6, 297–305 (2016).

S. Szczepanik, E. Godlewska, and R. Mania, “The Fe–Al compounds produced from powders” [in Polish] Kompozyty (Composites), 2, No. 4, 242–248 (2002).

C. Suryanarayana, “Recent developments in mechanical alloying,” Reviews Advanced Mater. Sci., 18, 203–211 (2008).

C. Suryanarayana, “Mechanical alloying and milling,” Progress Mater. Sci., 46, 1–184 (2001).

Q. He, C. Jia, and J. Meng, “Influence of iron powder particle size on the microstructure and properties of Fe3Al intermetallics prepared by mechanical alloying and spark plasma sintering,” Mater. Sci. Eng.: A, 428, 314–318 (2006).

C.C. Koch and J.D. Whittenberger, “Mechanical milling/alloying of intermetallics,” Intermetallics, 4, Issue 5, 339–355 (1996).

A.V. Laptev, “High-energy hot-pressing method in vacuum for production of materials with ultrafine structure and high durability,” Powder Metall. Met. Ceram, 40, No. 3–4, 8–19 (2001).

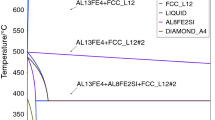

N.P. Lyakishev (ed.), Phase Diagrams of Metallic Systems [in Russian], Vol. 1, Mashinostroenie, Moscow (1996), p. 999.

Iron Aluminide Useful as Electrical Resistance Heating Elements, Patent USA 5976458, publication 1999-11-02.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Poroshkova Metallurgiya, Vol. 59, Nos. 7–8 (534), pp. 25–38, 2020.

Rights and permissions

About this article

Cite this article

Tolochyn, O., Bagliuk, H., Tolochyna, O. et al. Effect of Processing Parameters on the Structure and Properties of Powder Fe–Al Intermetallic Compounds Obtained by Sintering and Impulse Hot Pressing. Powder Metall Met Ceram 59, 375–385 (2020). https://doi.org/10.1007/s11106-020-00171-4

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-020-00171-4