Abstract

This review deals with heterogeneous hydroformylation catalysts, specifically metal complexes fixed in an organic polymer structure. It describes the main catalyst synthesis methods, provides data on hydroformylation of unsaturated compounds (including asymmetric hydroformylation), and shows how those compounds can be used. The special focus is on the systematization of data on heterogeneous catalysts developed on the basis of porous organic polymers. Due to their porous structure, resistance to organic media and the high concentration of heteroatoms they contain, these materials can be considered promising for developing highly active, selective and stable heterogeneous catalysts for hydroformylation of unsaturated compounds, particularly higher linear olefins.

Similar content being viewed by others

Currently, commercial oxo synthesis processes, wherein the key stage is hydroformylation of unsaturated compounds under homogeneous conditions with the use of cobalt and rhodium catalysts, are among the main methods for producing aldehydes and alcohols, which are in high demand for the production of surface-active agents, polymer plasticizers, and solvents. They also serve as starting reagents in the synthesis of a wide range of compounds of other classes [1]. Because the rate of the chemical reaction and its target product selectivity are quite high, hydroformylation in a homogeneous medium has a number of advantages making it possible to carry out the process on a large scale. Over the past decades, particular attention has been given to the development of processes using rhodium compounds as catalysts; they are most active in hydroformylation and enable the reaction to be conducted under considerably milder conditions (with the pressure being up to 3.0 MPa and the temperature up to 110°C) as compared with the use of cobalt catalysts (27.0–30.0 MPa, 140–160°C). However, the necessity for the stage wherein the product/catalyst mixture components are separated, which normally includes fractionation of aldehydes from a high-boiling catalyst-containing solvent (bottoms), imposes some limitations on the development of olefin hydroformylation processes with a chain length of C6 or higher [2]. The commercially implemented method for producing butanals by propylene hydroformylation in a two-phase medium with the use of the Rh/TPPTS water-soluble catalytic system [where TPPTS is triphenylphosphine-3,3′,3′′-trisulfonic acid trisodium salt] is unacceptable for hydroformylation of higher olefins due to their low solubility in water and, as a consequence, low reaction rate [3]. Development of heterogeneous catalysts is one of the most extensively studied approaches to the abovementioned problem of catalyst separation from reaction products. Research in this field is very important because highly efficient heterogeneous catalysts would enable essentially new oxo synthesis technologies to be developed, with potential advantages over the conventional ones. In particular, it could be expected that the separation stage would be significantly simpler and the capital expenses necessary to put a reactor unit into operation would be lower.

For historical perspective, mention should be made of the scientific studies where different types of inorganic carriers such as silicon oxide [4–7], zeolites [8–10], and activated carbon [11, 12] were used as materials for immobilization of metal complexes. The range of insoluble carriers used in the processes was considerably expanded thereafter, and at present the main metal fixing methods include: incorporation of metal nanoparticles into the structures of various materials [13, 18]; fixing the rhodium complexes in the structure of the material by intercalation [19]; encapsulation of phosphine or a phosphine complex into mesopores or nanopores of the carrier [20, 21]; the sol-gel method, “grafting” of a phosphine-containing hydrocarbon radical onto the carrier surface, and other methods of covalent bonding of phosphine fragments on an inorganic, hybrid or organic substrate, wherein rhodium is subsequently introduced [22–28]; fixing of phosphine or a phosphine complex on the surface by means of ionic interactions [29]; fixing of catalysts soluble in polar liquids (water and ionic liquid) in the thin hydrophilic layer of the carrier, which most frequently is silica gel SAPC/SIPC (Supported Aqueous/Ionic Liquid Phase Catalysts) [30, 31]; creation of structures containing single rhodium atoms, as per the “single atom” concept [32], such as the cases in which nano-objects (nanosheets and nanofibers) made of cobalt oxide [33] or zirconium oxide [34] were obtained and their catalytic properties were studied. Heterogeneous modified rhodium clusters [35] and an iron-based catalyst [36] are also reported to have been used.

Given the data published in relevant scientific and engineering papers over recent years [37, 38], it can be seen that creation of heterogeneous catalysts based on organic polymers is one of the most promising directions in this field of research. These materials have a broad spectrum of various properties that can be finely adjusted during synthesis, thus making it possible to obtain a number of catalysts suitable for hydroformylation of different substrates and solving many specific problems. Therefore, this review describes and systematizes data on the catalysts based on organic polymers as well as the specific features of the hydroformylation reaction where such catalysts are involved. The most successful in this field were the efforts made with the use of phosphorus-containing polymers, particularly the polyaromatic organic compounds (POPs—Porous Organic Polymers), which are given the greatest attention here. Also considered are heterogenized catalysts based on nitrogen-containing polymers.

1. HYDROFORMYLATION CATALYSTS BASED ON PHOSPHORUS-CONTAINING POLYMERS

Phosphorus-containing ligands are often used in homogeneous hydroformylation, because they improve stability, activity and selectivity of Rh-based catalytic systems. They are also used in some cases of hydroformylation on cobalt complexes. Therefore, most of the studies focused on the development of polymer-based catalysts imply that the phosphorus-containing fragments are fixed in the polymer structure and the obtained materials are treated with noble metal complexes thereafter. Rhodim catalysts based on a modified styrene and divinylbenzene copolymer were among the first to be obtained and studied [39–49]. The copolymer was chloromethylated [39] or brominated [40] by aromatic fragments and then subjected to the action of LiPPh2 in THF in order to obtain phosphine-containing polymers, onto which rhodium was later applied. The catalysts so obtained showed somewhat lower activity during pentene-1 hydroformylation [40] compared with the homogeneous analogs, while n-aldehyde selectivity in some cases was higher. Such catalysts can be used for methyl methacrylate hydroformylation as well [42]. The same research team fixed a bidentate phosphine ligand [43] in a similar manner in order to increase stability and selectivity of a rhodium complex. One of the obtained catalysts was efficiently used in twenty (20) successive reactions and did not become less active even when filtered in air.

Such phosphine-containing materials can be used for fixing other metals, namely ruthenium [46] and cobalt [47], active in hydroformylation. For instance, the PhCCo3(CO)9 cobalt clusters fixed on poly(benzyldiphenylphosphine/arsine)styrene were quite active during linear olefin hydroformylation [50].

The catalysts based on chloromethylated polystyrene-divinylbenzene are described in [48]; particular attention is given to the effect of the starting material cross-linking degree on the activity of the rhodium catalyst in propylene hydroformylation. The phosphine-containing polymers obtained thereby were sulfonated [49] to be used in propylene hydroformylation in aqueous phase.

The authors of [51] used a modified styrene monomer 1 to obtain an optically active phosphine ligand during copolymer synthesis (Fig. 1). The subsequent modification was carried out for the individual functional groups contained therein. Optical purity of the obtained aldehydes was much lower than in the case of similar soluble rhodium complexes. Slightly higher enantioselectivity was achieved by using bimetallic catalysts, which contained platinum and tin and were based on the aforesaid material [52, 53]. Also, a vinyl monomer, initially containing a phosphine fragment was used for copolymerization (2 in Fig. 1).

When a platinum complex fixed on a polymeric ligand synthesized using chiral (2S,4S)-N-(tert-butoxycarbonyl)-4-(diphenylphosphino)-2-[(diphenylphosphino)methyl]pyrrolidine [(–)-BPPM], was employed optically-pure-product yields over 70% during styrene hydroformylation were achieved [54, 55].

In [56], insoluble phosphorus-containing copolymers suitable for enantioselective hydroformylation are reported to have been obtained. Binaphos chiral ligand ([1-[2-(12,14-dioxa-13-phosphopentacyclo[13.8.0.02,11.03,8.018,23]tricosa-1(15),2(11),3,5,7,9,16,18,20,22-decaene-13-yloxy)-naphthene-1-yl]naphthalene-2-yl]dipheninephosphan), premodified by the method of introduction of vinyl fragments into the structure, was used as the monomer for copolymerization with ethylstyrene and divinylbenzene. In the experiment where a catalyst based on the aforesaid copolymer was used at 60°С under 2.0 MPa, the substrate was completely converted to aldehydes with the iso/n ratio equal to 5.3 and the iso-aldehyde (R) enantiomeric excess (ee) reaching 89%, which was comparable with the results obtained for the Rh(acac)/Binaphos homogeneous system, with the homogeneous catalyst activity remaining the same for six (6) cycles. As a follow-up to these studies, [57] describes hydroformylation of various gaseous substrates; for instance, 3,3,3-trifluoropropene was hydroformylated at 40°C under 8.0 MPa, and the total conversion rate reached 100%, with the iso/n ratio equal to 13.3 and product enantiomeric purity equal to 90% in S-configuration; also, the cis-2-butene reaction was conducted at 60°C under the syngas pressure of 3.2 MPa, where the substrate was quantitatively converted to 2-methylpropanal with an optical purity of 80%. The authors of [58] examined the same material in the course of asymmetric hydroformylation of a number of terminal olefins in the supercritical CO2 flow at 60°C under the total pressure of 12.0 MPa. The styrene-to-aldehydes conversion rate was 49%, with the iso/n ratio equal to 4.6 and ee (S) equal to 77%. The aldehyde yield during hexene-1 and octene-1 hydroformylation reached 40% and 47%, with the linear product prevailing therein (n/iso was 3.8 in both cases). A copolymer of a similar structure was studied in styrene and vinyl acetate hydroformylation reaction at 60°С under 2.0 MPa; 100% styrene conversion was reached in twelve (12) hours, wherein the iso/n ratio was 5.7; the conversion rate of vinyl acetate reached 87%, wherein the iso/n ratio was 5.3 and optical purity was 86% [59].

Another rhodium catalyst based on styrene and divinylbenzene copolymer was obtained by means of polyethylene glycol grafting; the phosphine fragment was fixed onto the terminal hydroxyl groups of polyethylene glycol [60], which made it possible to make the material amphiphilic and conduct hydroformylation in aqueous medium. Using Tentagel-S-NH2, a commercially available material of similar nature containing amino groups, and bis-3,4-diazophospholan optically active ligands, the authors of [61] developed enantioselective heterogenized rhodium catalysts that could be recycled many times.

It is suggested that hydroformylation over catalysts based on phosphine-modified styrene and divinylbenzene copolymers should be used for separation of ethylene from gas mixtures, where its content is comparatively low [62]. An example of using such a catalyst for hydroformylation of hexene-1 in supercritical СО2 can be found in [63].

A bidentate ligand, namely Nixantphos [4,5-bis(diphenylphosphino)-9,9-dimethylxanthene], was fixed on several different polymers to obtain both soluble and insoluble materials [64]. The insoluble materials included a polystyrene-based material with isocyanate groups as well as a material obtained from polyglycerol, hexamethylene diisocyanate and Nixantphos ligand, and the catalyst based on the latter material proved to be highly regioselective in octene-1 hydroformylation (97%). The procedure of fixing the Nixantphos on highly branched poly arylene oxindole is described in [65]; the obtained rhodium catalyst was highly active in five (5) successive reactions, with <0.3 ppm of rhodium washed out (beginning with the second cycle).

Phosphine-containing fragments were fixed on a chitosan biopolymer [66] through the reaction of chitosan amino groups with o-carbonyl phenyl–diphenylphosphine. The rhodium catalyst based on this material remained active during four (4) cycles (with octene-1 conversion rate of circa 75%). As the covalent fixing of phosphines is required to obtain hydroformylation catalysts, the functionalized polyethylene chips containing amino groups [65], and the Nafion resin, whose sulfo groups were chlorinated to form –SO2Cl and subjected to the action of LiPPh2 [68], can also be used.

Yet another approach should be described. This approach is based on graft polymerization, where a new polymer chain emerging from unsaturated phosphine ligands or their precursors is grafted onto the existing polymer. On the basis of (trimethylolpropane)-trimethylacrylate containing residual double bonds in the pores, rhodium catalysts of such type were obtained. Subsequently, these were used in flow-through hydroformylation of propylene [69] and hexene-1 [70] in gas phase and liquid phase, respectively. The γ-radiation effect on polypropylene in the presence of unsaturated phosphine ligands also brings about the grafting of phosphine-containing polymer fragments onto the polypropylene base [71, 72]. The obtained materials were efficiently used in hexene-1 hydroformylation, with <1.0% of rhodium washed out into the organic phase. The commercially available FibercatTM rhodium catalysts, based on polyethylene and produced in a similar way, were used in flow-through hydroformylation of ethylene [73] and worked steadily for twenty (20) h.

2. CATALYSTS BASED ON POROUS ORGANIC POLYMERS

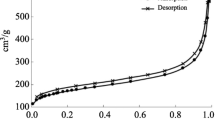

There are a number of contemporary studies that deal with the synthesis of porous organic polymers (POPs) notable for their extensive surface area, ability to modify it by various functional groups and the adjustability of sizes and shapes of their pores. These advantages favor using them as carriers for the immobilization of homogeneous complexes.

At present, the main method for synthesis of such polymers (for them to be used in catalysis) is template-free solvothermal radical polymerization [74]. The advantage of this method is that it does not require metal-containing compounds as a catalyst, which prevents contamination of the final catalyst with other metals and makes this method the most promising one for production of porous organic polymers [75]. The surface area and the shape and size of pores are quite important for the process of fixing a metal complex on the carrier surface. The required porosity is achieved by using monomers, which form a rigid porous polymeric structure under the polymerization conditions; thus the proper choice of a building block is critical for their synthesis. The methods for the synthesis of porous organic polymer carriers based on triphenylphosphine POL–PPh3 (where POL stands for porous organic ligand) were developed for the first time in 2014 [76]. Tris(4-vinylphenyl)phosphine (3vPPh3) was used as the starting monomer, and POL–PPh3 obtained through polymerization of that monomer had a high surface area (1086 m2/g), structural porosity, and high thermal stability (up to 440°C). With the help of X-ray photoelectron spectroscopy, it was found that there was coordination of rhodium with phosphorus atoms in a rhodium catalyst based on POL–PPh3, which indicated that rhodium atoms had been efficiently fixed on the carrier. Given the IR-, EXAFS-, NMR-spectroscopy, and transmission electron microscopy data, two probable structures were suggested for the complex [77]. It was implied that in either structure three strong phosphorus-rhodium coordination bonds were present; however, rhodium coordination in the first structure took place in the same plane with three phosphorus atoms, while in the second one three phosphorus atoms and a single rhodium atom formed a triangular pyramid. The polydentate bonding of rhodium with phosphorus was confirmed by the authors of [78]. In their opinion, the presence of a considerable excess of uncoordinated phosphorus prevented metal from being leached and, therefore, helped to improve the catalyst stability. The Rh/POL–PPh3 polymer complex actively catalyzed hydroformylation of ethylene, octene-1 and dodecene-1 at 120°С under the syngas pressure of 1.0 MPa. In all the cases aldehyde yields were close to 90% [76].

An alternative way of synthesis of the same catalyst, which includes preliminary formation of the Rh(3v-PPh3)(CO)(acac) complex, which is then subjected to solvothermal radical polymerization, results in a material wherein rhodium atoms are inside the volume of the polymer rather than on the surface, unlike the previous case (Fig. 2) [79]. The porosity characteristics and rhodium content in the catalysts obtained by different methods are virtually the same, while the catalytic activity in the hydroformylation reaction in the latter case is significantly lower because the active centers are difficult to access.

Methods for synthesis of a rhodium catalyst based on POL–PPh3 [79]: (a) one-stage synthesis and (b) sequential synthesis.

A decline in the polymer phosphorus content, when polyvinyl benzene fragments are introduced into the ligand structure, adversely affects both the activity and the stability of a heterogeneous catalyst [80]. The use of respective diphosphines containing a vinylic substitute during polymer synthesis makes it possible to keep a high concentration of the complexing phosphine groups and, at the same time, add flexibility to the polymer framework (Fig. 3) [81]. Due to the considerable expansion in the organic solvent, a catalyst with a ligand such as Rh/POL-dppe allows a hydroformylation under quasi-homogeneous conditions, which significantly increases its activity, with a minimal rhodium leaching. Furthermore, linear aldehyde selectivity (n/iso = 2.45 in the hydroformylation products such as octene-1 and dodecene-1) is even higher than when a similar homogeneous system, namely Rh(acac)(CO)2/dppe (n/iso circa 1.29), is used.

Monomers for the synthesis: 3—POL-dppe, 4—POL-dppm, 5—POL-dppb [81].

The wide variability of the monomers for the synthesis of porous organic ligands opens the way for obtaining catalysts with a wide variety of properties. For instance, a chiral monomer, namely (S)-5,5′-divinyl-BINAP {where BINAP is [2,2′-bis(diphenylphosphino)-1,1′-binaphtyl]}, was successfully synthesized and built into an organic polymer structure (Poly-1, Poly-2, Poly-3) (Fig. 4) [82]. In the course of styrene asymmetric hydroformylation, the catalysts based on all these three ligands were equally highly active, but the regioselectivity and enantioselectivity figures for the catalysts with Poly-1 and Poly-2 ligands having a porous structure were considerably higher than those for the non-porous Poly-3 material, even when compared with a similar homogeneous system. According to the authors, this is accounted for by the “chiral nanopockets” creating steric conditions that help to increase regioselectivity and enantioselectivity near the metal center. The Poly-3 ligand did not have a porous structure because of the presence of long carbon chains, and so it did not have such “nanopockets.”

CPOL synthesis based on BINAP, where 6 is divinylbenzene, 7—1,3,5-tri(4-vinylphenyl)benzene, and 8—ethylene glycol dimethacrylate [82].

It is worth noting that all the obtained catalysts proved to be sufficiently stable under the reaction conditions and remained equally active for seven (7) cycles. A study of the structure of an Rh/Poly-1 complex by the EXAFS method showed a rhodium atom coordinating with three (3) phosphorus atoms from BINAP and two (2) oxygen atoms from acetylacetonate; no Rh–Rh bonds were found therein, which suggested that there were no metallic rhodium clusters or particles. After seven (7) cycles the Rh/Poly-1 structure changed: acetylacetonate was replaced by a CO molecule and a hydrogen atom in the coordination sphere of rhodium.

Incorporation of the sterically hindered Xantphos [4,5-bis(diphenylphosphino)-9,9-dimethylxantene]into the POL–PPh3 polymer structure leads to some decline in activity of the Rh/CPOL–PPh3&Xantphos catalyst during octene-1 hydroformylation (100°С, 1.0 MPa), as compared with Rh/POL–PPh3, but regioselectivity increases nearly tenfold (n/iso 9 vs. 0.8) [83]. It is observed that although replacing a tris(4-vinylphenyl)phosphine by tris(phenyl)vinylene or divinylbenzene during ligand synthesis makes it possible to obtain catalysts with fairly high regioselectivity (n/iso 5.7 and 3.5, respectively), their resulting activity is even lower, because the phosphorus concentration in the polymer structure is lower too.

Using the BIPHEPHOS vinyl derivative {BP, 6,6′-[(3,3′-di-tert-butyl-5,5′-dimetoxy-1,1′-diphenyl-2,2′-diyl)bis(oxy)]bis(dibenzo[d,f][1,3,2]dioxaphosphepine)}as a comonomer during ligand synthesis made the octene-1 hydroformylation regioselectivity higher [84]. Within four 4 h, at 100°C under 1.0 MPa, with the catalyst based on the obtained copolymer (Rh/CPOL-BP&PPh3), the total conversion rate of octene-1 reached 97%; conversion to aldehydes reached 58%, and the n/iso ratio reached 49. Heptene-1 hydroformylation under similar conditions results in the same n/iso ratio, with the conversion rate reaching 98% and aldehyde selectivity reaching 52%. It should be noted that when internal alkenes (octene-2, heptene-2, butene-2, and an isomeric butene mixture [85]) are used as substrates, the linear aldehyde selectivity remains very high (n/iso 13.3, 11.5, and 56.0, respectively). A somewhat unexpected result was obtained in butеne-1 hydroformylation when a catalyst based on porous polymer phosphites was used, namely POL–P(OPh)3 and Rh/CPOL-BP&P(OPh)3 [86]: while activity was rather high, regioselectivity was lower than that for the phosphine analogs, with the n/iso ratio reaching 40.

By varying the porous structure characteristics and phosphorus concentration in the polymer through the use of tris(4-vinylphenyl)phosphine, divinylbenzene, and BIPHEPHOS and 1,2-bis(diphenylphosphino)ethane vinyl derivatives in different combinations as the comonomers, the authors of [87] found that the optimum combination of steric factors and saturation with complexing phosphorus-containing fragments was attained in the СPOL–BP&10PPh3 polymer. Furthermore, after application of rhodium the P/Rh ratio reached 253.2 helping to improve the catalyst stability. Using X-ray photoelectron spectroscopy and EXAFS spectroscopy it was shown that a rhodium atom coordinated with three (3) phosphorus atoms (two from BP and one from PPh3) and two (2) acetylacetonate-anion oxygen atoms, and that during the interaction with syngas under hydroformylation conditions the acetylacetonate was replaced by a CO molecule and a hydrogen atom in the coordination sphere of rhodium, which corresponded to the structure of a catalytically active complex under homogeneous conditions [85, 87]. The Rh/CPOL–BP&10PPh3 catalyst activity was examined in the case of propene hydroformylation in a fixed-bed reactor, where even under atmospheric pressure the reaction TOF value reached 360 h–1 and the n/iso ratio was 36. Increasing the gas mixture pressure up to 3.0 MPa resulted in the TOF value increasing up to 4555 h–1 and the n/iso ratio declining to 11.

The use of phosphite ligands in hydroformylation is complicated because their high sensitivity to water. However, the surface of porous organic polymers (POPs) is quite hydrophobic. The authors of [88] therefore examine hydrolytic resistance of a number of superhydrophobic polymers that had been obtained through radical polymerization of vinyl-substituted derivatives of triphenylphosphite (Fig. 5).

Monomers for the synthesis of carriers such as POL–P(O-t-Bu-Ph)3 (9), POL–P(OPh)3 (10), and POL–BINOL (11) [88].

With POL–P(O-tert-Bu-Ph)3 used as an example, it was shown that the polymer was subjected neither to hydrolysis nor to destruction while it was boiled for ten (10) days in toluene containing 5 wt % of water. The heterogeneous rhodium catalysts based on POL–P(O-tert-Bu-Ph)3 (9) and POL–P(OPh)3 (10) proved to be as active in octene-2 hydroformylation as the homogeneous complexes with corresponding low-molecular phosphites [88]. In this case, similar to the polymer carriers based on phosphine monomers [82], the catalyst activity depends significantly on whether the ligand is of porous structure, e.g. a rhodium complex applied to non-porous polyphosphite proved to be much less active in octene-2 hydroformylation. Under the same conditions, the aldehyde yield with the catalysts based on porous carrier ligands tended to be nearly quantitative, while in the non-porous polyphosphite case the maximum yield was only 62%. The rhodium complex applied to POL–P(O-tert-Bu-Ph)3 was active in hydroformylation not only of linear internal and cyclic olefins but also of a large number of unsaturated compounds with a complex structure, including heteroatomic ones [89]. The authors of [89] showed that even when the reaction was conducted in water, the catalyst properties remained the same for at least ten (10) cycles. The dependence of the aldehyde yield on the phosphorus/rhodium ratio in the catalyst has a maximum; the optimum catalyst activity and stability values are observed when there is a ninefold excess of phosphite groups relative to metal.

Another variety of porous organic ligands for heterogenization of hydroformylation rhodium catalysts (CPOL–BPa&PPh3) was obtained by solvothermal copolymerization of tris(4-vinylphenyl)phosphine and a substituted vinylic phosphoramidate ligand (BPa) [89]. The Rh/CPOL–ВPa&PPh3 catalyst remained active during ten (10) cycles in the course of hexene-1 hydroformylation, wherein the total conversion rate was 90%; aldehyde selectivity was 87.8%, and the n/iso ratio was 50.1. In diphenylacetylene hydroformylation this catalyst proved to be not only highly selective with respect to the formation of α,β-unsaturated aldehydes (79%) but also stereospecific with respect to the E-isomer (E/Z = 160) [90]. When a BPa fragment in the polymer structure was substituted by a more sterically hindered BINAP, the yield of α,β-unsaturated aldehydes grew even higher (90%), but regioselectivity declined (E/Z = 60). Catalytic activity of Rh/POL-BINAPa&PPh3 was also studied during hydroformylation of quite a number of symmetric and nonsymmetric alkynes, where their yields were 61–98% and the E/Z ratio in most cases was 40/1 [90].

It is also worth noting that there is another kind of phosphorus-containing polyaromatic network that can be used in hydroformylation, specifically the so-called Knitting Aryl Polymers (KAPs) [91], which are obtained through polycondensation of triphenylphosphine and different aromatic hydrocarbons (benzene, toluene, biphenyl, or 1,3,5-triphenylbenzene) with formaldehyde dimethylacetal. These materials have a high surface area (524 to 723 m2/g), and rhodium catalysts based on them remain as active as they were initially for at least three (3) successive reactions, but they do not have the regioselectivity typical of the phosphine rhodium complexes (the n/iso ratio is 0.51 to 0.83 for С6–С13 olefins).

The authors of [92] describe cases of using heterogeneous rhodium catalysts based on phosphorus-containing covalent organic frameworks (P–COFs) in styrene hydroformylation. The frameworks were synthesized through the Schiff reaction, and the structure and some structural characteristics of the P-COF-2 material are shown in Fig. 6. The authors note the high degree of crystallinity and porosity of the material. The surface area of P-COF-2 [based on tris(4-formylphenyl)phosphane and benzidine] reached 2387 m2/g and the pore volume—4.22 cm3/g, which exceeded the parameters of the known porous organic polymers based on triphenylphosphine.

The P-COF-2 material structure: (a) distribution of phosphorus and rhodium atoms as viewed by means of energy dispersive X-ray spectroscopy (SEM-EDS mapping); (b) visualization of a fragment of the assumed hexagonal crystalline lattice of the material; (c) and (d) microphotographs of the P-COF-2 material and Rh-P-COF-2 catalyst, respectively, taken with a transmission electron microscope.

The typical TOF values for the Rh–P–COFs catalysts in styrene hydroformylation at 100°C under the syngas pressure 2.0 MPa were 2000–3000 h–1, and the catalysts remained active in at least five successive experiments. The reaction regioselectivity expressed by the n/iso value was 1.0 for styrene, and for the linear alkenes, namely hexene-1 and octene-1, it was 1.1.

Thus, to conclude this section, it should be noted that certain success has been achieved in developing the heterogeneous hydroformylation catalysts based on porous organic polymers. The numerous methods of physical-chemical analysis make it possible to examine various parameters of new catalytic systems, which, in turn, makes them adjustable. The relationship between the fundamental parameters of heterogeneous hydroformylation catalysts and their behavior in catalytic processes has been determined, and new fields of application of such systems have been found, including those for the fine organic synthesis reactions. It is also known that a sample of shaped (granular) rhodium catalyst based on a phosphorus-containing porous polymer has been obtained for pilot tests, which are to be run during linear alkene hydroformylation in a continuous flow plant [93].

3. OTHER POLYMERS USED IN HETEROGENEOUS HYDROFORMYLATION

The polymers containing phosphine and phosphite fragments justly top the list of the polymer materials used as the basis for the development of hydroformylation catalysts, both in terms of the activity and selectivity values attained so far for such catalysts and in terms of the scientific papers written about them. This status fully corresponds to the position occupied by phosphorus-containing ligand complexes in homogeneous hydroformylation. The second important heteroatom contained in the polymers used to obtain hydroformylation catalysts is nitrogen. Quite often, nitrogen- and phosphorus-containing polymer catalysts are developed in parallel. For example, the authors of [71, 72], where polymer phosphorus-containing fragments were grafted onto polypropylene by means of γ-radiation, developed similar materials where vinylpyridine was used [94], and obtained a cobalt catalyst on its basis, which was then efficiently used in hexene-1 hydroformylation. The team that was developing acrylic copolymers of phosphine monomers [69, 70] synthesized a crosslinked copolymer of 2-vinylpyridine, methylacrylate and ethylene diacrylate [95 ] and created a rhodium catalyst, which was then used for propylene hydroformylation in a flow-through reactor. The catalyst activity declined over time and was accompanied by a change in colors of the particles; the authors assume that rhodium could have been reducing and taking metal form during the reaction. Also, a chloromethylated copolymer of styrene and divinylbenzene is reported to have been used to obtain a material containing positively charged –NR3+ groups with quaternized nitrogen atoms helping to keep the anions, namely [HOs3(CO)11]– and [HFe3(CO)11]– on its surface [96]. These quite unconventional catalysts were used in hydroformylation as well, but their activity was low, and there were significant losses of metals due to leaching.

On the basis of copolymers of vinylpyridine with divinylbenzene [97] and styrene with N-pyrrolidine pyridine [98], rhodium catalysts were developed and then used in olefin hydroformylation and proved to be comparatively active under the conditions explored. Hydroformylation using rhodium catalysts based on natural nitrogen-containing chitin and chitosan polymers was reported [99]. A catalyst based on chitosan modified with pyridine fragments was described in [66], but its activity during hydroformylation was lower than that of the phosphorus analog. Epoxy resin was obtained from monomer 13 (Fig. 7) [100], where a rhodium complex was used as the polymerization initiator, and therefore no separate metal application procedure was required. Although the catalyst activity declined after the first cycle, in the four (4) subsequent cycles the conversion rate and selectivity did not change.

The porous organic frameworks synthesized from nitrogen-containing monomers 14–17 (Fig. 7) can be used in rhodium hydroformylation as well [101]. They are characterized by high surface area values (1690– 1859 m2/g). Although the catalysts based on them are less active than their homogeneous analogs, some of them exceed an Rh/C catalyst in this respect and remain active during 4–5 successive reactions. It should be added that the POPs based on 6,6′-divinyl-2,2′-bipyridine have been efficiently used in obtaining a rhodium catalyst for a hydroformylation-related process, namely methanol carbonylation [102].

Materials with methylimidazole fragments, which form N-heterocyclic carbenium complexes (NHC–Rh) when rhodium is applied, were obtained from a chlorinated styrene–divinybenzene copolymer [103]. The catalysts so synthesized showed high activity and regioselectivity in hexene-1 hydroformylation (n/iso = 3.5–7.0), and, furthermore, they remained active in a number of successive reactions.

It should also be pointed out that nitrogen-containing materials open new applications for rhodium-based catalytic systems. Rhodium complexes with tertiary amines can catalyze tandem hydroformylation-hydrogenation of olefins with alcohols obtained thereby. This may be of practical interest for the chemical industry since much of the aldehydes produced in the world are further processed into alcohols. This reaction, wherein nitrogen-containing polymer materials are involved, is dealt with in [104–106]. The various polymers used in those materials contain amino groups, and fragments of pyridine, cyanide and cyanate. Another specific use of a rhodium catalyst based on a nitrogen-containing polymer [poly(4-vinylpyridine)] is hydroformylation under water-gas shift reaction conditions [107], when syngas for hydroformylation is evolved in situ from carbon monoxide and water.

There are examples of using sulfur-containing polymers in the synthesis of rhodium catalysts designed for hydroformylation [108]. Creation of catalysts based on metal-organic frameworks (MOF) is another interesting line of reaseach; some rhodium catalysts immobilized on MOFs and containing zinc [109–111] or chromium [112, 113] are known to have been used. As a rule, regioselectivity of such catalysts is quite low, but they can be used many times. According to the authors of [113], hydroformylation in the system that they have been studying occurs under homogeneous catalysis conditions. Under the syngas pressure, rhodium goes into the liquid phase in the form of rhodium hydrido-carbonyls, and after the pressure has been released it again coordinates with the carrier.

As an individual group of hydroformylation polymer-based catalysts we can single out the ones obtained from ion-exchange resins, where metal is retained on the polymer substrate due to electrostatic interactions. In the studies where anion-exchange resins are used (mainly of the Amberlyst type), rhodium is usually applied to the polymer in the form of a complex with TPPTS [114, 115] or TPPMS (monosulfonated triphenylphosphine sodium salt) [97, 116]. The catalysts obtained are used for hydroformylation in polar solvents (alcohols), where they can work steadily in a number of successive reactions. In particular, they were applied in a tandem hydroformylation–acetalization [116]. Cation-exchange resins are also known to have been used. The authors of [117] applied rhodium from the Rh(NO3)3 solution to the Nafion cation-exchange resin. In other papers the use of a more sophisticated approach is described where, first of all, rhodium complexes with ligands containing amino groups were obtained and then interacted with the H-forms of cation-exchange resins [118, 119]. The catalysts also remained active in a number of successive reactions, but their activity was quite low, and so was the n-aldehyde selectivity of the reactions that they catalyzed.

4. CONCLUSIONS

In summary, some methods for obtaining heterogeneous catalysts based on organic polymers for hydroformylation reactions, including asymmetric ones, have been considered and data on the use of those catalysts in hydroformylation of various unsaturated compounds have been systematized in this review. The relationship between the structures of catalysts and their behavior in catalytic processes, including criteria such as activity, selectivity, mechanical and thermal resistance and stability to the leaching of metal into the liquid phase, has been characterized. It is noted that rhodium catalysts based on porous organic polymers meet the aforesaid criteria best of all. This brings us to the conclusion that they have potential to be used in developing new oxo-synthesis processes with heterogeneous catalysts.

ADDITIONAL INFORMATION

D.P. Zhuchkov, ORCID: https://orcid.org/0000-0001-8480-0723

M.V. Nenasheva, ORCID: https://orcid.org/0000-0002-0770-8277

M.V. Terenina, ORCID: https://orcid.org/0000-0002-4336-9786

Yu.S. Kardasheva, ORCID: https://orcid.org/0000-0002-6580-1082

D.N. Gorbunov, ORCID: https://orcid.org/0000-0002-1603-8957

E.A. Karakhanov, ORCID: https://orcid.org/0000-0003-4727-954X

REFERENCES

Börner, A. and Franke R., Hydroformylation. Fundamentals, Processes, and Applications in Organic Synthesis, vol. 2, New York: John Wiley and Sons, 2016.

Gorbunov, D.N., Volkov, A.V., Kardasheva, Y.S., Maksimov, A.L., and Karakhanov, E.A., Petrol. Chem., 2015, vol. 55, p. 587. https://doi.org/10.1134/S0965544115080046

Kuntz, E., Chemtech., 1987, vol. 17, no. 9, p. 570.

Han, D., Li, X., Zhang, H., Liu, Zh., Li, J., and Li, C., J. Catal., 2006, vol. 243, no. 2, p. 318. https://doi.org/10.1016/j.jcat.2006.08.003

Zhou, W. and He, D., Chem. Commun., 2008, vol. 44, p. 5839. https://doi.org/10.1039/B812910J

Li, X., Ding Yu, Jiao, G., Li, J., Lin, R., Gong, L., Yan, L., and Zhu, H., Appl. Catal. A: Gen., 2009, vol. 353, no. 2, p. 266. https://doi.org/10.1016/j.apcata.2008.10.052

Neves, Â.C.B., Calvete, M.J.F., Pinho e Melo, T.M., and Pereira, M.M., Eur. J. Org. Chem., 2012, vol. 32, p. 6309. https://doi.org/10.1002/ejoc.201200709

Lenarda, M., Storaro, L., Ganzerla, R., J. Mol. Catal. A: Chem., 1996, vol. 111, no. 3, p. 203. https://doi.org/10.1016/1381-1169(96)00211-7

Oresmaa, L., Moreno, M.A., Jakonen, M., Suvanto, S., and Haukka, M., Appl. Catal. A: Gen., 2009, vol. 353, no. 1, p. 113. https://doi.org/10.1016/j.apcata.2008.10.028

Chansarkar, R., Kelkar, A.A., and Chaudhari, A.A., Ind. Eng. Chem. Res., 2009, vol. 48, no. 21, p. 9479. https://doi.org/10.1021/ie900269z

Román-Martinez, M.C., Dı́az-Auñón, J.A., Salinas-Martı́nez de Lecea, C., and Alper, H., J. Mol. Catal. A: Chem., 2004, vol. 213, no. 2, p. 177. https://doi.org/10.1016/j.molcata.2003.12.015

Zhao, Y.-H., Zhang, Y.-F., Wu, Zh.-K., and Bai, Sh.-L., Compos. Part B: Eng., 2016, vol. 84, p. 52. https://doi.org/10.1016/j.compositesb.2015.08.074

Xue, X., Song, Y., Xu, Y., and Wang, Y., New J. Chem., 2018, vol. 42, p. 6640. https://doi.org/10.1039/C8NJ00447A

Tan, M., Yuang, G., Wang, T., Vitidsant, T., Li, J., Wei, Q., Ai, P., Wu, M., Zheng, J., and Tsubaki, N., Catal. Sci. Technol., 2016, vol. 6, p. 1162. https://doi.org/10.1039/C5CY01355K

Ma, Y., Fu, J., Gao Zh., Zhang, L., Li Ch., and Wang, T., Catalysts, 2017, vol. 7, vol. 7(4), Article ID 103. https://doi.org/10.3390/catal7040103

Shätz, A., Reiser, O., and Stark, W.J., Chem. Eur. J., 2010, vol. 16, p. 8950. https://doi.org/10.1002/chem.200903462

Tan, M., Ishikuro, Yu., Hosoi, Yu., Yamane, N., Ai, P., Zhang, P., Yuang G. Wu, M., Yang, R., and Tsubaki, N., Chem. Eng. J., 2017, vol. 330, p. 863. https://doi.org/10.1016/j.cej.2017.08.023

Jagtap, S.A., Bhosale, M.A., Sasaki, T., and Bhanage, B.M., Polyhedron, 2016, vol. 120, p. 162. https://doi.org/10.1016/j.poly.2016.08.026

Luo, L., Li, H., Peng, Y., Feng, C., and Zeng, J., Chem NanoMat., 2018, vol. 4, p. 451. https://doi.org/10.1002/cnma.201800033

Su, P., Liu, X., Chen, Y., Liu, H., Zhu, B., Zhang, Sh., and Huang, W., Nanomaterials, 2018, vol. 8. article no. 755. https://doi.org/10.3390/nano8100755

Zhang, X., Lu, J., Jin, L., and Wei, M., Chin. Sci. Bull., 2008, vol. 53, no. 9, p. 1329. https://doi.org/10.1007/s11434-008-0071-5

Liu, C., Zhang, J., Liu, H., Qiu, J., and Zhang, X., Ind. Eng. Chem. Res., 2019, vol. 58, vol. 47, p. 21285. https://doi.org/10.1021/acs.iecr.9b03598

Kim, T., Celik, F.E., Hanna, D.G., Shylesh, S., Werner, S., and Bell, A.T., Top. Catal., 2011, vol. 54, p. 299. https://doi.org/10.1007/s11244-011-9664-3

Zhang, X., Lu, S., Zhong, M., Zhao, Y., and Yang, Q., Chin. J. Catal., 2015, vol. 36, no. 2, p. 168. https://doi.org/10.1016/S1872-2067(14)60228-X

van Leeuwen, P.W.N.M., Sandee, A.J., Reek, J.N.H, and Kamer, P.C., J. Mol. Catal. A: Chem., 2002, vols. 182– 183, p. 107. https://doi.org/10.1016/S1381-1169(01)00504-0

Sandee, A.J., Reek, J.N.H., Kamer, P.C., and van Leeuwen, P.W.N.M., J. Am. Chem. Soc., 2001, vol. 123, p. 8468. https://doi.org/10.1021/ja010150p

Gorbunov, D., Safronova, D., Kardasheva, Yu., Maximov, A., Rosenberg, E., and Karakhanov, E., ACS Appl. Mater. Interfaces, 2018, vol. 10, p. 26566. https://doi.org/10.1021/acsami.8b02797

Cunillera, A., Blanco, C., Gual, A., Marinkovic, J.M., Garcia-Suarez, E.J., Riisager, A., Claver, C., Ruiz, A., and Godard, C., ChemCatChem., 2019, vol. 11, p. 2195. https://doi.org/10.1002/cctc.201900211

Such-Basanez, I., Salinas-Martinez de Lecea, C., and Roman-Martinez, M.C., Curr. Catal., 2012, vol. 1, p. 100. https://doi.org/10.2174/2211544711201020100

Weiß, A., Giese, M., Lijewski, M., Franke, R., Wasserscheid, P., Haumann, M., Catal. Sci. Technol., 2017, vol. 7, p. 5562. https://doi.org/10.1039/C7CY01346A

Arhancet, J.P., Davis, M.E., Merola, J.S., and Hanson, B.E., Nature, 1989, vol. 339, no. 6224, p. 454. https://doi.org/10.1038/339454a0

Amsler, J., Sarma, B.B., Agostini, G., Prieto, G., Plessow, Ph.N., and Studt, F., J. Am. Chem. Soc., 2020, vol. 142, p. 5087. https://doi.org/10.1021/jacs.9b12171

Lang, R., Li, T., Matsumura, D., Miao, S., Ren, Y., Cui, Y., Tan, Y., Qiao, B., Li, L., and Wang, A., Angew. Chem. Int. Ed., 2016, vol. 55, p. 16054. https://doi.org/10.1002/anie.201607885

Wang, L., Zhang, W., Wang, S., Gao, Z., Luo, Z., Wang, X., Zeng, R., Li, A., Li, H., and Wang, M., Nature Commun., 2016, vol. 7, article no. 14036. https://doi.org/10.1038/ncomms14036

Liu, Sh., Dai, X., Wang, H., and Shi, F., Chin. J. Chem., 2020, vol. 38, p. 139. https://doi.org/10.1002/cjoc.201900427

Srivastava, A.K., Ali, M., Siangwata, S., Satrawala, N., Smith, G.S., and Joshi, R.K., Asian J. Org. Chem., 2020, vol. 9, p. 377. https://doi.org/10.1002/ajoc.201900649

Hanf, S., Rupflin, L.A., Gläser, R., Schunk, S.A., Catalysts, 2020, vol. 10, p. 510. https://doi.org/10.3390/catal10050510

Dzhardimalieva, G.I., Zharmagambetova, A.K., Kudaibergenov, S.E., Uflyand, I.E., Kinet. Catal., 2020, vol. 61, no. 2, p. 198. https://doi.org/10.1134/S0023158420020044

Čapka, M., Svoboda, P., Černý, M., and Hetflejê, J., Tetrahedron Lett., 1971, no. 50, p. 4787. https://doi.org/10.1016/S0040-4039(01)97616-6

Pittman, C.U. and Hanes, R.M., J. Am. Chem. Soc., 1976, vol. 98, p. 5402. https://doi.org/10.1021/ja00433a064

Lang, W.H., Jurewicz, A.T., Haag, W.O., Whitehurst, D.D., and Rollmann, L.D., J. Organomet. Chem., 1977, vol. 134, p. 85. https://doi.org/10.1016/S0022-328X(00)93615-5

Pittman, C.U., Honnick, W.D., and Yang, J.J., J. Org. Chem., 1980, vol. 45, no. 4, p. 684. https://doi.org/10.1021/jo01292a027

Pittman, C.U. and Hirao, A., J. Org. Chem., 1978, vol. 43, no. 4, p. 640. https://doi.org/10.1021/jo00398a026

Terreros, P., Pastor, E., and Fierro, J.L.G., J. Mol. Cat., 1989, vol. 53, p. 359. https://doi.org/10.1016/0304-5102(89)80068-9

Kalck, P., De Oliveira, E.L., Queau, R., and Peyrille, B., J. Organomet. Chem., 1992, vol. 433, p. C4. https://doi.org/10.1016/0022-328X(92)80146-O

Pittman, C.U. and Wilemon, G.M., J. Org. Chem., 1981, vol. 46, p. 1901. https://doi.org/10.1021/jo00322a031

De-An, C. and Pittman, C.U., J. Mol. Cat., 1983, vol. 21, p. 405. https://doi.org/10.1016/0304-5102(93)80137-J

Ro, K.S. and Woo, S.I., J. Mol. Cat., 1990, vol. 61, p. 27. https://doi.org/10.1016/0304-5102(90)85190-S

Ro, K.S. and Woo, S.I., Appl. Cat., 1991, vol. 69, p. 169. https://doi.org/10.1016/S0166-9834(00)83299-6

Wang, Y. and Lei, Z., React. Pol., 1991, vol. 15, p. 85. https://doi.org/10.1016/0923-1137(91)90151-D

Fritschel, S.J., Ackerman, J.J.H., Keyser, T., and Stille, J.K., J. Org. Chem., 1979, vol. 44, no. 18, p. 3152. https://doi.org/10.1021/jo01332a013

Pittman, C.U., Kawabata, Y., and Flowers, L.I., J. Chem. Soc. Chem. Commun., 1982, no. 9, p. 473. https://doi.org/10.1039/C39820000473

Parrinello, G., Deschenaux, R., and Stille, J.K., J. Org. Chem., 1986, vol. 51, p. 4189. https://doi.org/10.1021/jo00372a017

Parrinello, G. and Stille, J.K., J. Am. Chem. Soc., 1987, vol. 109, p. 7122. https://doi.org/10.1021/ja00257a036

Stille, J.K. and Parrinello, G., J. Mol. Cat., 1983, vol. 21, p. 203. https://doi.org/10.1016/0304-5102(93)80120-J

Nozaki, K., Itoi, Y., Shibahara, F., Shirakawa, E., Ohta, T., Takaya, H., and Hiyama, T., J. Am. Chem. Soc., 1998, vol. 120, no. 16, p. 4051. https://doi.org/10.1021/ja973408d

Nozaki, K., Shibahara, F., and Hiyama, T., Chem. Lett., 2000, vol. 29, no. 6, p. 694. https://doi.org/10.1246/cl.2000.694

Shibahara, F., Nozaki, K., and Hiyama, T., J. Am. Chem. Soc., 2003, vol. 125, no. 28, p. 8555. https://doi.org/10.1021/ja034447u

Shibahara, F., Nozaki, K., Matsuo, T., and Hiyama, T., Bioorg. Med. Chem. Lett., 2002, vol. 12, no. 14, p. 1825. https://doi.org/10.1016/S0960-894X(02)00267-6

Uozumi, Y. and Nakazono, M., Adv. Synth. Catal., 2002, vol. 344, p. 274. https://doi.org/10.1002/1615-4169(200206)344:3/4<274::AID-ADSC274>3.0.CO;2-S

Adint, T.T. and Landis, C.R., J. Am. Chem. Soc., 2014, vol. 136, p. 7943. https://doi.org/10.1021/ja501568k

Tenn, W.J., Singley, R.C., Rodriguez, B.R., and Della Mea, J.C., Catal. Commun., 2011, vol. 12, p. 1323. https://doi.org/10.1016/j.catcom.2011.05.001

Fujita, S.-I., Akihara, S., Fujisawa, S., and Arai, M., J. Mol. Catal. A: Chem., 2007, vol. 268, p. 244. https://doi.org/10.1016/j.molcata.2006.12.032

Ricken, S., Osinski, P.W, Eilbracht, P., and Haag, R., J. Mol. Cat. A: Chem., 2006, vol. 257, p. 78. https://doi.org/10.1016/j.molcata.2006.04.037

Verheyen, T., Santillo, N., Marinelli, D., Petricci, E., De Borggraeve, W.M., Vaccaro, L., and Smet, M., ACS Appl. Polym. Mater., 2019, vol. 1, p. 1496. https://doi.org/10.1021/acsapm.9b00240

Makhubela, B.C.E., Jardine, A., and Smith, G.S., Green Chem., 2012, vol. 14, p. 338. https://doi.org/10.1039/C1GC15979H

Koç, F., Michalek, F., Rumi, L., Bannwarth, W., and Haag, R., Synth., 2005, no. 19, p. 3362. https://doi.org/10.1055/s-2005-918479

Bryant, D.E. and Kilner, M., J. Mol. Cat. A: Chem., 2003, vol. 193, p. 83. https://doi.org/10.1016/S1381-1169(02)00493-4

Heinrich, B. and Hjortkjaer, J., J. Mol. Cat., 1993, vol. 81, p. 333. https://doi.org/10.1016/0304-5102(93)85019-P

Anderson, C., Nikitidis, A., Hjortkjaer, J., and Heinrich, B., Appl. Cat. A: Gen., 1993, vol. 96, p. 345. https://doi.org/10.1016/0926-860X(90)80021-6

Hartley, F.R., Murray, S.G., and Nicholson, P.N., J. Mol. Cat., 1982, vol. 16, p. 363. https://doi.org/10.1016/0304-5102(82)85020-7

Hartley, F.R., Murray, S.G., and Sayer, A.T., J. Mol. Cat., 1986, vol. 38, p. 295. https://doi.org/10.1016/0304-5102(86)85036-2

Zeelie, T.A., Root, A., and Krause, A.O.I., Appl. Cat. A: Gen., 2005, vol. 285, p. 96. https://doi.org/10.1016/j.apcata.2005.02.010

Kramer, S., Bennedsen, N.R., and Kegnæs, S., ACS Catalysis, 2018, vol. 8, no. 8, p. 6961. https://doi.org/10.1021/acscatal.8b01167

Sun, Q., Jiang, M., Shen, Z., Jin, Y., Pan, S., Wang, L., Meng, X., Chen, W., Ding, Y., Li, J., and Xiao, F.-S., Chem. Commun., 2014, vol. 50, p. 11844. https://doi.org/10.1039/C4CC03884C

Jiang, M., Yan, L., Ding, Y., Sun, Q., Liu, J., Zhu, H., Lin, R., Xiao, F., Jiang, Z., and Liu, J., J. Mol. Catal. A: Chem., 2015, vol. 404, p. 211. https://doi.org/10.1016/j.molcata.2015.05.008

Ren, Z., Lyu, Y., Feng, S., Song, X., and Ding, Y., Mol. Catal., 2017, vol. 442, p. 83. https://doi.org/10.1016/j.mcat.2017.09.007

Jiang, M., Yan, L., Sun, X., Lin, R., Song, X., Jiang, Z., and Ding, Y., React. Kinet. Mech. Catal., 2015, vol. 116, p. 223. https://doi.org/10.1007/s11144-015-0887-3

Sun, Q., Dai, Z., Meng, X., and Xiao, F.-S., Catal. Today, 2017, vol. 298, p. 40.

Sun, Q., Dai, Z., Liu, X., Sheng, N., Deng, F., Meng, X., and Xiao, F.-S., J. Am. Chem. Soc., 2015, vol. 137, no. 15, p. 5204. https://doi.org/10.1021/jacs.5b02122

Wang, T., Wang, W., Lyu, Y., Xiong, K., Li, C., Zhang, H., Zhan, Z., Jiang, Z., and Ding, Y., Chin. J. Catal., 2017, vol. 38, no. 4, p. 691. https://doi.org/10.1016/S1872-2067(17)62790-6

Li, C., Sun, K., Wang, W., Yan, L., Sun, X., Wang, Y., Xiong, K., Zhan, Z., Jiang, Z., Ding, Y., J. Catal., 2017, vol. 353, p. 123. https://doi.org/10.1016/j.jcat.2017.07.022

Li, C., Xiong, K., Yan, L., Jiang, M., Song, X., Wang, T., Chen, X., Zhan, Z., and Ding, Y., Catal. Sci. Tech., 2016, vol. 6, p. 2143. https://doi.org/10.1039/C5CY01655J

Wang, Y., Yan, L., Li, C., Jiang, M., Wang, W., and Ding, Y., Appl. Catal. A: Gen., 2018, vol. 551, p. 98. https://doi.org/10.1016/j.apcata.2017.12.013

Wang, Y., Yan, L., Li, C., Jiang, M., Zhao, Z., Hou, G., and Ding, Y., J. Catal., 2018, vol. 368, p. 197. https://doi.org/10.1016/j.jcat.2018.10.012

Li, C., Yan, L., Lu, L., Xiong, K., Wang, W., Jiang, M., Liu, J., Song, X., Zhan, Z., and Jiang, Z., Green Chem., 2016, vol. 18, p. 2995. https://doi.org/10.1039/C6GC00728G

Sun, Q., Aguila, B., Verma, G., Liu, X., Dai, Z., Deng, F., Meng, X., Xiao, F.-S., and Ma, S., Chem., 2016, vol. 1, no. 4, p. 628. https://doi.org/10.1016/j.chempr.2016.09.008

Tang, Y., Dong, K., Wang, S., Sun, Q., Meng, X., and Xiao, F.-S., Mol. Catal., 2019, vol. 474, article no. 110408. https://doi.org/10.1016/j.mcat.2019.110408

Jia, X., Liang, Z., Chen, J., Lv, J., Zhang, K., Gao, M., Zong, L., and Xie, C., Org. Lett., 2019, vol. 21, no. 7, p. 2147. https://doi.org/10.1021/acs.orglett.9b00459

Liang, Z., Chen, J., Chen, X., Zhang, K., Lv, J., Zhao, H., Zhang, G., Xie, C., Zong, L., and Jia, X., Chem. Commun., 2019, vol. 55, p. 13721. https://doi.org/10.1039/C9CC06834A

Jiang, M., Ding, Y., Yan, L., Song, X., and Lin, R., Chin. J. Catal., 2014, vol. 35, p. 1456. https://doi.org/10.1016/S1872-2067(14)60068-1

Liu, Y., Dikhtiarenko, A., Xu, N., Sun, J., Tang, J., Wang, K., Xu, B., Tong, Q., Heeres, H.J., He, S., Gascon, J., and Fan, Y., Chem. Eur. J., 2020. doi 10.1002/chem.202002150

Li, C., Wang, W., Yan, L., and Ding, Y., Front. Chem. Sci. Eng., 2018, vol. 12, p. 113. https://doi.org/10.1007/s11705-017-1672-9

Hartley, F.B., McCaffrey, D.J.A., Murray, S.G., Nicholson, P.N., Heinrich, B., Chen, Y., and Hjortkajaer, J., J. Mol. Catal., 1993, vol. 81, p. 333. https://doi.org/10.1016/0304-5102(93)85019-P

Heinrich, B., Chen, Y., and Hjortkajaer, J., J. Mol. Catal., 1993, vol. 80, p. 365. https://doi.org/10.1016/0304-5102(93)85009-I

Marrakchi, H., Effa, J.-B.N., Haimeur, M., Lieto, J., and Aune, J.-P., J. Mol. Catal., 1985, vol. 30, p. 101. https://doi.org/10.1016/0304-5102(85)80020-1

Yoneda, N., Nakagawa, Y., and Mimami, T., Catal. Today, 1997, vol. 36, p. 357. https://doi.org/10.1016/S0920-5861(96)00223-4

Terekhova, G.V., Kolesnichenko, N.V., Alieva, E.D., Markova, N.A., Trukhmanova, N.I., Slivinsky, E.V., and Plate, N.A., Russ. Chem. Bull., vol. 45., 1996, no. 7, p. 1583. https://doi.org/10.1007/BF01431790

Slivinskii, E.V. and Kolesnichenko, N.V., Russ. Chem. Bull., Int. Ed., 2004, vol. 53, no. 11, p. 2449. https://doi.org/10.1007/s11172-005-0138-2

Artner, J., Bautz, H., Fan, F., Habicht, W., Walter, O., Döring, M., and Arnold, U., J. Catal., 2008, vol. 255, p. 180. https://doi.org/10.1016/j.jcat.2008.02.003

Pilaski, M., Artz, J., Islam, H.-U., and Beale, A.M., Micropor. Mesopor. Mater., 2016, vol. 227, p. 219. https://doi.org/10.1016/j.micromeso.2016.03.010

Ren, Z., Liu, Y., Lyu, Y., Song, X., Zheng, C., Feng, S., and Jiang, Z., J. Catal., 2019, vol. 369, p. 249. https://doi.org/10.1016/j.jcat.2018.11.015

Gil, W., Boczoń, K., Trzeciak, A.M., Ziółkowski, J.J., Garcia-Verdugo, E., and Luis, S.V., Sans, V., J. Mol. Catal. A. Chem., 2009, vol. 309, p. 131. https://doi.org/10.1016/j.molcata.2009.05.007

Hunter, D.L. and Moore, S.E., Appl. Catal., 1985, vol. 19, p. 275. https://doi.org/10.1016/S0166-9834(00)81750-9

Kaneda, K., Kuwahara, H., and Imanaka, T., J. Mol. Catal., 1992, vol. 72, p. L27. https://doi.org/10.1016/0304-5102(92)85004-Y

Corain, B., Bosato, M., and Zecca, M., J. Mol. Catal., 1992, vol. 73, p. 23. https://doi.org/10.1016/0304-5102(92)80059-P

Mdleleni, M.M., Rinker, R.G., and Ford, P.C., Inorg. Chem. Acta, 1998, vol. 270, p. 345. https://doi.org/10.1016/S0020-1693(97)05868-4

Zong, H.J., Guo, X.Y., Tang, Q., Jin, Y., Li, Y.J., and Jiang, Y.Y., J. Macromol. Sci. – Chem., 1987, vol. 24, p. 277. https://doi.org/10.1080/00222338708074445

Vu, T.V., Kosslick, H., Schulz, A., Harloff, J., Paetzold, E., Lund, H., Kragl, U., Schneider, M., and Fulda, G., Micropor. Mesopor. Mater., 2012, vol. 154, p. 100. https://doi.org/10.1016/j.micromeso.2011.11.052

Vu, T.V., Kosslick, H., Schulz, A., Harloff, J., Paetzold, E., Radnik, J., Kragl, U., Fulda, G., Janiak, C., and Tuyen, N.D., Micropor. Mesopor. Mater., 2013, vol. 177, p. 135. https://doi.org/10.1016/j.micromeso.2013.02.035

Hou, C., Zhao, G., Ji, Y., Niu, Z., Wang, D., and Li, Y., Nano Research., 2014, vol. 7, p. 1364. https://doi.org/10.1007/s12274-014-0501-4

Vu, T.V., Kosslick, H., Schulz, A., Harloff, J., Paetzold, E., Schneider, M., Radnik, J., Steinfeldt, N., Fulda, G., and Kragl, U., Appl. Catal. A: Gen., 2013, vol. 468, p. 410. https://doi.org/10.1016/j.apcata.2013.09.011

Sartipi, S., Romero, M.J.V., Rozhko, E., Que, Z., Stil, H.A., de With, J., Kapteijn, F., and Gascon, J., ChemCatChem., 2015, vol. 7, p. 3243. https://doi.org/10.1002/cctc.201500330

Toth, I., Hanson, B.E., Guo, I., and Davis, M.E., Catal. Lett., 1991, vol. 8, p. 209. https://doi.org/10.1007/BF00764118

Diwakar, M.M., Deshpande R.M, and Chaudrahi, R.V., J. Mol. Cat. A: Chem., 2005, vol. 232, p. 179. https://doi.org/10.1016/j.molcata.2005.01.033

Carvalho, G.A., Gusevskaya, E.V., and dos Santos, E.N., J. Braz. Chem. Soc., 2014, vol. 25, p. 2370. https://doi.org/10.5935/0103-5053.20140254

Kanno, T., Tatsumoto, Y., and Kobayashi, M., React. Kinet. Catal. Lett., 1991, vol. 43, p. 237. https://doi.org/10.1007/BF02075439

Toth, I. and Hanson, B.E., J. Organomet. Chem., 1990, vol. 397, p. 109. https://doi.org/10.1016/0022-328X(90)85319-T

Balué, J., and Bayón, J.C., J. Mol. Cat. A: Chem., 1999, vol. 137, p. 193. https://doi.org/10.1016/S1381-1169(98)00124-1

Funding

The reported study was funded by RFBR, project number 19-13-50099.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare no conflict of interest requiring disclosure in this article.

Rights and permissions

Open Access. This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Zhuchkov, D.P., Nenasheva, M.V., Terenina, M.V. et al. Polymeric Heterogeneous Catalysts in the Hydroformylation of Unsaturated Compounds. Pet. Chem. 61, 1–14 (2021). https://doi.org/10.1134/S0965544121010011

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0965544121010011