Abstract

The digital transformation of manufacturing requires digitalization, including automatic and efficient data exchange. Model-based definitions (MBDs) capture digital product definitions, in order to eliminate error-prone information exchange associated with traditional paper-based drawings and to provide contextual information through additional metadata. The flow of MBDs extends throughout the product lifecycle (including the design, analysis, manufacturing, in service life, and retirement stages) and can be extended beyond the typical geometry and tolerance information within a computer-aided design. In this paper, the MBDs are extended to include materials information, via dynamic linkages. To this end, a model-based feature information network (MFIN) is created to provide a comprehensive framework that facilitates storing, updating, searching, and retrieving of relevant information across a product’s lifecycle. The use case of a damage tolerant analysis for a compressor bladed-disk (blisk) is demonstrated, in Ti-6Al-4V blade(s) linear friction welded to the Ti-6Al-4V disk, creating well-defined regions exhibiting grain refinement and high residuals stresses. By capturing the location-specific microstructure and residual stress values at the weld regions, this information is accessed within the MFIN and used for downstream damage tolerant analysis. The introduction of the MFIN framework facilitates access to dynamically evolving data for use within physics-based models (resulting in the opportunity to reduce uncertainty in subsequent prognosis analyses), thereby enabling a digital twin description of the component or system.

Similar content being viewed by others

Introduction

The concept of the digital twin aims to create a digital representation of a serializable component or system, which can be used to predict its future performance based on the current available knowledge [1, 2]. To realize a digital twin representation of a component requires: (1) state information, which is dynamically or periodically updated, (2) prognosis, which can come from a range of sources, including data driven models, analytical models, or physics-based simulations [1,2,3], and (3) a representation of the object or system in a form in which it can be appropriately interpreted [3]. The state information is constantly evolving throughout the product lifecycle, from design, manufacture, in service use, to eventual retirement [4]. This paper presents a framework for data exchange, archival, and retrieval, as well as dynamically updating pertinent information throughout the lifecycle of a component to realize the digital twin representation, which is demonstrated for prognosis of its service life.

Physics-based relationships incorporating the underlying microstructure and micromechanical descriptors of the material can be used within prognosis efforts to reduce the uncertainties within life predictions [5]. Classical life prediction methods involve regression fits through empirical test data. While the specimens used for these tests are, on average, representative of the material within the component, they are not specific to a serialized component or its geometry. The material is dictated by process to structure to property relationships [6]. The material’s microstructure is a result of the manufacturing history (processing route) and governs the properties [7]. Hence, by tracking the processing path and resulting microstructure, the ultimate performance of the material at any instance within the component can be more systematically determined [7]. Therefore, an efficient methodology for storing and exchanging the material’s process-structure-properties information is required, in order to integrate these relationships and apply them towards the evaluation of the component’s structural performance.

A structured methodology for storing and updating material information is desired to maintain associations between datasets and enable their seamless exchange across the lifecycle. Digital material databases can be used to store and collate material lifecycle data, including manufacturing process parameters, microstructural descriptors, mechanical properties, simulated data, and in-service usage conditions [8,9,10,11]. Since these datasets could be created or evolve as the material’s lifecycle progresses, dynamically updating the information stored within the database is necessary to facilitate downstream engineering analysis. The current work provides an integration framework between the database(s) and the simulation tool(s) for data exchange through contextual linkages between the datasets and the geometric features of the component.

The contextual and behavioral information composed of the product lifecycle metadata can be associated with the component’s design geometry through the usage of model-based definitions (MBDs) [12,13,14]. Classically, MBDs have been limited to exchanging geometric form, feature dimensional tolerance, and manufacturing process planning metadata [13, 14]. In the present paper, MBDs are expanded to include and exchange material information as shown in Fig. 1. Moreover, material information can vary spatially across the volume of the component (i.e., location-specific material definitions) [7], which necessitates tools to associate the material definition to its geometric location or features within the computer-aided design (CAD) models. To address this, past approaches have stored data within point clouds or reference points within CAD models [15, 16]. By extending this methodology, the current work presents a dynamically linked approach and proposes a framework, namely the model-based feature information network (MFIN), to connect material definitions to locations within the component’s geometry. As a way to demonstrate the utility of this method, a use case of location-specific microstructure and residual stresses from the manufacturing process is used within a damage tolerance analysis for a compressor-bladed disk.

MFIN Framework Methodology

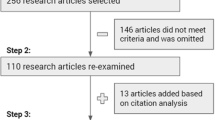

The broader objective of the Model-Based Feature Information Network (MFIN) is to create a comprehensive digital twin framework that facilitates storing, indexing, updating, translating, searching, and retrieving relevant information across a product’s lifecycle. The framework has been created by expanding an existing model-based definition capability for storing and exchanging quality inspection data, provided by an ANSI standard, namely the Quality Information Framework (QIF) 2.1 [17]. Kwon et al. [18] presented a data integration approach, for creating relationships between quality inspection data from QIF and design data from ISO Standard Exchange Protocol (STEP) format [19]. In the current work, the data model provided by the QIF framework has been directly utilized to create data linkages between feature definitions in a component, originating from its CAD model, to more broadly defined feature-specific metadata, including product lifecycle data originating from disparate sources during the design, manufacturing, and sustainment stages. The primary focus of this paper is to describe the MFIN framework and illustrate the implementation of the MFIN to enable storing and retrieval of material definitions and structural analysis information, with an emphasis on location-specific material data. With the motive of introducing the implemented framework, the current section describes: (a) necessary background on the existing QIF framework and its data structure, followed by (b) expansion of the framework to develop linking mechanism between features and externally stored material datasets and analysis information.

The premise for choosing QIF as the baseline for developing the MFIN is due to the advantages offered by the framework to define feature-specific information. QIF is a data model in the form of a neutral file format, namely extensible markup language (XML) (herein saved as a “.qif” file), which is obtained by converting the model definition of a component in a CAD model to an equivalent definition in XML. In the current demonstration, Siemens NX 11.0 CAD tool [20] is used, while the framework is general to integrate any commercial CAD tool. The translation of CAD to QIF is performed using a tool, namely MBDVidia [21], which converts the geometry, geometric features, geometric tolerances, and metadata associated to these features (including manufacturing information (PMI) [17]) to the XML definitions. Being a neutral file format, which is both human and machine readable, the QIF file can be used as an input for providing both the component geometry and associated metadata to several applications and systems. The data structure and mechanism used by QIF to leverage storing, indexing, and retrieving feature-specific information has been utilized to expand the framework to develop the MFIN—in order to include additional product lifecycle data. Lastly, the QIF data model is supported by the International Organization for Standardization (ISO 23,952:2020) as a recognized standard for authoring, storing, and exchanging information [22].

Within the QIF file, the structure and organization of the data elements and their associated datatypes are defined by its XML schema documents (XSD documents) [17], similar to other standard XML documents. The data within the QIF file are governed by two categories of schemas, namely QIF libraries and QIF applications. The QIF libraries schema contain structure of the data elements to define the product’s geometry (e.g., points, curves, surfaces, etc.), topology (e.g., vertices, edges, faces, etc.), as well as the features which are defined using the geometry (e.g., hole, pocket, thread, fillet, etc.). Whereas, the QIF applications schema is intended to describe the structure of the data elements for the product lifecycle metadata, which currently include schemas only for capturing inspection and measurement datasets. For extending the framework to include additional product lifecycle metadata and creating the MFIN, the existing QIF applications schema were appended with new schemas to define the structure of the data elements, which are collectively referred to as MFIN application schemas in this paper. All the XML data elements, which are generated following the QIF libraries schema and MFIN applications schema are grouped together within a top level element, namely, the QIFDocument [17], which creates a single QIF XML document (from here on referred to as MFIN XML).

In order to create logical relationships between the product lifecycle metadata and the associated features within the MFIN XML, a mechanism used by the existing QIF framework is to index data elements with unique identifiers. Firstly, in order to enable serialization and tracking of the datasets applicable to each individual component, the schema defines a unique identifier to its corresponding MFIN XML document. These identifiers are generated during the creation of MFIN XML as Universally Unique Identifiers (UUID) objects made of 128-bit numbers that follows the RFC 4122 standard [23]. An example of UUID is "25244977-74f1-4ba8-adea-2f7ef0367888". Secondly, every data element within each MFIN XML is indexed with a local identifier using a positive integer that take values incrementally as new data elements are added. These local identifiers can be used for cross referencing a data element within other data elements. Following this approach, each feature receives a local identifier used for referencing the specific feature within a product lifecycle metadata element, in order to establish a relationship between the metadata and the feature. Finally, the collection of local identifiers of all the metadata elements, with reference to a specific feature, form a network of lifecycle data mapped to all possible features, which can be used for tracking and extracting the feature-specific datasets.

While creating new MFIN application schemas to include new metadata, an important factor to be considered is whether the datasets are to be stored directly within the MFIN or stored externally in databases, local hard drives, or network drives. The associations between externally stored datasets and features within the MFIN XML have been created using a data linking mechanism. The choice of storing datasets externally and creating linkages to the MFIN as opposed to storing datasets directly within the MFIN has been made due to the following advantages. Firstly, it enables a dynamic capability wherein the externally stored data can be updated, and the revised data can be tracked and retrieved at any given point of time. Secondly the voluminous data across the lifecycle can lead to an oversized single file, while storing directly, which can be avoided by linking data and creating a smaller-sized MFIN file that is easier to share and exchange. Within the overall MFIN framework, provision for different definitions of a linkage has been accommodated, such as using a web hyperlink for cloud storage, file path of the files stored in local hard drives or network drives, or data identifiers specific to a database utilized for storing the datasets. For the current implementation, materials information is stored in material database software, and information pertinent to structural analysis is stored on a local hard drive. Correspondingly, two new schemas have been created, namely (1) MFINMaterialDefinition.xsd and (2) MFINAnalysis.xsd, to facilitate the necessary data linkages.

-

1.

The MFINMaterialDefinition.xsd schema defines the data structure based on the methodology for organization of datasets that prevails in the material database tools. A common structure within material database tools were the use of Graphical User Interface IDs (GUIDs) to reference individual material records and “Attribute IDs” to reference individual material datasets within each record. Hence, the MFINMaterialDefinition schema has been defined to create material definition linkages by grouping the material GUIDs and Attribute IDs with the corresponding local identifiers of features within the MFIN. This linking strategy enables using the flexibility of storing material datasets of different datatypes such as tabular, functional form, images or raw data files within the materials database. Furthermore, the data linkages are independent of the schema or the structure in which the datasets are organized and stored, since they are only dependent on the data identifiers. A common structure or schema is preferable to record and pass the material datasets without ambiguity, especially across supply chains. For instance, in the case of multiple material vendors, the material datasets and pedigree information can be stored following a common structure to ensure seamless tracking and reviewing of datasets. User-defined schemas can be created to structure and store datasets in the material databases, and these datasets can be seamlessly exchanged across the lifecycle via the data linkages enabled by the MFIN. Additionally, the access restrictions typically applicable to material datasets can be controlled by the access control filters in the materials database tool, while the MFIN only provides the paths to the data. The new schema has a provision for including metadata related to access control restrictions, user details, date, and time of linkage creation for tracking purposes.

-

2.

The MFINAnalysis schema defines a new MFINAnalysis element, which is created within the MFIN XML, for each performed analysis. In each of these data elements, the sub-elements primarily include the linkages for the analysis input file and the overall results file, which are stored either in the local hard drive (a link defined by the file path) or within the materials database (a link using a material GUID and the corresponding attribute ID). Being a data linkage, these files can be of any format either depending on the analysis software being used or customized result files generated by the user. Furthermore, within the schema, metadata elements capturing the type, date, and time of the analysis have been included.

In order to create new data linkages in MFIN XML, as well as retrieving information using the existing linkages, application program interfaces (APIs) or MFIN APIs have been created for enabling programming against the developed schemas. The current framework uses Python scripts to link to the developed APIs, thus the framework is software tool agnostic and can work with a multitude of commercial softwares. For every data element within the schemas, an API has been generated in the form of a Python class, using an automated process of generating source code binding [24]. Using the MFIN APIs, wrapper code(s) were developed for creating new linkages and retrieving datasets using existing linkages, which have been used for integrating the MFIN framework with materials database tool and structural analysis tool [25].

Integration of Materials Information and Structural Analysis within MFIN

The integration of materials databases within the MFIN framework was implemented and tested with two materials database tools, namely Granta MI [26] and MSC MaterialCenter [27]. Both of these databases have their own APIs to enable programmatic storing and retrieval of materials datasets. For the current demonstration, Granta’s materials database is used. A wrapper code has been developed using Granta’s APIs to generate a user interface, which facilitates browsing the database and selection of the material definitions, in order to create material definition linkages (i.e., the material record GUID and the Attribute IDs) to exchange via the MFIN APIs within the MFIN XML.

Material definitions apply to the bulk of the component, hence requiring the creation of linkages to volumetric features within the MFIN. The currently available volumetric feature definitions comprise typical geometries originating from the CAD tools, which are defined using its bounding surface entities (e.g., a cube is defined using its bounding faces made of edges and vertices). However, since the material definitions could potentially vary spatially across the volume of a component, a new mechanism to define these features has been adopted within the MFIN framework. The approach uses datum points to define these features, since points (1) are the most fundamental objects in 3D modeling and (2) enable defining individual locations within the volume for defining location-specific properties. The MFIN schema defines the PointClouds to generate the datum points, which do not necessarily get used for defining the geometry but can be used for the material definition associated with each point. In order to programmatically create the point features, a code has been created using the MFIN APIs, which accepts input point datasets (i.e., its spatial coordinates, X, Y, Z). These point datasets are supplied using a text file or a comma-space valued (CSV) file to the program. Hence, the process of creating material definition linkages to the spatial locations within the component is a semi-automated process, such that the material datasets for the selected spatial points are identified using the previously described wrapper code to browse and select the material definitions from the materials database. As opposed to generating the point clouds programmatically while creating data linkages, alternatively, the creation of datum points can also be accomplished with the original CAD model, which are translated while generating the MFIN XML.

The integration of the MFIN framework with finite-element (FE) analysis tools enables the exchange, storage, and retrieval of structural analysis results based on the component geometry and material definitions within the MFIN. The overall software architecture for this data integration is shown in Fig. 2. The integration of structural analysis within the MFIN framework was implemented and tested with two FE tools, namely MSC Patran/Nastran [28, 29] and Dassault’s ABAQUS [30]. The APIs specific to the FE tools have been used to complete the implementation and ensure the importing/exporting functionalities of data. For the current demonstration, Dassault’s ABAQUS is shown.

Software architecture for integration of the MFIN with a FE analysis tool, with programmatic steps to a import analysis model geometry and material data within the FE tool, b overlay point features on the analysis model mesh, c extract and incorporate material data linked to the point features within a user-defined material model, d exporting analysis input and results files from the FE tool, and e generate feature-specific results

The analysis model generation process has been developed as a semi-automated process, to retrieve the component geometry and material definitions from the MFIN XML (as shown in Fig. 2a). The process is initiated from the FE analysis tool, using a user input form that requires two inputs, namely (a) the location of the MFIN XML file and (b) the MFIN UUID. First, the model geometry is retrieved from the MFIN for importing within the FE tool. Due to the current limitations with the FE tool to directly import the model geometry using a QIF file format, an alternative neutral file format, namely ISO STEP AP 214 [31], has been used. The STEP file is generated by translating the native CAD file, which has been done using the in-built STEP translators in Siemens NX 11.0 CAD tool and linked to the MFIN XML via the file’s location. Next, the materials definition linkages within the MFIN are utilized to dynamically retrieve the materials data from the database in a CSV file format. For each materials data file that gets generated, the corresponding feature information (including point features) is retrieved from the MFIN for use within the structural analysis tool. Both the features and the material data file paths are grouped and stored in a feature correlation file, which informs the relationship between the spatial position and the material datasets within the imported STEP geometry.

After importing the model geometry and material data files within the FE tool, the analysis model is manually meshed, loads and boundary conditions are applied, following which an input model definition file (INP file) is generated. For incorporating location-specific material definitions in the analysis, firstly, the point cloud features are programmatically extracted from the feature correlation file and overlaid on the analysis model mesh (shown in the step in Fig. 2b). The imported analysis geometry, from STEP file, might have a shifted reference coordinate system from the coordinate system in the MFIN, which would require corresponding corrections to the positions of the point features prior to overlaying. Afterwards, the mesh elements are mapped to the nearest point feature from its centroid position, thereby picking and applying the material data linked to the corresponding point feature in semi-automated fashion. Based on the analysis requirements, a customized script is to be used (shown in the step in Fig. 2c), to utilize the location-specific material data within the material model. Since the retrieval and utilization of materials information within the analysis is programmatically executed via the MFIN point clouds with minimal human involvement, the MFIN enhances the analysis process by reducing chances for human in the loop errors, as well as significantly decreasing the time for generation of an analysis model.

At the end of an analysis, the input file (INP file) and the overall results file (ODB file) are exported from the FE tool (as shown in the step in Fig. 2d) and archived by creating new linkages within the MFIN, following the MFINAnalysis schema. Additionally, if feature-specific result files and plots are extracted using the overall results file (shown in Fig. 2e), linkages are generated to the corresponding features within MFIN XML. Once the linkages for analysis information are created within the MFIN, these datasets can be retrieved and used for lifecycle analysis, as illustrated with a use case in the next section.

Use Case: Analysis of a Ti-6Al-4V Compressor Blisk

A linear friction welded (LFW) [32] bladed-disk component, also referred to as blisk, is demonstrated as a use case for the MFIN framework to include spatially varying material definitions for incorporating within damage tolerant analysis. The intent is to emphasize that the presented methodology for including and exchanging location-specific material information can be utilized to provide material state information across a component to inform life predictions. For the present use case, a Ti-6Al-4V blisk is used based on its geometric complexity and location-specific material state near the weld. The LFW process results in steep thermal gradients across the weld region, leading to the generation of spatially varying microstructures and residual stresses across the weld region [32,33,34,35]. While the present work is a demonstration of the MFIN applicability, the material’s data are obtained from past studies published in the literature [35,36,37]. Using the MFIN framework, the microstructural information and residual stresses are spatially linked within the component’s geometric model for subsequent damage tolerance analysis. One of the fundamental tenets of the digital twin is that by including this updated material state definitions, the resulting uncertainty in the subsequent lifing analysis can be reduced. Accordingly, a comparison has been performed to demonstrate the variations generated in the resulting fatigue life with and without using location-specific material definitions. It is important to note that there are two viewpoints for defining the digital twin. One viewpoint suggests the requirement of a physical asset as a necessary ingredient prior to creating a digital twin, whereas the other viewpoint suggests that a digital twin or a digital prototype can be created before the physical production of a component or a system [3]. Other than this primary difference, both viewpoints share potential applications and benefits of the digital twin, which includes the usage of information at various stages throughout the life cycle and the fusion of modeling and simulation with physical testing and measurements. In this work, we did not necessarily want to exclude either definition, as our primary intent is to describe and illustrate the MFIN framework. For the present use case, we have illustrated the digital twin from an as-designed stage. Hence, the microstructural and residual stress state information have been included in the nominal part definition of the component. Additionally, the MFIN framework can be used to create digital twins after the production of the component, by following a similar approach including state information from the post-production stages.

First, a blisk component with 48 blades was created as a CAD model, with approximate geometric dimensions similar to [38]. Since the blisk sections are axisymmetric about the z axis, 1/48th of the blisk was modeled, as shown in Fig. 3a–c. For the axisymmetric portion of the component, three features were defined: the disk, weld region, and blade as shown in Fig. 3c. The disk section was modeled as a 2D sketch in x–z plane as shown in Fig. 3d,which was revolved by 7.5° about the z direction. The weld region and the blade region were modeled as shown in Fig. 3e, f, respectively. Within the weld region, a datum reference frame X–Y-Z has been defined, which is used for defining location-specific material definitions. The origin of this new reference frame is situated at the center of the weld region, with the X axis orthogonal to the weld interface (Fig. 3e). The CAD file was converted into derivative QIF (i.e., the MFIN XML) and STEP file formats.

A customized material record of Ti-6Al-4V was created within the Granta MI database and comprised of physical, elastic, and mechanical properties of the material, as well as spatially varying information across the component, which include residual stress field and the average grain size of the material relative to the LFW (based on characterization data reported in [35]). After optimal parameters were determined for linear friction welding of Ti-6Al-4V to Ti-6Al-4V plates [35], the average grain sizes \((d_{{{\text{avg}}}} ) \) for the globular \(\alpha\)-phase was characterized at 7 locations across the weld region [35], as shown in Fig. 4a, c. The average grain sizes, \(d_{{{\text{avg}}}}\), of the microstructure were \(1.65 {\mu m}\) at the weld interface and \(9.62 {\mu m}, 8.90 {\mu m}, 11.06 {\mu m}\), respectively, moving away from both sides of the weld center in a symmetric fashion [35], and these values were archived in the database. For the disk and the blade regions, a uniform \(d_{{{\text{avg}}}}\) value of \(11.06 {\mu m}\) has been defined. Finally, the residual strain distributions characterized in [35] were used to create the residual stress components (\(\sigma_{{{\text{xx}}}} \left(\text{ X} \right)\), \(\sigma_{{{\text{yy}}}} \left( \text{X} \right)\), \(\sigma_{{{\text{zz}}}} \left( \text{X} \right)\), in which the details are described in “Appendix” 1), as a function of the distance from the weld interface (X axis), as shown in (Fig. 4b).

Spatially varying material definitions stored within the materials database and linked to the weld region in the MFIN using point features: a weld region with 7 locations linked to the average grain size information, b residual stress components (\(\sigma_{{{\text{xx}}}}\), \(\sigma_{{{\text{yy}}}}\), \(\sigma_{{{\text{zz}}}}\)) as a function of locations across the weld region in X direction, (values for the 7 locations shown here with markers), and c corresponding microstructure images (shown here for 5 of these locations)

By including the process induced residual stresses and microstructural information, more precise damage tolerant assessment of components can be determined [39, 40]. First, the in-service stresses in the blisk were obtained using a structural analysis via the FE method, in which the average grain size information of the Ti-6Al-4V material is used to inform the constitutive response of the material. A simple elastoplastic material model has been chosen based on the Johnson–Cook [41] type hardening rule as shown in Eq. (1), wherein the flow stress (\(\overline{\sigma }\)) is a function of the equivalent plastic strain (\(\overline{\varepsilon }\)) and temperature (\(T\)). The parameters \(A\), \(B\), \(n\), \(m\), \(T_{{{\text{room}}}}\), and \({\text{T}}_{{{\text{melt}}}}\) correspond to the yield stress, strain hardening coefficient, strain hardening exponent, temperature exponent, room temperature, and melting temperature, respectively, whose values used for Ti-6Al-4V [36, 37] are shown in Table 1.

The grain size dependency has been incorporated in Eq. (1), wherein the yield stress (\(A\)) follows a Hall–Petch [42, 43] relationship as shown in Eq. (2). The friction stress (\(A_{{{\text{HP}}}}\)) and the Hall–Petch strengthening coefficient (\(K_{{{\text{HP}}}}\)) values for Ti-6Al-4V [36] are shown in Table 1.

Two FE models have been created: (Model 1) considering a constant average grain size for the entire blisk of 11.06 \({\mu m}\) and (Model 2) incorporating location-specific grain size information across the weld region. The variations in the average grain size and the corresponding yield stress (A) (computed using Eq. (2) across the weld region, for the two models, are shown in Fig. 5a. Herein, the A values are computed dynamically by extracting the \({\text{d}}_{{{\text{avg}}}}\) values from the database using the MFIN linkages while creating the analysis model.

Material definitions, applied loading, and boundary conditions for the finite-element analysis model: a for Models 1 and 2, the average grain size (\(d_{{{\text{avg}}}}\)) and the corresponding Johnson–Cook model’s yield stress (A) parameter defined at different locations across the weld region and b axisymmetric model of blisk with centrifugal load about the z axis and fixed displacement boundary conditions defined on the disk region’s inner surface labeled as S

The compressor blisk was simulated from its rest condition to an overspeed condition above its typical maximum rotational speed [44] during service for the present demonstration. To acquire the maximum loads, a static analysis has been performed on an axisymmetric sector of the blisk (1/48th of the blisk), as shown in Fig. 5b. A centrifugal load has been applied on the blisk about the z axis, with a spin speed of \(\omega = 15,500 {\text{rpm}}\) at room temperature (Fig. 5b). The shrink fit loads, due to the interference fit between the shaft and the blisk, have been ignored in the current analysis. For the boundary conditions, a displacement constraint has been applied on the inner surface S of the bore, in all the three directions (\(u_{x} = u_{y} = u_{z} = 0\)) (Fig. 5b). Firstly, due to the complexity in the blisk geometry, especially in the weld region (which is also of primary interest in this study), a mesh constituting quadratic tetrahedral elements has been used for this region (the use of quadratic elements also provides higher resolution due to additional integration points as compared to linear elements). Further, to ensure a conformal mesh near the interfaces between disk and weld as well as weld and the blade region (i.e., to avoid distorted tetrahedral elements in the disk and blade region near their interfaces with weld region), linear hexahedral elements were defined throughout for the disk and the blade regions. Hence, a combination of hexahedral and tetrahedral elements has been used for the entire blisk. Based on a sensitivity analysis performed by running a series of simulations by decreasing the mesh element size until the maximum principal stresses in the locations within the weld region did not change with further element size reduction (i.e., a converged mesh), linear hexahedral mesh elements of average size 0.5 mm were determined and used in the disk and blade regions, while quadratic tetrahedral mesh elements of average size 0.7 mm were determined and used for the weld region. Additionally, due to the different mesh types used, tie constraints have been applied between the interfacial regions of the disk and weld, as well as the blade and weld. Lastly, the residual stresses were not included in the FE model; for simplicity, this information is reserved for the damage tolerant analysis that follows.

At the end of the FE analysis, the analysis input and output files for Models 1 and 2 have been stored in a local hard drive and archived as file linkages within the MFIN. The stress fields were extracted for all the three regions of the blisk component, and the maximum principal stresses \((\sigma_{I} )\) were computed for each element for both the models (shown in Fig. 6a). The \(\sigma_{I}\) values were stored within the Granta database along with the associated centroidal positions of the elements. In order to visualize the variation in the maximum principal stress distribution across the weld region, between the two models, a line scan along X direction (shown in Fig. 6a and same as shown in Fig. 4a) was performed to probe values, which is shown in Fig. 6b. The values were probed at 0.5 mm interval, wherein the maximum principal stress at a particular location was picked from the nearest elemental centroid position. The increasing trend observed in maximum principal stresses along X for both Models 1 and 2 (Fig. 6b) was as expected since (1) the applied centrifugal load is a function of radius, and it increases as we move radially outward (i.e., along + X direction) and (2) the blisk section area is thinner as we move from disk to weld to blade region. Between Models 1 and 2, since the average grain size variations and correspondingly the variations in yield stress are maximum at the center of the weld region (Fig. 6a), one would expect to observe significant differences in the maximum principal stresses at this location (i.e., at X = 0). However, in the present loading scenario, the locations near the weld center does not experience yielding and since the grain size dependency in Model 2 is active only after yielding, the differences observed in resulting stresses between the two models are not necessarily highest at the weld center. Furthermore, yielding is experienced in the locations within the weld region closer to the blade region. Although, at these locations, the variations in \({\upsigma }_{{\text{I}}}\) (Fig. 6b) between Models 1 and 2 are small in magnitude, as they possess minor variations in their yield stress as shown in Fig. 6a. However, due to equilibrium after the FE simulation, the differences in the maximum principal stresses between Models 1 and 2 are observed at other locations near the weld center (between X = 0 and X = 3).

Maximum principal stress (\(\sigma_{I}\)) distribution generated in the blisk component: a contour plots for the entire blisk component using Models 1 and 2 (i.e., without and with using average grain-size information, respectively). The stress variation in the two models is very subtle and to articulate this minor difference, b shows the variation in \(\sigma_{I}\) across the weld region (along the X axis) for Models 1 and 2. The values of \(\sigma_{I}\) at the two locations of interest for damage tolerance analysis have been highlighted wherein the direction of \(\sigma_{I}\) is also oriented along the X axis

A conventional damage-tolerance analysis [45] was followed, which is typically performed at locations with high stress within the component that are deemed as critical. At the selected locations, the presence of a crack is assumed, with an initial length \(a_{i}\) representing the largest flaw that can be missed during the inspection process. The crack is oriented perpendicular to the applied stress direction, such that the crack grows under the applied stress, following mode I crack growth. More details related to the damage tolerant methodology are presented in “Appendix” 2. Typically, the number of life cycles for the crack to grow to a final crack length \(a_{f}\), corresponding to the crack length at which the stress intensity \((K_{I} )\) factor reaches the critical value related to the fracture toughness of the material \((K_{{{\text{IC}}}} )\), is computed as the number cycles to failure. Conventionally, engine components are pulled out of service and inspected for a crack and if its length reaches 0.76 mm (1/33 of an inch), the component is retired and if otherwise, the components are returned back to service [46]. Hence, in the current analysis, the number of cycles for the initial crack to grow to this standard length has been estimated, which can be used to decide and plan the inspection interval for the component under consideration.

Two locations have been selected from the FE analysis (shown in Fig. 6a, b) for placement of a crack. The first location was chosen wherein the difference in the maximum principal stresses between the two models (Model 1 and 2) was maximum. Hence, within the weld region, a location which is at a distance of 1 mm from the weld center along the X direction was selected, with values of \(\sigma_{I}\) being 759 MPa and 700 MPa for Model 1 and Model 2 (oriented along the X direction) (Fig. 6b), respectively. The second location for the analysis was selected at a location wherein the tensile residual stress component is maximum along the maximum principal stress direction. For this purpose, a location at a distance of 2.5 mm from the weld center along the X direction (shown in Fig. 6b with \(\sigma_{I}\) values of 927 MPa and 960 MPa for Model 1 and Model 2, respectively) was selected, wherein the direction of maximum principal stress was along + X and the corresponding component of residual stress \((\sigma_{{{\text{xx}}}} )\) (shown in Fig. 4b) was maximum. An embedded elliptical crack is assumed to be present at the selected locations, with initial length \(a_{i} = 0.10 {\text{mm}}\) (semi-minor axis length) and constant semi-major axis length of \(c = 0.76{\text{ mm}}\). In both these locations, the direction of \(\sigma_{I}\) is to be oriented orthogonal to crack faces (representing an opening mode). Since the direction of the maximum principal stress is along the + X direction at both the locations, the crack plane is oriented parallel to the weld center plane (as shown in Fig. 7a, b), at a distance of 1 mm and 2.5 mm, respectively, along the X axis and propagating along the Z direction. Finally, for the analysis at both of these locations of interest, a constant final crack length of \(a_{f} = 0.76\) mm (i.e., 1/33 of an inch) has been used.

Variation in the crack length (a) versus number of cycles (N) between the two cases, without (shown in blue) and with (shown in red) using spatially varying average grain size and residual stress information for locations at a distance of a 1 mm and b 2.5 mm from the weld center along the + X direction

For estimating the number of cycles to final crack length (\(N_{f}\)), a well-established damage tolerant analysis is used, based on linear elastic fracture mechanics, which superimposes the residual stress state into an effective stress intensity factor based on the Walker model [47], as shown in "Appendix" 2. The \(\sigma_{{{\text{xx}}}}\) component of the residual stress has been used as \(\sigma_{{{\text{RS}}}}\) for both locations of interest (since \(\sigma_{I}\) is along X) to calculate the effective stress intensity value [Eq. (16)]. The values of \(\sigma_{{{\text{RS}}}}\) has been computed by first retrieving the functional form \(\sigma_{{{\text{xx}}}} \left( X \right)\) from the materials database and evaluating for both the locations of interest (i.e., X = 1 and X = 2.5), with values \(\sigma_{{{\text{RS}}}} = 16.68 {\text{MPa}}\) and \(\sigma_{{{\text{RS}}}} = 35.59 {\text{MPa}}\), respectively. Finally, the crack length (a) versus the number of cycles (\(N\)) has been plotted for each of the locations as shown in Fig. 7a, b. In each of these plots, the fatigue life curves have been generated for both the cases—with and without using location-specific material definitions.

In Fig. 7, the variation in the estimated fatigue life, (\(N_{f}\)), while including location-specific material information (i.e., average grain size and residual stresses) within the damage-tolerance analysis has been shown. For the two locations within the weld region considered in this analysis, we have demonstrated cases of overly conservative prediction (shown in Fig. 7a) and potentially inaccurate prediction (shown in Fig. 7b) of fatigue life while not including the location-specific material information in the analysis. In the present illustration, the uncertainty in estimating the number of cycles and corresponding inspection interval for a component in service could be potentially reduced by including location-specific material information. The access to location-specific material information and its inclusion within the lifing analysis has been achieved by utilizing the data linkages enabled by the MFIN framework. The location-specific definitions in the present use case were an outcome of the manufacturing process of the compressor blisk component, i.e., representing the underlying material state within the component at the end of its manufacturing. The inclusion of process-induced material state information, and its usage in performance analysis, demonstrates the usage of process–structure–property–performance relationship. Model 1 is the historical approach, which treats each portion of the blisk component as a monolithic structure in its approach to analysis. In Model 2, specific material location information is captured, via the MFIN framework, thus enabling a higher degree of precision in the design, production, inspection, and sustainment of the blisk. While the demonstration case is intended to provide a simple proof of concept, the MFIN framework enables the use of more sophisticated physics-based models by providing connectivity and therefore accessibility to pertinent process history induced materials information. By using the location-specific linking strategy presented in this work, the necessary material state information can be linked to specific component features, which reduces the uncertainty in our predictive models by harnessing the history and state of the material.

The use of data linking approach meets the requirement for several critical elements, necessary for creating a digital twin. Specifically, the approach creates dynamic connectivity to material datasets, enabling tracking and providing updated data regarding the material state at any given point in the lifecycle of the component. The availability of the current material state information can be utilized to make future predictions of the component’s performance. In this work, the material data linkages have been used to provide material information to a commercial FE analysis code, for performing an analysis. Within the digital twin framework, the access to other commercial engineering software/code(s) which are useful for design and analysis of a component can be achieved by using necessary schemas and wrapper code(s). Herein, the material data linkages can be utilized to inform the material information pertinent to a component using an approach similar to the presented work.

Further, the methodology of linking, tracking, and retrieving material data can be expanded to other datasets produced during different stages of the product lifecycle. Since the linkages are created between a feature and the information applicable at the feature, a network of lifecycle data applicable to the feature can be created by the MFIN. This starts to form a complete digital thread [48] of lifecycle data, which is necessary for supplying relevant information and creating the digital twin of the component. Hence, the MFIN framework would potentially complement data management systems, such as product lifecycle management systems [49], which are used to store product lifecycle data, by serving as a portal to access, exchange, and utilize feature-specific lifecycle metadata. For retrieval of datasets specific to a feature, a user-interface can be developed (as shown in a schematic in Fig. 8a), wherein the desired datasets can be retrieved using its feature’s unique identifier. For instance, during the maintenance and repair of the component, an image of the component with a crack developed during its service, in a specific location (shown in an illustration in Fig. 8b, c) can be linked and accessed using the MFIN. During the design of the newer version of the component, the prior knowledge of the crack location from the digital twins of predecessor components can be used to identify critical feature locations and explore newer opportunities to design and develop manufacturing processes for achieving desirable properties at these critical locations in the component.

An illustration of using a a graphical user interface which can be created for the MFIN, to retrieve specific lifecycle data (for example, maintenance data) applicable to either a specific feature and/or its component, by specifying its feature ID and UUID, respectively, leading to either b the retrieval of an image of the entire component (part level search) or c retrieval of an image of a feature (feature-level search) with a crack detected during its maintenance and repair inspections

Conclusion

This paper presents a framework, namely a Model-based Feature Information Network (MFIN) for storing, updating, and retrieving material information applicable to a component throughout its product lifecycle, in order to realize the concept of digital twin. The framework involves a data model in an XML file format (MFIN XML), defined by its schemas (MFIN application schemas), to create data linkages between the component’s geometry and feature definitions originating from its CAD model and material definitions stored in a materials database software. For defining location-specific material definitions within a component, the framework has adopted the use of point clouds to define distinct locations within its design model, wherein linkages to the applicable material datasets have been created. In order to create the linkages of material definitions or utilizing the existing linkages to extract material datasets applicable to a feature, programmatic methods, or wrapper code(s) have been created by using application-program interface (API) functionalities of both the MFIN and material database software. These wrapper code(s) have been utilized to provide material definitions for structural analysis, thereby creating a data integration between the MFIN and FE analysis tool. Additionally, the MFIN application schemas have been created to capture the analysis model definition and analysis result datasets, for future usage and to make decisions during the product lifecycle. The key benefits from the presented work are as follows:

-

The capability to include and exchange location-specific material definitions has been illustrated with a use case, wherein a linear friction welded Ti-6Al-4V compressor blisk component has been used. Within the regions in the blisk component, manufacturing process induced microstructure information (i.e., average grain size) and residual stress fields have been included and utilized for damage tolerance analysis. The variation in the estimated fatigue life, with and without including location-specific material information, has been demonstrated. Hence, by including and utilizing location-specific material state definitions, uncertainties in fatigue life estimates can be potentially reduced. Furthermore, the demonstrated capability to include location-specific information can also be extended for providing access to pertinent processing induced material state information applicable at specific locations within the component and using them within other sophisticated physics-based predictive models, thereby potentially minimizing the uncertainties in these predictive models.

-

The developed linking methodology creates dynamic linkages to the material data, thereby allowing continual updating of the material information applicable to the component and its features. The linkages provide access to the current material state information at a given point in its lifecycle, which can be retrieved and utilized to forecast the future performance of the component.

Furthermore, the presented framework and methodology are expandable to meet other needs for realizing a digital twin as follows:

-

The data integration between the MFIN and a commercial FE analysis code has been presented in this work, wherein the material information applicable to a component is provided using linkages in the MFIN, for the analysis. Similarly, the framework can be expanded to access and utilize other commercial software code(s), which could be useful for design and analysis of a component, by including necessary schemas and wrapper code(s) to create the data integration.

-

The MFIN framework presented in this paper has been limited with the focus on capturing material data applicable to the component. However, the same approach is expandable to form linkages to store and exchange other product lifecycle data which are applicable to the component and its features. While doing so, the MFIN starts to form a network of lifecycle data mapped to the features in the component, thereby creating a digital thread for data exchange. Thereby, for each serialized component, there will be a MFIN file, containing the linkages to the lifecycle data from design to retirement. These data linkages, from a fleet of components, can be used to provide datasets for informing decision making during the design, manufacturing, and sustainment stages of a newer version of the component.

References

Tuegel EJ, Ingraffea AR, Eason TG, Spottswood SM (2011) Reengineering aircraft structural life prediction using a digital twin. Int J of Aerosp Eng. https://doi.org/10.1155/2011/154798

Glaessgen E, Stargel D (2012, April). The digital twin paradigm for future NASA and US Air Force vehicles. In: 53rd AIAA/ASME/ASCE/AHS/ASC structures, structural dynamics and materials conference and 20th AIAA/ASME/AHS adaptive structures conference 14th AIAA. Honolulu, Hawaii (p. 1818). https://doi.org/10.2514/6.2012-1818

Grieves M, Vickers J (2017). Digital twin: Mitigating unpredictable, undesirable emergent behavior in complex systems. In: Transdisciplinary perspectives on complex systems. Springer, Cham, pp. 85–113. https://doi.org/10.1007/978-3-319-38756-7

Tuegel EJ, Kobryn P, Zweber JV, Kolonay RM (2017, January). Digital Thread and Twin for Systems Engineering: Design to Retirement. In: 55th AIAA Aerospace Sciences Meeting. Grapevine, Texas (p. 0876). https://doi.org/10.2514/6.2017-0876

Christodoulou L, Larsen JM (2004) Using materials prognosis to maximize the utilization potential of complex mechanical systems. JOM 56:15–19. https://doi.org/10.1007/s11837-004-0027-4

National Research Council (2008) Integrated computational materials engineering: a transformational discipline for improved competitiveness and national security. National Academies Press, Washington

Furrer DU, Dimiduk DM, Cotton JD, Ward CH (2017) Making the case for a model-based definition of engineering materials. Integr Mater Manuf Innov 6:249–263. https://doi.org/10.1007/s40192-017-0102-7

Sangid MD, Matlik JF, Keskin A, Thacker BH, Bichon, BJ, Ball DL, Engelstead SP, Ward C, Venkatesh V, Kim HA, Saraf V, Gorham R (2017, January). Integrating ICME practices into design systems and structural analysis. In: 55th AIAA Aerospace Sciences Meeting. Grapevine, Texas. (p. 0874). https://doi.org/10.2514/6.2017-0874

Ramalhete PS, Senos AMR, Aguiar C (2010) Digital tools for material selection in product design. Mater Des 31:2275–2287. https://doi.org/10.1016/j.matdes.2009.12.013

Arnold SM, Holland FA, Bednarcyk BA, Pineda EJ (2015) Combining material and model pedigree is foundational to making ICME a reality. Integr Mater Manuf Innov 4:37–62. https://doi.org/10.1186/s40192-015-0031-2

Bolcavage A, Brown PD, Cedoz R, Cooper N, Deaton C, Hartman DR, Keskin A, Ma K, Matlik JF, Modgil G, Stillinger JD (2014) Integrated computational materials engineering from a gas turbine engine perspective. Integr Mater Manuf Innov 3:13. https://doi.org/10.1186/2193-9772-3-13

Briggs C, Brown GB, Siebenaler D, Faoro J, Rowe S (2010, April). Model-Based Definition. In: 51st AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference 18th AIAA/ASME/AHS Adaptive Structures Conference 12th. Orlando, Florida. (p. 3138). https://doi.org/10.2514/6.2010-3138

Ruemler SP, Zimmerman KE, Hartman NW, Hedberg T, Barnard Feeny A (2017) Promoting model-based definition to establish a complete product definition. J Manuf Sci Eng Trans ASME 139:1–7. https://doi.org/10.1115/1.4034625

Hedberg T, Lubell J, Fischer L, Maggiano L, Feeney AB (2016) Testing the digital thread in support of model-based manufacturing and inspection. J Comput Inf Sci Eng 16:1–10. https://doi.org/10.1115/1.4032697

Miller AMD, Alvarez R, Hartman N (2018) Towards an extended model-based definition for the digital twin. Comput Aided Des Appl 15:880–891. https://doi.org/10.1080/16864360.2018.1462569

Gopalakrishnan S, Hartman NW, Sangid MD (2020) Integrating materials model-based definitions into design, manufacturing, and sustainment: a digital twin demonstration of incorporating residual stresses in the lifecycle analysis of a turbine disk. J Comput Inf Sci Eng 21:1–25. https://doi.org/10.1115/1.4048426

Morse E, Heysiattalab S, Barnard-Feeney A, Hedberg T (2016) Interoperability: Linking Design and Tolerancing with Metrology. Proc CIRP 43:13–16. https://doi.org/10.1016/j.procir.2016.04.106

Kwon S, Monnier LV, Barbau R, Bernstein WZ (2020) Enriching standards-based digital thread by fusing as-designed and as-inspected data using knowledge graphs. Adv Eng Inform 46:101102. https://doi.org/10.1016/j.aei.2020.101102

Pratt MJ (2001) Introduction to ISO 10303—the STEP standard for product data exchange. J Comput Inf Sci Eng 1:102–103. https://doi.org/10.1115/1.1354995

Siemens (2017) NX 11.0 CAD Software. Munich, Germany. https://docs.plm.automation.siemens.com/tdoc/nx/11.0.1/nx_help#uid:xid1128415:index_exnx. Accessed 16 November 2020

Capvidia (2016) MBDVidia 4.0 Software. Houston, Texas. https://www.capvidia.com/products/mbdvidia. Accessed 16 November 2020

International Organization for Standardization (2016) Automation systems and integration—Quality information framework (QIF)—An integrated model for manufacturing quality information (ISO 23952:2020). Retrieved from https://www.iso.org/standard/77461.html

Leach P, Mealling M, Salz R (2005) RFC 4122: A universally unique identifier (UUID) URN namespace. (https://www.ietf.org/rfc/rfc4122.txt)

Bigot PA (2014) PyXB: Python XML Schema Bindings. https://pyxb.sourceforge.net/. Accessed 16 November 2020

Astheimer RL, Del Re K, Gopalakrishnan S, Hartman NW, Sangid MD (2019, June). Extending model based definition to capture product behavior and contextual information using a model based feature information network. Proceedings of CAD'19. Singapore. (pp 253–257). https://doi.org/10.14733/cadconfP.2019.253-257

Granta Design Ltd (2016) Granta MI. Cambridge, UK. https://www.ansys.com/products/materials/granta-mi/. Accessed 16 November 2020

MSC Software (2016) Material center. Newport Beach, CA, USA. https://www.mscsoftware.com/product/materialcenter. Accessed 16 November 2020

MSC Software (2016) NASTRAN, Version 2016.0. Newport Beach, CA, USA. https://www.mscsoftware.com/product/msc-nastran. Accessed 16 November 2020

MSC Software (2016) PATRAN, Version 2016.0. Newport Beach, CA, USA. https://www.mscsoftware.com/product/patran. Accessed 16 November 2020

Dassault Systèmes Simulia Corporation (2018) Abaqus/CAE Simulia. Johnston, RI, USA. https://www.3ds.com/products-services/simulia/services-support/support/documentation/. Accessed 16 November 2020

International Organization for Standardization (2010) Industrial automation systems and integration—Product data representation and exchange—Part 214: Application protocol: Core data for automotive mechanical design processes (ISO 10303-214). Retrieved from https://www.iso.org/standard/43669.html

Li W, Vairis A, Preuss M, Ma T (2016) Linear and rotary friction welding review. Int Mater Rev 61:71–100. https://doi.org/10.1080/09506608.2015.1109214

Turner R, Gebelin JC, Ward RM, Reed RC (2011) Linear friction welding of Ti-6Al-4V: Modelling and validation. Acta Mater 59:3792–3803. https://doi.org/10.1016/j.actamat.2011.02.028

Grujicic M, Arakere G, Pandurangan B, Yen CF, Cheeseman BA (2012) Process modeling of Ti-6Al-4V linear friction welding (LFW). J Mater Eng Perform 21:2011–2023. https://doi.org/10.1007/s11665-011-0097-8

Bandyopadhyay R, Rotella J, Naragani D, Park JS, Eff M, Sangid MD (2019) Residual Strain Analysis in Linear Friction Welds of Similar and Dissimilar Titanium Alloys Using Energy Dispersive X-ray Diffraction. Metall Mater Trans A 50:704–718. https://doi.org/10.1007/s11661-018-5034-0

Pan Z, Shih DS, Tabei A, Garmestani H, Liang SY (2017) Modeling of Ti-6Al-4V machining force considering material microstructure evolution. Int J Adv Manuf Technol 91:2673–2680. https://doi.org/10.1007/s00170-016-9964-7

Li Y, Wang H, Gong D (2012) The interrelation of the parameters in the Paris equation of fatigue crack growth. Eng Fract Mech 96:500–509. https://doi.org/10.1016/j.engfracmech.2012.08.016

Spasic I (2012) https://grabcad.com/library/blisk. Accessed 16 November 2020

John R, Larsen JM, Buchanan DJ, Ashbaugh NE (2001, October) Incorporating residual stresses in life prediction of turbine engine disks. In: Proceedings from NATO RTO (AVT) Symposium on Monitoring and Management of Gas Turbine Fleets for Extended Life and Reduced Costs. Manchester, UK. https://apps.dtic.mil/dtic/tr/fulltext/u2/p014133.pdf

Enright M, Chan K (2004) Extension of a microstructure-based fatigue crack growth model for predicting fatigue life variability. In: Probabilistic Aspects of Life Prediction. STP1450-EB, W Johnson, B Hillberry, (Eds.). (pp. 87–103). https://doi.org/10.1520/STP11281S

Johnson GR, Cook WH (1985) Fracture characteristics of three metals subjected to various strains, strain rates, temperatures and pressures. Eng Fract Mech 21:31–48. https://doi.org/10.1016/0013-7944(85)90052-9

Hall EO (1951) The deformation and ageing of mild steel: II Characteristics of the Lüders deformation. Proc Phys Soc London, Sect B 64:742–747. https://doi.org/10.1088/0370-1301/64/9/302

Petch NJ (1953) The cleavage strength of polycrystals. J Iron Steel Inst 173(5):25–28

Cláudio RA, Branco CM, Gomes EC, Byrne J, Harrison GF, Winstone MR (2004) Fatigue life prediction and failure analysis of a gas turbine disc using the finite-element method. Fatigue Fract Eng Mater Struct 27(9):849–860

Cook CH, Spaeth CE, Hunter DT, Hill RJ (1982, April). Damage tolerant design of turbine engine disks. In: ASME 1982 International Gas Turbine Conference and Exhibit. London, England. American Society of Mechanical Engineers Digital Collection. https://doi.org/10.1115/82-GT-311

Annis Jr CG, VanWanderham MC, Harris Jr JA, Sims DL (1980, March). Gas Turbine Engine Disk Retirement-for-Cause: An Application of Fracture Mechanics and NDE. In: Turbo Expo: Power for Land, Sea, and Air. American Society of Mechanical Engineers. New Orleans, Louisiana. (Vol. 79665, p. V01BT02A033). https://doi.org/10.1115/80-GT-127

Walker K (1970). The Effect of Stress Ratio During Crack Propagation and Fatigue for 2024-T3 and 7075-T6 Aluminum. In: Effects of Environment and Complex Load History on Fatigue Life, ASTM International, M Rosenfeld (Ed.), West Conshohocken, PA, (pp. 1–14). https://doi.org/10.1520/STP32032S

Kraft EM (2016, January). The air force digital thread/digital twin-life cycle integration and use of computational and experimental knowledge. In: 54th AIAA aerospace sciences meeting. San Diego, California. (p. 0897). https://doi.org/10.2514/6.2016-0897

Lee SG, Ma YS, Thimm GL, Verstraeten J (2008) Product lifecycle management in aviation maintenance, repair and overhaul. Comput Ind 59:296–303. https://doi.org/10.1016/j.compind.2007.06.022

Zhang JM, Zhang Y, Xu KW, Ji V (2007) Anisotropic elasticity in hexagonal crystals. Thin Solid Films 515:7020–7024. https://doi.org/10.1016/j.tsf.2007.01.045

Kasemer M, Quey R, Dawson P (2017) The influence of mechanical constraints introduced by β annealed microstructures on the yield strength and ductility of Ti-6Al-4V. J Mech Phys Solids 103:179–198. https://doi.org/10.1016/j.jmps.2017.03.013

Kartal ME (2013). Analytical solutions for determining residual stresses in two-dimensional domains using the contour method. Proc Math Phys Eng Sci 469(2159):20130367. https://doi.org/10.1098/rspa.2013.0367

Bouchard PJ, Budden PJ, Withers PJ (2012) Fourier basis for the engineering assessment of cracks in residual stress fields. Eng Fract Mech 91:37–50. https://doi.org/10.1016/j.engfracmech.2012.05.004

Pan J, Lin SH (2005) Fracture mechanics and fatigue crack propagation. Fatigue testing and analysis, vol 1. Elsevier, Amsterdam, pp 237–284

Acknowledgements

The authors would like to extend their thanks to the funding provided by MxD 15-11-08 (Capturing Product Behavioral and Contextual Characteristics through a Model‐based Feature Information Network), as well as the entire MxD 15-11-08 team. In particular, the authors would like to thank Rosemary Astheimer (Purdue University) for project management and support, Kevin Del Re (Purdue University) for GUI implementation, Daniel Campbell (Capvidia) for supporting the QIF-based schema development, David Seidensticker (MSC Software) for implementation of structural analysis tool (using MSC’s APIs) and materials database integration, and Tom Searles and Clay Records (Materials Data Management) for Granta MI implementation. After the end of the MxD 15-11-08 project, additional support for MDS and SG was provided by the IN-MaC (Indiana Manufacturing Competitiveness Center) Faculty Fellow award, which focuses on the digital transformation of the manufacturing sector through applied research in time compression and scaling technologies. Software license extensions from Granta MI and Capvidia were greatly appreciated. And the authors would like to extend a sincere thanks to Aidan Molnar (Purdue University) for integration of the ABAQUS APIs within the MFIN framework.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interests

The authors declare that they have no conflict of interests.

Appendices

Appendix 1: Acquisition of Residual Stress Datasets

For creating residual stress data, the reported characterization data [35] obtained using energy dispersive X-ray diffraction (EDD) were used as a starting point. A sample of linear friction welded Ti-6Al-4V to Ti-6Al-4V plate was characterized by the diffracted intensity of high energy X-rays captured with detectors, by performing rotations to the sample, thereby obtaining the lattice strains in the \(\alpha\) and \(\beta \) phases of Ti-6Al-4V corresponding to different families of planes along a series of scanned locations relative to the weld region. Using the acquired datasets, the elastic strain tensor at each scanned location has been computed and reported in [35]. This process was repeated for multiple locations spatially near the weld, by performing multiple line scans across the sample. From the reported residual strain tensors, for the present work, we acquired datasets corresponding to the \(\alpha\) phase of Ti-6Al-4V, having family of planes with Miller indices (i.e., three digit Miller indices{h,k,l}) values of {102}. A coordinate mapping was performed to associate the reported residual strain datasets with the coordinate system used in the current work (i.e., \(\varepsilon_{11} , \varepsilon_{22} , \varepsilon_{33}\) in [35] correspond to \(\varepsilon_{\text{ZZ}} ,\) \(\varepsilon_{\text{XX}} , \varepsilon_{\text{YY}}\), respectively). For each of the reported spatially varying residual strain components, data were extracted at 91 locations within the weld region (45 locations on each side of the weld interface and 1 location at the weld interface). The Young modulus \((E_{hkl} )\) and Poisson ratio \((\nu_{{{\text{hkl}}}} )\) corresponding to {102} were computed using Eqs. (3) and (4) [50], which are necessary for computing the residual stress components.

In Eqs. (3) and (4), the lattice parameters \( a = 2.931 \) and \( c = 4.660 \) for the \(\alpha\)-phase were used [35]. The elastic compliance matrix terms (\(s_{ij} )\) were obtained from the elastic stiffness matrix \( (C_{ij} )\), for which \(C_{11} = 169.66{\text{ GPa}}, C_{12} = 88.66 {\text{GPa}}, C_{13} = 61.66 {\text{GPa}}, C_{33} = 181 {\text{GPa}}, C_{44} = 42.50 {\text{GPa}}, C_{66} = 40.5 {\text{GPa}}\) values corresponding to the \(\alpha\)-phase of Ti-6Al-4V [51] have been used.

The residual stress components \({\upsigma }_{{{\text{xx}}}}\), \({\upsigma }_{{{\text{yy}}}}\), \({\upsigma }_{{{\text{zz}}}}\) were computed using the tensorial equation [Eq. (5)], wherein \(i,j \) are the free indices and \(\lambda_{ij}\) represents the Kronecker delta.

After obtaining the residual stress components (in MPa) for each of the 91 locations within the weld region, a regression fit is applied, in order to create a functional form to define the residual stress distribution. A Fourier type fit was chosen to fit the residual stress data [52, 53], and the function form of the residual components \({\upsigma }_{{{\text{XX}}}} \left( \text{X} \right)\), \({\upsigma }_{{{\text{YY}}}} \left( \text{X} \right)\), \({\upsigma }_{{{\text{ZZ}}}} \left( \text{X} \right)\) used for the case study is shown below in Eqs. (6)–(8). In the study [35], the symmetry of \(\varepsilon_{\text{XX}}\) and \(\varepsilon_{\text{ZZ}}\) components of residual strains across the weld center were reported; however, we observe an asymmetry in the \({\upsigma }_{{{\text{XX}}}}\), \({\upsigma }_{{{\text{YY}}}} \) and \({\upsigma }_{{{\text{ZZ}}}}\) components of the residual stresses about the weld center (shown in Fig. 4b), which is due to the contribution of the asymmetry in \(\varepsilon_{\text{YY}}\) component that is included while evaluating the stress components using Eq. (5).

Appendix 2: Formulation to Include Residual Stresses within Damage Tolerance Analysis

The stage II crack growth can be described using the Paris law [Eq. (9)], wherein the rate of crack propagation (\(\frac{{{\text{d}}a}}{{{\text{d}}N}}\)) is a function of the driving force for the crack growth, namely the effective stress intensity range (\(\Delta K_{{{\text{eff}}}}\)). The parameters \({\text{C}}\) and \({\text{n}}\) are the Paris constants for the material at a given R ratio. For this analysis, the values of \({\text{C}}\) and \({\text{n }}\) for Ti-6Al-4V at \(R\sim 0\) and at room temperature were used as shown in Table 1 [37].

In order to account for the residual stresses within the analysis, the \(\Delta K_{{{\text{eff}}}}\) is modified using a Walker model [Eq. (10)] [47], which typically captures the effects on the crack growth rate due to changing R ratios. Herein, within the R ratio term, the applied stress is superposed with the component of residual stress \((\sigma_{{{\text{RS}}}} )\) along the direction of \({\upsigma }_{{\text{I }}}\) [Eq. (11)], which is the X direction in this study. For the current case study, \(\sigma_{{I,{\text{min }}}} = 0\) and \(\sigma_{{I,{\text{max }}}} \) are the \({\upsigma }_{{\text{I}}}\) value obtained from the FE analysis for the Models 1 and 2 at each of the two locations (Fig. 6b). The Walker exponent \(m\) in Eq. (10) is a material-dependent parameter and the value applicable for Ti-6Al-4V at room temperature has been used as reported in Table 1 [37].

Similarly, within the maximum stress intensity \((K_{{{\text{max}}}} )\) term [as defined in Eq. (12)] for a given crack length \(\left( a \right)\), the residual stress component (\({\upsigma }_{{{\text{RS}}}} )\) has been superposed with applied maximum stress \(\sigma_{{I,{\text{max}}}}\). The term \(f\left( \frac{a}{c} \right)\) represents an expression of the geometric correction factor as a function of the crack dimensions. For an embedded elliptical crack in the current case study, an approximate \(f\left( \frac{a}{c} \right)\), as shown in Eq. (13) [54], has been utilized, which is applicable for crack lengths \(a\) much smaller than the width of crack growth plane such as in the current case.

The equations Eqs. (11)–(13) have been substituted in Eq. (10), followed by further substituting Eq. (10) in Eq. (9). Finally, Eq. (9) is rewritten to obtain \({\text{d}}N\) as a function of \({\text{d}}a\), which can be integrated to compute fatigue life cycles (\(N_{f}\)) as crack grows from a length \(a_{i}\) to \(a_{f}\) as shown in Eq. (16).

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Gopalakrishnan, S., Hartman, N.W. & Sangid, M.D. Model-Based Feature Information Network (MFIN): A Digital Twin Framework to Integrate Location-Specific Material Behavior Within Component Design, Manufacturing, and Performance Analysis. Integr Mater Manuf Innov 9, 394–409 (2020). https://doi.org/10.1007/s40192-020-00190-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40192-020-00190-4