Abstract

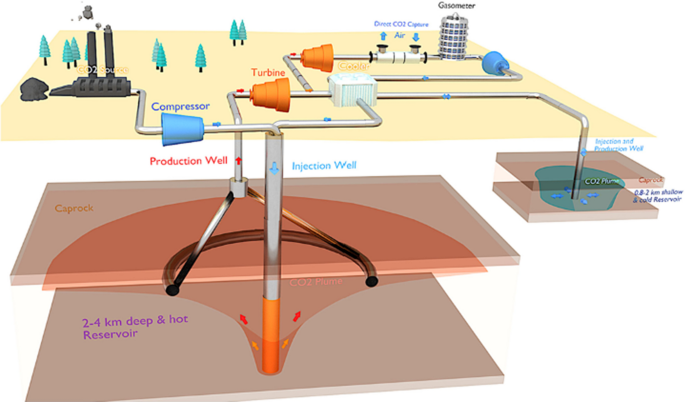

Human activities have led to a massive increase in \(\hbox {CO}_{2}\) emissions as a primary greenhouse gas that is contributing to climate change with higher than \(1\,^{\circ }\hbox {C}\) global warming than that of the pre-industrial level. We evaluate the three major technologies that are utilised for carbon capture: pre-combustion, post-combustion and oxyfuel combustion. We review the advances in carbon capture, storage and utilisation. We compare carbon uptake technologies with techniques of carbon dioxide separation. Monoethanolamine is the most common carbon sorbent; yet it requires a high regeneration energy of 3.5 GJ per tonne of \(\hbox {CO}_{2}\). Alternatively, recent advances in sorbent technology reveal novel solvents such as a modulated amine blend with lower regeneration energy of 2.17 GJ per tonne of \(\hbox {CO}_{2}\). Graphene-type materials show \(\hbox {CO}_{2}\) adsorption capacity of 0.07 mol/g, which is 10 times higher than that of specific types of activated carbon, zeolites and metal–organic frameworks. \(\hbox {CO}_{2}\) geosequestration provides an efficient and long-term strategy for storing the captured \(\hbox {CO}_{2}\) in geological formations with a global storage capacity factor at a Gt-scale within operational timescales. Regarding the utilisation route, currently, the gross global utilisation of \(\hbox {CO}_{2}\) is lower than 200 million tonnes per year, which is roughly negligible compared with the extent of global anthropogenic \(\hbox {CO}_{2}\) emissions, which is higher than 32,000 million tonnes per year. Herein, we review different \(\hbox {CO}_{2}\) utilisation methods such as direct routes, i.e. beverage carbonation, food packaging and oil recovery, chemical industries and fuels. Moreover, we investigated additional \(\hbox {CO}_{2}\) utilisation for base-load power generation, seasonal energy storage, and district cooling and cryogenic direct air \(\hbox {CO}_{2}\) capture using geothermal energy. Through bibliometric mapping, we identified the research gap in the literature within this field which requires future investigations, for instance, designing new and stable ionic liquids, pore size and selectivity of metal–organic frameworks and enhancing the adsorption capacity of novel solvents. Moreover, areas such as techno-economic evaluation of novel solvents, process design and dynamic simulation require further effort as well as research and development before pilot- and commercial-scale trials.

Similar content being viewed by others

Introduction

Renewable energy technologies have been dramatically progressing over the past decade. The levelised cost of electricity for wind and solar energy technologies has been reduced by 66 and 85%, respectively. This means that the levelised cost of energy for solar was approximately six times higher only a decade ago (Lazard 2018). Despite this speed of maturity in renewable technologies, we still rely on fossil-based fuels to generate the global energy demand. The energy demand globally is expected to be nearly met by from fossil-based fuel (coal, natural gas and oil), which constitutes 78% by 2040 (Cao et al. 2020). While waiting for renewable energy technologies to fully mature enough and replace fossil-based fuel, carbon capture storage and utilisation of fossil-based emissions are crucial as a transition state (Zhang et al. 2016, 2020a). For instance, integrated gasification combined cycle (IGCC) is a common approach coupled with carbon capture and storage in clean coal power plants. In a country such as India, transportation and electricity generation contribute to 45% of the country’s total greenhouse gas emissions (Ashkanani et al. 2020).

Furthermore, coal is considered the current and the future fuel in India, where there are total reserves of approximately 150 gigatons. Thus, the IGCC process along with carbon capture looks crucial. In terms of coal reserves, India comes third globally after the USA and Russia as first and second (Ashkanani et al. 2020). Globally, coal is the largest energy source for electricity generation and the second-largest feedstock source of primary energy (Wei et al. 2020). However, with the current rate of \(\hbox {CO}_{2}\) emissions globally and with a \(\hbox {CO}_{2}\) level in the atmosphere higher than 409 ppm, anthropogenic activities have caused more than \(1\,^{\circ }\hbox {C}\) global warming than that of the pre-industrial level, of which higher than \(0.3\,^{\circ }\hbox {C}\) was due to coal-burning (Wei et al. 2020; Osman et al. 2020a). In 2015 the Paris agreement was developed which aims to limit global warming to \(2\,^{\circ }\hbox {C}\) by 2100, while attempting to limit the increase to \(1.5\,^{\circ }\hbox {C}\) (Fawzy et al. 2020). Thus, investigating carbon capture technologies is of great importance as it is considered the only solution to mitigate \(\hbox {CO}_{2}\) emissions from industrial-scale power generation plants, which could lower those emissions by 50% by 2050 (Wei et al. 2020; Wienchol et al. 2020; International Energy Agency 2008). It is worth noting that the cost of reducing \(\hbox {CO}_{2}\) emissions will dramatically increase by 140% if carbon capture and storage technologies are not considered (GCCSI 2017).

Three main technologies are being utilised in carbon capture: pre-combustion, post-combustion and oxyfuel combustion routes. Here, the first two routes represent 96.6% of the literature work until 2018, while oxy-reforming technology showed only 3.4% of the total publications (Omoregbe et al. 2020). The utilisation of liquid solvents in pre- and post-combustion technologies is usually done in an absorber packed-bed in a counter-current directions, where the fuel gas (pre-combustion) or the exhausted flue gas (post-combustion) is pumped from the bottom of the reactor to the top, while simultaneously, the flow of the chemical or physical solvent flows from top to bottom. Temperature or a pressure swing is then applied to release the majority of absorbed \(\hbox {CO}_{2}\) from the \(\hbox {CO}_{2}\)-rich physical or chemical solvent, while the \(\hbox {CO}_{2}\) lean chemical or physical solvent is sent back to the absorber reactor. Finally, the captured \(\hbox {CO}_{2}\) is compressed and utilised in gas recovery, oil recovery, agriculture, soda ash manufacturing, food industry and production of value-added chemicals and fuels or stored in geological reservoirs or saline aquifers (Ashkanani et al. 2020; Miranda-Barbosa et al. 2017; Tarkowski and Uliasz-Misiak 2019).

Globally, there are 22 demo projects for carbon capture and storage based on power generation with the majority share of pre- and post-combustion projects, nearly equalling 10 and 9, respectively. There are only three demo projects based on oxyfuel combustion projects (Vega et al. 2020). In terms of countries that invest in carbon capture and storage, the USA is leading the world with seven projects, and China comes second with five demo projects. For carbon capture technologies to become economic feasible, having adequate carbon pricing is crucial either in carbon tax or carbon allowances. By 2019, carbon tax significantly varied from one country to another, with values ranging from a few dollars to one hundred $/tonne of \(\hbox {CO}_{2}\). At the same time, pricing for carbon allowances was approximately $35.4 per tonne of \(\hbox {CO}_{2}\) equivalent within the European Union Emission Trading Scheme by July 2019 (Kárászová et al. 2020). This value of carbon allowance started at $5.17/tonne \(\hbox {CO}_{2}\) equivalent in May 2017 and is expected to reach $47.25/tonne \(\hbox {CO}_{2}\) equivalent by 2023 (Kárászová et al. 2020). Comparing the net present value of various types of power plants integrated with carbon capture technology, pulverised coal was the cheaper option under low carbon prices. Simultaneously, the IGCC power plants were desirable only when the carbon price was high (Huang et al. 2020; Bohm et al. 2007). Thus, the carbon pricing is considered as one of the most effective ways to encourage the deployment of carbon capture and storage technologies.

This review offers the most up-to-date advancements in carbon capture, storage and utilisation technologies to help mitigate climate change. It outlines the advantages and disadvantages of each route with its readiness for commercialisation to decarbonise the industrial sector. Moreover, the review suggests steps and future guidelines from gaps in the literature using bibliometric analysis. Overall, this critical review aims to benefit the academics working in the decarbonisation field alongside the policies of carbon capture, storage and utilisation technologies and will focus on themes that face the development and potentially face the commercialisation of capture, storage and utilisation technologies and their future.

\(\hbox {CO}_2\) capture technologies

In carbon capture storage and utilisation, there are mainly three technologies that are being utilised: pre-combustion, oxyfuel combustion and post-combustion technologies.

Pre-combustion

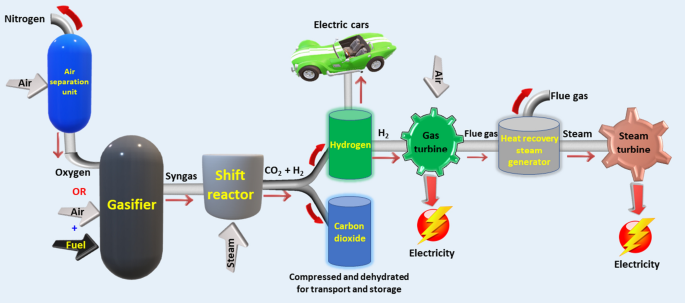

In this decarbonisation route, traditional fuels (coal or natural gas) are reacting with air or \(\hbox {O}_{2}\) and with or without steam to produce mainly synthesis gas, which is a mixture of carbon monoxide (CO) and hydrogen (\(\hbox {H}_{2}\)), also known as fuel gas or syngas as shown in Fig. 1. The main two processes for producing syngas are shown in Eqs. (1) and (2) for partial oxidation and steam reforming reactions, respectively (Jansen et al. 2015).

In the case of using steam reforming, the typical reformer products are 43% \(\hbox {H}_{2}\), 11% CO, 21% \(\hbox {H}_{2}\hbox {O}\) and 6% \(\hbox {CO}_{2}\) (Osman et al. 2018a). When the partial oxidation and steam reforming are deployed in pre-combustion simultaneously, the process is called auto-thermal reforming, where the heat released from the exothermic nature of the partial oxidation can drive the endothermic steam reforming reaction. The syngas mixture is then cooled down and cleaned up from impurities such as hydrogen sulphide, hydrochloric acid, mercury and carbonyl sulphide (Cao et al. 2020). The purified syngas is then subjected to the water-gas shift reaction (WGSR) by reacting the CO with steam (\(\hbox {H}_{2}\)O) as shown in Eq. (3), to increase the % \(\hbox {CO}_{2}\) and facilitate the \(\hbox {CO}_{2}\) separation in later stages along with the production of \(\hbox {H}_{2}\) fuel as decarbonised fuel, which only produces \(\hbox {H}_{2}\)O when combusted.

Finally, \(\hbox {CO}_{2}\) is separated through various physical and chemical absorption processes for either storage or utilisation (Kumar et al. 2018; Li et al. 2019a). In the chemical industry, the pre-combustion approach is mature and has been utilised for \(\hbox {CO}_{2}\) capture for nearly a century (higher than 95 years). For power generation purposes, the \(\hbox {H}_{2}\)-rich fuel can be used in a Rankine + Brayton combine cycle plant. Although \(\hbox {CO}_{2}\) separation herein is much easier and requires lower energy than other techniques such as post-combustion, it still needs energy for reforming, air separation and improvements in the efficiency of energy recovery within the process. Additionally, further purification stages are required when oil or coal is utilised to eliminate impurities, ash and sulphur-containing compounds. In the first generation of the integrated gasification combined cycle (IGCC), the main cause for efficiency loss was the WGSR step, which was responsible for 44% of the total efficiency loss. This was due to the energy required for steam generation along with the heat released within the WGSR process as it is an equilibrium limited and exothermic process.

On the other hand, \(\hbox {CO}_{2}\) produced through the pre-combustion process is characterised by high pressure. \(\hbox {CO}_{2}\) is then undergoing compression and liquefication for storage or transportation purposes at low power requirements. Moreover, it promotes the production of \(\hbox {H}_{2}\) as a fuel that can be used in fuel cells (after further purification), transportation or as a building block in the production of value-added chemicals (Osman et al. 2020a). Another big benefit of the pre-combustion route is the flexibility of the outputs where \(\hbox {H}_{2}\) production or power generation can easily be switched according to the demand.

Pre-combustion technology consists of an air separation unit for oxygen separation (not mandatory). Then the fuel is reacting with air or \(\hbox {O}_{2}\) to produce mainly synthesis gas, which is then sent to the shift reactor unit to produce hydrogen and \(\hbox {CO}_{2}\). The produced hydrogen can be used to fuel electric cars or to produce electricity through a gas turbine, while the flue gas is sent to the heat recovery and steam generation unit for electricity production. Finally, the \(\hbox {CO}_{2}\) is compressed and dehydrated for transport and storage purposes

The separation of the \(\hbox {H}_{2}\) and \(\hbox {CO}_{2}\) mixture in the pre-combustion route can be done using physical or chemical absorption techniques via syngas scrubbing using a liquid solvent selective to carbon dioxide and hydrogen sulphide as acid compounds (Jansen et al. 2015). The main common chemical solvent is amine-based, and its absorption capacity is higher at lower partial pressure than that of physical solvents that require higher partial pressure. On the other hand, the physical solvents’ loading relies on the partial pressure of the \(\hbox {CO}_{2}\), according to Henry’s law. Generally, at low temperatures and high partial pressures, the physical solvents’ performance is high as those conditions provide better sorption capacity. Physical solvents suffer from drawbacks such as low \(\hbox {CO}_{2}\)–\(\hbox {H}_{2}\) selectivity, high solvent viscosity, thermal stability, corrosivity, toxicity and flammability (Ashkanani et al. 2020). Regarding low-temperature \(\hbox {CO}_{2}\) separation, many techniques are being deployed, such as cooling, compression, condensation, flashing along with cryogenic distillation that is commercially used in the food industry. However, it is mainly used for highly concentrated \(\hbox {CO}_{2}\) streams (higher than 90%) and not adequate for dilute \(\hbox {CO}_{2}\) streams.

The purity of the produced hydrogen in the pre-combustion approach is not a priority, while the \(\hbox {CO}_{2}\) separation is. Thus, for high-purity \(\hbox {H}_{2}\) and \(\hbox {CO}_{2}\), advancement in separation technologies is crucial. Adsorptive reactors and membrane reactors are promising where the integration of reaction and separation occurs in a single unit to lower the energy requirement, as well as the formation of by-products, while increasing the overall efficiency of the process. In adsorptive reactor technology, a selective solid \(\hbox {CO}_{2}\) adsorbent is utilised to facilitate the removal of \(\hbox {CO}_{2}\) from the stream and hence, shift the equilibrium reaction towards \(\hbox {H}_{2}\) production. The characteristics for those adsorbents are high \(\hbox {CO}_{2}\) adsorption capacity, mechanically robust, fast sorption, selective and stable during multiple \(\hbox {CO}_{2}\) adsorption and regeneration cycles. For instance, due to the deteriorating \(\hbox {CO}_{2}\) adsorption capacity at elevated temperatures, adsorbents such as zeolites, metal–organic frameworks and activated carbons are not suitable. Various designed adsorbent systems have been utilised, such as promoted calcium carbonate, hydrotalcite and others in that approach. For membrane reactors, the palladium membrane or its alloy is the most commonly used. However, palladium is prone to sulphur poisoning and deactivation even at a lower reaction temperature (Osman et al. 2016), while the silica-based membrane is not, thus, superior in this perspective.

Nevertheless, silica membranes are not stable at high temperatures and pressures. Dense polymeric membranes are cheap materials; however, they are thermally unstable and not selective to hydrogen. In this perspective, the carbon molecular sieve membranes (CMSMs) showed good performance as they are resistant to sulphur poisoning and robust materials. Recently, Cao et al. (2020) integrated both adsorptive reactors and membrane reactors in multiple cycles for the pre-combustion route and showed good performance for 750 hours of syngas exposure and a temperature of \(250\,^{\circ }\hbox {C}\) and pressure of 25 bar, with CMSMs as adsorptive reactors.

Overall, the pre-combustion technology is promising in carbon capture storage and utilisation, while there are many challenges to improving its overall efficiency. For instance, the solvent regeneration temperature needs to be conducted at a lower temperature than currently used to avoid any reduction in the solvent. Thus, ionic liquids are being utilised to overcome this issue, as they are characterised with their negligible volatility (Zhou et al. 2021; Krishnan et al. 2020; McDonald et al. 2014). On the other hand, selecting the appropriate ionic liquid is not an easy task due to the existence of possible structures from various anion and cation combinations which requires trial and error to find the best separation performance (Lu et al. 2019). For that purpose, computer-aided molecular design (CAMD) is recently being used to find out the best combinations to design ionic liquids structurally. (Zhou et al. 2021) have investigated 10116 solubility data along with 463 hydrogen solubility data from the literature of ionic liquids with modelling to find out the best ionic liquids for pre-combustion technology. They found out that the most promising ionic liquid solvents are hydroxyl (OH)-ammonium (\(\hbox {NH}_3\)) and hydroxyl-imidazolium ([\(\hbox {Tf}_{2}\hbox {N}\)]) bis (trifluoromethyl sulphonyl) amide at \(40\,^{\circ }\hbox {C}\) and 30 bars according to industrial pre-combustion conditions.

In theory, the pre-combustion route could offer a cheaper cost than that of post-combustion and oxyfuel combustion routes by 38–45 and 21–24%, respectively (Portillo et al. 2019). However, due to the retrofitting of current facilities, this added costing and complexity to the set-up process have limited its commercialisation.

Oxyfuel combustion

In the oxyfuel combustion route, the carbon-based fuel is combusted in re-circulated flue gas and pure oxygen (\(\hbox {O}_{2}\)) stream, rather than air, hence limiting its commercialisation potential due to the high cost of \(\hbox {O}_{2}\) separation and production as shown in Fig. 2. However, the \(\hbox {CO}_{2}\) capture and separation are easy, and the oxyfuel combustion method is considered as the most promising energy-efficient route among the main three methods (pre-, post- and oxyfuel), with a low-efficiency penalty of 4% compared with 8–12% for the post-combustion route (Wienchol et al. 2020). The reduction in the volume of exhausted flue gas and nitrogen gas emissions (NOx) along with the increasing boiler efficiency can be achieved by applying the oxyfuel combustion route in power systems. One big challenge in such a route is the supply of pure oxygen as its separation is an energy-intensive and costly process in the air separation unit. For example, cryogenic distillation is the only proven technology for producing a large amount of \(\hbox {O}_{2}\) with high purity for large-scale utilisation (Chen et al. 2019). Thus, investigating new novel routes of air separation is quite important herein, such as ion-transport and oxygen-transport membranes along with chemical looping methods (Shin and Kang 2018; Martinez and Hesse 2016; Chen et al. 2018a; Shi et al. 2018). To resolve the problem associated with the energy needed for cryogenic air separation, oxygen-transport membranes were introduced, known as the mixed ionic–electronic conducting membrane (MIEC) (Portillo et al. 2019; Kotowicz and Balicki 2014). Carbo et al. reported that the inclusion of oxygen-transport membranes in oxyfuel combustion could reach an economic saving in the range of 19–50%, compared to that of post-combustion technology (Carbo et al. 2009). There is recently a drastic increase in publications concerned with oxygen-transport membranes, where an average publications in 1985 were 30 publications compared to 200 in 2012 (Portillo et al. 2019).

Oxyfuel combustion technology consists of an air separation unit for oxygen separation (mandatory). Then the carbon-based fuel is combusted in the re-circulated flue gas and pure oxygen (\(\hbox {O}_2\)) stream in a boiler. Then the flue gas is sent to the particle removal unit, followed by the cooler and condenser unit to remove water and then to the sulphur removal unit before sending it again to the cooler and condenser unit. Finally, the \(\hbox {CO}_{2}\) is compressed and dehydrated for transport and storage purposes

Interestingly, the utilisation of the chemical looping method can enhance the net power plant efficiency by 3% when employed in oxyfired along with IGCC and instead of the air separation unit. Furthermore, capital costing of the power plant and electricity costing will decrease by 10–18 and 7–12%, respectively (Wienchol et al. 2020; Cormos 2020). One such advantage of using the oxyfuel combustion route is that it can be employed in current or new power plants along with utilisation of various types of fuels such as municipal solid waste or lignocellulosic biomass.

The integration between bioenergy and carbon capture and storage is called BioCCS or BECCS, leading to a negative carbon approach for climate change mitigation. It was reported that in oxyfuel combustion of lignocellulosic biomass, the accumulative emissions of \(\hbox {CO}_{2}\) of net electricity production was \(-\,0.27\,\hbox {kgCO}_{2}\,\hbox {MJel}^{-1}\) (Gładysz and Ziȩbik 2016). While the integration of carbon capture along with municipal solid waste incineration has led to emissions of \(-\,0.70\,\hbox {kgCO}_{2},\hbox {eq\,kg}^{-1}\) of wet waste feedstock (Pour et al. 2018). This, in turn, showed that BECCS could be an effective way of achieving decarbonisation and the negative carbon technology for climate change abatement along with oxyfuel combustion.

Interestingly, there are twenty BECCS projects globally that include waste-to-energy, ethanol production, combustion of biomass and co-firing, biomass gasification and biogas plants (Pour et al. 2017; Bui et al. 2018c). Nevertheless, still, there are challenges in the BECCS approach, such as the higher cost of biomass compared to fossil-based fuel, such as coal along with high levelised cost of electricity and lower efficiency. When including air separation and \(\hbox {CO}_{2}\) purification and compression units in the oxyfuel combustion system, the cycle efficiency decreases by 9–13% points as those are energy-intensive units. Thus, to make the overall process attractive for commercialisation, process and heat integrations are inevitable herein. For instance, the utilisation of heat generated from the compressor cooling systems in the units, as mentioned above, along with the steam cycle, showed that it is an effective method in this case (Chen et al. 2019). Moreover, the pressurised oxyfuel combustion cycle showed better performance than that of the traditional atmospheric cycle and could increase the efficiency by 3% points (Hong et al. 2010).

There is a growing global interest to prove the feasibility of the oxyfuel combustion technology with different demonstration projects and pilot-scale plants being deployed since the last decade; however, capacities are all lower than 100 MWth (Strömberg et al. 2009; Cook 2009). Wei et al. (2020) reported that the utilisation of biomass in oxyfuel combustion using the supercritical \(\hbox {CO}_{2}\) cycle showed a reduction of \(-\,3.7\) megatonnes of \(\hbox {CO}_{2}\) per annum. Furthermore, BECCS technology will be more economically feasible than fossil-based fuel if the carbon tax is higher than $28.3 per tonne of \(\hbox {CO}_{2}\).

Post-combustion

The capture and separation of dilute \(\hbox {CO}_{2}\) in an oxidant environment from the flue gas of a combustion system is called the post-combustion route (Zhang et al. 2020a, b). Before \(\hbox {CO}_{2}\) capture, the exhaust flue gas emissions go through denitrification and desulphurisation along with dust removal and cooling to prevent solvent degradation (Wu et al. 2020). Then the flue gas containing mainly \(\hbox {CO}_{2}\), \(\hbox {H}_{2}\hbox {O}\) and \(\hbox {N}_{2}\), is then fed counter-currently to the absorber that contains the solvent, as shown in Fig. 3. The scrubbed gas is then washed with water, followed by \(\hbox {CO}_{2}\) regeneration. Usually, the captured \(\hbox {CO}_{2}\) is then compressed into supercritical fluid and then transported for storage in geological reservoirs or saline aquifers. As the flow rate of \(\hbox {CO}_{2}\) is high, and its concentration is low in flue gas streams, along with its inherently stable nature, an energy-intensive process is required for solvent regeneration.

Monoethanolamine absorption is considered as the most common and only commercialised method in the post-combustion approach, while other absorbents are used as well, such as 2-amino-2-methyl-1-propanol and N-methyldiethanolamine and others (Karnwiboon et al. 2019; Ochedi et al. 2020). The adsorption route is also used in post-combustion in the form of either temperature swing or pressure swing adsorption processes along with calcium looping (Bui et al. 2018b). Amine solutions are the most common solvents due to their high \(\hbox {CO}_{2}\) absorption capacity and good selectivity towards acidic gases (Rochelle 2009). Nevertheless, they suffer from drawbacks such as the corrosivity of amines, high energy footprint during regeneration, degradation and hence, solvent loss and evaporation. Although the monoethanolamine chemisorption, as mentioned, is the only commercially available method, the capital along with the operating costing herein is expensive; thus, some projects based on that technology have been shut down (Schlissel 2018). To decrease the capital costing associated with the post-combustion technology, membrane separation could be a suitable technology as it requires a low energy need, low carbon footprint, low operational cost and easy retrofitting and scaling up with the current power plants (Vakharia et al. 2018). At the same time, there are many challenges associated with membrane separation, such as water condensation on the membrane, rapid diminution of selectivity and permeance after operation along with emissions (NOx and SOx) that pass through the membrane. Some membranes also suffer from difficult temperature adjustment and fluctuation in humidity that causes a drastic change in the transport characteristics of the membrane (Pfister et al. 2017).

Post-combustion technology, where the hot flue gas is cooled first and then sent to a \(\hbox {CO}_{2}\)-absorber unit that usually contains monoethanolamine solvent as traditional sorbent. Then the \(\hbox {CO}_{2}\)-rich absorbent is sent to the \(\hbox {CO}_{2}\)-stripper unit to release the \(\hbox {CO}_{2}\) gas, while the \(\hbox {CO}_{2}\)-lean absorbent is sent back to the \(\hbox {CO}_{2}\)-absorber unit. Finally, pure \(\hbox {CO}_{2}\) is compressed and dehydrated for transport in pipelines and storage purposes

For the adsorption route, metal–organic frameworks (MOFs) possess some interesting characteristics such as the functionalised pore morphology and tailored structures that could work properly in \(\hbox {CO}_{2}\) carbon capture. MOFs materials can exist in higher than 75,000 different structures, which help facilitate specific pore-structure materials for the carbon sequestration approach. Despite that, none of the MOFs materials has been deployed at the industrial scale due to the intense energy required for regeneration and their rapid structure instability (Qazvini and Telfer 2020). MOFs modification could be done through the functionalisation with polar groups or the loading of exposed metal sites within the MOFs structure (Zhou et al. 2019; Ding et al. 2019; Jiang et al. 2019). Furthermore, computational screening modelling strategies are a powerful tool for finding optimum performing materials among thousands of adsorbents, such as MOFs materials. Regarding the vacuum swing adsorption, there is a common relationship between pellet porosity and pellet size for all materials at the optimal adsorbent performance (Farmahini et al. 2020). Furthermore, computational simulations could be used for designing new photo-reactive MOFs materials with high adsorption and desorption capacities. One major drawback of using adsorbents such as MOFs in carbon capture and storage is the energy-intensive nature associated with the desorption process in the form of a large amount of pressure or temperature swing. Sunlight as an external stimulus can facilitate the desorption process with lower energy demand over photoresponsive MOFs materials such as diarylethene and azobenzene. Park et al. (2020), with the aid of computational modelling, synthesised Mg-IRMOF-74-III (with azopyrdine attached to its unsaturated metal sites) material that showed a \(\hbox {CO}_{2}\) adsorption capacity of \(89.6\,\hbox {cm}^3\,\hbox {g}^{-1}\), that is the highest value within photoresponsive MOFs reported in the literature.

Although the pre-combustion technology offers higher efficiency than that of post-combustion technology, it is more expensive. To reduce the cost associated with the pre-combustion route, finding a superior absorption solvent is crucial. Currently, post-combustion technology is the most mature and widely used route among the three main routes of carbon capture and storage (Wienchol et al. 2020; Wang et al. 2011a). However, due to the dilution of \(\hbox {CO}_{2}\) comes from the flue gas by \(\hbox {N}_{2}\) from the air, this reduces the partial pressure of \(\hbox {CO}_{2}\) and increases the additional cost in the electricity generation by approximately 60–70% for the new infrastructure or 220–250% for the retrofitting (Portillo et al. 2019).

As mentioned earlier, chemisorption using amine-based solvents is a ready technology for retrofitting of current power plants. Based on that technology, pilot-scale power plants that have been implemented showed a \(\hbox {CO}_{2}\) absorption capacity of 80 tonnes per day (Vega et al. 2020). It is projected that the first integrated commercial carbon capture and storage along with coal-fired power plants will be open by 2020–2025. Consequently, it will be utilised in the rest of the carbon-intensive commercial-scale processes afterward. Vega et al. (2020) compared traditional and novel technologies that are used in carbon capture and storage areas such as post-combustion (traditional) and partial oxy-combustion (novel). At the pilot-scale of the absorption route, novel along with blend solvents have been deployed to reduce the energy footprint of the overall process before demonstration-scale trials. There are desirable properties in novel solvents such as the high cyclic capacities, low production cost, low corrosiveness, lower degradation and thus lower by-products along with the environmental impact. Over the currently deployed pilot power plants, \(\hbox {CO}_{2}\) capacity was in the range of 0.1 to 1 tonne per day at a low capacity level, while the high capacity level showed values in the range of 10–80 tonnes per day (Vega et al. 2020). Shell company developed a new \(\hbox {CO}_{2}\) capture method (\(\hbox {Shell Cansolv}^{\mathrm{TM}}\)) based on amine solvent technology (Stéphenne 2014). The proposed technology is appropriate for various industries such as refineries, energy production, mining and chemical industry processes. One such advantage of the CansolvTM solvent is that the required regeneration energy for capturing one tonne of \(\hbox {CO}_{2}\) is in the range of 2.5–2.9 GJ per tonne of \(\hbox {CO}_{2}\). Which is lower than the most common solvent, monoethanolamine, as it showed regeneration energy of 3.5 GJ per tonne of \(\hbox {CO}_{2}\) (Yun et al. 2020; Krishnamurthy 2017; James et al. 2019). Yun et al. investigated the techno-economic feasibility of monoethanolamine as a traditional absorption solvent and modulated amine blend (MAB) as a novel solvent in the carbon capture and storage technology. The novel solvent has an advantage over the common solvent in the regeneration energy required for capturing one tonne of \(\hbox {CO}_{2}\), which was 2.17 GJ per tonne of \(\hbox {CO}_{2}\), where monoethanolamine common solvent as mentioned earlier showed a value of 3.50 GJ per tonne of \(\hbox {CO}_{2}\). The technoeconomic evaluation revealed that the cost for \(\hbox {CO}_{2}\) capture in the Republic of Korea for monoethanolamine and Modulated Amine Blend solvents were 35.50 and 25.70 per tonnes of \(\hbox {CO}_{2}\), respectively (Yun et al. 2020).

The decarbonisation of the industrial sector will require an assessment of the technology readiness level (TRL) of different carbon capture, storage and utilisation techniques. Pre-combustion (natural gas processing) is the only capture technology that has reached commercial scale (TRL9) (Bui et al. 2018a). Other capture technologies such as adsorption post-combustion, oxyfuel combustion (coal power plants), pre-combustion (IGCC), membrane polymeric (natural gas), BECCS technology and direct air capture are in the demonstration scale (TRL7), while, in pilot-scale (TRL6), there are membrane polymeric (power plants), post-combustion (biphasic solvents), chemical looping combustion as well as calcium carbonate looping technologies. The remaining capture technologies are ranging from laboratory-scale plant (TRL5) to proof of concept (TRL3) such as membrane dense inorganic, oxyfuel combustion (gas turbine), ionic liquid post-combustion and low-temperature separation pre-combustion technologies.

Regarding carbon storage technology, post-combustion (amine) in power plants, saline formations and \(\hbox {CO}_{2}\)-enhanced oil recovery are the only three technologies that have reached commercial scale (TRL9) (Campbell 2014; Singh and Stéphenne 2014). While other technologies such as \(\hbox {CO}_{2}\)-enhanced gas recovery and depleted oil and gas fields are still in the demonstration level (TRL7), other storage technologies such as ocean storage and mineral storage are in infant stages of formulation (TRL2) and proof of concept in laboratory tests (TRL3), respectively. On the other hand, the transport technologies either onshore and offshore pipelines along with transport ships are both mature (TRL9) (Bui et al. 2018a). An important aspect during the early stages of CCUS deployment is the development of appropriate infrastructure, whereby the consolidation of multiple \(\hbox {CO}_{2}\) sources can provide an opportunity to take advantage of economies of scale in carbon capture.

\(\hbox {CO}_{2}\) separation methods from flue gas in combustion capture process

Numerous exceptional separation techniques are utilised through the combustion method for the \(\hbox {CO}_{2}\) separation of flue gas. These techniques are absorption, microalgae, membrane separation, adsorption and cryogenics (Fig. 4) (Osman et al. 2020a; Li et al. 2012a).

Absorption is an entrenched \(\hbox {CO}_{2}\) separation procedure utilised in the synthetic and petroleum area up to date. Absorption divides into two classifications: (1) physical, where it relies on both temperature and pressure (absorption happens at extraordinary pressures and low value of temperatures), and (2) chemical, where absorption of \(\hbox {CO}_{2}\) relies upon neutralising acid-base response (Li et al. 2011c). Remarkable of the favoured solvents are amines (for example, monoethanolamine), solutions of ammonia, Selexol, Rectisol and fluorinated solvents. The common current addition is ionic liquids, which have shown incredible potential in the absorption of \(\hbox {CO}_{2}\) and are likewise eco-friendly (Hasib-ur Rahman et al. 2010).

Microalgae bio fixation is a suitable procedure for the expulsion of \(\hbox {CO}_{2}\) of flue gases. This procedure demands the utilisation of photosynthetic organisms (microalgae) for anthropogenic carbon capture and storage. Marine microalgae have been proposed to be of more prominent potential because they have more distinguished carbon stabilisation rates than land plants (Ben-Mansour et al. 2016). Microalgal culturing is very costly; however, the technique creates different composites of high worth that can be utilised for income production. Microalgal photosynthesis further commands to precipitation of calcium carbonate that can aid as an enduring sink for carbon (Nakamura and Senior 2005).

The separation based on membranes substances depends on the variances in the interactions that occurred within gases and the materials of the membrane, that adjusted to permit several pieces to transfer discriminatory into the membrane (Li et al. 2011c). Membranes have extraordinary merit in \(\hbox {CO}_{2}\) separation in pre-combustion capture and post-combustion \(\hbox {CO}_{2}\) separation. A broad category of diverse membrane materials and methods are obtainable, some of which now on the industrial field, and potentially related to \(\hbox {CO}_{2}\) separation. The enforcement and related cost of technologies based on membrane separation in extensive range \(\hbox {CO}_{2}\) capture principally rely totally on the membrane materials. Adsorptive separation is a hybrid separating technique which operates on the principle of varieties in adsorption and desorption properties of the component of the hybrid (Li et al. 2012a). The cryogenic \(\hbox {CO}_{2}\) separation procedure utilises the basis of liquid case temperature and pressure variation in component gases of flue gas. In this procedure, cooling and condensation of \(\hbox {CO}_{2}\) occur, then extracted from the flue gases (Song et al. 2012).

Absorbents and their performance

Absorption is a technique of transporting the matters from their vapour state to the fluid phase as long as that the vapour is dissolvable in that fluid (Abdeen et al. 2016). In the state of \(\hbox {CO}_{2}\), the solubility of the gas is conditioned on the solvent’s physical and chemical features. Contingent upon the solvent utilised, the gas parts can be easily dissolved physically or are bound chemically to the solvent designated as physical or chemical absorption or a hybrid of both processes (Koytsoumpa et al. 2018). If the particles of vaporous of \(\hbox {CO}_{2}\) are combined with liquid particles with inadequate intermolecular forces, the absorption is defined as physical absorption.

Thermal energy demands through chemical solvents are extremely more necessary than those for physical solvents that are attributed to the energy augmented through the reboiler of the stripper column (Koytsoumpa et al. 2018; Jansen et al. 2015). In the case of physical solvents, the loading limit of the solvents is in a practical direct reliance within the partial pressure of the parts to be separated and the solvent loading as indicated by Henry’s law, deducting its recovery through pressure throttling. The destruction of \(\hbox {CO}_{2}\) in the physical fluid solution is ascribed to the Van der Waals or interactivity electrostatic and is typical at tremendous pressure and lowered value of temperature (Koytsoumpa et al. 2018; Theo et al. 2016).

The chemical or reactive absorbents comprise amines, blends, ionic liquids, aqueous solvents, ammonia, etc. The blends were then created to merge the positive features of diverse absorbents, and concurrently overcoming their negative features. The physical absorbents comprise solvents like Rectisol, Selexol, etc. To be applied as an absorbent, a solvent should possess the required features such as exceptional reactivity and absorptivity with \(\hbox {CO}_{2}\), great stability below elevated thermal and fixed chemical exposure, moderate vapour pressure, suitable renewability, low environmental impact and cost-effective to apply (Sreedhar et al. 2017a, b). Amines such as monoethanolamine and diethanolamine were the newest and the most usually applied absorbents attributed to their economical cost, excellent reactivity and a remarkable rate of absorption. Nevertheless, they undergo several obstacles like diminishing in the oxidative atmosphere, intense renewal energy demand, restricted \(\hbox {CO}_{2}\) storing potential and corrosive features by foaming and fouling components (van der Zwaan and Smekens 2009).

Gao et al. (2016) have revealed a trial of a 30 wt% monoethanolamine-methanol compared to aqueous 30 wt% monoethanolamine solvent in a pilot-plant testbed, which involves the whole absorption and desorption. The outcomes showed that monoethanolamine-methanol solvent possessed a more accelerated \(\hbox {CO}_{2}\) absorption rate and lowered regenerating energy-consuming compared to aqueous monoethanolamine solvent (Fig. 5). Recovery heat duty of monoethanolamine-methanol solvent at best-operating statuses was lower than that of aqueous monoethanolamine solvent which revealed that monoethanolamine-methanol possessed a potential to displace aqueous monoethanolamine solvent in manufacturing \(\hbox {CO}_{2}\) pilot plant.

Cyclic amine piperazine was applied as a promoter attributed to its prompt production of carbamates with carbon dioxide. Ma et al. (2016) have studied the influences of different additives of piperazine and Ni(II) ( were utilised as an absorbent in the bubbling reactor) on \(\hbox {CO}_{2}\) absorption performance and ammonia escape rate. Also, they compared the efficiency of the mixed additive in the extraction technique with that of pure ammonia solution (Fig. 6). The obtained performance for the absorption of \(\hbox {CO}_{2}\) was higher by 72% at the addition of 2 wt% \(\hbox {NH}_{3}\) solution with piperazine (25 mmol/L) and Ni(II) (50 mmol/L), as compared to that performed by 3 wt% \(\hbox {NH}_{3}\) solution without any addition. Furthermore, the loss in of the \(\hbox {NH}_{3}\) amount was approximately 1/3 compared in the case of using a 3 wt% of \(\hbox {NH}_{3}\) solution without any addition.

2-Amino-2-methyl-1propanol was further reviewed in the literature due to its excellent absorption potential, special resistance for degradation and corrosion and more extraordinary selectivity (Sreedhar et al. 2017a; Kim et al. 2013). The blend of 2-amino-2-methyl-1propanol and piperazine is beneficial where it managed to lessen in regeneration energy with a 20% and reducing in the rate of circulation absorbent by (45%), away from a notable increment in thermal and oxidative decay resistances (Sreedhar et al. 2017a). Khan et al. (2016) have investigated reviews a post-combustion procedure of capture of \(\hbox {CO}_{2}\) of flue gas by utilising aqueous amine blend of 2-amino-2-methyl-1-propanol and piperazine. The specific rate of absorption for the blends ranged between \(14.6\times 10^{-6}\) and \(26.8 \times 10^{-6}\,\hbox {kmol/m}^{2}\,\hbox {s}\). The measured highest rate of \(\hbox {CO}_{2}\) absorbed was (99.63%) at the greatest content of piperazine (10 wt%) in the blend. The most chief \(\hbox {CO}_{2}\) loading potential was (0.978) to the greatest content of piperazine. The regeneration performance was detected within the range of 90.93–98.93% and the found best performance was (98.93%) at using the greatest content of 2-amino-2-methyl-1propanol (28 wt%).

a Regeneration heat duty for monoethanolamine (MEA) and monoethanolamine-methanol (MEA-methanol) solvent, b regeneration heat duty for monoethanolamine-methanol solvent c for monoethanolamine solvent. Adapted with permission from Gao et al. (2016), Copyright 2020, Elsevier

Diethylenetriamine possesses three amino groups (two principal and one secondary). In contrast to monoethanolamine, diethylenetriamine displayed more special reactivity (Salvi et al. 2014), lower heat of reaction although with sufficient \(\hbox {CO}_{2}\) absorbing potential (Kim et al. 2014), more elevated rate of mass transference (Fu et al. 2012) and smaller heat capacity for regeneration (Zhang et al. 2014). Sulpholane behaves like a physical additive within the chemical absorption system, attributed to its extraordinary stability and special resistance towards corrosion. The diethylenetriamine–pentamethyldiethylenetriamine mixed-amine solvent was affirmed as a biphasic solvent. The pentamethyldiethylenetriamine duties as the proton acceptor, i.e. extracted the zwitterion and improved the \(\hbox {CO}_{2}\) absorption in diethylenetriamine, securing great \(\hbox {CO}_{2}\) capacity (Wang et al. 2020a). Wang et al. (2020a) have found that the sulpholane enhanced the rate of \(\hbox {CO}_{2}\) absorption via diethylenetriamine–pentamethyldiethylenetriamine–sulpholane solvent (1.3 times) compared to that diethylenetriamine–pentamethyldiethylenetriamine solvent. Figure 7 demonstrates the chemical structures and carbon atom label of the species in the diethylenetriamine–pentamethyldiethylenetriamine–sulpholane biphasic solvent. The \(\hbox {CO}_{2}\) was captured over diethylenetriamine corresponding to the zwitterionic mechanism and provided carbamate to the solvent. If more \(\hbox {CO}_{2}\) was absorbed in the solvent, the quantities of liberating diethylenetriamine and pentamethyldiethylenetriamine at the solution reduced, and a higher amount of diethylenetriamine and pentamethyldiethylenetriamine have owned a proton. Contrasted with untreated pentamethyldiethylenetriamine and sulpholane, the formed diethylenetriamine–carbamate, protonated diethylenetriamine and pentamethyldiethylenetriamine, bicarbonate was further hydrophilic and possessed large polarity, causing to a more durable ability to merge with water than untreated pentamethyldiethylenetriamine and sulpholane.

The chemical structures and carbon atom label of the diethylenetriamine–pentamethyldiethylenetriamine–sulpholane biphasic solvent. Adapted with permission from Wang et al. (2020a), Copyright 2020, Elsevier

Hence, throughout \(\hbox {CO}_{2}\) absorption within the solvent, the uniform solution was split to hydrophilic and hydrophobic phases. Also, it is denoted that the hydrophobic sulpholane and untreated pentamethyldiethylenetriamine were dispersed off the higher layer, whereas the hydrophilic parts were dispersed off the below layer due to the density variation. Therefore, the hydrophobic sulpholane developed the hydrophilic–hydrophobic division within the \(\hbox {CO}_{2}\) stored solution, which improves the phase division, as presented in Fig. 8.

The influence of the addition of enzyme carbonic anhydrase was examined on monoethanolamine, methyldiethanolamine, 2-amino-2-methyl-1propanol and potassium carbonate (\(\hbox {K}_{2}\hbox {CO}_{3}\)) (Gladis et al. 2017). The \(\hbox {K}_{2}\hbox {CO}_{3}\) was tried as an absorbent due to its economic value, the moderate value of enthalpy demands, lowering toxicity, small solvent losses and extraordinary resistance for decomposition. To counterpoise the lowering rate of mass transfer, promoters, biological enzymes, organics and alkaline amino acids were stated to be utilised (Endo et al. 2011; Russo et al. 2013).

Wang et al. (2019) have synthesised spherical pellets of \(\hbox {K}_2\hbox {CO}_3\) comprising varying amounts of \(\hbox {Al}_2\hbox {O}_3\) for \(\hbox {CO}_{2}\) capture (Fig. 9). The activated alumina promoted sorbent pellets arranged with 50 wt% of \(\hbox {K}_{2}\hbox {CO}_{3}\) hold the most chief \(\hbox {CO}_{2}\) adsorption potential (0.0023 mol/g). Besides, the urea additive (15 wt%) can also improve \(\hbox {CO}_{2}\) separation (\(\sim \,0.0031\,\hbox {mol } \hbox {CO}_{2}/\hbox {g}\)) of the pellets filled with 50 wt% of \(\hbox {K}_{2}\hbox {CO}_{3}\). The enriched \(\hbox {CO}_{2}\) capture is attributed to the notably improved sorbent pellets’ porosity as a sequence of urea decay. Furthermore, the urea sorbent pellets keep the exceptional compressive strength (18.96 MPa) and excellent resistance towards corrosion (retain about 99.41% of its original weight after 4000 rotations).

The synthesis process of \(\hbox {K}_{2}\hbox {CO}_{3}\) pellets sorbents. Adapted with permission from Wang et al. (2019), Copyright 2020, Elsevier

Adsorption

The concept of adsorption is interpreted as the emerging adhesion between atoms, ions or molecules, whether in a liquid or gaseous or solid state, and the surface. The ions, atoms or particles that adhere to create a film on the substance’s surface in which they are bound and are termed as an adsorbate, while the substance on which they appended is named adsorbent. Adsorption is diverse from absorption due to, in absorption, the absorbate (fluid) is dissolved via an absorbent, whether solid or liquid. Adsorption forms on the outside surface, while absorption entails the whole material volume. Sorption is correlated to the couple manners, while desorption is considered as counter-reaction or reversed the adsorption process (Ben-Mansour et al. 2016; Abd et al. 2020).

Adsorption may begin physically; this requires ineffective Van der Waals forces (physisorption). Likewise, it might happen chemically, which demands covalent bonding (chemisorption), and it may happen attributed to the electrostatic attraction. The most prominent chemical adsorption and absorption systems, in \(\hbox {CO}_{2}\) capture techniques, include the interaction within chemicals that leads to the creation of molecular structures based on \(\hbox {CO}_{2}\), following which recovery of the uptake \(\hbox {CO}_{2}\) is achieved over an adequate rise in temperature via heat treatment. The regeneration method spends the greatest of the potential demand in \(\hbox {CO}_{2}\) capture. So, there is a necessity to promote energetic substances and methods for \(\hbox {CO}_{2}\) uptake that can considerably lessen operation expenditure via the decline in expenditure of regeneration (Ben-Mansour et al. 2016).

The physical adsorbents which used in \(\hbox {CO}_{2}\) adsorption whether carbonaceous and non-carbonaceous substances, as shown in Table 1, demands lowering value energy in the contrasting to that required in the case of using the chemical adsorbents. This can be explained that in the physical adsorbents, not new bonds are created between the carbon dioxide and the surface of the used adsorbent; hence, this ultimately results in reducing the energy demanded regeneration process (Abd et al. 2020).

Carbonaceous materials adsorbents

Carbonaceous materials typically were composited of carbon and additional linked material that can consider unique features like environmentally benign, extraordinary stability feature whether the thermal and chemical behaviour, exceptional conduction mechanism (heat and electrical characteristics) or surpassing strength. Besides, these materials have numerous merits such as low-cost, effective, simple composition from materials settled in nature, extraordinary distinct surface area, unique pore volume, and they are fine weight substances (Abd et al. 2020; Lozano-Castelló et al. 2002).

Activated carbon materials Over the ages, the porous carbon adsorbents have emerged as proper substances for \(\hbox {CO}_{2}\) uptake ascribed to the physical adsorption of \(\hbox {CO}_{2}\) on their surface, signifies the energy that demands the regeneration process was declined. Besides, the excellent \(\hbox {CO}_{2}\) adsorption will be performed ascribed to their porous feature. Also, these materials can be efficiently qualified to combine exceptional surface features and necessary beneficial groups that can assist in enhancing the resulting interaction between the adsorbent substances and \(\hbox {CO}_{2}\) which are crucial for providing an extraordinary \(\hbox {CO}_{2}\) adsorption potential (Li et al. 2019b; Singh et al. 2019). The activated carbons were fabricated of carbonaceous substances through pyrolysis at high temperatures and special pressure in the activation furnace (Kosheleva et al. 2019). The resulting from this process is extraordinary surface area and heterogeneous pore structure. Besides, an inert gas (nitrogen or argon) was applied in the carbonisation step to eliminate any volatile parts to fabricate enriched carbon specimens. After that, the fabricated specimen was activated in the existence of the oxidising agent (oxygen, steam or carbon dioxide) at a wide range of elevated temperatures (Mahapatra et al. 2012).

The activation stage among the carbonaceous substances and the oxidising agents is an endothermic reaction, as explained in the following:

The carbon dioxide was preferably utilised as an activation agent than steam ascribing to its capacity to produce particles that have tight micropores nature that satisfies the characteristics of molecules of carbon dioxide, while steam is beneficial to compose particles with mesopores feature (González et al. 2009; Román et al. 2008).

The influence of nitrogen incorporating with the activated carbon was estimated to behave that the carbon dioxide uptake performance is managed via porosity character and nitrogen ratio. Recently, He et al. (2021) have synthesised activated carbons via carbonisation and potassium hydroxide KOH activation employing rice husk as a raw material. The studied samples show remarkably surface area about \(\approx 1496\,\hbox {m}^{2}\,\hbox {g}^{\text {-1}}\), and micropore volume of \(44.7 \times 10^{-2}\,\hbox {cm}^3\,\hbox {g}^{-1}\). Also, compared with the biochar to KOH as (1:5) ratio sample, chitosan modified (biochar/KOH as 1:5) sample displays remarkable \(\hbox {CO}_{2}\) uptake achievement \(0.00583\,\hbox {mol}\,\hbox {g}^{-1}\), which can be ascribed to the creation of the \(\hbox {CO}_{2}\)-philic active sites on activated carbons surface via nitrogen species. The isosteric heat of \(\hbox {CO}_{2}\) uptake for chitosan modified (biochar/KOH as 1:5) sample is extremely higher than that of the non-modified sample. The adsorption performance of the modified sample with chitosan can be suitably represented via the Freundlich model (Fig. 10). The large ideal adsorption solution theory (IAST) selectivity factor to the modified sample with chitosan designates their unique adsorption selectivity for \(\hbox {CO}_{2}\) over doping with nitrogen.

A Activated carbon prepared by varying biochar and KOH mass ratios, B large ideal adsorption solution theory (IAST) selectivity factors of (a) biochar/KOH(1:5) (AC-5), (b) chitosan@ biochar/KOH(1:5) (CAC-5), (c) chitosan@biochar/KOH(1:6) (CAC-6) and (d) chitosan@biochar/KOH(1:7) (CAC-7) at 298 K, 0–101 kPa, C isosteric heat of \(\hbox {CO}_{2}\) uptake on (a) biochar/KOH (1:5) (AC-5), (b) chitosan@biochar/KOH(1:5) (CAC-5), (c) chitosan@biochar/KOH(1:6) (CAC-6) and (d) chitosan@ biochar/KOH (1:7) (CAC-7) estimated, and D \(\hbox {CO}_{2}\) adsorption isotherms of (a) biochar/KOH(1:5) (AC-5) sample fitted to various isotherm models. Adapted with permission from He et al. (2021), Copyright 2020, Elsevier

Activated carbons were prepared using two stages of activation steps from different types of waste and low-value lignocellulosic biomass such as potato peel waste, barley waste and miscanthus with surface areas (\(\hbox {m}^{2}/\hbox {g}\)) of 833 (Osman et al. 2019), 692 (Osman et al. 2020c) and 1368 (Osman et al. 2020b), respectively. Singh et al. (2019) have presented the manufacture of activated porous carbon spheres for D-glucose carbonisation with a unique potassium acetate for carbon dioxide uptake. The obtained spheres shape activated porous carbon possesses a specific surface area of \(\approx 1920\,\hbox {m}^{2}/\hbox {g}\), spherical shape for surface morphology and special pore volume of \(\approx 0.9\,\hbox {cm}^{{3}}/\hbox {g}\). The activated porous carbon spheres display outstanding achievement, and manifest carbon dioxide uptakes ranged between 0.00196 to 0.00662 mol/g at different operating conditions. Furthermore, the samples exhibit efficient carbon dioxide uptake achieved 0.02008 mol/g at a temperature of \(0\,^{\circ } \hbox {C}\) and pressure of 30 bar and achieved 0.01408 mol/g in the case the temperature raised to \(25\,^{\circ } \hbox {C}\) and pressure 30 bars (Fig. 11). This achievement could be ascribed to the extremely revealed porous construction of the studied materials.

A Activated porous carbon spheres fabricated from d-glucose, B \(\hbox {CO}_{2}\) adsorption isotherms of (a) activated porous carbon spheres sample, (b) activated porous carbon spheres—1 g of potassium acetate, (c) activated porous carbon spheres—2g of potassium acetate, (d) activated porous carbon spheres—3g of potassium acetate, and (e) activated porous carbon spheres—4 g of potassium acetate at \(0\,^{\circ } \hbox {C}\), and C \(\hbox {CO}_{2}\) adsorption isotherms of activated porous carbon spheres—3 g of potassium acetate at (a) \(0\,^{\circ } \hbox {C}\), (b) \(10\,^{\circ } \hbox {C}\) and (c) \(25\,^{\circ } \hbox {C}\). Adapted with permission from Singh et al. (2019), Copyright 2020, Elsevier

To sum up, the activated carbon adsorbents exhibit remarkable merits such as low value for regeneration energy, simple to restore, low regeneration temperature, an abundance of raw materials and extraordinary thermal stability; mainly the uptake achievement improves if the applied pressure of carbon dioxide rises.

Carbon nanotube materials Carbon nanotube materials are being examined in \(\hbox {CO}_{2}\) uptake area ascribed to their attractive physical and chemical features such as great conduction behaviour whether thermal or electrical, besides the feasibility to develop their surfaces through attaching a chemical duty group, the exceptional yield for uptake storage potential. Further, the carbon nanotubes were achieved as a proper adsorbent for \(\hbox {CO}_{2}\) uptake (Abuilaiwi et al. 2010; Srivastava and et al. 2003). Recently, Ghosh and Ramaprabhu (2019) have studied transition metal (iron, cobalt and nickel) salt-encapsulated nitrogen-doped bamboo-like carbon nanotubes for \(\hbox {CO}_{2}\) uptake across a broad range of temperature and pressure (Fig. 12). The observed results reveal that the \(\hbox {CO}_{2}\) adsorption potential completely improves for all transition metals covered the nitrogen-doped bamboo-like carbon nanotubes in both the pressure range. Further, the adsorption potentials lessen with the increment in temperature to all the studied samples inferring that physical uptake is the principal adsorption mechanism. Also, the sample used the Fe as an encapsulating metal shows the most chief adsorption potential, whereas the sample used Ni as an encapsulating metal uptake was the least between the studied samples. Furthermore, the adsorption potentials of the Fe encapsulated the nitrogen-doped bamboo-like carbon nanotubes is reached 0.0015 mol/g, whereas the Co covered the nitrogen-doped bamboo-like carbon nanotubes uptakes 0.00115 mol/g, and the Ni coated the nitrogen-doped bamboo-like carbon nanotubes uptakes 0.00098 mol/g at 298 K which increment with the reduction in temperature.

Synthesis of transition metal (iron, cobalt and nickel) salt-encapsulated nitrogen-doped bamboo-like carbon nanotubes. Adapted with permission from Ghosh and Ramaprabhu (2019), Copyright 2020, Elsevier

Also, Su et al. (2011) have prepared multiwalled carbon nanotubes were functionalised with a large weight load of 3-aminopropyltriethoxysilane to examine their performances in the \(\hbox {CO}_{2}\) uptake. The adsorption potential of multiwalled carbon nanotubes@ 3-aminopropyltriethoxysilane was significantly impacted through the existence of vapour of water. Whereas raising the water amount, the uptake potential increased, which revealed that the uptake process is an exothermic reaction. Also, they observed that the uptake potential declined with increasing temperature. The \(\hbox {CO}_{2}\) uptake potential reached 0.0026 mol/g at 293 K for multiwalled carbon nanotubes@ 3-aminopropyltriethoxysilane. The outcome implies that the solid multiwalled carbon nanotubes@ 3-aminopropyltriethoxysilane are a promising system for \(\hbox {CO}_{2}\) uptake.

Jena et al. (2019) have presented the synthesis of the nanohybrid (3-aminopropyl) triethoxysilane@zinc oxide@ multiwalled carbon nanotubes. The nanohybrid displays mesoporous features possessing a unique surface area (\(\sim 27\,\hbox {m}^{2}/\hbox {g}\)) with a pore size of about 3.8 nm. The multiwalled carbon nanotubes surface that is adjusted with the zinc oxide considerably enhances the \(\hbox {CO}_{2}\) uptake potential (0.00132 mol/g). Furthermore, the increase in the ZnO density that is attached at the surface of multiwalled carbon nanotubes produced a tremendous affinity for the sake of \(\hbox {CO}_{2}\) uptake at low pressure.

Graphene Graphene is a unique category of carbonaceous substances with superior adsorption potential and lately got extensive consideration (Abdel Maksoud et al. 2020). Various investigations applied different strategies to qualify the surface of graphene and introduce an extraordinary surface area and acceptable pore volume (Kumar and Xavior 2014). Recently, Varghese et al. (2020) have progressed the graphene oxide foam via the ultraviolet irradiation and investigated for \(\hbox {CO}_{2}\) uptake potential (Fig. 13). They found that \(\hbox {CO}_{2}\) recover potential increased as the ultraviolet exposure increase. The \(\hbox {CO}_{2}\) recover potential reached about 90% for the graphene oxide foam exposed to 5 hours for ultraviolet irradiation and reached 91% as the exposed time for ultraviolet irradiation increased to ten hours in contrast to the untreated graphene oxide foam were recovered 65% of \(\hbox {CO}_{2}\). Furthermore, with boosting the regeneration temperature, the \(\hbox {CO}_{2}\) recovery improved.

Hsan et al. (2019) have confirmed chitosan grafted graphene oxide aerogels for \(\hbox {CO}_{2}\) uptake. The result of the uptake potential of \(\hbox {CO}_{2}\) via the prepared grafted sample is around 0.26 mmol/g at the pressure 1 bar, which is notably greater in contrast to the uptake potential of pure chitosan sample. The outcomes affirm that this examination assists to decrease the cost-effectiveness of adsorbents where chitosan is abundant with a large amount in marine waste, and therefore, this research intends to decrease the cost of \(\hbox {CO}_{2}\) uptake with suitable temperature and pressure.

Wang et al. (2020c) have combined unique hierarchical porous C acquired from poly(p-phenylenediamine) with reduced graphene oxide for \(\hbox {CO}_{2}\) uptake technology. The obtained reduced graphene oxide on poly(p-phenylenediamine) sample has a surface area around \(860\,\hbox {m}^{2}/\hbox {g}\) besides it displays superior \(\hbox {CO}_{2}\) uptake potential (0.00465 mol/g at a temperature of 298 K and pressure of 5 bar).

Meng and Park (2012) have declared that exfoliated nanoplate of graphene was a highly proper adsorbent for \(\hbox {CO}_{2}\) uptake. The graphene nanoplate was synthesised from graphene oxide through a low-temperature approach. The treated adsorbents performed an extraordinary \(\hbox {CO}_{2}\) removal of about 0.056 mol/g. Further, the remarkable adsorption potential of graphene nanoplates was ascribed to the larger inter-layer spacing and essential interior volume. The treated graphene nanoplates showed excellent capture uptake (248 wt%) at the operating conditions. Also, Hong et al. (2013) have proposed progressing the basicity via improving the surface of graphite using 3-aminopropyl-triethoxysilane, which can increase the \(\hbox {CO}_{2}\) removal. The outcomes stated that amine adjustment enhances the \(\hbox {CO}_{2}\) uptake; hence, the increment of the basicity is the principal factor in advancing \(\hbox {CO}_{2}\) uptake which is agreeable with the adherent molecules of amine that attached into the graphite surface.

a Synthetic stages of graphene oxide foam and ultraviolet irradiation (UV-GOF), b \(\hbox {CO}_{2}\) adsorption isotherms of untreated graphene oxide foam (GOF) and treated graphene oxide foam via ultraviolet irradiation (UV-GOF) adsorbents and c \(\hbox {CO}_{2}\) and \(\hbox {N}_{2}\) adsorption selectivity of untreated graphene oxide foam (GOF) and treated graphene oxide foam via ultraviolet irradiation (UV-GOF) adsorbents at different pressures. Adapted with permission from Varghese et al. (2020), Copyright 2020, Elsevier

Non-carbonaceous dry adsorbents

Zeolites Zeolites are another category of physical adsorbents found in nature and can be manufactured in the investigation laboratory also it comprises a microporous crystalline framework compositing of aluminosilicates. Zeolites were broadly applied in the carbon dioxide elimination in the concern of their molecular sieving influence, and the electrostatic interactions occurred among carbon dioxide and alkali cations inside the zeolite frameworks (Singh et al. 2020). The gas uptake features of the zeolites are notably reliant upon the size, the density of charges and the distribution of the commutable cations in the pored framework (Zhang et al. 2008).

The replacement of aluminium ions with silicon ions produces a negative charge, that can be rebalanced via the exchangeable cation into the construction of alkalies such as sodium and potassium cations or alkaline earth metal calcium and magnesium ions. Zeolites possess many traditional kinds such as zeolite A, X and Y or natural zeolites such as chabazites, clintopiles, ferrierites and mordenite (Dong et al. 1999). The zeolites 13X and 5A that possess reasonable pores size exhibit more proper for \(\hbox {CO}_{2}\) uptake than their rival that have pores with little sizes such as Chabazite and Na-A in the low applied pressures (Song et al. 2018). Mason et al. (2015) have reported that the zeolite 5A (Na0.28Ca0.36AlSiO4) including Linde Type A composition and zeolite 13X(NaAlSi1.18O4.36) with Faujasite composition comprising calcium and sodium cations exhibited amazing \(\hbox {CO}_{2}\) uptake potential 0.0031 mol/g at pressure 0.15 bar.

Wang et al. (2020b) have prepared X zeolite via waste rice hull ash and qualified via rare-earth metals (La and Ce) ion-exchange into the zeolite (Fig. 14). The NaX exhibited high \(\hbox {CO}_{2}\) uptake (\(0.0061\,\hbox {mol}\,\hbox {g}^{-1}\)), whereas LaLiX shows \(0.0043\,\hbox {mol}\,\hbox {g}^{-1}\) for \(\hbox {CO}_{2}\) uptake. Also, the selectivity of carbon dioxide and nitrogen for LaNaX was improved more than three times. Further, the qualified zeolite samples lost about 3.5% of its original adsorption over 20 adsorption-desorption cycles.

Liu et al. (2020) have prepared (3-Aminopropyl)-triethoxysilane and alkyl-functionalised- (3-Aminopropyl)-triethoxysilane and grafted it on zeolite beta by a reflux reaction. The results showed that the alkyl-functionalised- (3-Aminopropyl)-triethoxysilane @ zeolite displayed an uptake potential of about 0.00144 mol/g. Also, the studied absorbent sample displayed an extraordinary uptake rate of about \(\sim\) 0.7 min (after 90% of the whole uptake potential in five min), and great stability after 20 cycles. Furthermore, alkyl-functionalised- (3-Aminopropyl)-triethoxysilane @ zeolite beta provided more chief uptake potential and stability than (3-Aminopropyl)-triethoxysilane @ zeolite at \(\hbox {CO}_{2}\) mixture uptake and \(\hbox {CO}_{2}\) flow regeneration.

The affected metal ions incorporated in the zeolitic framework could likewise promote the \(\hbox {CO}_{2}\) uptake potentials. Theoretical and practical examination of nontreated zeolite (13X), lithium comprising zeolite (LiX) and polymetallic zeolite (LiPdAgX) with Faujasite composition proved that the LiPdAgX system is a more efficient candidate not alone for \(\hbox {CO}_{2}\) uptake but likewise for the selectivity of carbon dioxide and nitrogen as compared to 13X and LiX samples. Further, the LiPdAgX system presented \(\sim\) 25% greater \(\hbox {CO}_{2}\) uptake and \(\sim\) 180% more chief selectivity (Chen et al. 2018b).

Notwithstanding the superior merits of affected metal qualified zeolite, the progress remarked in the isosteric heat of uptake was not notably great. A related statement decided that the thermal conductivity was improved through the incorporation of palladium and silver ions within the zeolite framework could efficiently consume the heat of uptake, appearing in the enrichment of the \(\hbox {CO}_{2}\) uptake potential at post-combustion uptake conditions (Chen et al. 2017).

Isotherms of uptake of \(\hbox {CO}_{2}\) via a NaX zeolite, b LaNaX zeolite, c CeNaX zeolite, d LaLiX zeolite and e CeLiX zeolite Adapted with permission from Wang et al. (2020b), Copyright 2020, Elsevier

Silica materials The materials based on silica are different types of adsorbed non-carbonaceous substances for carbon dioxide uptake, which distinguish with an extraordinary surface area, pore size and excellent mechanical stability. Silica is commonly applied as a support on which different substances are combined for \(\hbox {CO}_{2}\) elimination. Consequently, most of the investigation goes on adsorbents based on silica are principally induced in adjusting several natures of silica and utilising proper amines types since numerous investigations noted the performance of silica materials-based adsorbents for \(\hbox {CO}_{2}\) (Qin et al. 2014; Sanz-Pérez et al. 2018).

Henao et al. (2020) have estimated the \(\hbox {CO}_{2}\) uptake performance of a range of amine-functionalised silicas with distinct pore compositions: SBA-15 (2D hexagonal), SBA-11 (3D cubic) and disordered silica. The rice husk ash was utilised as a silica source. Afterwards, the silica is functionalised by polyethyleneimine through wet impregnation. The \(\hbox {CO}_{2}\) uptake achievement is considered sensitive to the pore characteristics of the silica supports and the impregnated value of polyethyleneimine. Between the developed samples, the polyethyleneimine on SBA-15 presented the most superior amine employ and \(\hbox {CO}_{2}\) uptake potential (0.0616 g for every 1g of \(\hbox {CO}_{2}\)) under moderate conditions.

Minju et al. (2017) have prepared sorbents and used three amines (tetraethylenepentamine, tetraethylenepentamine acrylonitrile and a hybrid of aminopropyltrimethoxysilane coupled with the two amines individually) for the surface qualification intention. The \(\hbox {CO}_{2}\) uptake isotherms of the modified samples revealed that the sorbents coupled with aminopropyltrimethoxysilane presented excellent uptake achievement than the other samples. The specimen, including a hybrid of aminopropyltrimethoxysilane and tetraethylenepentamine, exhibited the most remarkable achievement between the other samples for a \(\hbox {CO}_{2}\) uptake potential about of 0.00326 mol/g. The tetraethylenepentamine acrylonitrile immobilised sorbents displayed more accelerated kinetics at all applied temperatures.

Lashaki and Sayari (2018) have examined the influence of the provider pore composition on the \(\hbox {CO}_{2}\) uptake achievement of triamine-tethered SBA-15 silica. The SBA-15 silica compounds assistance by varying pore extents and pore volumes have been manufactured, accompanied via triamine functionalisation by grafting process. The results of \(\hbox {CO}_{2}\) uptake estimations confirmed the certain influence of support large pore size and extraordinary pore capacity on uptake features, with the former signifying predominant. Also, the exceptional pore promotes showing the principal surface density about amine groups, and exceptional \(\hbox {CO}_{2}\) elimination (\(\sim \,0.0019\,\hbox {mol}\,\hbox {g}^{-1}\)). Further, if the pore capacity declined to 47% of its original value of samples including likewise pore sizes, the \(\hbox {CO}_{2}\) adsorption declined to \(\sim\)63% and more delayed adsorption kinetics has been seen.

Fayaz and Sayari (2017) have examined the hydrothermal durability of triamine-grafted commercial-grade silica for \(\hbox {CO}_{2}\) adsorption. The results of uptake showed extraordinary \(\hbox {CO}_{2}\) uptake of 0.0019 mol/g at best grafting statuses (\(1.5\,\hbox {cm}^{3}\) of amino silane per each gram of silica with a small volume of water). Also, the increase of the duration exposure time for steam lessened \(\hbox {CO}_{2}\) capture to 44% of its original value. Nonetheless, the \(\hbox {CO}_{2}\) uptake decreased (21–4%) with increasing the adsorption temperatures by \(25\,^{\circ }\hbox {C}\).

Metal–organic frameworks materials Metal–organic frameworks materials are a unique type of adsorbed substances that have fabricated via the incorporation of metal cations combined with the coordination bonds (Li et al. 2012a, b). The metal-organic frameworks materials had classified as organic-inorganic mixtures, superporous solid materials. Among the identified substances to time, metal–organic frameworks possess an exceptional uptake surface area for every gram. They hold an outstanding achievement for \(\hbox {CO}_{2}\) uptake, able to be flexible in whether structure and function behaviours. All these unique features made these materials broadly applied in the investigation operations of \(\hbox {CO}_{2}\) capture.

Further, the metal–organic frameworks have appeared and first performed via Hoskins and Robson and further recognised as coordination polymers (Abd et al. 2020; Düren 2007). Further to the unique structural chemistry of metal–organic frameworks, the composition agents such as extraordinary surface area around \(7\times 10^3\,\hbox {m}^{2}/\hbox {g}\) and exceptional pore volume (\(\sim \,4.5\,\hbox {cm}^{{3}}/\hbox {g}\)) besides with more comfortable control of the pore structure and surface and the other concerning characteristics of metal–organic frameworks, which offer a marked state for their utilisation in the area of \(\hbox {CO}_{2}\) uptake (Farha et al. 2012). The high surface area to weight ratio in the metal–organic frameworks is a remarkably critical agent for their \(\hbox {CO}_{2}\) uptake potential at low pressures, which allow them to perform more reliable \(\hbox {CO}_{2}\) uptake than other substances such as zeolites. Moreover, the metal–organic frameworks had well utilised for the selective uptake of \(\hbox {CO}_{2}\) by utilising the force of polarisable for the \(\hbox {CO}_{2}\) molecule and quadrupole moment.

Liu et al. (2012) have revealed that the metal–organic frameworks possess numerous merits such as tunable three-dimensional construction, exceptional values of the surface area, managed pore configurations and tunable porosity of surface characteristics. The cations and a broad array of organic varieties can work to compose metal–organic frameworks. A couple of relevant principles pointers for choosing a suite metal–organic framework for \(\hbox {CO}_{2}\) uptake are that the porosity of the studied adsorbent must be proper with the \(\hbox {CO}_{2}\) molecules’ radius. Moreover, the studied adsorbent should originate with polar, where the porosity of the surface possesses a more considerable \(\hbox {CO}_{2}\) storing ascribing to that the carbon dioxide particles possess electric quadrupole moments. Consequently, examining these criteria in the form of the metal–organic frameworks adsorbents can turn in a tremendous enhancement of the \(\hbox {CO}_{2}\) uptake.

Li et al. (2011a) have divided the metal–organic frameworks into two classes; rigid and dynamic. The rigid type of metal–organic frameworks should possess tunable frameworks that produce more pores alike to zeolite substances. In contrast, the dynamic kind possesses simple frameworks whose constructions alternate via outer influences alike pressure, temperature and the incorporated molecules. The numerous current procedures are to perform an untreated metal position overlying the porous via the release of the molecule of the coordinating solvent.

The enrichment in the potential of metal–organic frameworks to uptake \(\hbox {CO}_{2}\) of the mix of the various gases is reliant on the fundamental features of the metal–organic frameworks. Further, the enrichment is depended on the characteristics of the gases or mix that uptake in the metal–organic frameworks. These features comprise the construction and configuration of the metal–organic frameworks, fabrication and porous of metal–organic frameworks (Li et al. 2011a).

For example, Millward and Yaghi (2005), Furukawa et al. (2010) and Li et al. (1999) has developed four separated uptake materials of metal–organic frameworks, viz. metal–organic framework-180, metal–organic framework-200, metal–organic framework-2015 and metal–organic framework-210. The metal–organic framework-210 uptake material displayed outstanding porous of the surface and extraordinary carbon dioxide uptake achievement. Metal–organic framework-210 uptake material presented carbon dioxide removal of about 2.87 g/g of \(\hbox {CO}_{2}\). The fabricated adsorbent possesses a density of the bulk around 0.25 g per unit volume, the volume of porous of \(3.6\,\hbox {cm}^{3}\) per gram and a more exceptional surface area of \(6240\,\hbox {m}^{2}\) per gram that is the greatest recorded for all crystalline substances. Further, they observed that metal–organic framework-2, metal–organic framework-505, \(\hbox {Cu}_3(\hbox {BTC})_2\) (BTC = 1,3,5-benzene tricarboxylate), isoreticular metal–organic frameworks-11, isoreticular metal–organic frameworks-3 and isoreticular metal–organic frameworks-6 are considerably suitable adsorbents for carbon dioxide elimination. Additionally, they suggested metal–organic framework-177 that possesses a particularly exceptional surface area (\(4.5\times 10^3\hbox {m}^{2}/\hbox {g}\)) with \(\hbox {CO}_{2}\) removal of \(\sim 0.014\,\hbox {mol}\,\hbox {g}^{-1}\) at 35 bars.

The uptake achievement of metal–organic frameworks materials has further enhanced via using a suitable linker, which can alter the surface of adsorbents whether the porous and exceptional surface area for carbon dioxide particles. Zheng et al. (2013) have developed an expanded 4,4-paddlewheel combined metal–organic framework-505 analog of a nanostructured rectangular diisophthalate associated by alkyne associations. The produced adsorbent exhibited extraordinary \(\hbox {CO}_{2}\) uptake of \(0.024\,\hbox {mol}\,\hbox {g}^{-1}\) at room temperature and unique selectivity.