Abstract

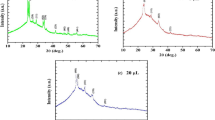

Layers of zinc oxide (ZnO) on glass substrates were grown by chemical bath deposition method. This method refers to solvo-thermal methods of crystal growth. When either ethylene-diamine-tetraacetic acid (EDTA) or ammonia was used as a complex agent, very weak adhesion of ZnO nanoparticles to the surface of glass substrates was noted, and when washing, the samples on the surfaces were removed by a water flow under pressure. When EDTA and ammonia were used together, the adhesion of ZnO nanoparticles to glass substrates increased dramatically. According to X-ray diffraction data, all sediments belong to the hexagonal syngony and correspond to the wurtzite-type ZnO structure. Optical absorption measurements showed that the band gap varied from 3.58 to 3.97 eV. The density of beams from ZnO nanowires on the substrate surface varied depending on the ratio between EDTA and ammonia.

Similar content being viewed by others

REFERENCES

M. M. Ali, J. Basrah Res. (Sciences) 37, 49 (2011).

P. B. Taunk, R. Das, D. P. Bisen, et al., Karbala Int. J. Modern Sci. 1, 159 (2015).

S. Temel, F. O. Gokmen, and E. Yaman, Eur. Sci. J., 13, 28 (2017).

F. Özütok and S. Demiri, Digest J. Nanomater. Biostruct. 12, 309 (2017).

H. Khallaf, G. Chai, O. Lupan, et al., J. Phys. D 42, 135304 (2009).

Y. G. Taofeek and E. H. Olusegun, Int. J. Sci. Technol. Res. 1, 24 (2012).

R. R. Krishnan, G. Sanjeev, R. Prabhu, and V. P. M. Pillai, JOM 70, 739 (2018).

O. Reyes, D. Maldonado, J. Escorcia-García, and P. J. Sebastian, J. Mater. Sci.: Mater. Electron. 29, 15535 (2018).

A. K. Yildirim, Materiali in Tehnologije 52, 667 (2018).

A. S. Ibraheam, Y. Al-Douri, J. M. S. Al-Fhdawi, et al., Microsyst. Technol. 22, 2893 (2016).

A. K. Yıldırım, Int. J. Eng. Res. Online 6, 5 (2018).

R. Bhowmik, M. N. Murty, and E. S. Srinadhu, PMC Phys. B 1, 20 (2008).

A. N. Fouda, M. Marzook, H. M. Abd El-Khalek, et al., Silicon 9, 809 (2017).

S. I. Drapak, S. V. Gavrylyuk, Z. D. Kovalyuk, and O. S. Lytvyn, Inorg. Mater. 47, 847 (2011).

L. N. Obolenskaya, M. A. Zaporozhets, G. M. Kuzmicheva, et al., Crystallogr. Rep. 60, 406 (2015).

B. Thomas, S. Deepa, and K. Prasanna Kumari, Ionics 25, 2 (2018).

K. L. P. Thi, L. T. Nguyen, N. H. Ke, et al., J. Electron. Mater. 47, 6302 (2018).

Z. Yuan, J. Electron. Mater. 44, 1187 (2015).

Z. R. Khan, M. S. Khan, M. Zulfequar, and M. Shahid Khan, Mater. Sci. Appl. 2, 340 (2011).

H. Kumar and R. Rani, Int. Lett. Chem., Phys. Astron. 14, 26 (2013).

M. R. Bodke, Y. Purushotham, and B. N. Dole, Cerâmica 64, 91 (2018).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Önal, M., Altıokka, B. Optimization of EDTA–Ammonia Ratio for Chemically Deposited Layers of ZnO Nanoparticles. Crystallogr. Rep. 65, 1237–1241 (2020). https://doi.org/10.1134/S1063774520070135

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1063774520070135