Abstract

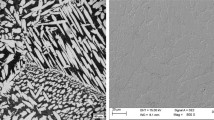

Electrochemical studies and microstructure analysis of directionally solidified hypoeutectic and eutectic aluminum-copper alloys were performed. Optical and scanning electron microscopy studies of corroded specimens with columnar and equiaxed microstructures in 0.1 M, 0.5 M, and 1 M NaCl solutions were conducted. Low-rate potential scanning and alternating current (AC) electrode impedance measurements were conducted to study the corrosion resistance of four aluminum-copper alloys. The concentration of Cu in the alloys proved to be a key factor in the corrosion resistance of the Al-Cu alloys, which controlled the fraction of α and θ phases and the morphological distribution of these phases. The addition of Cu provides cathodic sites that increase adjacent anodic activity and higher corrosion susceptibility of the Al-Cu alloys, as compared with pure Al. Arise in the Cu amount that is linked to an increased concentration of the Al2Cu intermetallic or theta phase results in a higher susceptibility to corrosion for the studied alloys. A microstructural morphology related to a decreased area of contact between the α-phase and the Al2Cu intermetallic phase enhances the corrosion resistance of the Al-Cu alloys. For the Al-1wt.%Cu alloy increasing the content of Cl− produces a beneficial result related to a more resistive passive film. For the rest of the studied alloys with nobler corrosion potentials, the increase in Cl− results in a decrease in their corrosion resistance.

Similar content being viewed by others

References

Z.S. Smialowska, Pitting Corrosion of Aluminum, Corros. Sci., 1999, 41, p 1743–1767. https://doi.org/10.1016/j.corsci.2011.11.010

M.A. Amin, S.S. Abd El Rehim, S.O. Moussa, and A.S. Ellithy, Pitting Corrosion of Al and Al-Cu Clloys by ClO4− Ions in Neutral Sulphate Solutions, Electrochim. Acta, 2008, 53, p 5644–5652. https://doi.org/10.1016/j.electacta.2008.03.010

K.A. Yasakau, M.L. Zheludkevich, and M.G.S. Ferreira, Role of Intermetallics in Corrosion of Aluminum Alloys. Smart Corrosion Protection, Elsevier Ltd., Amsterdam, 2018, https://doi.org/10.1016/b978-0-85709-346-2.00015-7

A. Boag, R.J. Taylor, T.H. Muster, N. Goodman, D. McCulloch, C. Ryan, B. Rout, D. Jamieson, and A.E. Hughes, Stable Pit Formation on AA2024-T3 in a NaCl Environment, Corros. Sci., 2010, 52, p 90–103. https://doi.org/10.1016/j.corsci.2009.08.043

K. Zhou, B. Wang, Y. Zhao, and J. Liu, Corrosion and Electrochemical Behaviors of 7A09 Al-Zn–Mg–Cu Alloy in Chloride Aqueous Solution, Trans. Nonferrous Met. Soc. China, 2015, 25, p 2509–2515. https://doi.org/10.1016/S1003-6326(15)63869-9

R. Arrabal, B. Mingo, A. Pardo, M. Mohedano, E. Matykina, and I. Rodríguez, Pitting Corrosion of Rheocast A356 Aluminium Alloy in 3.5wt.% NaCl Solution, Corros. Sci., 2013, 73, p 342–355. https://doi.org/10.1016/j.corsci.2013.04.023

X. Hui Zhao, Y. Zuo, J. Mao Zhao, J. Ping Xiong, and Y. Ming Tang, A Study on the Self-Sealing Process of Anodic Films on Aluminum by EIS, Surf. Coatings Technol., 2006, 200, p 6846–6853. https://doi.org/10.1016/j.surfcoat.2005.10.031

X. Wang, J. Wang, and C. Fu, Characterization of Pitting Corrosion of 7A60 Aluminum Alloy by EN and EIS Techniques, Trans. Nonferrous Met. Soc. China, 2014, 24, p 3907–3916. https://doi.org/10.1016/S1003-6326(14)63550-0

W.R. Osório, L.C. Peixoto, R. Garcia, and A. Garcia, Corrosion Behavior of Hypoeutectic Al-Cu Alloys in H2SO4 and NaCl Solutions, Acta Metall. Sin. (English Lett.), 2009, 22, p 241–246. https://doi.org/10.1016/S1006-7191(08)60095-2

A. Banu, M. Marcu, O. Radovici, C. Pirvu, and M. Vasilescu, Electrodissolution Studies of Three Aluminum Alloys in Acid, Neutral and Alkaline Solutions, Rev. Roum. Chim., 2006, 51, p 193–198

I.L. Muller and J.R. Galvele, Pitting Potential of High Purity Binary Aluminium Alloys-I. AlCu alloys. Pitting and Intergranular Corrosion, Corros. Sci., 1977, 17, p 179–193. https://doi.org/10.1016/0010-938X(77)90044-0

Y. Kim, R.G. Buchheit, and P.G. Kotula, Effect of Alloyed Cu on Localized Corrosion Susceptibility of Al-Cu Solid Solution Alloys: Surface characterization by XPS and STEM, Electrochim. Acta, 2010, 55, p 7367–7375. https://doi.org/10.1016/j.electacta.2010.06.069

K.A. Yasakau, M.L. Zheludkevich, and M.G.S. Ferreira, Corrosion and Corrosion Protection of Aluminum Alloys, Elsevier, 2018, https://doi.org/10.1016/B978-0-12-409547-2.13870-3

A.S. Román, C.M. Méndez, C.E. Schvezov, A.E. Ares, Shape Casting: 5th International Symposium 2014, in: Shape Cast. TMS 2014, pp. 301–308. https://doi.org/10.1002/9781118888100

A.E. Ares, L.M. Gassa, C.M. Méndez, C.E. Schvezov, Corrosión Electroquímica de las Aleaciones Al-Cu en Solución de Cloruro de Sodio, in: Nales Del 11° Congr. Binacional Metal. y Mater., 2011

A.S. Román, C.M. Méndez, and A.E. Ares, Aleaciones Al-Cu: Estructuras de Solidificaciòn y Comportamiento Electroquìmico, An. AFA., 2014, 25, p 57–62. https://doi.org/10.31527/analesafa.2014.25.2.57

W.R. Osório, J.E. Spinelli, I.L. Ferreira, and A. Garcia, The roles of Macrosegregation and of Dendritic Array Spacings on the Electrochemical Behavior of an Al-4.5 wt% Cu Alloy, Electrochim. Acta., 2007, 52, p 3265–3273. https://doi.org/10.1016/j.electacta.2006.10.004

N. Birbilis and R.G. Buchheit, Electrochemical Characteristics of Intermetallic Phases in Aluminum Alloys, J. Electrochem. Soc., 2005, 152, p B140. https://doi.org/10.1149/1.1869984

A.C. Vieira, A.M. Pinto, L.A. Rocha, and S. Mischler, Effect of Al2Cu Precipitates Size and Mass Transport on the Polarisation Behaviour of Age-Hardened Al-Si-Cu-Mg Alloys in 0.05 M NaCl, Electrochim. Acta., 2011, 56, p 3821–3828. https://doi.org/10.1016/j.electacta.2011.02.044

A.S. Román, C.M. Méndez, C. Schvezov, A.E. Ares, Electrochemical Properties of Al-Cu Alloys in NaCl Solutions, in TMS 2015, Characterization of Minerals, Metals, and Materials 2015, 2015, pp. 727–734. https://doi.org/10.1007/978-3-319-48191-3_92

A.E. Ares, L.M. Gassa, C.E. Schvezov, S.F. Gueijman, Relationship between Structure and Properties of Al-Cu Alloys, in: Shape Cast. 4th International Symposium (TMS, 2011), pp. 207–214. https://doi.org/10.1002/9781118062050.ch25

W.R. Osório, J.E. Spinelli, C.M.A. Freire, M.B. Cardona, and A. Garcia, The Roles of Al2Cu and of Dendritic Refinement on Surface Corrosion Resistance of Hypoeutectic Al-Cu Alloys Immersed in H2SO4, J. Alloys Compd., 2007, 443, p 87–93. https://doi.org/10.1016/j.jallcom.2006.10.010

A.S. Román, C.M. Méndez, and A.E. Ares, Corrosion Resistance of Al-Cu Alloys in Function of the Microstructure, Mater. Sci. Forum, 2014, 786, p 100–107. https://doi.org/10.4028/www.scientific.net/MSF.783-786.100

A.S. Román, C.M. Méndez, A.E. Ares, Comportamiento Electroquímico de las Aleaciones Al-Cu en Soluciones 1 M y 0,5 M de NaCl, in SAM/CONAMET, 2014

J.A. Spittle, Columnar-to-Equiaxed Grain Transition in as Solidified Alloys, Int. Mater. Rev., 2006, https://doi.org/10.1179/174328006X102493

A.E. Ares and C.E. Schvezov, Solidification Parameters during the Columnar-to-Equiaxed Transition in Lead-Tin Alloys, Metall. Mater. Trans. A., 2000, 31, p 1611–1625. https://doi.org/10.1007/s11661-000-0171-6

A.E. Ares and C.E. Schvezov, Influence of Solidification Thermal Parameters on the Columnar-to-Equiaxed Transition of Aluminum-Zinc and Zinc-Aluminum Alloys, Metall. Mater. Trans. A, 2007, 38, p 1485–1499. https://doi.org/10.1007/s11661-007-9111-z

A.E. Ares, L.M. Gassa, S.F. Gueijman, and C.E. Schvezov, Correlation Between Thermal Parameters, Structures, Dendritic Spacing and Corrosion Behavior of Zn-Al Alloys with Columnar to Equiaxed Transition, J. Cryst. Growth, 2008, 310, p 1355–1361. https://doi.org/10.1016/j.jcrysgro.2007.11.169

S.F. Gueijman, C.E. Schvezov, and A.E. Ares, Vertical and Horizontal Directional Solidification of Zn-Al and Zn-Ag Diluted Alloys, Mater. Trans., 2010, 51, p 1861–1870. https://doi.org/10.2320/matertrans.M2010036

D.B. Carvalho, A.L. Moreira, D.J. Moutinho, J.M. Filho, O.L. Rocha, and J.E. Spinelli, The Columnar to Equiaxed Transition of Horizontal Unsteady-State Directionally Solidified Al-Si alloys, Mater. Res., 2013, 17, p 498–510. https://doi.org/10.1590/S1516-14392014005000015

A.E. Ares, S.F. Gueijman, and C.E. Schvezov, An Experimental Investigation of the Columnar-to-Equiaxed Grain Transition in Aluminum-Copper Hypoeutectic and Eutectic Alloys, J. Cryst. Growth, 2010, 312, p 2154–2170. https://doi.org/10.1016/j.jcrysgro.2010.04.040

C. M. Rodriguez, Relación entre la Microestructura y la Microdureza de las Aleaciones Al-Cu Solidificadas Direccionalmente, Mg. Thesis, National University of San Martín (2013) http://www.isabato.edu.ar/tesis/rodriguez-mm-2013/

G. Petzow, Metallographic Etching, 2nd ed., ASM International, New York, 2008

G. Vander Voort, Metallography and Microstructures, in ASM Handbook (ASM International, 2004)

W.S. Rasband, ImageJ, U. S. National Institutes of Health, Bethesda, Maryland, USA. https://imagej.nih.gov/ij/, 1997–2018

M.D. Abramoff, P.J. Magalhaes, and S.J. Ram, Image Processing with ImageJ, Biophoton. Int., 2004, 11(7), p 36–42

ASTM E112-13, Standard Test Methods for Determining Average Grain Size, ASTM International, West Conshohocken, PA, 2013, www.astm.org

U.A. Siqueira, Solidification Thermal Parameters Affecting the Columnar- to-Equiaxed, Transition, 2002, 33, p 2107–2118. https://doi.org/10.1007/s11661-002-0042-4

M.A. Martorano, C. Beckermann, and C. Gandin, A Solutal Interaction Mechanism for the Columnar-to-Equiaxed Transition in Alloy Solidification, Metall. Mater. Trans., 2003, https://doi.org/10.1007/s11661-003-0311-x

H. Baker, Alloys Phase Diagrams vol. 3, in ASM Handbook (ASM International, 1998), pp. 279–336

M. Prates de Campos Filho, G.J. Davies, Solidifiçao e Fundicao de Metais e Suas Ligas, 1978, pp. 10–90. (in Portuguese)

W.R. Osório, C.M. Freire, and A. Garcia, The Fffect of the Dendritic Microstructure on the Corrosion Resistance of Zn-Al Alloys, J. Alloys Compd., 2005, 397, p 179–191. https://doi.org/10.1016/j.jallcom.2005.01.035

A.E. Ares and L.M. Gassa, Corrosion Susceptibility of Zn-Al Alloys with Different Grains and Dendritic Microstructures in NaCl Solutions, Corros. Sci., 2012, 59, p 290–306. https://doi.org/10.1016/j.corsci.2012.03.015

O.L. Rocha, C.A. Siqueira, and A. Garcia, Heat Flow Parameters Affecting Dendrite Spacings during Unsteady-State Solidification of Sn-Pb and Al-Cu Alloys, Metall. Mater. Trans. A., 2003, 34, p 995–1006. https://doi.org/10.1007/s11661-003-0229-3

J.R. Scully, T.O. Knight, R.G. Buchheitt, and D.E. Peeblest, Electrochemical Characteristics of the Al2Cu, Al3Ta and Al3Zr Intermetallic Phases and Their Relevancy to the Localized Corrosion of Al Alloys, Corros. Alum. Alum. Alloy., 1993, 35, p 185–195. https://doi.org/10.1016/0010-938X(93)90148-A

H.-H. Strehblow, P. Marcus, Mechanisms of Pitting Corrosion, in: P. Marcus (Ed.), Corrosion Mechanisms in Theory and Practice, 3rd edn. (CRE Press, Pennsylvania, 2012), p. 382. https://doi.org/10.1002/maco.200390104

K.D. Ralston, N. Birbilis, and C.H.J. Davies, Revealing the Relationship Between Grain Size and Corrosion Rate of Metals, Scr. Mater., 2010, 63, p 1201–1204. https://doi.org/10.1016/j.scriptamat.2010.08.035

F.J. Martin, G.T. Cheek, W.E. O’Grady, and P.M. Natishan, Impedance Studies of the Passive Film on Aluminium, Corros. Sci., 2005, 47, p 3187–3201. https://doi.org/10.1016/j.corsci.2005.05.058

P.M. Natishan and W.E. O’Grady, Chloride Ion Interactions with Oxide-Covered Aluminum Leading to Pitting Corrosion: a Review, J. Electrochem. Soc., 2014, 161, p C421–C432. https://doi.org/10.1149/2.1011409jes

A.S. Román, C.M. Méndez, and A.E. Ares, Corrosion Resistance of Al-Cu Alloys in Function of the Microstructure, Mater. Sci. Forum., 2014, https://doi.org/10.4028/www.scientific.net/MSF.783-786.100

M. Büchler, T. Watari, and W.H. Smyrl, Investigation of the Initiation of Localized Corrosion on Aluminum Alloys by using Fluorescence Microscopy, Corros. Sci., 2000, 42, p 1661–1668. https://doi.org/10.1016/S0010-938X(00)00020-2

G. Frankel, Electrochemical Techniques in Corrosion: status, Limitations, and Needs, J. ASTM Int., 2008, 5, p 1–27. https://doi.org/10.1520/JAI101241

A.S. Roman, C.M. Méndez, C.E. Schvezov, A.E. Ares, Electrochemical properties OF Al-Cu alloys in NaCl solutions, in TMS Annual Meeting (2015). https://doi.org/10.1007/978-3-319-48191-3_92

M. Orazem and B. Tribollet, Electrochemical Impedance Spectroscopy, Wiley, Hoboken, 2008, p 157–159

W.R. Osório, E.S. Freitas, and A. Garcia, EIS and Potentiodynamic Polarization Studies on Immiscible Monotectic Al-In Alloys, Electrochim. Acta, 2013, 102, p 436–445. https://doi.org/10.1016/j.electacta.2013.04.047

R. Orozco-Cruz, R. Galván-Martínez, E.A. Martínez, I. Fernández-Gómez, La técnica de Espectroscopia de Impedancia Electroquímica (EIS) aplicada al estudio de degradación de aleaciones de aluminio en solución salina, in XXV Congr. LA Soc. Mex. ELECTROQUÍMICA (2010), pp. 693–703

R. Oltra and M. Keddam, Application of Impedance Technique to Localized Corrosion, Corros. Sci., 1988, 28, p 1–18. https://doi.org/10.1016/0010-938X(88)90002-9

V.F. Lvovich, Impedance Spectroscopy Applications to Electrochemical and Dielectric Phenomena, Wiley, Hoboken, 2012

J.C.S. Fernandes and M.G.S. Ferreira, Electrochemical Impedance Studies on Pure Aluminium in Carbonate Solution, J. Appl. Electrochem., 1990, 20, p 874–876. https://doi.org/10.1007/BF01094320

L. Chen, N. Myung, P.T.A. Sumodjo, and K. Nobe, Comparative Electrodissolution and Localized Corrosion Study of 2024Al in Halide Media, Electrochim. Acta, 1999, 44, p 2751–2764. https://doi.org/10.1016/S0013-4686(98)00397-1

P. Marcus, F. Mansfeld, Electrochemical Impedance Spectroscopy, in Analytical Methods in Corrosion Science and Engineering (Taylor/Fr, Boca Raton, 2005), pp 463–507. https://doi.org/10.1201/9781420028331

G. Šekularac and I. Milošev, Corrosion of Aluminium Alloy AlSi7Mg0.3 in Artificial Sea Water with Added Sodium Sulphide, Corros. Sci., 2018, 144, p 54–73. https://doi.org/10.1016/j.corsci.2018.08.038

A.S. Roman, C.M. Mendez, C.E. Schvezov, A.E. Ares, Electrochemical Behavior of Al-lwt.%Cu and Al-4.5wt.%Cu alloys, in TMS Annual Meeting (2014)

J.R. Scully, D.E. Peebles, A.D. Romig, D.R. Frear, and C.R. Hills, Metallurgical Factors Influencing the Corrosion of Aluminum, AI-Cu, and AI-Si Alloy Thin Films in Dilute Hydrofluoric Solution, Metall. Trans. A., 1992, 23, p 2641–2655. https://doi.org/10.1007/BF02658068

C.M. Rodriguez, A.E. Candia, C.E. Schvezov, M.R. Rosenberger, and A.E. Ares, Influencia de los parámetros térmicos sobre la microestructura de las aleaciones Al-Cu solidificadas direccionalmente, An. AFA., 2011, 23, p 42–50. https://doi.org/10.31527/analesafa.2013.23.2.42

Acknowledgments

Support by National Council for Scientific and Technical Research (CONICET) and National Agency of Scientific and Technological Promotion of Argentina (ANPCyT) under PICT-2017-0079 grant are duly acknowledged. A. S. Román thanks CONICET for the scholarship awarded to carry out this work. C.A. Gervasi duly acknowledges the Buenos Aires Commission for Scientific and Technical Research (CICBA) as a staff member of this Institution.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Román, A.S., Méndez, C.M., Gervasi, C.A. et al. Corrosion Resistance of Aluminum-Copper Alloys with Different Grain Structures. J. of Materi Eng and Perform 30, 131–144 (2021). https://doi.org/10.1007/s11665-020-05344-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-05344-1