Abstract

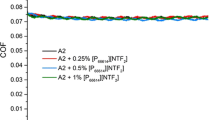

Ionic liquids (ILs) are potential lubricant additives that can potentially perform simultaneously as friction modifiers and anti-wear agents. In addition, they possess good thermal stability, they are non-flammable, they have high polarity with negligible volatility, etc. These characteristics make them also ideal for polar lubricants, like water-based fluids. In this work, the friction and wear mechanisms of stainless steel 316L tested in water-based lubricants containing three different ionic liquids, i.e. Tributylmethylphosphonium dimethylphosphate, (2-hydroxyethyl) trimethylammonium dimethylphosphate and 1-butyl-1-methylpyrrolidinium tris(pentafluoroethyl)trifluorophosphate, have been investigated and compared with a reference water-based lubricant containing dodecanoic acid (Lauric acid, C12) as a well-known organic friction modifier. All lubricants formulated with the three ionic liquids showed frictional values lower than the water-based lubricant alone, but higher than the lubricant formulated with C12. A detailed surface adsorption study using Quartz Crystal Microbalance with Impedance measurements (QCM-I) revealed differences in the adsorption kinetics, strength of the adsorption bonds to the metallic surface and also different viscoelastic properties of the adsorbed layers for all the different additives. In the case of one of the ionic liquids (1-butyl-1-methylpyrrolidinium tris(pentafluoroethyl)trifluorophosphate), a tribofilm is formed after some sliding cycles and a significant friction to values lower than that of C12 is observed. A detailed surface and sub-surface investigation of the structure and the chemistry of the wear tracks using SEM/FIB, S(T)EM, and XPS showed that an oxide-rich tribolayer built in the wear track was the cause for the decrease in both wear rate and coefficient of friction. The other ionic liquids were not able to create a tribofilm on the surface of the steel and therefore friction and wear values were higher.

Similar content being viewed by others

References

Singh, H., Gulati, I.L.: Tribological behavior of base oils and their separated fractions. Wear (1991). https://doi.org/10.1016/0043-1648(91)90130-M

Zhou, Y., Dyck, J., Graham, T.W., Luo, H., Leonard, D.N., Qu, J.: Ionic liquids composed of phosphonium cations and organophosphate, carboxylate, and sulfonate anions as lubricant antiwear additives. Langmuir (2014). https://doi.org/10.1021/la5032366

Rudnick, L.R.: Lubricant additives: Chemistry and Applications, 2nd edn. Taylor & Francis, London (2009)

Zabawski, E.: Seren-ZDDP: life is full of accidental discoveries. Tribol. Lubr. Technol. 73, 6 (2017)

Spikes, H.: The history and mechanisms of ZDDP. Tribol. Lett. 17, 469 (2004)

Zhou, Y., Qu, J.: Ionic liquids as lubricant additives: a review. ACS Appl. Mater. Interfaces (2017). https://doi.org/10.1021/acsami.6b12489

Dorr, N., Merstallinger, A., Holzbauer, R., Pejakovic, V., Brenner, J., Pisarova, L., Stelzl, J., Frauscher, M.: Five-stage selection procedure of ionic liquids for lubrication of steel-steel contacts in space mechanisms. Tribol. Lett. (2019). https://doi.org/10.1007/s11249-019-1185-4

Wasserscheid, P., Welton, T. (eds.): Ionic Liquids in Synthesis, 2nd edn. Wiley, Weinheim (2008)

Ye, C., Liu, W., Chen, Y., Yu, L.: Room-temperature ionic liquids a novel versatile lubricant. Chem. Commun. (2001). https://doi.org/10.1039/b106935g

Somers, A., Howlett, P., MacFarlane, D., Forsyth, M.: A review of ionic liquid lubricants. Lubricants (2013). https://doi.org/10.3390/lubricants1010001

Bermudez, M.D., Jimenez, A.E., Sanes, J., Carrion, F.J.: Ionic liquids as advanced lubricant fluids. Molecules (2009). https://doi.org/10.3390/molecules14082888

Qu, J., Luo, H., Toops, J.T., West, B.H., Blau, P.J., Dai, S., Papke, B.L., Gao, H., Kheireddin, B., Chen, C.: Ionic liquids as multi-functional lubricant additives to enhance engine efficiency. Final Rep NFE-12-03876 (2016). https://doi.org/10.2172/1246776

Xiao, H.: Ionic liquids lubricants: basics and applications. Tribol. Trans. (2017). https://doi.org/10.1080/10402004.2016.1142629

Perkin, S., Albrecht, T., Klein, J.: Layering and shear properties of an ionic liquid, 1-ethyl-3-methylimidazolium ethylsulfate, confined to nano-films between mica surfaces. Phys. Chem. Chem. Phys. (2010). https://doi.org/10.1039/b920571c

Huang, G., Yu, Q., Ma, Z., Cai, M., Liu, W.: Probing the lubricating mechanism of oil-soluble ionic liquids additives. Tribol. Int. (2017). https://doi.org/10.1016/j.triboint.2016.08.027

Liu, X., Zhou, F., Liang, Y., Liu, W.: Tribological performance of phosphonium based ionic liquids for an aluminum-on-steel system and opinions on lubrication mechanism. Wear (2006). https://doi.org/10.1016/j.wear.2006-03.018

Perkin, S.: Ionic liquids in confined geometries. Phys. Chem. Chem. Phys. (2012). https://doi.org/10.1039/C2CP23814D

Mu, Z., Zhou, F., Zhang, S., Liang, Y., Liu, W.: Effect of the functional groups in ionic liquid molecules on the friction and wear behavior of aluminum alloy in lubricated aluminum-on-steel contact. Tribol. Int. (2005). https://doi.org/10.1016/j.triboint.2004.10.003

Jiang, D., Hu, L., Feng, D.: Crown-type ionic liquids as lubricants for steel-on-steel system. Tribol. Lett. (2011). https://doi.org/10.1007/s11249-010-9726-x

Qu, J., Chi, M., Meyer, H.M., Blau, P.J., Dai, S., Luo, H.: Nanostructure and composition of tribo-boundary films formed in ionic liquid lubrication. Tribol. Lett. (2011). https://doi.org/10.1007/s11249-011-9800-z

Lawes, S.D.A., Hainsworth, S.V., Blake, P., Ryder, K.S., Abbott, A.P.: Lubrication of steel/steel contacts by choline chloride Ionic liquids. Tribol. Lett. (2010). https://doi.org/10.1007/s11249-009-9495-6

Bernat, S., Armada, S., Espallargas, N.: Effect of contamination on the friction and wear of carboxylic acids in aqueous lubricants. Tribol. Lett. (2018). https://doi.org/10.1007/s11249-018-1116-9

Technical Note: The principles of QCM-I, Quartz crystal microbalance with impedance analysis. https://www.gamry.com/assets/Uploads/QCM-I-principles.pdf.

Saftics, A., Prosz, G.A., Turk, B., Peter, B., Kurunczi, S., Horvath, R.: In-situ viscoelastic properties and chain conformation of heavily hydrated carboxymethyl dextran layers: a comparative study using OWLS and QCM-I chips coated with waveguide material. Sci. Rep. (2018). https://doi.org/10.1038/s41598-018-30201-6

Voinova, M.V., Rodahl, M., Johnson, M., Kasemo, B.: Viscoelastic acoustic response of layered polymer films as fluid-solid interfaces: continuum mechanics approach. Phys. Scr. (1999). https://doi.org/10.1238/Physica.Regular.059a00391

McNamara, T.P., Blanford, C.F.: A sensitivity metric and software to guide the analysis of soft films measured by a quartz crystal microbalance. Analyst. (2016). https://doi.org/10.1039/C6AN00143B

Hamrock, B.J., Dowson, D.: Ball Bearing Lubrication-The Elastohydrodynamics of Elliptical Contacts. Wiley, New York (1981)

Zavieh, A.H., Espallargas, N.: Effect of 4-point bending and normal load on the tribocorrosion-fatigue (multi-degradation) of stainless steels. Tribol. Int. (2016a). https://doi.org/10.1016/j.triboint.2016.03.016

Shirley, D.A.: High-resolution X-ray photoemission spectrum of the valance bands of gold. Phys. Rev. B (1972). https://doi.org/10.1103/PhysRevB.5.4709

Du, B., Johannsmann, D.: Operation of the quartz crystal microbalance in liquids: derivation of the elastic compliance of a film from the ratio of bandwidth shift and frequency shift. Langmuir (2004). https://doi.org/10.1021/la035965l

Nalam, P.C., Clasohm, J.N., Mashaghi, A., Spencer, N.D.: Macrotribological studies of poly(L-Iysine)-graft-poly(ethylene glycol) in aqueous glycerol mixtures. Tribol. Lett. (2010). https://doi.org/10.1007/s11249-009-9549-9

Acharya, B., Chestnut, M., Marek, A., Smirnov, A.I., Krim, J.: A combined QCM and AFM study exploring the nanoscale lubrication mechanism of silica nanoparticles in aqueous suspension. Tribol. Lett. (2017). https://doi.org/10.1007/s11249-017-0898-5

Zachariah, Z., Nalam, P.C., Ravindra, A., Ra, A., Mohanlal, A., Wang, K., Castillo, R.V., Espinoza-Marzal, R.M.: Correlation between the adsorption an the nanotribological performance of fatty acid-based organic friction modifiers on stainless steel. Tribol. Lett. (2020). https://doi.org/10.1007/s11249-019-1250-z

Fry, B.M., Moody, G., Spikes, H.A., Wong, J.S.S.: Adsorption of organic friction modifier additives. Langmuir (2020). https://doi.org/10.1021/acs.langmuir.9b03668

Zavieh, A., Espallargas, N.: The effect of friction modifiers on tribocorrosion and tribocorrosion-fatigue of austenitic stainless steel. Tribol. Int. (2017). https://doi.org/10.1016/j.triboint.2017.03.008

Willenbruch, R.D., Clayton, C.R., Oversluizen, M., Kim, D., Lu, Y.: An XPS and electrochemical study of the influence of molybdenum and nitrogen on the passivity of austenitic stainless steel. Corros. Sci. (1990). https://doi.org/10.1016/0010-938X(90)90106-F

Zavieh, A., Espallargas, N.: The role of surface chemistry and fatigue on tribocorrosion of austenitic stainless steel. Tribol. Int. (2016b). https://doi.org/10.1016/j.triboint.2016.07.020

Clayton, C.R.: A bipolar model of the passivity of stainless steel: the role of Mo addition. J Electrochem. Soc. (1986). https://doi.org/10.1149/1.2108451

Liu, Y., Shen, L.: From langmuir kinetics to first- and second-order rate equations for adsorption. Langmuir (2008). https://doi.org/10.1021/la801839b

Nalam, P.C., Pham, A., Veronica Castillo, R., Espinosa-Marzal, R.M.: Adsorption behavior and nanotribology of amine-based friction modifiers on steel surfaces. J. Phys. Chem. C (2019). https://doi.org/10.1021/acs.jpcc.9b02097

Acknowledgements

The authors would like to acknowledge the financial support from the M-ERA.NET GreenCOAT project with Project Number 4153 as well as the financial support from The Research Council of Norway. Norwegian Micro- and Nano-fabrication facility, NorFab, is also acknowledged for providing the characterization facilities.

Funding

The project is funded by The Research Council of Norway in the form of M-ERA.NET GreenCOAT project with Project Number 4153.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests that could have influence on the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Khanmohammadi, H., Wijanarko, W. & Espallargas, N. Ionic Liquids as Additives in Water-Based Lubricants: From Surface Adsorption to Tribofilm Formation. Tribol Lett 68, 130 (2020). https://doi.org/10.1007/s11249-020-01377-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11249-020-01377-8