Abstract

Alkali-activated materials are a promising type of binder candidate as a substitute to Portland cement. Fly ashes can be used as binder precursors giving higher environmental benefits. In the present research, fly ashes (Type F) containing different amounts of unburned carbonaceous matter have been used to formulate mortars. Serious problems concerning the workability in the fresh state have been found when high carbon content are reached. An attempt to avoid the preliminary treatments used to eliminate the unburned matter is carried out by exploiting different mix-design receipts obtained by changing the water/binder ratio, the ratio of the alkaline activators and using different types of superplasticizer additives. Data so far collected underline that a high amount of unburned carbonaceous matter can not only compromise the mechanical properties of the materials, but also the rheological ones and underline the necessity to develop ad hoc additives for this type of binders.

Similar content being viewed by others

1 Introduction

Environmental issues are steadily and earnestly driving the building industry towards the production of low impact materials. This goal can be achieved in different ways, such as casting new composites using recycled aggregates (Manzi et al. 2013, 2017; Tam et al. 2018; Chen et al. 2019) deriving from demolished concrete or exploiting wastes of different origin as fine aggregates (Bursi et al. 2017; Saccani et al., 2017; Gayana and Chandar 2018; Yang and Lee 2019). A further approach is based on the formulation of binders that can be either traditional Portland mixed with wastes having pozzolanic activity (Karim et al. 2011; Hanif et al. 2017; Hemalatha and Ramaswamy 2017; Juenger et al. 2019) or alkali-activated wastes containing silica and alumina (Mustafa Al Bakri et al. 2011; Bignozzi et al. 2014; Carabba et al. 2016,2017a; Monticelli et al. 2016; Cui et al. 2019; Hwang and Shahsavari 2019; Matsuda et al. 2019; Zhang et al. 2019; Saccani et al. 2020). In both cases, fly ashes are usually found to provide positive effects. However, the chemical composition of fly ashes can largely change because of the different chemical composition of the starting fuels as well as the different combustion conditions. It has already been underlined that high amounts of unburned matter can compromise the use of fly ashes as pozzolanas (Fernandez-Jimenez and Palomo 2005; Ha et al. 2005). Problems may be faced also in the formulation of alkali-activated materials. The scanty mechanical strength of these low-value fly ashes can be increased by formulating blended binders with Portland or granulated blast furnace slag (Mejía et al. 2015; Shearer et al. 2016; Valencia-Saavedra et al. 2018). Large particles of unburned matter can be eliminated by sieving (van Riessen and Chen-Tan 2013), but smaller particles remain in the binder. The fine fraction of unburned carbon was effectively separated in the fraction below 46 μm using an air classifier (Kang et al. 2013). Another possible way of obtaining high mechanical properties from high carbon fly ashes was found by eliminating the unburned carbon by calcination (Won and Kang 2015) or applying two-steps mixed curing treatment based on hoven and microwave heating (Hong and Kim 2019). In the present study, the overall performance of two different batches of fly ashes deriving from the same plant has been investigated. Strong workability problems have been faced in formulating mortars containing the high amount of carbon during the mixing stage. The workability was so low that hindered the casting process. A possible solution to the problem was attempted through the development of different mix-designs to provide acceptable workability. Consequently, either a change in the ratio of the alkaline activators was made, or water-reducing additives, formulated for traditional Portland composites, were used. These additives are usually reported to restore sufficient workability when high volume fly ash cement binders are formulated with fly ashes with a high loss on ignition (LOI) values. Avoiding all the preliminary processes devised to eliminate the unburned carbon could reduce the environmental impact deriving from the energy consumption related to those processes. Properties in the fresh state as well as in the cured one have been studied also as a function of the curing temperature.

2 Experimental Investigation

2.1 Materials

2.1.1 Fly Ashes

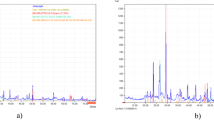

Two batches of fly ashes (Type F), deriving from the same plant (Torrevaldaliga, Rome, Italy), have been investigated. One batch, hereafter labelled as FA(LCC) has a low carbon content while the second one FA(HCC) has a higher carbon content. The specific gravity is 2310 kg/m3 and 2195 kg/m3 for FA(LCC) and FA(HCC) respectively. The chemical composition of the two batches is reported in Table 1. The size distribution has been obtained through a laser granulometry instrument (Mastersizer 2000, Malvern), and is reported in Fig. 1. In this range of dimension, the FA(LCC) shows a higher dimension than the FA(HCC). The highest difference in the composition is related to the amount of carbon, which is almost double in the FA(HCC). A slight amount of sulfur is contained in the same batch probably deriving from the fuel. Eventually, the X-ray analysis of batches has been carried out by means of a Philips PW1830 diffractometer. The diffractograms are reported in Fig. 2. No remarkable differences can be detected between the investigated fly ashes, both characterized by a high amorphous content. Both the XRD patterns show crystalline phases of quartz, mullite and hematite plus a broad amorphous hump.

2.1.2 Alkaline Activators

The sodium silicate solution used was a viscous liquid produced for the cement industry with a water content of 56 wt%, the SiO2/Na2O oxide composition ratio of 2.07 and a density of 1.53 g/cm3. An 8 M water solution of sodium hydroxide was used.

2.1.3 Superplasticizer Additives

Two different types of commercially available superplasticizer additives, commonly used in the ordinary Portland cement (OPC) concrete industry, were used: (i) an acrylic acid copolymer (hereafter named S) with a density of 1.08 g/cm3 and a yellow liquid appearance color; (ii) a polycarboxylic ether with a density of 1.04 g/cm3 and a brown liquid appearance color (named G). The additives amounts have been added according to the guidelines of the producers.

2.1.4 Aggregate

Normalized silica sand according to EN 196-1 Standards (EN 196-1) with a maximum aggregate size dmax = 2 mm and density ρ = 2.64 g/cm3 was used as fine aggregate. The fine aggregate has a water absorption of 0.2%, according to EN 196-1 Standards (EN 196-1).

2.2 Mix Design and Casting Procedures

In Table 2 the composition and the relative tags of the investigated mortars (named M followed by the kind of fly ashes, i.e., FA(LCC) and FA(HCC)) are reported. Mix design, that is the ratio between fly ashes, sand, activators and water of M-FA(LCC) was performed according to a previous research (Carabba et al. 2017b) to obtain Na2O/SiO2, SiO2/Al2O3 and Na2O/Al2O3 ratios of 0.12, 3.45 and 0.42 respectively. This composition allowed for obtaining good mechanical properties. The others mortars have been formulated to obtain the same workability as the one of M-FA(LCC), but with the batch of fly ashes containing the higher amount of carbon (i.e., FA(HCC)). In all the mixes the total amount of fly ash, alkaline activators and sand was maintained constant. M-FA(HCC)-1 was prepared with the same amount of NaOH solution and sodium silicate solution as in M-FA(LCC), while M-FA(HCC)-2 was prepared by changing the ratio of the two alkaline activators to have the same overall amount of NaOH and sodium silicate solution. This composition had different Na2O/SiO2, SiO2/Al2O3 and Na2O/Al2O3. Finally, M-FA(HCC)-S and M-FA(HCC)-G were prepared with the same amount of NaOH solution and sodium silicate solution as in M-FA(HCC)-1, with the further addition of the superplasticizers S and G, respectively. In all the M-FA(HCC) mixes, the amount of water was adjusted to maintain the same workability as the one of M-FA(LCC). Workability is one of the most important parameter in practical application, this is why this criterion was selected to compare the different mortars. Mortar samples were prepared using a Hobart mixer with a procedure similar to the one used for conventional cement mortar prepartion. Mixing was performed by first adding sodium hydroxide to the fly ashes and subsequently pouring the silicate in the vessel. When necessary, the water reducing additives were added allowing one minute of further mixing. After 3 min of stirring, the natural sand was added to the paste. The whole procedure lasts for 10 (or 11) mins. The amount of added water provided the same workability to all the investigated mortars.

After the mixing stage mortars were poured in 40 × 40 × 160 mm metal molds and vibrated for 1 min on a shaker-table and finally kept for 24 h in sealed polyethylene bags at 20 °C. After demolding, samples have been cured in two conditions that are (1) 20 °C and 60 ± 10 R.H. and (2) 38 °C and 90 ± 10 R.H. for 28 days.

2.3 Characterization Tests

2.3.1 Workability

After the mixing process, mortars were cast in a truncated conical mould (Fig. 3) with a circular base (100 mm of diameter at the bottom, 70 mm of diameter at the top and 60 mm height), according to EN 1015-3 Standard (EN 1015-3).

After removing the mold the collapsed mortar has been shaken by means of a jolting device. The final dimension (i.e. the diameter) of the spread mass was measured in two perpendicular directions and the workability (W) was determined according to Eq. (1)

where dm is the average diameter of the two readings and d° is the lower diameter of the truncated conical ring, i.e. 100 mm. The mix design reported in Table 2 allowed obtaining similar workability as subsequently reported.

2.3.2 Density and Pore Size Distribution

Mortars bulk density has been determined according to the EN 772-13 Standard (EN 772-13) at 28 days of curing. The pore size distribution in the range from 10 to 0.004 μm of samples extracted from the prisms at 28 days was investigated by means of mercury intrusion porosimetry (MIP, Carlo Erba 2000 instrument equipped with a macropore unit Model 120, Fison Instruments). Samples, which had a volume approximately equal to 1 cm3, were cut by a diamond saw, dried under vacuum, and kept under a P2O5 dried atmosphere in a vacuum dry box until MIP was performed.

2.3.3 Mechanical Tests

Mechanical tests (compression) on all samples were performed according to EN 196-1 Standard (EN 196-1) at room temperature and R.H. 60 ± 10% by means of 100 kN Volpert Amsler instrument with a 50 mm/min displacement rate. The test was repeated on six samples at 28 days of curing at both 20 and 38 °C.

2.3.4 Microstructure

Microstructural analysis was performed by means of scanning electron microscopy (SEM XL20 type, FEI Instruments) on unperturbed fractured samples obtained after the flexural test and metallized under vacuum with aluminum. Operating conditions were set at 20 kV and the vacuum condition was below 10–4 Torr.

3 Results and Discussion

Table 3 reports the workability and the bulk density of the tested mixtures. The high amount of unburnt particles in the fly ashes caused a decrease in workability. The different mix designs proposed have almost the same workability of M-FA(LCC), but have lower values of density. To reach the fixed value of workability a higher water/binder (w/b) is requested, particularly for M-FA(HCC)-1. It is important to notice that the use of both superplasticizer additives is not sufficient to reach the M-FA(LLC) workability and a further increase in the water amount and consequently of the w/b ratio is necessary. The origin of this effect is presently not fully understood, also on account of the unknown structure of the proprietary additives. The most probable explanation could be the preferential absorption of the additives on the carbon particles, de-activating the effect on the binders powders. However, considering the original use of the additives in Portland systems, a possible effect deriving from the substitution of calcium ion with sodium ions or the different concentration of other anions should be further investigated. Similar results are found in literature concerning water-reducing additives (Oderji et al. 2019).

MIP results are reported in Fig. 4. The most evident feature is that the M-FA(HCC)-1 sample clearly shows a higher total intruded mercury volume, specifically in the range from 0.1 to 4 μm typical of capillary porosity. This can be explained by the high w/b ratio of the mortar, i.e. by the excess of water needed to improve the workability. All the other samples show, among them, close results. In accordance with a low w/b ratio and possibly to the more favorable conditions of alkalis concentration, the M-FA(HCC)-2 mortar shows the lowest capillary porosity of all samples. The best conditions as concerns density (Table 3) and porosity (Fig. 4) are thus achieved by changing the ratio of the alkaline activators. The effect of the superplasticizer additives only partially manages to decrease the porosity in the previous range.

Figure 5 summarizes the values of the mechanical properties of samples cured at 20 and 38 °C for 28 days.

The decrease in the mechanical strength caused by the presence of a high amount of unburned matter on samples cured at low temperature is remarkable. One of the main causes of this is the different w/b ratio in the mortars necessary to obtain suitable workability that leads to higher overall porosity, as confirmed by MIP measurements (Fig. 4). While the different ratios of alkaline activators partially restore the strength, the use of superplasticizer additives proves to be rather ineffective. It should be noted however that other parameters can influence the development of alkali-activated gels and consequenly affect the mechanical properties. The change in the activators ratio (sample M-FA(HCC)-2) has led to different reaction conditions. It should be underlined, however, that previous experiments carried out with low carbon fly ashes had underlined how, when keeping the w/b costant, the M-FA(HCC)-1 provided the higher mechanical strength.Thus the improved mechanical strength of M-FA(HCC)-2 should derive mainly from different factors.

On observing the difference in the values obtained by curing the samples at a higher temperature, it is also clear that the unburned fraction strongly delays the development of the polymerized structure. Indeed, the compressive strength of M-FA(LCC) is almost the same at the two temperatures, which means that 3D structure responsible for the mechanical properties can be almost completely obtained at room conditions. In all the other mortars, values increase up to a 140% in the case of M-FA(HCC)-1 and reaching a value above 20 MPa. According to the values, it is clear that for samples with high C content the adoption of high-temperature curing has a positive effect.

The increase in the extent of the reactions at higher temperature is also qualitatively confirmed by SEM analysis. As an example, Figs. 6 and 7 report the microstructure of M-FA(HCC)-2 cured at different temperatures. While at 20 °C the smooth surface of fly ashes is almost unreacted and some particles tend to easily detach from the matrix (Fig. 6), in the samples at 38 °C reaction products become distinguishable on the surface and the cenospheres are more adherent to the matrix (Fig. 7).

Figures 8 and 9 show the microstructure of the material close to the external surface of the mortar specimens, i.e. the one not in contact with the mold. Only two compositions are reported (i.e., M-FA(HCC)-1 and M-FA(HCC)-S), but the same microstructure is found also in M-FA(HCC)-2 and M-FA(HCC)-G.

A thick layer of small roundish carbonaceous particles is formed. This is a clear evidence of the presence of a bleeding phenomenon, which compromises the homogeneity and possibly the chemical composition in the bulk of the material. This point seems to suggest that the improvement in mechanical performance found in M-FA(HCC)-2, where less water was added compared to all the other mortars, derives from the higher homogeneity of the materials. On adding higher amounts of water, the bleeding process is probably altering the chemical balance between fly ashes and activators reducing the reaction product developed during the curing stage. Moreover, the use of a higher amount of silicate, that has a higher viscosity than the sodium hydroxide solution, decreases the bleeding tendency of the mixture. It should be outlined that the dimension of many of the particles is below 1.0 μm. These particles are not detected in the results of laser granulometry and are probably responsible for the reduced workability caused by FA(HCC). The negative effect of the high amount of carbonaceous particles in fly ashes has already been reported in the literature (Lee et al. 2010; Kang et al. 2013), but as reported elsewhere (Leiva et al. 2008; Valencia-Saavedra et al. 2018) it is still possible to produce mortars with acceptable properties provided a tailored mix design and curing treatment is obtained. The necessity to develop ad hoc additives is also underlined since traditional water-reducing systems used for Portland prove to be quite ineffective.

4 Conclusions

High contents of unburned particles in fly ashes compromise the properties of the derived alkali-activated mortars not only in the cured state but particularly in the fresh state, leading to the impossibility to cast the materials according to the mix-design of lower unburned carbon samples. Acceptable mechanical properties can be obtained provided an ad hoc composition and curing process are formulated leading to reduced bleeding effects, thus creating more homogeneous conditions in the material. Traditional water-reducing additives designed to be used in Portland cement composites are rather ineffective as to what concerns the increase in workability. This underlines the need to develop specific formulations for this new class of materials.

Availability of data and materials

The data and materials are available.

Abbreviations

- LOI:

-

Loss on ignition

- FA(LCC):

-

Fly ashes with a low carbon content

- FA(HCC):

-

Fly ashes with a higher carbon content

- OPC:

-

Ordinary Portland cement

- S:

-

Acrylic acid copolymer

- G:

-

Polycarboxylic ether

- Q:

-

SiO2

- M:

-

Al6Si2O13

- H:

-

Fe2O3

- dmax :

-

Maximum aggregate size

- ρ :

-

Density

- W :

-

Workability

- dm :

-

Average diameter

- d° :

-

The lower diameter of the truncated conical ring

- w/b ratio:

-

Water/binder ratio

- L/b ratio:

-

Liquid/binder ratio

References

Bignozzi, M. C., Manzi, S., Natali, M. E., Richard, W. D. A., & van Riessen, A. (2014). Room temperature alkali activation of fly-ash: the effect of Na2O/SiO2 ratio. Construction and Building Materials, 69, 262–270.

Bursi, E., Barbieri, L., Lancellotti, I., Saccani, A., & Bignozzi, M. (2017). Lead waste glasses management: chemical pre-treatment for use in cementitious composite. Waste Management & Research, 35(9), 958–966.

Carabba, L., Manzi, S., & Bignozzi, M. C. (2016). Superplasticizer addition to carbon fly ash geopolymers activated at room temperature. Materials, 9, 1–15.

Carabba, L., Manzi, S., Rambaldi, E., Ridolfi, G., & Bignozzi, M. C. (2017a). High-temperature behaviour of alkali-activated composites based on fly ash and recycled refractory particles. Journal of Ceramic Science and Technology, 8, 377–387.

Carabba, L., Santandrea, M., Carloni, C., Manzi, S., & Bignozzi, M. C. (2017b). Steel fiber reinforced geopolymer matrix (S-FRGM) composites applied to reinforced concrete structures for strengthening applications: a preliminary study. Composites Part B, Engineering, 128, 83–90.

Chen, X., Shi, D., Shen, N., Li, S., & Liu, S. (2019). Experimental study and analytical modelling on fatigue properties of pervious concrete made with natural and recycled aggregates. International Journal of Concrete Structures and Materials, 13, 10.

Cui, Y., Wang, D., Wang, Y., Sun, R., & Rui, Y. (2019). Effects of the n(H2O: Na2Oeq) ratio on the geopolymerization process and microstructures of fly ash based geopolymers. Journal of Non Crystalline Solids, 511, 19–28.

EN 1015-3. (2007). Determination of consistence of fresh mortars by flow table.

EN 196-1. (2016). Methods of testing cement - Part 1: determination of strength.

EN 772-13. (2002). Determination of net and gross dry density.

Fernandez-Jimenez, A., & Palomo, A. (2005). Composition and microstructure of alkali activated fly ash binder effect of the activator. Cement and Concrete Research, 35, 1984–1992.

Gayana, B. C., & Chandar, K. R. (2018). Sustainable use of mine waste and tailings with suitable admixture as aggregates in concrete pavements - A review. Advances in Concrete Construction, 6, 221–243.

Ha, T.-H., Muralidharan, S., Bae, J.-H., Ha, Y.-C., Lee, H.-G., Park, K. W., et al. (2005). Effect of unburnt carbon on the corrosion performance of fly ash cement mortar. Construction and Building Materials, 19, 509–515.

Hanif, A., Lu, Z., & Li, Z. (2017). Utilization of fly ash cenosphere as lightweight filler in cement-based composites - A review. Construction and Building Materials, 144, 373–384.

Hemalatha, T., & Ramaswamy, A. (2017). A review on fly ash characteristics - Towards promoting high volume utilization in developing sustainable concrete. Journal of Cleaner Production., 147, 546–559.

Hong, S., & Kim, H. (2019). Robust synthesis of coal bottom ash-based geopolymers using additional microwave heating and curing for high compressive strength properties. Korean Journal of Chemical Engineering, 36, 1164–1171.

Hwang, S. H., & Shahsavari, R. (2019). High calcium cementless fly ash binder with low environmental footprint: Optimum Taguchi design. Journal of American Ceramic Society, 102, 2203–2217.

Juenger, M. C. G., Snellings, R., & Bernal, S. A. (2019). Supplementary cementitious materials: new sources, characterization, and performance insights. Cement and Concrete Research, 122, 257–273.

Kang, N. H., Chon, C. M., Jou, H. T., & Lee, S. (2013). Effect of particle size and unburned carbon content of fly ash from Hadong power plant on compressive strength of geopolymers. Korean Journal of Materials Research, 23(9), 510–516.

Karim, M. R., Zain, M. F. M., Jamil, M., Lai, F. C., & Islam, M. N. (2011). Strength development of mortar and concrete containing fly ash: a review. International Journal of Physical Sciences, 6(17), 4137–4153.

Lee, S., Seo, M.-D., Kim, Y.-J., Park, H.-H., & Kim, T.-N. (2010). Unburned carbon removal effect on compressive strength development in a honeycomb briquette ash-based geopolymer. International Journal of Mineral processing, 97, 20–25.

Leiva, C., Vilches, L. F., Vale, J., Olivares, J., & Fernandez-Pereira, C. (2008). Effect of carbonaceous matter contents on the fire resistance and mechanical properties of coal fly ash enriched mortars. Fuels, 87, 2977–2982.

Manzi, S., & BignozziMazzotti, M. C. C. (2013). Short and long-term behavior of structural concrete with recycled concrete aggregate. Cement and Concrete Composites, 37, 312–318.

Manzi, S., Mazzotti, C., & Bignozzi, M. C. (2017). Self-compacting concrete with recycled concrete aggregate: Study of the long-term properties. Construction and Building Materials, 157, 582–590.

Matsuda, A., Maruyama, I., Meawad, A., Pareek, S., & Araki, Y. (2019). Reaction, phases, and microstructure of fly ash-based alkali-activated materials. Journal Advanced Concrete Technology, 17, 93–101.

Mejía, J. M., Rodríguez, E., Mejía de Gutierrez, R., & Gallego, N. (2015). Preparation and characterization of a hybrid alkaline binder based on a fly ash with no commercial value. Journal of Cleaner Production, 104, 346–352.

Monticelli, C., Natali, M. E., Balbo, A., Chiavari, C., Zanotto, F., Manzi, S., et al. (2016). Corrosion behavior of steel in alkali-activated fly ash mortars in the light of their microstructural, mechanical and chemical characterization. Cement and Concrete Research, 80, 60–68.

Mustafa Al Bakri, A. M., Kamarudin, H., Bnhussain, M., Khairul, N. I., Rafiza, A. R., & Izzat, A. M. (2011). Chemical reactions in the geopolymerisation process using fly ash—based geopolymer: a review. Australian Journal of Basic and Applied Sciences, 5(7), 1199–1203.

Oderji, S. Y., Chen, B., Shakya, C., Ahmad, M. R., & Shah, S. F. A. (2019). Influence of superplasticizers and retarders on the workability and strength of one-part alkali-activated fly ash/slag binders cured at room temperature. Construction and Building Materials, 229, 116891.

Saccani, A., Bignozzi, M., Barbieri, L., Lancellotti, I., & Bursi, E. (2017). Effect of the chemical composition of different types of recycled glass used as aggregates on the ASR performance of cement mortars. Construction Building Materials, 154, 804–809.

Saccani, A., Manzi, S., I., Lancellotti, L., & Barbieri, (2020). Manufacturing and durability of alkali activated mortars containing different types of glass waste as aggregates valorization. Construction and Building Materials, 237, 117733.

Shearer, C. R., Provis, J. L., Bernal, S. A., & Kurtis, K. E. (2016). Alkali-activation potential of biomass-coal co-fired fly ash. Cement and Concrete Composites, 73, 62–74.

Tam, V. W. Y., Soomro, M., & Evangelista, A. (2018). A review of recycled aggregate in concrete applications (2000–2017). Construction and Building Materials, 172, 272–292.

Valencia-Saavedra, W., Mejìa de Gutiérrez, R., & Gordillo, M. (2018). Geopolymeric concretes based on fly ash with high-unburned content. Construction and Building Materials, 165, 697–706.

van Riessen, A., & Chen-Tan, N. (2013). Beneficiation of Collie fly ash for synthesis of geopolymer: Part 1 - Beneficiation. Fuel, 106, 569–575.

Won, J.-H., & Kang, S.-G. (2015). Processing parameters affecting the nano scale-microstructure and mechanical strength of coal ash-based geopolymer. International Journal of Precision Engineering and Manufacturing, 16, 1335–1340.

Yang, K., & Lee, K. (2019). Shear friction characteristics and modification factor of concrete prepared using expanded bottom ash and dredged soil granules. International Journal of Concrete Structures Materials, 13, 50.

Zhang, H., Li, L., Sarker, P. K., Long, T., Shi, X., Wang, Q., et al. (2019). Investigating various factors affecting the long-term compressive strength of heat-cured fly ash geopolymer concrete and the use of orthogonal experimental design method. International Journal Concrete Structures Materials, 13, 63.

Acknowledgements

The authors wish to thank P. Carta and Dr. F. Gabelli for their useful assistance in sample preparation and characterizations.

Funding

Not applicable.

Author information

Authors and Affiliations

Contributions

SM: Conceptualization, Methodology, Validation, Investigation, Resources, Visualization, Writing-Original draft preparation and Editing. AS: Conceptualization, Methodology, Validation, Investigation, Resources, Data curation, Visualization, Writing-Original draft preparation and Editing. LB: Investigation, Resources, Data curation, Visualization. IL: Methodology, Validation, Resources, Supervision. All authors read and approved the final manuscript.

Authors’ information

Stefania Manzi, Assistant Professor in Department of Civil, Chemical, Environmental and Materials Engineering, University of Bologna, Via Terracini 28, 40131 Bologna, Italy.

Andrea Saccani, Associate Professor in Department of Civil, Chemical, Environmental and Materials Engineering, University of Bologna, Via Terracini 28, 40131 Bologna, Italy.

Luca Baldazzi, Teaching tutor in Department of Civil, Chemical, Environmental and Materials Engineering, University of Bologna, Via Terracini 28, 40131 Bologna, Italy.

Isabella Lancellotti, Associate Professor in Department of Engineering “Enzo Ferrari”, University of Modena and Reggio Emilia, Via Vivarelli 10, 41125 Modena, Italy.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

The authors state that the research was conducted according to ethical standards.

Consent for publication

The authors consent for publication.

Competing interests

The authors declare that they have no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Journal information: ISSN 1976-0485 / eISSN 2234-1315

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Manzi, S., Saccani, A., Baldazzi, L. et al. Mix-design and Properties of Mortars from Alkali-activated Fly Ashes Containing High Amounts of Unburned Carbon Matter. Int J Concr Struct Mater 14, 59 (2020). https://doi.org/10.1186/s40069-020-00435-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s40069-020-00435-8