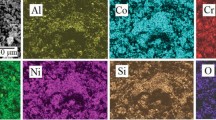

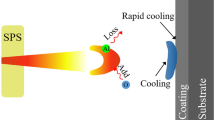

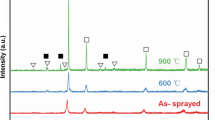

The high entropy alloy (HEA) coatings are potential candidates for advanced application in the protection of steel and other traditional alloys due to their excellent physical and mechanical performance. The AlCoCrFeNi alloy series were favorably studied due to comparably low cost and stable performance. In this research, the AlCoCrFeNi coatings were prepared through surface mechanical abrasion treatment (SMAT). The process implied the comprehensive effect of cold welding and friction. The submicron-size SiC particles were added into the raw materials in different amounts. For SMAT, a high-energy ball milling method was adopted to promote the alloying of metals, disperse SiCp, and combine the powder to the carbon steel substrate. Afterward, the phase composition, microstructure of coatings, and distribution of reinforcement were detected through XRD and SEM analysis, separately, and the effect of SiC particles content on the properties of the coatings was analyzed. The results show that the addition of submicron-sized SiC significantly improved the density and stiffness of the HEA coating and diminished defects and surface roughness. Сoatings containing SiC display enhanced adhesion force and wear resistance. The proposed mechanism is that the submicron SiC particles promoted mechanical alloying of pure metal and intensified the adherence and cold welding of the coating. Especially, herein, the addition of 15 wt.% SiC granted the best comprehensive properties of the coating. Excessive SiC content led to the deterioration of coating plasticity and the growth of cracks.

Similar content being viewed by others

References

J.W. Yeh, S.K. Chen, S.J. Lin, J.Y. Gan, T.S. Chin, T.T. Shun, C.H. Tsau, S.Y. Chang, “Nanostructured high-entropy alloys with multiple principal elements: novel alloy design concepts and outcomes,” Adv. Eng. Mater., 6, No. 5, 299–303 (2004).

S. Kumar, P. Rani, A. Patnaik, A. Kumar Pradhan, and V. Kumar, “Effect of cobalt content on wear behaviour of Al0.4FeCrNiCox (x = 0, 0.25, 0.5, 1.0 mol.) high entropy alloys tested under demineralised water with and without 3.5% NaCl solution,” Mater. Res. Expres., 6, 1–13 (2019).

X. Li, Y. Feng, B. Liu, D. Yi, X. Yang, W. Zhang, G. Chen, Y. Liu, and P. Bai, “Influence of NbC particles on microstructure and mechanical properties of AlCoCrFeNi high-entropy alloy coatings prepared by laser cladding,” J. Alloys Compd., 788, No. 5, 485–494 (2019).

N. Haghdadi, T. Guo, A. Ghaderi, P.D. Hodgson, M.R. Barnett, and D.M. Fabijanic, “The scratch behaviour of AlxCoCrFeNi (x = 0.3 and 1.0) high entropy alloys,” Wear, 428–429, 293–301 (2019).

L. Guo, D. Xiao, W. Wu, S. Ni, and M. Song, “Effect of Fe on microstructure, phase evolution and mechanical properties of (AlCoCrFeNi)100–xFex high entropy alloys processed by spark plasma sintering,” Intermetallics, 103, 1–11 (2018).

J.M. Zhu, H.M. Fu, H.F. Zhang, A.M. Wang, H. Li, and Z.Q. Hu, “Microstructures and compressive properties of multicomponent AlCoCrFeNiMox alloys,” Mater. Sci. Eng. A, 527, 26, 6975–6979 (2010).

L. Rogal, Z. Szklarz, P. Bobrowski, D. Kalita, G. Garzel, A. Tarasek, M. Kot, and M. Szlezynger, “Microstructure and mechanical properties of Al–Co–Cr–Fe–Ni base high entropy alloys obtained using powder metallurgy,” Met. Mater. Int., 25, 930–945 (2019).

Y. Yu, J. Wang, J.S. Li, J. Yang, H.C. Kou, and W.M. Liu, “Tribological behavior of AlCoCrFeNi(Ti0.5) high entropy alloys under oil and MACs lubrication,” J. Mater. Sci. Technol., 32, 470–476 (2016).

Y. Dong and Y. Lu, “Effects of tungsten addition on the microstructure and mechanical properties of neareutectic AlCoCrFeNi2 high-entropy alloy,” J. Mater. Eng. Perform., 27, 109–115 (2018).

Y. Dong, K. Zhou, Y. Lu, X. Gao, T. Wang, and T. Li, “Effect of vanadium addition on the microstructure and properties of AlCoCrFeNi high entropy alloy,” Mater. Des., 57, 67–72 (2014).

V. Ferrari, W. Wolf, G. Zepon, F.G. Coury, M.J. Kaufman, C. Bolfarini, C.S. Kiminami, and W.J. Botta, “Effect of boron addition on the solidification sequence and microstructure of AlCoCrFeNi alloys,” J. Alloys Compd., 775, 1235–1243 (2019).

E. Colombini, M. Lassinantti Gualtieri, R. Rosa, F. Tarterini, M. Zadra, A. Casagrande, and P. Veronesi, “SPS-assisted Synthesis of SiCp reinforced high entropy alloys: reactivity of SiC and effects of premechanical alloying and post-annealing treatment,” Powder Metal., 61, No. 1, 64–72 (2018).

W. Luo, Y. Liu, and J. Shen, “Effects of binders on the microstructures and mechanical properties of ultrafine WC–10%AlxCoCrCuFeNi composites by spark plasma sintering,” J. Alloys Compd., 791, 540– 549 (2019).

L. Rogal, D. Kalita, A. Tarasek, P. Bobrowski, and F. Czerwinski, “Effect of SiC nano-particles on microstructure and mechanical properties of the CoCrFeMnNi high entropy alloy,” J. Alloys Compd., 708, 344–352 (2017).

Y.K. Mu, Y.D. Jia, L. Xu, Y.F. Jia, X.H. Tan, J. Yi, G. Wang, and P.K. Liaw, “Nano oxides reinforced high-entropy alloy coatings synthesized by atmospheric plasma spraying,” Mater. Res. Lett., 7, No. 8, 312– 319 (2019).

Y. Peng, W. Zhang, T. Li, M. Zhang, B. Liu, Y. Liu, Li Wang, and S. Hu, “Effect of WC content on microstructures and mechanical properties of FeCoCrNi high-entropy alloy/WC composite coatings by plasma cladding,” Surf. Coat. Technol., 385, 1–9 (2020).

Y.F. Meng, J.P. Zhang, C.Y. Duan, C. Chen, X.M. Feng, and Y.F. Shen, “Microstructures and properties of W–Cu functionally graded composite coatings on copper substrate via high-energy mechanical alloying method,” Adv. Powder Technol., 26, 392–400 (2015).

W. Li, P. Liu, and P.K. Liaw, “Microstructures and properties of high-entropy alloy films and coatings: a review,” Mater. Res. Lett., 6, No. 4, 199–229 (2018).

J.F. Archard, “Contact and rubbing of flat surfaces,” J. Appl. Phys., 24, 981–987 (1953).

Acknowledgement

The Project was supported by the Open Fund for Jiangsu Key Laboratory of Advanced Manufacturing Technology (No. HGAMTL-1710) and China Postdoctoral Science Foundation (2018M632313). The authors gratefully acknowledge these funds.

Author information

Authors and Affiliations

Corresponding author

Additional information

Published in Poroshkova Metallurgiya, Vol. 59, Nos. 7–8 (534), pp. 85–96, 2020.

Rights and permissions

About this article

Cite this article

Chen, K., Wang, T., Wang, X. et al. Effect of Submicron SiC Particles on the Properties of Alcocrfeni High Entropy Alloy Coatings. Powder Metall Met Ceram 59, 424–433 (2020). https://doi.org/10.1007/s11106-020-00176-z

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-020-00176-z