Abstract

For composite materials, the system response changes abruptly with a change in the properties of the material. Therefore, attaining significant knowledge about the effect of the material composition on the material properties is crucial. The researchers are looking for new computational methods which can predict these alterations so that the effort in experimental testing can be reduced. In this direction, this paper presents a robust and novel methodology of validating the estimation of the composite’s effective through a multi-scale approach by a set of standardized experimentation. These effective properties are estimated through the mean-field homogenization technique whose parameters are driven from the image analysis of Scanning Electron Microscopy (SEM) images. The predicted results are validated with the results obtained by the experimentation as per ASTM E1876 standard. The estimated error between the predicted properties and the experimental values increased with the increase of alumina particle fraction in the matrix. The mean-field homogenization lags behind the experiments for the parameters defined by the image analysis method than the experimental results. The upper bounds of the mean-field homogenization can be used for the composites with higher reinforcement volume fraction.

Similar content being viewed by others

References

Chawla N, Shen YL (2001) Mechanical behavior of particle reinforced metal matrix composites. Adv Eng Mater 3(6):357–370. https://doi.org/10.1002/1527-2648(200106)3:6<357::AID-ADEM357>3.0.CO;2-I

Rawal S (2001) Metal-matrix composites for space applications. Jom 53(4):14–17. https://doi.org/10.1007/s11837-001-0139-z

Sarmasti AB, Yazdanirad M, Nouri Khezrabad M, Karbalaie M (2011) Effect of alumina particle size and thermal condition of casting on microstructure and mechanical properties of stir cast Al-Al2O 3 composites. Mater Sci Technol 27(11):1653–1656. https://doi.org/10.1179/1743284710Y.0000000020

Koczak MJ, Khatri SC, Allison JE, Bader MG (1993) Metal-Matrix Composites for Ground Vehicle, Aerospace, and Industrial Applications. Fundamentals of Metal-Matrix Composites, 297–326. https://doi.org/10.1016/b978-0-08-052371-2.50020-1

Singh S, Singh I, Dvivedi A Design and development of novel cost-effective casting route for the production of metal matrix composites (MMCs) (2017). Int J Cast Metals Res 6(30):356–364. https://doi.org/10.1080/13640461.2017.1323605

Chaturvedi SK, Tzeng GY (1991) Micromechanical modeling of material damping in discontinuous fiber three-phase polymer composites. Compos Eng 1(1):49–60. https://doi.org/10.1016/0961-9526(91)90025-N

Guden M, Hall IW (1998) Dynamic properties of metal matrix composites: a comparative study. Mater Sci Eng A 242(1–2):141–152. https://doi.org/10.1016/s0921-5093(97)00516-9

Lesieutre GA, Yarlagadda S, Yoshikawa S, Kurtz SK, Xu QC (1993) Damped structural composite material using resistively-shunted piezoelectric ceramic short fibers. Collect Tech Papers - AIAA/ASME Structures, Structural Dynamics Mater Conf (pt 6):3238-3243

Vaidya UK, Dadzie P-E, Haque A, Mahfuz H, Jeelani S (1997) Nondestructive evaluation and characterization of microfibers modified textile carbon-phenolic and carbon-carbon composites. J Reinf Plast Compos 16(11):968–1001. https://doi.org/10.1177/073168449701601101

Mura T (2013) Micromechanics of defects in solids. Mechanics of Elastic and Inelastic Solids. Springer Science & Business Media. https://doi.org/10.1007/978-94-009-3489-4

Eshelby JD (1957) The determination of the elastic field of an ellipsoidal inclusion, and related problems. Proc Royal Soc A: Math Phys Eng Sci 241(1226):376–396. https://doi.org/10.1098/rspa.1957.0133

Christensen RM, Waals FM (1972) Effective stiffness of randomly oriented fibre composites. J Compos Mater 6(3):518–535. https://doi.org/10.1177/002199837200600307

Halpin JC, Jerine K, Whitney JM (1971) The laminate analogy for 2 and 3 dimensional composite materials. J Compos Mater 5(1):36–49. https://doi.org/10.1177/002199837100500104

Mori T, Tanaka K (1973) Average stress in matrix and average elastic energy of materials with misfitting inclusions. Acta Metall 21(5):571–574. https://doi.org/10.1016/0001-6160(73)90064-3

Benveniste Y (1987) A new approach to the application of Mori-Tanaka's theory in composite materials. Mech Mater 6(2):147–157. https://doi.org/10.1016/0167-6636(87)90005-6

Abaimov SG, Trofimov A, Sergeichev IV, Akhatov IS (2019) Multi-step homogenization in the Mori-Tanaka-Benveniste theory. Compos Struct. https://doi.org/10.1016/j.compstruct.2019.03.073

Imani SM, Goudarzi AM, Rabiee SM, Dardel M (2018) The modified Mori-Tanaka scheme for the prediction of the effective elastic properties of highly porous ceramics. Ceram Inter 44(14):16489–16497. https://doi.org/10.1016/j.ceramint.2018.06.066

Kamarian S, Shakeri M, Yas MH (2016) Natural frequency analysis and optimal design of CNT/fiber/polymer hybrid composite plates using Mori-tanaka approach, GDQ technique, and firefly algorithm. Polym Compos 39(5):1433–1446. https://doi.org/10.1002/pc.24083

Tran VP, Brisard S, Guilleminot J, Sab K (2018) Mori–Tanaka estimates of the effective elastic properties of stress-gradient composites. Int J Solids Struct 146:55–68. https://doi.org/10.1016/j.ijsolstr.2018.03.020

Sobhaniaragh B, Batra RC, Mansur WJ, Peters FC (2017) Thermal response of ceramic matrix nanocomposite cylindrical shells using Eshelby-Mori-Tanaka homogenization scheme. Compos Part B 118:41–53. https://doi.org/10.1016/j.compositesb.2017.02.032

Yılmaz O, Buytoz S (2001) Abrasive wear of Al2O3-reinforced Aluminium-based MMCs. Compos Sci Technol 61:2381–2392

Kok M (2005) Production and mechanical properties of Al2O3 particle-reinforced 2024 Aluminium alloy composites. J Mater Process Technol 161:381–387

Suthar J, Patel KM (2018) Processing issues, machining, and applications of aluminium metal matrix composites. Mater Manuf Process 33(5):499–527. https://doi.org/10.1080/10426914.2017.1401713

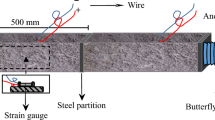

Standard Test Method for Dynamic Young's Modulus, Shear Modulus, and Poisson's Ratio by Impulse Excitation of Vibration. ASTM E1876, ASTM International, United States, 1–17

Praveen AP, Rajamohan V, Mathew AT (2019) Material and mechanical characterization of multi-functional carbon nanotube reinforced hybrid composite materials. Exp Tech 43(3):301–314. https://doi.org/10.1007/s40799-019-00316-0

Daramola OO, Olajide JL, Adediran AA, Adewuyi BO, Ayodele TT, Desai DA, Sadiku ER (2020) Multiscale analysis and experimental validation of the effective elastic modulus of epoxy-dioctahedral phyllosilicate clay composite. Heliyon 6(6):e04008. https://doi.org/10.1016/j.heliyon.2020.e04008

Sangghaleh A, Halali M (2009) Effect of magnesium addition on the wetting of alumina by aluminium. Appl Surf Sci 255:8202–8206. https://doi.org/10.1016/j.apsusc.2009.05.044

Bouhfid N, Raji M, Boujmal R, Essabir H, Bensalah M-O, Bouhfid R, Qaiss AeK. (2019) Numerical modeling of hybrid composite materials. Modelling of Damage Processes in Biocomposites, Fibre-Reinforced Composites and Hybrid Composites, 57–101. https://doi.org/10.1016/b978-0-08-102289-4.00005-9

Gitman IM, Askes H, Sluys LJ, Valls OL (2004) The concept of representative volume for elastic, hardening and softening materials. International Summer School - IPME conference. XXXII International Summer School - IPME Conference: Advanced Problems in Mechanics. p 1-5

Babu KP, Mohite PM, Upadhyay CS (2018) Development of an RVE and its stiffness predictions based on mathematical homogenization theory for short fibre composites. Int J Solids Struct 130-131:80–104. https://doi.org/10.1016/j.ijsolstr.2017.10.011

Klusemann B, Svendsen B (2010) Homogenization methods for multi-phase elastic composites: comparisons and benchmarks. Tech Mech 30(4):374–386

Yi I, Wiedmaier J, Schmauder S (2015) Modeling and simulation of mechanical properties of nano particle modified polyamide 6. J Mater Sci Chem Eng 3(1):80–87

Ogierman W, Kokot G (2016) A study on fiber orientation influence on the mechanical response of a short fiber composite structure. Acta Mech 227(1):173–183

Soni G, Singh R, Mitra M, Falzon BG (2014) Modelling matrix damage and fibre matrix interfacial decohesion in composite laminates via a multi-fibre multilayer representative volume element (M2RVE). Int J Solids Struct 51(2):449–461

Chang CY, Chang MY, Huang JH (2004) Vibration analysis of rotating composite shafts containing randomly oriented reinforcements. Compos Struct 63(1):21–32

Tandon GP, Weng GJ (1986) Average stress in the matrix and effective moduli of randomly oriented composites. Compos Sci Technol 27(2):111–132. https://doi.org/10.1016/0266-3538(86)90067-9

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection and analysis were performed by Mr. Anuj Sharma, Prof. Vikas Rastogi and Prof. Atul kumar agrawal The first draft of the manuscript was written by Mr. Anuj Sharma and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they do not have any conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sharma, A., Rastogi, V. & Agrawal, A. Estimation and Experimental Validation of Mean-Field Homogenised Effective Properties of Composite. Exp Tech 45, 445–456 (2021). https://doi.org/10.1007/s40799-020-00411-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40799-020-00411-7