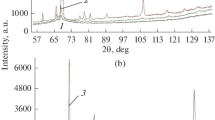

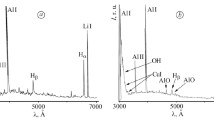

We study the accumulation of deuterium in coatings made of FeCrAl alloys and stainless steel, as well as (for comparison) in the Zr1%Nb alloy under the conditions of their saturation with a hydrogen isotope (deuterium) from a gaseous medium. By the method of nuclear reactions, we measure the space distribution of the concentration of deuterium in the coatings after their saturation at a temperature of 450°C (PD = 2·10–3 Pa for 120 min). It is shown that, for the investigated temperature and pressure, deuterium does not penetrate into the bulk of the coatings and is adsorbed in their subsurface regions from which it is then desorbed at a heating temperature higher than the room temperature by 20–30°С.

Similar content being viewed by others

References

B. A. Kalin and A. A. Shmakov, “Behavior of hydrogen in zirconium reactor alloys,” Phys. Khim. Obrab. Mater., No. 1, 78–84 (2005).

S. J. Zinkle, K. A. Terrani, J. C. Gehin, L. J. Ott, and L. L. Snead, “Accident tolerant fuels for LWRs: A perspective,” J. Nucl. Mater., 448, 374–379 (2014).

Y. Yan, T. A. Burtseva, and M. C. Billone, “High-temperature steam-oxidation behavior of Zr–1Nb cladding alloy E110,” J. Nucl. Mater., 393, 433–448 (2009).

D. Levchuk, F. Koch, H. Maier, and H. Bolt, “Deuterium permeation through Eurofer and a-alumina coated Eurofer,” J. Nucl. Mater., 328, 103–106 (2004).

G. D. Tolstolutskaya, I. E. Kopanets, V. V. Ruzhytskiy, V. A. Belous, and A. V. Nikitin, “Composition and thickness of coatings for protection of Zr1Nb alloy against hydrogen saturation,” Probl. Atom. Sci. Tech., No. 1 (89), 184–188 (2014).

G. D. Tolstolutskaya, I. E. Kopanets, V. V. Ruzhytskiy, V. A. Bilous, A. S. Kuprin, V. D. Ovcharenko, R. L. Vasilenko, and S. A. Leonov, “Decrease of hydrogen saturation of zirconium alloys at modification of surface by complex ion-plasma treatment,” Probl. Atom. Sci. Tech., No. 2 (96), 119–123 (2015).

А. S. Kuprin, V. А. Belous, V. N. Voyevodin, V. V. Bryk, R. L. Vasilenko, V. D. Ovcharenko, E. N. Reshetnyak, G. N. Tolmachova, and P. N. V’yugov, “Vacuum-arc chromium-based coatings for protection of zirconium alloys from the high-temperature oxidation in air,” J. Nucl. Mater., 465, 400–406 (2015).

J. C. Brachet, M. Le Saux, M. Le Flem, S. Urvoy, E. Rouesne, T. Guilbert, C. Cobac, F. Lahogue, J. Rousselot, M. Tupin, P. Billaud, C. Hossepied, F. Schuster, F. Lomello, A. Billard, G. Velisa, E. Monsifrot, J. Bischoff, and A. Ambard, “On-going studies at CEA on chromium coated zirconium based nuclear fuel claddings for enhanced accident tolerant LWRs fuel,” in: Proc. TopFuel-2015 WRFP Meeting (Zurich, Sept. 13–17, 2015) (2015), pp. 31–38.

Y. Yamamoto, B. A. Pint, K. A. Terrani, K. G. Field, Y. Yang, and L. L. Snead, “Development and property evaluation of nuclear grade wrought FeCrAl fuel cladding for light water reactors,” J. Nucl. Mater., 467, 703–716 (2015).

I. I. Aksenov, V. A. Belous, Yu. A. Zadneprovskiy, A. S. Kuprin, N. S. Lomino, V. D. Ovcharenko, and O. V. Sobol, “Influence of nitrogen pressure on silicon content in Ti–Si–N coatings deposited by the vacuum-arc method,” in: Proc. Internat. Symp. on Discharges and Electrical Insulation in Vacuum, ISDEIV No. 5625887 (2010), pp. 497–500.

A. I. Zhukov, V. F. Rybalko, G. D. Tolstolutskaya, I. E. Kopanets, and L. S. Verkhorobin, “Determination of the profile of occurrence of deuterium in materials according the reaction yields of the products of nuclear reactions,” Vopr. Atom. Nauki Tekh., No. 1 (58), 2 (59), 133–135 (1992).

A. Yu. Kem, “Determination of the relationship between fractality and sorption ability of the surface of powder substrate under the conditions of gas-phase saturation,” in: Proc. Eighth Internat. Symp. “Powder Metallurgy: Surface Engineering, New Powder Composite Materials. Welding” (April 10–12, 2013, Minsk), Minsk (2013), p. 92.

V. V. Ruzhytskyi, G. D. Tolstolutskaya, I. E. Kopanets, A. V. Nikitin, and S. A. Karpov, “Kinetics of redistribution of ion-implanted deuterium in Zr in the processes of the post implantation annealing,” Probl. Atom. Sci. Tech., No. 5 (81), 30–35 (2012.

S. Fryska and J. Baranowska, “Microstructure of reactive magnetron sputtered S-phase coatings with a diffusion sublayer,” Vacuum, 142, 72–80 (2017.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Fizyko-Khimichna Mekhanika Materialiv, Vol. 56, No. 1, pp. 39–46, January–February, 2020.

Rights and permissions

About this article

Cite this article

Tolstolutska, H.D., Ruzhytskyi, V.V., Kopanets, I.E. et al. Specific Features of Saturation with Deuterium of Vacuum-Arc Coatings Based on Iron. Mater Sci 56, 34–42 (2020). https://doi.org/10.1007/s11003-020-00394-1

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11003-020-00394-1