Abstract

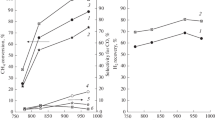

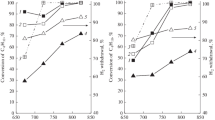

A study of methanol steam reforming (MSR) in the presence of a Ni0.2–Cu0.8/Ce0.3Zr0.7O2-δ catalyst in conventional and membrane reactors has revealed that the hydrogen yield in a reactor with a Pd–Cu membrane is higher than that in a conventional flow reactor. It has been shown that the Pd–Cu alloy membrane exhibits high hydrogen permeability. Methanol steam reforming in the membrane reactor provides the production of high-purity hydrogen, because a stream of pure hydrogen free from any impurities is effluent from the permeate zone. Measurements of the hydrogen permeability of the Pd–Cu alloy foil membrane in the membrane reactor before and after catalysis have been conducted.

Similar content being viewed by others

REFERENCES

F. Dawood, M. Anda, and G. M. Shafiullah, Int. J. Hydrogen Energy 45, 3847 (2020).

N. L. Garland, D. C. Papageorgopoulos, and J. M. Stanford, Energy Procedia 28, 2 (2012).

A. B. Yaroslavtsev, I. A. Stenina, and D. V. Golubenko, Pure Appl. Chem. 92, 1147 (2020).

M. V. Tsodikov, A. V. Chistyakov, F. A. Yandieva, et al., Catal. Ind. 3, 4 (2011).

F. Hasegawa, S. Yokoyama, and K. Imou, Bioresour. Technol. 101, 109 (2010).

R. S. Kempegowda, P. V. Pannir Selvam, Ø. Skreiberg, and K.-Q. Trana, J. Chem. Technol. Biotechnol. 87, 897 (2012).

E. Yu. Mironova, A. A. Lytkina, M. M. Ermilova, et al., Int. J. Hydrogen Energy 40, 3557 (2015).

H. Jeong, K. I. Kimb, T. H. Kimb, et al., J. Power Sources 159, 1296 (2006).

G.-S. Wu, D.-S. Mao, G.-Z. Lu, et al., Catal. Lett. 130, 177 (2009).

L. Yong-Feng, D. Xin-Fa, and L. Wei-Ming, Int. J. Hydrogen Energy 29, 1617 (2004).

L. Ma, B. Gong, T. Tran, and M. S. Wainwright, Catal. Today 63, 499 (2000).

A. A. Lytkina, N. V. Orekhova, M. M. Ermilova, et al., Int. J. Hydrogen Energy 44 (26), 13 310 (2019).

C.-Z. Yao, L.-C. Wang, Y.-M. Liu, et al., Appl. Catal., A 297, 151 (2006).

J.-P. Shen and C. Song, Catal. Today 77, 89 (2002).

T. Shishido, Y. Yamamoto, H. Morioka, et al., . Appl. Catal., A 263, 249 (2004).

O. Jakdetchai, N. Takayama, and T. Nakajima, Kinet. Catal. 46, 56 (2005).

G. Águila, J. Jiménez, S. Guerrero, et al., Appl. Catal., A 360, 98 (2009).

J. Agrell, H. Birgersson, M. Boutonnet, et al., J. Catal. 219, 389 (2003).

A. A. Lytkina, N. V. Orekhova, M. M. Ermilova, et al., Pet. Chem. 57, 1219 (2017).

S. Yang, F. Zhou, Y. Liu, et al., Int. J. Hydrogen Energy 44, 7252 (2019).

T. Valdés-Solís, G. Marbán, and A. B. Fuertes, Catal. Today 116, 354 (2006).

J. Papavasiliou, G. Avgouropoulos, and T. Ioannides, Appl. Catal., B 69, 226 (2007).

X. Zhang and P. Shi, J. Mol. Catal., A 194, 99 (2003).

Y. Liu, T. Hayakawa, T. Tsunoda, et al. Top. Catal. 22, 205 (2003).

A. A. Lytkina, N. V. Orekhova, M. M. Ermilova, and A. B. Yaroslavtsev, Int. J. Hydrogen Energy 43, 198 (2018).

M. R. Rahimpour, F. Samimi, A. Babapoor, et al., Chem. Eng. Process. 121, 24 (2017).

N. A. Al-Mufachi, N. V. Rees, and R. Steinberger-Wilkens, Renew. Sust. Energy Rev. 47, 540 (2015).

A. A. Lytkina, N. V. Orekhova, and A. B. Yaroslavtsev, Pet. Chem. 58, 911 (2018).

S. Kim, S.-W. Yun, B. Lee, et al., Int. J. Hydrogen Energy 44, 2330 (2019).

E. Yu. Mironova, M. M. Ermilova, N. V. Orekhova, et al., Catal. Today 236, 64 (2014).

A. Iulianelli, P. Ribeirinha, A. Mendes, and A. Basile, Renew. Sust. Energy Rev. 29, 355 (2014).

A. Iulianelli, T. Longo, and A. Basile, J. Membr. Sci. 323, 235 (2008).

K. Zhang and J. D. Way, Sep. Purif. Technol. 186, 39 (2017).

V. M. Ievlev, K. A. Solntsev, A. I. Sitnikov, et al., Inorg. Mater.: Appl. Res. 7, 586 (2016).

V. M. Ievlev, A. A. Maksimenko, S. V. Kanykin, et al., Kondens. Sredy Mezhfazn. Granitsy, No. 4, 521 (2016).

V. M. Ievlev, K. A. Solntsev, A. I. Dontsov, A. A. Maksimenko, S. V. Kannykin, Tech. Phys. 61, 467 (2016).

E. C. Arvaniti, M. C. G. Juenger, S. A. Bernal, et al., Mater. Struct. 48, 3687 (2015).

I. A. Stenina, T. L. Kulova, A. M. Skundin, and A. B. Yaroslavtsev, Mater. Res. Bull. 75, 178 (2016).

ACKNOWLEDGMENTS

This work was performed using the equipment of the Shared-Use Centers “Analytical Center for the Problems of Deep Oil Refining and Petroleum Chemistry” and “New Petrochemical Processes, Polymer Composites, and Adhesives” at the Topchiev Institute of Petrochemical Synthesis of the Russian Academy of Sciences.

Funding

This work was supported by the Russian Science Foundation, project no. 19-19-00232; the catalyst synthesis and testing were performed under a state task of the Ministry of Education and Science of the Russian Federation at the Topchiev Institute of Petrochemical Synthesis of the Russian Academy of Sciences.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

The authors declare that there is no conflict of interest regarding the publication of this manuscript.

Additional information

Translated by M. Timoshinina

Rights and permissions

About this article

Cite this article

Mironova, E.Y., Lytkina, A.A., Ermilova, M.M. et al. Methanol Steam Reforming in a Reactor with a Palladium–Copper Membrane in the Presence of a Nickel–Copper Catalyst. Pet. Chem. 60, 1232–1238 (2020). https://doi.org/10.1134/S0965544120110158

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0965544120110158