Abstract

The study evaluated removal efficiency of 43 pesticides from water by thin-film composite polyamide membrane indigenously prepared by interfacial polymerization of 1,3-phenylenediamine and 1,3,5 trimesoyl chloride coated on asymmetric polysulfone support. Membrane performance was evaluated by gas and liquid chromatography mass spectroscopy determination of multiple pesticides remaining in feed and permeated water following the application of pesticides each @ 0.02, 0.05, and 0.10 mg/L in de-ionized water. The membrane was most efficient in the rejection of persistent organochlorine insecticides, viz. endosulfans (100%), dichlorodiphenyltrichloroethane (95%), and hexachlorocyclohexane (92%). Out of 43 selected pesticides, 33 were removed by > 80%. Size exclusion mass transfer played a significant role for molecules to pass through the membrane as observed for endosulfan isomers, endosulfan sulphate, and difenoconazole with molecular weight > 400. Pesticide rejection was also related to hydrophobicity (Log P). Hydrophobic pesticides with log P > 4.5 were rejected by > 80%, while monocrotophos with less hydrophobicity (log P = − 0.22) exhibited poor rejection (38%). Water flux decreased with an increase in pesticide concentration. The process of pesticide filtration was optimized at 200 psi. The results indicated the potential of the membrane to remove pesticides from water.

Similar content being viewed by others

Introduction

The aquatic environment is contaminated by various organic and inorganic substances like pesticides, pharmaceuticals, etc., originating from industrial, municipal, or agricultural activities (Yadav et al. 2015; Jabali et al. 2018). During the last few decades, pesticides are being used heavily in agriculture to ensure high crop yield. However, the continuous and indiscriminate use of pesticides, their misuse, spillage, improper storage, handling, and disposal has resulted in the presence of their residues in various environmental compartments including ground and surface water (Mondal et al. 2018) serving as the primary source of drinking around the world (Loos et al. 2009).

Thus, removal of pesticides from water is a major challenge for environmental scientists and engineers. Water treatment technologies, specifically conventional filtration, coagulation-flocculation and sedimentation have been reported to be ineffective in removing pesticides from drinking water (Ormad et al. 2008), while some other techniques, viz. advance oxidation process, photodegradation, etc., have been reported to have some drawbacks like production of many hazardous by-products (Sharma and Bhattacharya 2016). The application of pressure-driven membrane technologies for the removal of pollutants from water and wastewater is increasing to meet the stringent water quality standards. Moreover, no hazardous material is produced by this method and is also cost-effective (Bhattacharya 2006). These membranes are capable of removing hardness, natural organic matter, and other organic micro-molecules like pesticides, etc. (Khin et al. 2012).

Among the many types of membranes, nanofiltration (NF) and reverse osmosis (RO) technologies have been considered as the most appropriate pressure-driven membrane process for the removal of pesticides from contaminated water sources (Plakas and Karabelas 2012; Shon et al. 2013). High water permeability and rejection of solutes are features that make low-pressure-driven membranes economically viable in water softening applications, attractive for water purification and removal of harmful organic solutes from water (Yangali-Quintanilla et al. 2010). Limited studies on removal of some pesticides like herbicides (Wang et al. 2010; Riungu et al. 2012; Hidalgo et al. 2013; Musbah et al. 2013; Karimi et al. 2016); fungicides (Drazevic et al. 2013), and insecticides (Pang et al. 2010; Karimi et al. 2016) have been reported using RO and NF membranes. The thin-film composite (TFC) polyamide RO membrane prepared on polysulfone support in our laboratory was evaluated for the removal of only two phenyl urea herbicides (Mehta et al. 2015, 2017). Thus, regarding the potential for exposure of multi pesticide residue to water, the present work is aimed to improve the filtration of pesticides from water, which provides challenges to industrial or other users with emerging membrane technologies TFC membrane with cross-flow filtration process and reinforces the engagement between research and application aspects.

Materials and methods

Pesticide selection

A total of 43 pesticides were selected for study which included 24 pesticides recommended for agricultural use in cereals and vegetables in India (DPPQS 2020) along with 19 non-agricultural pesticides [banned/restricted organochlorines (OC: 15), organophosphorus (OP: 2), carbamate (1), and synthetic pyrethroid (SP: 1) for domestic use], the occurrence of which have been reported in the aquatic environment (Mondal et al. 2018). Among the recommended pesticides, 13 were insecticides [5 OP, 4 neonicotinoids, 2SP, 1 OC, and 1carbamate], seven fungicides (3 triazole, 1 bezimidazole, 1 phenylamide, 1 phosphorothiolate, and 1 triazolobenzothiazole), and four herbicides (2 chloroacetamide, 1 urea, and 1 triazine). The analytical standard pesticides were purchased from Sigma-Aldrich, USA.

Preparation and characterization of TFC membrane

The TFC membrane used in this experiment was prepared by the interfacial polymerization reaction of 1,3-phenylenediamine (in water) and 1,3,5-trimesoyl chloride (in hexane). Polysulfone membrane was made by wet-phase separation technique from its N,N-dimethyl formamide solution, and the cross-linked polyamide layer was coated on polysulfone support by interfacial polymerization as described by Mehta et al. (2015). The membrane surface–water interaction was analysed by drop shape analyser (DSA 100, Kruss, Germany). The charge behaviour in terms of zeta potential of membrane sample was analysed by Zeta-CAD, France, version 1.04. Surface topography of the membranes was captured by scanning electron microscope (JMS-7100F, Russia).

Filtration studies

Pesticide filtration was carried out by a cross-flow filtration technique at 1.4 MPa pressure. The schematic diagram of the cross-flow filtration set-up is depicted in Supplementary Fig. 1. The cross-flow filtration set-up was also reported in the previous study (Mehta et al. 2015). There were four cells kept in series and perforated support on which membrane could be placed. The active membrane surface area in each cell was 0.00152 m2. TFC membrane was compacted ~ 2 h before taking separation data. Water was spiked using the standard stock solution (10 mg/L) of 43 pesticides at three different levels (20, 50, and 100 µg/L) and then subjected to filtration studies. All the experiments were carried out in de-ionized water.

The rejection (R%) of pesticides by filtration was calculated by

where Cf and Cp is the concentration (µg/mL) of feed and permeate, and the flux was calculated from the relation:

where L indicates the volume of permeate in a litre, T is the time in hours, and A is the active membrane area (m2).

Determination of pesticides

Pesticides in water were determined by a modified liquid–liquid extraction method in which 250 mL water was taken in a separating funnel followed by the addition of a saturated NaCl solution (10 mL, Rankem, India) and mixed well. Liquid–liquid partitioning was done with dichloromethane/ethyl acetate (8:2) (HPLC grade, Finner, India) thrice (30 + 20 + 20 mL), and the organic layer was collected after passing through Na2SO4 (SRL, India). The combined organic extract was completely evaporated by a rotary evaporator (Eyela CCA-1110, N-1000), and the residue was dissolved in 2 mL ethyl acetate (J.T. Baker). An aliquot (1 mL) was taken in a vial for analysis in GC–MS/MS, and another 1 mL was dried and dissolved by the same volume of methanol (J.T. Baker) for analysis in LC–MS/MS. For method validation, respective water samples were spiked with known pesticide concentration (0.02, 0.05, and0.10 mg/L) and analysed following the same procedure.

The residues of 43 pesticides were determined by gas chromatography and (triple quadruple) mass spectrometry (GC–MS/MS, Agilent 7890 A, 7693A autosampler, GC-7000 TQD) and liquid chromatography mass spectrometry (LC–MS/MS, Waters Alliance-2695, ESCi™ interface, Micromass® Quattro Micro™). The operating conditions of GC–MS/MS and LC–MS/MS for analysis of pesticides are presented in Supplementary Table 1. Identification of pesticides was made by comparison of retention times of the peaks and ratio of mass/charge (m/z) of ions using quantifier and qualifier ions in multiple reaction monitoring (MRM) mode with those of standard pesticide compounds (Supplementary Table 2). Under these operating conditions, the chromatogram produced by GC–MS for 30 pesticides and by LC–MS for 13 pesticides is presented in Fig. 1.

Statistical analysis

Relative standard deviation (RSD) was calculated for the data on the rejection of pesticides by the TFC membrane as follows:

where s is the standard deviation of three observations on pesticide rejection, and m is the mean value. The correlation coefficient (r) between the pesticide property and rejection (%) was also determined (Gomez and Gomez 1984) using MS Excel.

Results and discussion

Method validation for pesticide analysis in water

Quantitation ability of the instruments was ascertained by acceptable linearity (correlation coefficient, r2 = 0.977–0.999) of the calibration curve (0.005–1 mg/L), limit of detection (LOD = 0.005 mg/L), limit of quantification (LOQ = 0.02 mg/L), recovery and precision as RSD as shown in Supplementary Table 3. Average recovery of the pesticides was in the range of 70.7–107.1% for 0.02 mg/L (RSD = 5.8–16.7), 71.5–109.7% for 0.05 mg/L (RSD = 4.8–16.5), and 76.9–110.9% for 0.10 mg/L (RSD = 4.8–17.6) well within the European Union (EC 2017) acceptable range for recovery (70–120%) and RSD (≤ 20%). These results indicated that the analytical method was efficient and also reliable for determination of pesticides in experimental feed and permeate water samples.

Membrane characteristics

The molecular weight cut-off (MWCO) of the base polysulfone membrane is 80KDa using dextran, whereas the nMWCO of the prepared TFC membrane is 94% for glucose molecule. The salt (NaCl) rejection performance of the TFC membrane is 95% for 2000 mg/L at 1.38 mPa. The membrane can be comparable with different membranes, as depicted in Table 1, though operating parameters are somewhat different (Tang et al. 2009a, b). The water permeability of the TFC membrane is 20.2–17.9 Lm−2 h−1 depending upon the pesticides in it.

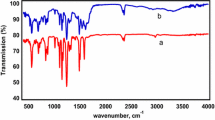

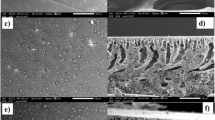

The contact angle of the polysulfone membrane (79.7°) was decreased in the TFC membrane (57.4°), indicating the development of relatively more hydrophilic character in the TFC membrane due to its polyamide network compared to the base polysulfone membrane (Mehta et al. 2015). The polyamide on the membrane surface after the interfacial polymerization reaction resulted in negative zeta potential (− 19.17 mV). Scanning electron micrograph (SEM) of the polyamide TFC membrane showed characteristic differences concerning asymmetric polysulfone topographic surface (Fig. 2). The micrographs showed the pores on the polysulfone surface (Fig. 2a), whereas granule like appearance spread over the TFC membrane (Fig. 2b) surface.

Pesticide removal by membrane filtration

Rejections of pesticides by the TFC membrane were estimated by determination of pesticide remaining in feed and permeate water. Rejection efficiency (R%) of insecticides applied at three concentration levels (0.02–0.10 mg/L) varied for different chemical classes viz. organochlorines (66–100%), organophosphorus (32–100%), neo-nicotinoids (61–98%), synthetic pyrethroids (74–94%), and carbamates (81–100%). Rejection of other pesticide classes was obtained in the range of 60–100% for fungicides and 82–100% for herbicides (Table 2).

Among the pesticides, insecticide endosulfan (α, β, and sulphate), fungicide difenoconazole, and herbicide butachlor were rejected by 100% at all the concentration level. For most of the other selected OC insecticides (viz. β and γ-HCH, op and pp-DDT, op and pp-DDD, op and pp-DDE) as well as ethion and atrazine, the average rejection was > 90%. Majority of the remaining pesticides (18 nos.) including insecticides (viz. aldrin, α- and δ-HCH, dieldrin, acetamiprid, imidacloprid, thiacloprid, α-cypermethrin, bifenthrin, permethrin, carbaryl, carbofuran, and chlorpyrifos), fungicides (metalaxyl, isoprothiolane, and tricyclazole), and herbicides (alachlor and isoproturon) exhibited 80–90% rejection by the membrane (Table 2). Moderate rejection (60–80%) was observed for three more insecticides (dicofol, dimethoate, and thiamethoxam) and three fungicides (carbendazim, hexaconazole, and tetraconazole). However, rejection of most of the OP insecticides (malathion, parathion, methyl parathion, and monocrotophos) was < 60% with the lowest observed for monocrotophos (37.8%). Overall, the average rejection was found in the order of OC insecticides (93%) > herbicides (92%) > carbamate insecticides (88%) > fungicides (81%) > neo-nicotinoids (79%) > OP insecticides (64%) (Table 2). Most significantly, the TFC membrane exhibited the highest efficiency in removing the persistent OC insecticides (93%), including endosulfan (100%), DDT (95%), and HCH (92%).

Size exclusion mass transfer played a major role in preventing molecules to pass through the membrane. Bruggen and Vandecasteele (2002) proposed an empirical relationship between the effective diameter (D) and molecular weight (MW) of a pesticide using the equation: D = A(MW)B, where A = 0.065 and B = 0.438. This correlation is valid for the molecular weight range up to 600 Da and thus the MW directly proportional to molecular size. The rejection rate is positively correlated with molecular weight, as well as molecular width (Kiso et al. 2002). Under the present experimentation, it has been observed for endosulfan isomers, endosulfan sulphate, and difenoconazole with molecular weight (MW) > 400. A significant positive correlation (r = 0.33–0.37) between pesticide rejection and MW was obtained (Table 2) at 5% level. The increasing trend in pesticide rejection with an increase in MW also is depicted in Fig. 3a (for 23 pesticides). Such type of relationship was also reported for bentazone, primicarb, and vinclozoline using commercial NF70 membrane (Chen et al. 2004). However, the relationship was not significant (r = 0.25) at higher concentration level (0.10 mg/L).

Another important factor influencing pesticide rejection is hydrophobicity, Log P (Kiso et al. 2002). More hydrophobic pesticides (log P > 4.5) like op-DDT, bifenthrin, aldrin, permethrin, α-cypermethrin, ethion, difenoconazole, α-endosulfan, chlorpyrifos, and butachlor exhibited good rejection by the membrane (80–100%), whereas pesticides with lower hydrophobicity like dimethoate (log P = 0.7) and thiamethoxam (− 0.13) exhibited low rejection(< 80%), and remarkably low rejection (38%) was observed for monocrotophos (log P = − 0.22) (Table 2). Similar behaviour of hydrophilic pesticides like monocrotophos towards membrane filtration was reported earlier (Khin et al. 2012). The relationship of pesticide rejection by a membrane with hydrophobicity is shown in Fig. 3b. The correlation coefficient (r = 0.42–0.49) was highly significant (at 1% level) at all concentrations (Table 2). The increasing trend in pesticide rejection with an increase in Log P is presented in Fig. 3 (for 19 pesticides).

Charge exclusion caused by electrostatic interactions between membrane and pesticides from the permeated solution also plays major role in pesticide retention (Kosutic et al. 2005). The TFC membrane used under this experiment was negatively charged and is expected to reject anionic pesticides more than the uncharged one. The pesticides used for this study were mostly non-polar in nature. Therefore, the low polar pesticides like methyl parathion, parathion, thiamethoxam exhibited relatively low rejection (48.3–66.6%). However, some non-polar pesticides like DDTs and HCHs were more rejected due to high molecular size. Molecules with high dipole moment (> 3D) are usually less rejected as they orient in such a way that they easily pass through the membrane (Bruggen et al. 2001; Bhattacharya 2006). Lower rejection of synthetic pyrethroids (80–84%) with high MW (> 400) might be due to higher dipole moment.

Pesticide rejection by membrane filtration is also related to water flux (Chen et al. 2004). With an increase in pesticide loading in feed water from 20 to 100 µg/L, water flux decreased from 20.2 to 17.9 Lm−2 h−1(Fig. 4). Under the present experimental condition in de-ionized water, membrane fouling might have occurred due to the interaction of individual pesticides with membrane pores resulting in low water flux leading to high rejection of pesticides (Mehta et al. 2015). It has been reported that with an increase in operating pressure water flux was increased, leading to a lower rejection of diuron (Wang et al. 2010). Therefore, the cross-flow filtration technique used with operating pressure at 200 psi appears to be optimum to maintain the rejection efficiency of the membrane for 43 pesticides.

Pesticide removal from potable water by membrane process is strongly related to the particular solute properties like molecular weight cut-off (MWCO), molecular size, acid dissociation constant (− pKa), charge exclusion, density, and hydrophilicity (− Log P) which determine the strength of pesticide-membrane physico-chemical interaction and also membrane fouling, system pressure, and modelling (Khin et al. 2012; Plakas and Karabelas 2012; Shon et al. 2013; Musbah et al. 2013). Since the different types of organic contaminants are present in nature, the substance having higher molecular weight/size/width and octanol–water partition coefficient (Log P) gets higher rejection (Yangali-Quintanilla et al. 2010; Shon et al. 2013). Low rejection of polar pesticides may also be attributed to charge distribution on the membrane, preferential orientation of the polar pesticides towards the membrane, and attraction between the opposite charges leading to increased permeation (Riungu et al. 2012). Overall, the performance of the cross-flow filtration technique using TFC membrane is comparable and in some cases appeared to be better than those reported techniques viz. polyvinylidene fluoride (PVDF) membrane for removal of DDTs (Pang et al. 2010), NF 90 for atrazine (Hidalgo et al. 2013; Musbah et al. 2013), and NF-DK1812 for diuron (Wang et al. 2010).

Conclusions

The polyamide TFC membrane was used for filtration in a wide range of pesticides (43 nos., MW 189–423 Da) with a total load of 0.86 to 4.30 mg/L in de-ionized water. The membrane was highly useful for the removal of persistent OC insecticides like endosulfan, DDT, and HCH (92–100%) from water. Size exclusion played a significant role for complete rejection of pesticides with MW > 400 (viz. endosulfans, difenoconazole, etc.). Pesticides with good hydrophobicity, log P > 4.5, were rejected by > 80%. Overall, 33 out of 43 pesticides were removed by > 80%. The performance of the membrane was comparable or even better than some reported commercial NF membranes. The laboratory-made TFC membrane may be applicable for purification of real samples of ground and surface water for drinking. In addition to pesticides, other organic pollutants might also be removed from water by this membrane.

References

Bhattacharya A (2006) Remediation of pesticide-polluted waters through membranes. Sep Purif Rev 35:1–38

Bruggen VD, Vandecasteele C (2002) Modelling of the retention of uncharged molecules with nanofiltration. Water Res 36:1360–1368

Bruggen VD, Everaert K, Wilms D, Vandecasteele C (2001) Application of nano-filtration for removal of pesticides, nitrate and hardness from ground water: rejection properties and economic evaluation. J Membr Sci 193:239–248

Chen SS, Taylor JS, Mulford LA, Norris CD (2004) Influences of molecular weight, molecular size, flux and recovery for aromatic pesticide removal by nanofiltration membranes. Desalination 160:103–111

DPPQS (2020) Major uses of pesticides. Directorate of plant protection quarantine & storage. Available at <https://ppqs.gov.in/divisions/cib-rc/major-uses-of-pesticides> (Accessed on March, 2020)

Drazevic E, Kosutic K, Dananic V, Pavlovic DM (2013) Coating layer effect on performance of thin film nanofiltration membrane in removal of organic solutes. Sep Purif Technol 118:530–539

EC (2017) Guidance document on analytical quality control and method validation procedures for pesticide residues and analysis in food and feed. European commission.SANTE/11813/2017.https://ec.europa.eu/food/sites/food/files/plant/docs/pesticides_mrl_guidelines_wrkdoc_2017-11813.pdf (Accessed 12 Nov 2018)

Gomez KA, Gomez AA (1984) Statistical procedures for agricultural research, 2nd edn. Wiley, New York, p 63

Hidalgo AM, Leon G, Gomez M, Murcia MD, Barbosa DS, Blanco P (2013) Application of the solution-diffusion model for the removal of atrazine using a nanofiltration membrane. Desalin Water Treat 51:2244–2252

Jabali Y, Millet M, El-Hoz M (2018) Determination of 16 polycyclic aromatic hydrocarbons (PAHs) in surface and groundwater in North Lebanon by using SPME followed by GC–ITMS/MS. Euro-Mediterr J Environ Integr 3:24

Karimi H, Rahimpour A, Kebria MRS (2016) Pesticides removal from water using modified piperazine-based nanofiltration (NF) membranes. Desalin Water Treat 57:24844–24854

Kasutic K, Furac L, Sipos L, Kunst B (2005) Removal of arsenic and pesticides from drinking water by nanofiltration membranes. Sep Purif Technol 42:137–144

Khin MM, Nair AS, Babu VJ, Murugana R, Ramakrishna S (2012) A review on nanomaterials for environmental remediation. Energy Environ Sci 5:8075–8109

Kiso Y, Mizuno A, Othman RAA, Jung YJ, Kumano A, Ariji A (2002) Rejection properties of pesticides with a hollow fiber NF membrane (HNF-1). Desalination 143:147–157

Loos R, Gawlik BM, Locoro G, Rimaviciute E, Contini S, Bidoglio G (2009) EU-wide survey of polar organic persistent pollutants in European river waters. Environ Pollut 157:561–568

Mehta R, Brahmbhatt H, Saha NK, Bhattacharya A (2015) Removal of substituted phenyl urea pesticides by reverse osmosis membranes: laboratory scale study for field water application. Desalination 358:69–75

Mehta R, Brahmbhatt H, Bhattacharya A (2017) Tuning separation behavior of tailor-made thin film poly (piperazine-amide) composite membranes for pesticides and salts from water. Desalination 404:280–290

Mondal R, Mukherjee A, Biswas S, Kole RK (2018) GC-MS/MS determination and ecological risk assessment of pesticides in aquatic system: a case study in Hooghly River basin in West Bengal India. Chemosphere 206:217–230

Musbah I, Ciceron D, Saboni A, Alexandrova S (2013) Retention of pesticides and metabolites by nanofiltration by effects of size and dipole moment. Desalination 313:51–56

Ormad MP, Miguel N, Claver A, Matesanz JM, Ovelleiro JL (2008) Pesticides removal in the process of drinking water production. Chemosphere 71:97–106

Pang W, Gao N, Xia S (2010) Removal of DDT in drinking water using nanofiltration process. Desalination 250:553–556

Plakas KV, Karabelas AJ (2012) Removal of pesticides from water by NF and RO membrane—a review. Desalination 287:255–265

Riungu NJ, Hesampour M, Pihlajamakia A, Manttari M, Home PG, Ndegwa GM (2012) Removal of pesticides from water by nano-filtration. J Eng Comput Appl Sci 1:50–60

Sharma S, Bhattacharya A (2016) Drinking water contamination and treatment techniques. Appl Water Sci 7:1043–1067

Shon HK, Phuntsho S, Chaudhary DS, Vigneswaran S, Cho J (2013) Nanofiltration for water and wastewater treatment—a mini review. Drink Water Eng Sci 6:47–53

Tang CY, Kwon Y, Leckie JO (2009a) Effect of membrane chemistry and coating layer on physio-chemical properties of thin film composite polyamide RO and NF membranes. I. FTIR and XPS characterization of polyamide and coating layer chemistry. Desalination 242:149–167

Tang CY, Kwon Y, Leckie JO (2009b) Effect of membrane chemistry and coating layer on physiochemical properties of thin film composite polyamide RO and NF membranes II. Membrane physiochemical properties and their dependence on polyamide and coating layers. Desalination 242:168–182

Wang Y, Shu L, Jegatheesan V, Gao B (2010) Removal and adsorption of diuron through nanofiltration membrane: the effects of ionic environment and operating pressures. Sep Purif Technol 74:236–241

Yadav IC, Devi NL, Syed JH, Cheng Z, Li J, Zhang G, Jones KC (2015) Current status of persistent organic pesticides residues in air, water, and soil, and their possible effect on neighbouring countries: a comprehensive review of India. Sci Total Environ 511:123–137

Yangali-Quintanilla V, Maenga SK, Fujioka T, Kennedy M, Amy G (2010) Proposing nanofiltration as acceptable barrier for organic contaminants in water reuse. J Membr Sci 362:334–345

Acknowledgements

The authors express their gratitude to Export Testing Laboratory, Department of Agricultural Chemicals, BCKV for instrumental facilities for pesticide analysis, and Membrane Science and Separation Technology Division, CSIR-CSMCRI for filtration technology. Financial assistance received by A. Mukherjee as Senior Research Fellowship from Dow Agro Science India Pvt. Ltd. is thankfully acknowledged.

Funding

The author(s) received no specific funding for this work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have declared no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Mukherjee, A., Mehta, R., Saha, S. et al. Removal of multiple pesticide residues from water by low-pressure thin-film composite membrane. Appl Water Sci 10, 244 (2020). https://doi.org/10.1007/s13201-020-01315-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13201-020-01315-y