Abstract

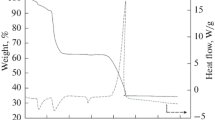

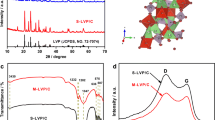

Nanostructured carbon–coated composite cathode materials LiFe0.5Mn0.5PO4/C (LFMP/C) are prepared by the mechanochemically assisted solid-state synthesis using different reagent mixtures and carbon as reducing and covering agent. The effect of the precursors, gas release during the solid-state reaction, and of the intensity of high-energy ball milling on the porous structure and electrochemistry of LFMP/C is studied using DSC/TG/MS, XRD, SEM, TEM, standard contact porosimetry (MSCP), EIS, CV, and GVC. It is shown that the particle size and porosity of LFMP/C strongly depend on the chosen precursors and intensity of mechanical impact. The higher the intensity, the more effective incorporation of carbon black in the pores formed in LFMP, which leads to improved electronic conductivity and better access of the electrolyte to the surface of the electrode, while smaller particles provide improved Li diffusion in the bulk of LFMP. As a result, the cyclability and high-rate performance of the LFMP/C composites are improved.

Similar content being viewed by others

References

Liu PS, Chen GF (2014) General introduction to porous materials. In: porous materials: processing and applications, Butterworth-Heinemann, pp 1-20

Pei Z, Li Z, Zheng X (2016) Porous materials for lithium-ion batteries. J Nanosci Nanotechnol 16(9):9028–9049

Song J, Kim J, Kang T, Kim D (2017) Design of a porous cathode for ultrahigh performance of a Li ion battery: an overlooked pore distribution. Sci Rep 7(1):42521

Vu A, Qian Y, Stein A (2012) Porous electrode materials for lithium-ion batteries – how to prepare them and what makes them special. Adv Energy Mater 2(9):1056–1085

Volfkovich YM, Filippov AN, Bagotsky VS (2014) Structural properties of porous materials and powders used in different fields of science and technology. Springer, London

Tian X, Zhou Y, Wu G, Wang P, Chen J (2017) Controllable synthesis of porous LiFePO4 for tunable electrochemical Li-insertion performance. Electrochim Acta 229:316–324

Tian X, Chen W, Jiang Z, Jiang ZJ (2020) Porous carbon-coated LiFePO4 nanocrystals prepared by in situ plasma-assisted pyrolysis as superior cathode materials for lithium ion batteries. Ionics 26(6):2715–2726

Guo FA, Kong Z, Wang T, Liu X, Xu ZG, Fu A, Li Y, Guo P, Guo YG, Li H (2020) Porous microspheres consisting of carbon-modified LiFePO4 grains prepared by a spray-drying assisted approach using cellulose as carbon source. Ionics 26(6):2737–2746

Zhang X, Hou M, Tamirate AG, Zhu H, Wang C, Xia Y (2020) Carbon coated nano-sized LiMn0.8Fe0.2PO4 porous microsphere cathode material for Li-ion batteries. J Power Sources 448:227438

Kosova N, Devyatkina E (2004) On mechanochemical preparation of materials with enhanced characteristics for lithium batteries. Solid State Ionics 172(1-4):181–184

Bograchev DA, Volfkovich YM, Sosenkin VE, Podgornova OA, Kosova NV (2020) The influence of porous structure on the electrochemical properties of LiFe0.5Mn0.5PO4 cathode materials prepared by mechanochemically assisted solid-stets synthesis. Energies 13:542

Volfkovich YM, Bagotzky VS (1994) The method of standard porosimetry. 2. Investigation of the formation of porous structures. J Power Sources 48(3):339–348

Volfkovich YM, Sakars AV, Volinsky AA (2005) Application of the standard porosimetry method for nanomaterials. Int J Nanotechnol 2(3):292–302

Kosova NV, Devyatkina ET, Slobodyuk AB, Petrov SA (2012) Submicron LiFe1-yMnyPO4 solid solutions prepared by mechanochemically assisted carbothermal reduction: the structure and properties. Electrochim Acta 59:404–411

Kosova NV, Kulova TL, Nikolskaya NF, Podgornova OA, Rychagov AY, Sosenkin VE, Volfkovich YM (2019) Effect of porous structure of LiCoPO4 on its performance in hybrid supercapacitor. J Solid State Electrochem 23(7):1981–1990

Wang K, Hou MY, Yuan SY, Yu HC, Wang YG, Wang CX, Xia YY (2015) An additional discharge plateau of Mn3+ in LiFe0.5Mn0.5PO4 at high current rates. Electrochem Commun 55:6–9

Zhuang H, Bao Y, Nie Y, Qian Y, Deng Y, Chen G (2019) Synergistic effect of composite carbon source and simple pre-calcining process on significantly enhanced electrochemical performance of porous LiFe0.5Mn0.5PO4/C agglomerations. Electrochim Acta 314:102–114

Lecce DD, Hassoun J (2015) Lithium transport properties in LiMn1−αFeαPO4 olivine cathodes. J Phys Chem C 119(36):20855–20863

Yang CC, Chen WH (2016) Microsphere LiFe0.5Mn0.5PO4/C composite as high rate and long-life cathode material for lithium-ion battery. Mater Chem Phys 173:482–490

Dominko R, Goupil JM, Bele M, Gaberscek M, Remskar M, Hanzel D, Jamnik J (2005) Impact of LiFePO4/C composites porosity on their electrochemical performance. J Electrochem Soc 152(5):A858–A863

Pan F, Chen X, Li H, Xin X, Chang Q, Jiang K, Wang WI (2011) Influence of carbon coating porosity on the electrochemical performance of LiFePO4 cathode. Electrochem Commun 13(7):726–729

Acknowledgements

The authors are grateful to Dr. K.B. Gerasimov from ISSMC SB RAS for conducting thermal analysis.

Funding

The work was partially supported by the Russian Foundation for Basic Research (grant no. 19-03-00746).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Fig. S1

Rietveld refined XRD patterns of the LFMP/C samples (PDF 2362 kb)

Rights and permissions

About this article

Cite this article

Kosova, N.V., Podgornova, O.A., Volfkovich, Y.M. et al. Optimization of the cathode porosity via mechanochemical synthesis with carbon black. J Solid State Electrochem 25, 1029–1037 (2021). https://doi.org/10.1007/s10008-020-04877-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10008-020-04877-8