Abstract

Three groups of Romanian acacia honey, i.e., pure, directly adulterated (by mixing the pure honey with three sugar syrups), and indirectly adulterated (by feeding the bees with the same syrups), were characterized and discriminated based on their physicochemical parameters. Moisture, ash, 5-hydroxymethylfurfural (HMF), reducing sugars (fructose and glucose), and sucrose contents, free acidity, diastase activity, ratio between stable carbon isotopes of honey and its proteins (δ13CH and δ13CP) were evaluated. Adulteration led to a significant increase in sucrose content, HMF level, and Δδ13C = δ13CH‒δ13CP as well a decrease in reducing sugar content and diastase activity. Principal component analysis (PCA) and linear discriminant analysis (LDA) were applied to experimental data in order to distinguish between pure and adulterated honey. The most relevant discriminative parameters were diastase activity, HMF, sucrose, and reducing sugar contents. Posterior classification probabilities and classification functions obtained by LDA revealed that 100% of honey samples were correctly assigned to their original group.

Similar content being viewed by others

Introduction

Honey is a natural foodstuff produced by honey bees from flower nectar (blossom honey) as well as from the secretions of all plant parts other than flowers or excretions of sap-sucking insects on the plants (honeydew honey)1. It consists of sugars (70–85%), water (10–20%), and low amounts of other compounds, including proteins (especially enzymes), amino acids, organic acids, phenolic compounds, vitamins, and minerals2,3,4,5,6,7,8,9,10,11,12,13,14,15,16. Monosaccharides (fructose and glucose) represent about 75–95% of sugars, disaccharides (sucrose, maltose, isomaltose, turanose, nigerose, trehalose) about 10–15%, trisaccharides and higher sugars (maltotriose, dextrins, raffinose) up to 2%2,3,5,13,15,17,18,19,20. The bees convert disaccharides and trisaccharides from nectar into monosaccharides, e.g., sucrose into glucose and fructose (in the presence of invertase), maltose and maltotriose into glucose3,5. Moreover, glucose can be converted into gluconic acid and hydrogen peroxide in the presence of glucose oxidase enzyme3,5,13. Honey composition and properties can be heavily influenced by botanical and geographical origin, climate, season, harvesting time, processing and storage conditions. Due to its high price and limited availability, the honey is often subjected to adulteration. It can be made either directly, usually by mixing with different inexpensive sugar syrups (of sugar cane or beet, corn, rice, date, agave, inulin, inverted sugar, glucose, fructose), or indirectly, by feeding the bees with various sugars2,5,7,10,13,14,15,16,19,20,21,22,23,24,25,26,27,28,29,30,31. The demand for authentic and high quality honey has recently increased. In this context, finding the most effective methods to detect honey adulteration is an imperative issue.

Traditionally, honey adulteration is detected by measurements of relevant physicochemical parameters [e.g., moisture, ash, proline, 5-hydroxymethylfurfural (HMF), reducing sugar (RS) and non-reducing sugar (NRS) contents, electrical conductivity, diastase activity (DA), free acidity (FA), pH, rheological parameters]. These targeted analytical techniques, which are generally performed by applying traditional chemistry methods, imply sample preparation to separate a compound/a group of compounds and ulterior treatment to determine its concentration. Advanced methods based on electrochemical analysis, flow injection analysis, biosensors (e.g., e-tongue, e-nose), differential scanning calorimetry, gas and liquid chromatography (GC-FID, HPLC), mass spectrometry (GC–MS, LC–MS, IRMS), NMR and infrared (NIR, FT-IR, and Raman) spectroscopy have been developed during the last three decades for the detection of honey adulterants7,10,13,14,15,16,19,20,21,22,23,24,26,27,29,30,31,32,33. Each method used to detect the adulteration has its specific advantages and limitations. Traditional physicochemical analysis methods have commonly high sensitivity and selectivity. They are frequently used in the honey trade, although some of them are relatively time-consuming and require complex equipment. Non-targeted methods based on NMR spectroscopy involve high sensitivity and reproducibility, but substantial capital, operational, and maintenance costs. Techniques based on infrared spectroscopy are simple, fast, non-destructive, and relatively inexpensive, but large datasets are needed to obtain accurate results. Methods implying gas and liquid chromatography are able to detect adulteration by determining the profiles of sugars, amino acids, phenolics, and flavonoids, but they are generally time-consuming, expensive, and require skilled operators. However, there is an advanced technique, i.e., isotope ratio mass spectrometry (IRMS), that overcomes the common limitations of advanced methods and it is used as a reference technique to detect the addition of sugar syrups13,15,19,21,22,23,24,26,29,31,32. The ratio between stable carbon isotopes for a sample (of plant, honey, or honey extracted proteins), Rsample = (13C/12C)sample, is determined using a mass spectrometer and expressed depending on an internal standard (st), commonly Vienna Pee Dee Belemnite (VPDB), as δ13C (‰) defined by Eq. (1). A negative value of δ13C indicates that the sample is depleted in heavy isotope (13C), whereas a positive value shows that the sample is enriched in 13C relative to the standard. The ratio of heavy and light carbon isotopes for VPDB is Rst = (13C/12C)st = 0.0112372. The values of δ13C for C4 plants (that fixate CO2 into 4-carbon compounds via the Hatch-Slack photosynthetic cycle) are in the range of − 20 ÷ − 10‰, whereas those for C3 plants (that use the Calvin–Benson–Bassham cycle to fixate CO2 into 3-carbon compounds) are of − 33 ÷ − 21‰13,15,21,29,31,32. C3 plants, which represent about 85% of plant species, are the main nectar source for bees. An adulteration is suspected if the difference between the value of δ13C for honey and that for its extracted proteins, Δδ13C = δ13CH–δ13CP, is not in the range [‒1, 1]13,15,31. IRMS method is useful in detecting the adulteration of honey with sugar syrups derived from C4-plants, e.g., sugar cane, corn, but it fails to detect the adulteration with those obtained from C3-plants, e.g., sugar beet. Morever, there is some concern about the precision and accuracy of this technique. IRMS method coupled with targeted physicochemical analysis methods and chemometrics (multivariate data analysis) can be a very effective alternative to discriminate between pure and adulterated honey.

Principal component analysis (PCA) and linear discriminant analysis (LDA) are dimensionality reduction techniques which are widely applied to characterize and classify food4,8,9,10,11,13,15,16,18,22,23,25,26,30,33,34,35,36. PCA, an unsupervised approach, aims at finding a lower dimensional space, while retaining as much variability as possible. New variables [principal components (PCs)], which are linear functions of independent variables in the original data set, are defined by determining the eigenvectors and eigenvalues of data covariance matrix. The eigenvector with the highest eigenvalue represents the direction of largest variation, the one with the second highest eigenvalue is the orthogonal direction with the next largest variation, and so forth. PCA allows visualization of data structure and identification of possible data groups. Accordingly, it is often used prior to LDA, a supervised approach which considers predefined groups15,18,25. Linear discriminant (LD) and classification functions are obtained by applying LDA technique to multivariate data sets. LD functions highlight the differences among the groups by maximizing the between-group variance and minimizing the within-group variance, whereas classifications functions determine to which predefined group each sample can be assigned15,18,25,35,37.

Romania is an important honey producer and exporter in Europe with an annual output over 20,000 t in recent years, of which about half is exported25. Acacia, lime, rape, sunflower, and polyfloral are the most common Romanian honey types6,18,25,38. This paper has aimed at evaluating the ability of physicochemical analysis methods specified in the national standard coupled with IRMS technique and chemometrics to discriminate between pure and adulterated Romanian acacia honey. Adulteration was performed directly, by mixing pure acacia honey with 3 different sugar syrups, as well as indirectly, by feeding the bees with the same syrups. In order to distinguish between pure, directly and indirectly adulterated honey, PCA and LDA were applied to experimental results in terms of moisture, ash, HMF, RS (fructose and glucose), and NRS (sucrose) contents, FA, DA, and Δδ13C = δ13CH–δ13CP. There are no studies in the related literature on the detection of Romanian honey adulteration by bee-feeding based on physicochemical analysis methods and IRMS technique.

Materials and methods

Honey samples

The research was developed in collaboration with a beekeeper from Vâlcea county of Romania, who agreed to participate to the study with 12 hives (H1–H12), each of them containing 3 colonies of Apis mellifera carpatica. Three acacia honey types were prepared and analyzed, i.e., authentic or pure (P), indirectly (I) adulterated by bee-feeding with sugar syrups, and directly (D) adulterated by mixing P honey with the same syrups. Three types of industrial syrups (S1–S3 in Table 1), which are commonly employed for bee-feeding, were used for adulterating.

Data on the experiments performed to obtain pure and adulterated honey are summarized in Table 2. P honey was produced in 3 hives (H1–H3) without bee-feeding with sugar syrups, whereas I adulterated honey was obtained in 9 hives (H4–H12) as follows: H4–H6 hives were fed with S1, H7–H9 with S2, and H10–H12 with S3. 1 L of sugar syrup was fed in each hive (H4–H12) once every 3 days, between April 1st and May 5th, 2017. Honey was collected from each hive according to Romanian standard SR 784-139 and following an “average-taking” protocol22. D adulterated honey was prepared by mixing P honey with S1–S3 syrups (1/1 mass ratio). According to data presented in Table 2, 23 samples of honey were physicochemically analyzed. Prior to analysis, all samples were homogenized for 10 min using a mixer.

Physicochemical analysis

Physicochemical parameters in terms of moisture content, ash content, FA, RS content, sucrose content, DA, and HMF content were determined based on Romanian standard SR 784-340. This standard was harmonized with Official methods of analysis of Association of Official Analytical Chemists (AOAC)41 and Harmonized methods of the European honey commission42.

Moisture content was measured at 20 °C with an Atago Digital Refractometer RX-5000i (Atago, USA). Ash content was evaluated as follows: a honey sample (5 g) was desiccated in a platinum dish, kept in a thermostat at 80 °C for 4 h, and further calcined at 550 °C in a laboratory furnace (Nabertherm, Germany). FA was determined by the titrimetric method, i.e.: 10 g of honey sample was dissolved in 75 mL of CO2-free water in a 250 mL beaker. The solution was magnetically stirred and titrated to pH 8.3 by adding 0.05 N NaOH solution. The pH was measured using a Mettler Toledo SevenMulti pH meter S40 (Mettler Toledo, Canada). RS were evaluated by reducing Soxhlet’s modification of Fehling’s solution by titration at boiling point against a solution of reducing sugars in honey in the presence of methylene blue as indicator. The difference in concentrations of invert sugar before and after the hydrolysis was multiplied by 0.95 to obtain the apparent sucrose content. DA was evaluated using a buffered solution of honey and soluble starch incubated at 40 °C. 1 mL volumes of this solution were taken at regular intervals (5 min) and their absorbance was measured at 660 nm in a Perkin Elmer Luminescence Spectrophotometer LS-50B (Perkin Elmer, UK). For HMF determination, 5 g of honey sample was mixed with 25 mL distilled water. After clarifying with Carrez reagents (I and II), the solution was diluted to 100 mL with distilled water. Absorbance of this clarified solution was measured at 284 and 336 nm in a Perkin Elmer Luminescence Spectrophotometer LS-50B (Perkin Elmer, UK) using as a reference the same solution containing 0.2% (m/v) sodium bisulphate.

The analysis of 13C/12C stable isotope ratio for honey and protein fraction extracted from honey was carried out according to the Official Methods of Analysis 998.1243. The values of 13C/12C ratio were determined using a Thermo Scientific FlashEA 1112 HT elemental analyzer (EA) coupled to a Delta V Continuous Flow Isotope Ratio Mass Spectrometer (CF-IRMS) (Thermo Fisher Scientific, Waltham, MA, USA) and expressed depending on PDB internal standard as δ13CH and δ13CP. The proteins extraction involved mixing 10–12 g of honey sample with 4 mL of distilled water in a 50 mL centrifuge tube. After addition of 2 mL of 2/3 N sulphuric acid and 2 mL of 10% sodium tungstate solutions, the tube was heated to 80 °C until protein precipitated. The supernatant was removed after centrifuging and rinsing with 50 mL of distilled water. After drying in an oven (75 °C) for 6 h, the protein sample (200 μg) was placed into a tin capsule for analysis.

All reagents used for physicochemical analyzes were analytical grade and were purchased from Merck (Darmstadt, Germany).

Statistical analysis

Univariate (one-way ANOVA) and multivariate (PCA and LDA) analyzes of physicochemical parameters were performed using Statistica 10 (StatSoft, Inc) and XLSTAT 2019.1 (Excel). A standardized data matrix with 23 rows (number of samples) and 8 columns (number of physicochemical parameters), containing autoscaled variable values, was used in PCA. In order to obtain a correct predictive classification, in LDA the samples were divided based on a selection algorithm into a training set consisting of 16 samples and a validation set containing 7 samples (one sample of each honey type, i.e., P, D1–D3, I1–I3). Accordingly, a data matrix with 16 rows and 8 columns was used to select the predictors with higher discriminative power and to build linear discriminant functions and classification functions, whereas a data matrix with 7 rows and 8 columns was used to validate the models. Raw data entered the multivariate analysis and these data were autoscaled by the software. LDA was applied using forward stepwise (FS) method (8 steps, tolerance value = 0.01, F to enter value = 1, F to remove value = 0) and considering P, D, and I honey as predefined groups. In FS setting, the variables entered into the discriminant function model one by one and only the variables which contributed significantly to the discrimination between groups (with low levels of partial Wilks’ Lambda and large F values, respectively) were selected. At each step, the multiple correlation (R2) for each variable with all other variables included in the model was calculated. Tolerance value of a variable, which is a measure of its redundancy, was determined as 1 − R2.

Results and discussions

Experimental results

Table 3 contains mean, standard deviation, and variation range of characteristic physicochemical parameters of pure and adulterated honey (23 samples). Characteristic value of moisture, ash, RS, sucrose, and HMF contents, FA, and DA were compared with limit levels specified in the national standard SR 784-340, whereas the values of δ13CH, δ13CP, and Δδ13C = δ13CH‒δ13CP were compared with those reported in the related literature15,19,21,23,24,26,29,31,32.

Moisture content is a relevant parameter as it affects the viscosity, density, taste, flavour, colour, crystallization, and fermentation of honey2,5,17,32. A high water content can accelerate the crystallization as well as produce fermentation during the storage2,6,12,17,32. It is observed that only I1 and D1 samples contain more moisture than the regulated limit (max. 20%). The mean values of moisture content for I (18.8%) and D (19.2%) samples are similar and higher than the mean value of P samples (16.8%).

Ash or mineral content is an indicator affecting the colour and flavour of honey. Usually, the higher the ash content, the darker the colour and the stronger the flavour5. The mean values of ash content for P (0.0081%), I (0.0113%), and D (0.0047%) samples are much lower than the imposed limit (max. 0.5%). There were no differences in colour and flavour among the samples.

FA is mainly due to the presence of organic acids in equilibrium with lactones or internal esters and inorganic ions, e.g., chloride, sulphate, phosphate, and it can heavily influence the honey taste2,5,7,17,28. An increase in FA can occur over time as effect of acid formation (e.g., gluconic acid from glucose, formic and levulinic acids from HMF) as well as in the case of fermentation (by producing acetic acid from ethylic alcohol resulted in the fermentation process in the presence of honey yeasts)5,12. All samples have values of FA much lower than the regulated limit (max. 40 meq/kg). The mean values of FA for I (5.5 meq/kg) and D (5.0 meq/kg) samples are similar and about 7 times higher than the mean value of P samples (0.75 meq/kg).

All adulterated samples have values of sucrose content higher than the regulated limit (max. 5%). The mean value of sucrose content for I samples (9.71%) is higher than those of D and P samples (6.38% and 3.79%). On the other hand, all adulterated samples have values of RS (fructose and glucose) content lower than the imposed limit (min. 70%). The mean value of RS content for I samples (63.3%) is lower than those of D and P samples (65.9% and 70.5%). Accordingly, the honey samples adulterated by bee-feeding contain more sucrose which has not been converted to fructose and glucose.

DA and HMF content are indicators of honey freshness. A high quality honey is characterized by high values of DA and low level of HMF. In the case of heating or storage for a long time, DA decreases and HMF content increases (HMF can be produced by fructose and glucose decomposition)5,12,26,32. Moreover, a higher value of HMF content can indicate an adulteration with inverted sugar syrup, because HMF can be formed by heating sucrose solutions to obtain inverted syrup, whereas a low level of DA can be an effect of an indirect adulteration5. All adulterated samples have values of HMF content higher and of DA lower than the regulated limits (max. 15 mg/kg and min. 6.5 Gothe units/g). The mean value of HMF content for I samples (29.9 mg/kg) is higher than those of D and P samples (21.2 mg/kg and 1.21 mg/kg), whereas the mean value of DA for I samples (5 Gothe units/g) is lower than those of D and P samples (6.5 Gothe units/g and 13.9 Gothe units/g).

The values of δ13CH and δ13CP (− 24.4 ÷ − 23.0 and − 24.8 ÷ − 23.5 for P, − 26.5 ÷ − 12.3 and − 30.0 ÷ − 19.6 for I, − 25.0 ÷ − 17.0 and − 28.3 ÷ − 24.4 for D honey) are within the ranges reported by other researchers15,19,21,23,24,26,29,31,32. Levels of Δδ13C = δ13CH–δ13CP for I and D samples (3.4 ÷ 11.6 and 3.0 ÷ 8.5) are more than 5 times higher than those for P samples (0.4 ÷ 0.6). These results indicate that P honey is pure (values of Δδ13C are in the range [− 1, 1]), whereas I and D samples are adulterated.

The data summarized in Table 3 highlight that some physicochemical parameters of adulterated honey are within the limit levels specified in the national standard. Consequently, only checking these parameters is not sufficient to detect the adulteration. Physicochemical analysis methods coupled with chemometrics could be an effective alternative to discriminate between pure and adulterated honey.

Statistical analysis

One-way ANOVA was used to determine the effect of honey type, i.e., pure (P), directly adulterated (D1–D3), and indirectly adulterated (I1-I3), on the physicochemical parameters considered in the experimental research. Data summarized in Supplementary Table S1 (Fcr = 2.741, F ≥ 52.5, and p value ≤ 1.2 × 10–9) reveal that the influence of honey type on all physicochemical parameters is statistically significant.

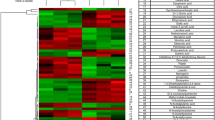

PCA and LDA were applied to discriminate between pure and adulterated honey samples based on their physicochemical parameters (independent variables or predictors). Eight independent variables were considered in the multivariate analysis, i.e., moisture, ash, RS, sucrose, and HMF contents, FA, DA, and Δδ13C.

PCA results referring to eigenvalues, explained variance of principal components (PCs), and factor (PC) coordinates of variables are presented in Supplementary Tables S2 and S3. Tabulated data highlight that the eigenvalues corresponding to PC1 (4.32), PC2 (1.78), and PC3 (1.32) are greater than 1 and these first three PCs explain 92.8% (54.0% + 22.3% + 16.5%) of the total variance. Depending on their coordinates in the first three PCs (factor loadings), the most important variables are as follows: (i) DA (0.99), HMF content (− 0.91), FA (− 0.91), Δδ13C (lv = − 0.73), RS content (0.69), and sucrose content (− 0.68) for PC1, (ii) moisture content (0.71) for PC2, and (iii) ash content (0.70) for PC3.

Only PC1 and PC2 were retained in the analysis, because the cumulative percentage of total variance explained by them (76.3%) was higher than 70%16. Projections of variables and cases (honey samples) on the factor-plane PC1–PC2 are shown in Fig. 1. Based on the sign and magnitude of factor loadings, PC1 can discriminate between pure honey samples with high values of DA and RS content along with low levels of FA, Δδ13C, HMF and sucrose contents and adulterated samples. Projections of cases on the factor-plane PC1–PC2 highlight a good discrimination between P, D, and I honey groups on the PC1 direction. PC1 coordinates of P samples (3.5 ÷ 3.9) correspond to higher values of DA (13.6 ÷ 14.2 Gothe units/g) and RS content (68.7 ÷ 72.5%) along with lower levels of FA (0.75 ÷ 0.77 meq/kg), Δδ13C (0.4 ÷ 0.6‰), HMF content (1.18 ÷ 1.25 mg/kg), and sucrose content (3.75 ÷ 3.85%). Concurrently, PC1 coordinates of D1–D3 samples (− 0.6 ÷ 0) and I1–I3 samples (− 1.9 ÷ − 1.4) correspond to lower values of DA (6.30 ÷ 6.53 and 4.94 ÷ 5.11 Gothe units/g) and RS content (64.8 ÷ 67.2 and 57.5 ÷ 67.3%) as well as to higher levels of FA (4.8 ÷ 5.2 and 3.9 ÷ 6.6 meq/kg), Δδ13C (3 ÷ 8.5 and 3.4 ÷ 11.6‰), HMF content (18.3 ÷ 25.2 and 22.9 ÷ 41.3 mg/kg), and sucrose content (6.08 ÷ 6.74 and 6.76 ÷ 15%). On the other hand, PC2 can discriminate between the samples adulterated with S1 syrup (with PC2 coordinates of 2.1 ÷ 2.3 for I1 and 1.2 ÷ 1.5 for D1 samples), having high values of moisture content (21.9 ÷ 22.6% and 20.6 ÷ 21.1%, respectively) and those adulterated with S2 and S3 syrups (with PC2 coordinates of − 2.5 ÷ 0.5), which had lower levels of moisture content (15.9 ÷ 20.1%). Accordingly, PC1 is mostly related to the adulteration and PC2 to the type of syrup used to adulterate the honey. It appears in the bi-plot (Fig. 1) that the separation on PC1 direction is comparable in magnitude to that on PC2 direction. However, it must be considered that PC1 accounts for 54.0% of the total variance, while PC2 only 22.3%.

LDA was applied to obtain the variables with higher discriminative power and their corresponding discriminant and classification functions. The most important discriminative physicochemical parameters determined by FS method were DA, HMF, sucrose, and RS contents. Accordingly, only these parameters were further taken into account to determine discriminant and classification functions. The first linear discriminant (LD1) function explains 98.7% of the discriminative power, whereas the second (LD2) accounts for 1.3%, the eigenvalues corresponding to LD1 and LD2 functions being of 785.23 and 10.04, respectively. Values of standardized linear discriminant function coefficients and factor structure coefficients (factor loadings) are summarized in Table 4. Standardized discriminant function coefficients represent partial (corrected for the other predictors) contribution of each predictor to the discriminant function score, whereas structure coefficients denote the simple correlations (not corrected for the other predictors) between predictors and discriminant functions scores. Tabulated data on standardized coefficients highlight that LD1 function is negatively correlated with RS content, positively correlated with DA, sucrose and HMF contents, and DA has the most significant effect. On the contrary, LD2 function is positively correlated with RS content, negatively correlated with DA, sucrose and HMF contents, and DA has an insignificant effect. Both types of coefficients indicate that DA and sucrose content had the largest contribution to the discrimination by LD1 and LD2, respectively.

Projections of training honey samples on the factor-plane LD1–LD2 are presented in Fig. 2. P honey samples are plotted much further to the right in the scatterplot than D and I ones, LD1 scores being as follows: 41.58 ÷ 45.12 for P, − 11.44 ÷ − 9.49 for D, and − 19.03 ÷ − 17.22 for I samples. Accordingly, LD1 function separates all three honey classes (groups). Taking into account the factor loadings represented in LDA bi-plot (Fig. 2), LD1 function mostly discriminates between pure and adulterated honey, the most discriminative predictor being DA (13.6 ÷ 14.2, 6.30 ÷ 6.53, and 4.94 ÷ 5.11 Gothe units/g for P, D, and I honey classes). On the other hand, LD2 function discriminates between D and I honey types (LD2 scores of 1.67 ÷ 5.54 for D and − 3.63 ÷ − 2.56 for I samples), the most discriminative predictor being sucrose content (6.08 ÷ 6.74% for D and 6.76 ÷ 15% for I). LD1 function accounts for 98.7% of the discriminative power, consequently the most significant discrimination is possible for all three honey types by this function. Mean values of factor scores for each group (centroids) and 95% confidence ellipses for training set as well as projections of validation honey samples on the factor-plane LD1–LD2 are also shown in Fig. 2. It is observed that all points corresponding to LD1 and LD2 scores for validation set are included in the ellipses corresponding to their group.

Honey samples (cases) were classified into the group to which they were closest. Mahalanobis distances between each case and the group centroids were calculated. According to Bayes rule, the probability that a case belongs to a group, i.e., posterior classification probability (PP), was determined depending on squared Mahalanobis distance (SMD) and a priori classification probability (APP). APP values were assumed to be proportional to the number of samples in each group (APPP = 0.25, APPD = 0.375, and APPI = 0.375). A case can be classified based on largest value of PP. Prior and posterior classification and levels of SMD and PP for training (T) and validation (V) sets are summarized in Supplementary Table S4.

Moreover, linear classification functions based on linear discriminant functions were determined for each honey group. Table 5 contains characteristic coefficients of classification functions, i.e., cij and cj, where i and j denote independent variable and group, respectively. These linear classification functions can be used directly to classify cases, i.e., a case is assigned to the group for which it has the highest value of classification function score (CFS). Values of CFS determined from raw data for both T and V sets are also summarized in Supplementary Table S4. Classification (confusion) matrices presented in Supplementary Table S5 reveal that 100% of honey samples were correctly assigned to their original group for both T and V sets.

Conclusions

The paper aimed at measuring various physicochemical parameters of honey samples and discriminating the pure and adulterated honey based on these parameters using PCA and LDA as chemometric tools. Acacia pure (P) and indirectly (I) adulterated honey, obtained by bee-feeding with 3 different industrial sugar syrups, were produced in a small apiary in the Vâlcea county of Romania, whereas directly (D) adulterated honey was prepared by mixing P honey with the same syrups. Honey samples were analysed in terms of moisture, ash, HMF, RS (glucose and glucose), and sucrose contents, FA, DA, δ13CH, and δ13CP.

Adulteration led to an increase in water content (by about 10%), FA (about 7 times), sucrose content (2.6 and 1.7 times for I and D samples, respectively), HMF content (about 25 and 18 times for I and D samples, respectively), and Δδ13C = δ13CH‒δ13CP (about 17 and 15 times for I and D samples, respectively) as well a decrease in RS content (by about 10%) and DA (2.8 and 2.1 times for I and D samples, respectively) than the mean value of P samples. For the types and dosage of sugar syrups used in this study, indirect adulteration had effects similar to those produced by direct adulteration. The values of DA, HMF, sucrose, and RS contents for D and I honey samples were not within the ranges imposed by the national standard.

Moisture, ash, RS, sucrose, and HMF contents, FA, DA, and Δδ13C, were the physicochemical parameters considered in the multivariate analysis. According to PCA, the 8-dimensional feature space was reduced to a 2-dimensional one, where the directions of new axes were defined by PC1 and PC2 eigenvectors. PC1, explaining 54.0% of total variance, was dominated by DA, HMF content, FA, Δδ13C, RS and sucrose contents, whereas PC2, accounting for 22.3% of total variance, was dominated by moisture content. Three well separated honey groups (P, D, and I) on the PC1 direction were obtained by projecting the honey samples on the factor-plane PC1–PC2. Starting from these predefined groups, forward stepwise LDA revealed that the most important discriminative physicochemical parameters were DA, HMF, sucrose, and RS contents. Linear discriminant functions and classification functions were built based on a training dataset and then these models were validated using a validation dataset. Cases were classified based on the largest values of posterior classification probability and classification function score. Characteristic confusion matrices of both training and validation sets indicated that 100% of honey samples were correctly assigned to their original group. Accordingly, the evaluation of physicochemical parameters using PCA and LDA was very effective to discriminate between pure, directly and indirectly adulterated honey. Based on the physicochemical parameters in terms of DA, HMF, sucrose, and RS contents, any sample of acacia honey could be simply and quickly classified as pure, directly or indirectly adulterated by means of classification functions obtained by applying LDA. However, the study has some limitations, e.g., a small number of acacia honey samples, a relative similarity of them (all coming from the same producer and being produced within the same few months). The analysis could be extended using numerous samples of different types of honey collected from several producers over a longer period.

References

Codex Alimentarius Commission. Codex Standard for honey. CODEX STAN 12-1981. Food and Agriculture Organization of the United Nations and the World health Organization. Rome, Italy (2001).

Al-Farsi, M. et al. Quality evaluation of Omani honey. Food Chem. 262, 162–167. https://doi.org/10.1016/j.foodchem.2018.04.104 (2018).

Ball, D. W. The chemical composition of honey. J. Chem. Educ. 84(10), 1643–1646. https://doi.org/10.1021/ed084p1643 (2007).

Conti, M. E., Canepari, S., Finoia, M. G., Mele, G. & Astolfi, M. L. Characterization of Italian multifloral honeys on the basis of their mineral content and some typical quality parameters. J. Food Compos. Anal. 74, 102–113. https://doi.org/10.1016/j.jfca.2018.09.002 (2018).

Da Silva, P. M., Gauche, C., Gonzaga, L. V., Costa, A. C. O. & Fett, R. Honey: Chemical composition, stability and authenticity. Food Chem. 196, 309–323. https://doi.org/10.1016/j.foodchem.2015.09.051 (2016).

Mărghitaș, L. A. et al. Physicochemical and bioactive properties of different floral origin honeys from Romania. Food Chem. 112, 863–867. https://doi.org/10.1016/j.foodchem.2008.06.055 (2009).

Naila, A., Flint, S. H., Sulaiman, A. Z., Ajit, A. & Weeds, Z. Classical and novel approaches to the analysis of honey and detection of adulterants. Food Control 90, 152–165. https://doi.org/10.1016/j.foodcont.2018.02.027 (2018).

Nayik, G. A. & Nanda, V. Physico-chemical, enzymatic, mineral and colour characterization of three different, varieties of honeys from Kashmir valley of India with a multivariate approach. Pol. J. Food Nutr. Sci. 65(2), 101–108. https://doi.org/10.1515/pjfns-2015-0022 (2015).

Nayik, G. A., Suhag, Y., Majid, I. & Nanda, V. Discrimination of high altitude Indian honey by chemometric approach according to their antioxidant properties and macro minerals. J. Saudi Soc. Agric. Sci. 17, 200–207. https://doi.org/10.1016/j.jssas.2016.04.004 (2018).

Oroian, M., Ropciuc, S., Paduret, S. & Todosi, E. Rheological analysis of honeydew honey adulterated with glucose, fructose, inverted sugar, hydrolysed inulin syrup and malt wort. LWT Food Sci. Technol. 95, 1–8. https://doi.org/10.1016/j.lwt.2018.04.064 (2018).

Pascual-Mate, A. et al. Sugar composition and sugar-related parameters of honeys from the northern Iberian Plateau. J. Food Compos. Anal. 74, 34–43. https://doi.org/10.1016/j.jfca.2018.08.005 (2018).

Saxena, S., Gautam, S. & Sharma, A. Physical, biochemical and antioxidant properties of some Indian honeys. Food Chem. 118, 391–397. https://doi.org/10.1016/j.foodchem.2009.05.001 (2010).

Se, K. W., Wahab, R. A., Syed Yaacob, S. N. & Ghoshal, S. K. Detection techniques for adulterants in honey: Challenges and recent trends. J. Food Compos. Anal. 80, 16–32. https://doi.org/10.1016/j.jfca.2019.04.001 (2019).

Siddiqui, A. J., Musharraf, S. G., Choudhary, M. I. & Rahman, A. U. Application of analytical methods in authentication and adulteration of honey. Food Chem. 217, 687–698. https://doi.org/10.1016/j.foodchem.2016.09.001 (2017).

Wu, L. et al. Recent advancements in detecting sugar-based adulterants in honey—A challenge. Trends Anal. Chem. 86, 25–38. https://doi.org/10.1016/j.trac.2016.10.013 (2017).

Yilmaz, M. T. et al. Steady, dynamic and creep rheological analysis as a novel approach to detect honey adulteration by fructose and saccharose syrups: Correlations with HPLC-RID results. Food Res. Int. 64, 634–646. https://doi.org/10.1016/j.foodres.2014.07.009 (2014).

Gomes, S., Dias, L. G., Moreira, L. L., Rodrigues, P. & Estevinho, L. Physicochemical, microbiological and antimicrobial properties of commercial honeys from Portugal. Food Chem. Toxicol. 48, 544–548. https://doi.org/10.1016/j.fct.2009.11.029 (2010).

Isopescu, R. D. et al. Characterization of Romanian honey based on physico-chemical properties. Revista de chimie (Bucharest) 65(4), 381–385, http://www.revistadechimie.ro/pdf/ISOPESCU%20R.pdf%204%2014.pdf (2014).

Simsek, A., Bilsel, M. & Goren, A. C. 13C/12C pattern of honey from Turkey and determination of adulteration in commercially available honey samples using EA-IRMS. Food Chem. 130, 1115–1121. https://doi.org/10.1016/j.foodchem.2011.08.017 (2012).

Wang, S. et al. Detection of honey adulteration with starch syrup by high performance liquid chromatography. Food Chem. 172, 669–674. https://doi.org/10.1016/j.foodchem.2014.09.044 (2015).

Çinar, S. B., Ekşi, A. & Coşkun, İ. Carbon isotope ratio (13C/12C) of pine honey and detection of HFCS adulteration. Food Chem. 157, 10–13. https://doi.org/10.1016/j.foodchem.2014.02.006 (2014).

Cordella, C., Militão, J. S. L. T., Clément, M. C., Drajnudel, P. & Cabrol-Bass, D. Detection and quantification of honey adulteration via direct incorporation of sugar syrups or bee-feeding: Preliminary study using high-performance anion exchange chromatography with pulsed amperometric detection (HPAEC-PAD) and chemometrics. Anal. Chim. Acta 531, 239–248. https://doi.org/10.1016/j.aca.2004.10.018 (2005).

Guler, A., Bakan, A., Nisbet, C. & Yavuz, O. Determination of important biochemical properties of honey to discriminate pure and adulterated honey with sucrose (Saccharum officinarum L.) syrup. Food Chem. 105, 1119–1125. https://doi.org/10.1016/j.foodchem.2007.02.024 (2007).

Guler, A. et al. Detection of adulterated honey produced by honeybee (Apis mellifera L.) colonies fed with different levels of commercial industrial sugar (C3 and C4 plants) syrups by the carbon isotope ratio analysis. Food Chem. 155, 155–160. https://doi.org/10.1016/j.foodchem.2014.01.033 (2014).

Isopescu, R. D., Josceanu, A. M., Colta, T. & Spulber, R. Romanian Honey: Characterization and Classification, Honey Analysis Vagner de Alencar Arnaut de Toledo, IntechOpen. https://www.intechopen.com/books/honey-analysis/romanian-honey-characterization-and-classification (2017).

Kukurová, K., Karovičová, J., Kohajdová, Z. & Bíliková, K. Authentication of honey by multivariate analysis of its physico-chemical parameters. J. Food Nutr. Res. 47(4), 170–180, http://www.vup.sk/en/download.php?bulID=84 (2008).

Li, S., Shan, Y., Zhu, X., Zhang, X. & Ling, G. Detection of honey adulteration by high fructose corn syrup and maltose syrup using Raman spectroscopy. J. Food Compos. Anal. 28, 69–74. https://doi.org/10.1016/j.jfca.2012.07.006 (2012).

Özcan, M., Arslan, D. & Ceylan, D. A. Effect of inverted saccharose on some properties of honey. Food Chem. 99, 24–29. https://doi.org/10.1016/j.foodchem.2005.07.009 (2006).

Padovan, G. J., De Jong, D., Rodrigues, L. P. & Marchini, J. S. Detection of adulteration of commercial honey samples by the 13C/12C isotopic ratio. Food Chem. 82, 633–636. https://doi.org/10.1016/S0308-8146(02)00504-6 (2003).

Sobrino-Gregorio, L., Bataller, R., Soto, J. & Escriche, I. Monitoring honey adulteration with sugar syrups using an automatic pulse voltammetric electronic tongue. Food Control 91(254–260), 2018. https://doi.org/10.1016/j.foodcont.2018.04.003 (2018).

Tosun, M. Detection of adulteration in honey samples added various sugar syrups with 13C/12C isotope ratio analysis method. Food Chem. 138, 1629–1632. https://doi.org/10.1016/j.foodchem.2012.11.068 (2013).

Cengiz, M. M., Tosun, M. & Topal, M. Determination of the physicochemical properties and 13C/12C isotope ratios of some honeys from the northeast Anatolia region of Turkey. J. Food Compos. Anal. 69, 39–44. https://doi.org/10.1016/j.jfca.2018.02.007 (2018).

Wang, J. et al. Identification of acacia honey adulteration with rape honey using liquid chromatography–electrochemical detection and chemometrics. Food Anal. Methods 7, 2003–2012. https://doi.org/10.1007/s12161-014-9833-7 (2014).

Hanganu, A., Todașcă, M. C., Chira, N. A., Maganu, M. & Roșca, S. The compositional characterisation of Romanian grape seed oils using spectroscopic methods. Food Chem. 134, 2453–2458. https://doi.org/10.1016/j.foodchem.2012.04.048 (2012).

Rios, F. et al. A chemometric approach: Characterization of quality and authenticity of artisanal honeys from Argentina. J. Chemometr. 28, 834–843. https://doi.org/10.1002/cem.2654 (2014).

Tociu, M., Todașcă, M. C., Bratu, A., Mihalache, M. & Manolache, F. Fast approach for fatty acid profiling of dairy products fats using 1H-NMR spectroscopy. Int. Dairy J. 83, 52–57. https://doi.org/10.1016/j.idairyj.2018.03.005 (2018).

Tharwat, A., Gaber, T., Ibrahim, A. & Hassanien, A. E. Linear discriminant analysis: A detailed tutorial. AI Commun. 30(2), 169–190, https://www.researchgate.net/publication/316994943_Linear_discriminant_analysis_A_detailed_tutorial (2017).

Stoica-Guzun, A., Dobre, L. M., Stroescu, M. & Dobre, T. Rheology of some selected Romanian honey. Bull. Roman. Chem. Eng. Soc. 2(1), 36–44, http://sicr.ro/wp-content/uploads/2015/07/BRChES_vol.2_nr.1_2015.pdf (2015).

SR 784-1 Honey. Requirements for producers (2009).

SR 784-3 Honey. Analysis methods (2009).

AOAC. Official methods of analysis, 15th ed. In (ed. Helrich, K) (Association of Official Analytical Chemists, Inc., Arlington, 1990) https://law.resource.org/pub/us/cfr/ibr/002/aoac.methods.1.1990.pdf.

Bogdanov, S., Martin, P. & Lüllmann, C. Harmonised methods of the European honey commission. Apidologie, extra issue, 1–59, http://www.apis.admin.ch/host/doc/pdfhoney/IHCmethods_e.pdf (1997).

AOAC official method 998.12. C-4 plant sugars in honey. Internal standard stable carbon isotope ratio method. 44.4.18A, http://files.foodmate.com/2013/files_2709.html (2005).

Author information

Authors and Affiliations

Contributions

M.E.C. conceived the experiments, performed the physicochemical analyzes, and contributed to the conception of article; O.C.P. had a substantial contribution to the conception of article, statistical analysis, and interpretation of results; A.C.D. performed the physicochemical analyzes; T.D. and D.R.S. analyzed the results. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Crăciun, M.E., Pârvulescu, O.C., Donise, A.C. et al. Characterization and classification of Romanian acacia honey based on its physicochemical parameters and chemometrics. Sci Rep 10, 20690 (2020). https://doi.org/10.1038/s41598-020-77685-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-020-77685-9

This article is cited by

-

Effects of apitherapy against salivary gland disorder after radioactive iodine therapy for differentiated thyroid cancer

Annals of Nuclear Medicine (2023)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.