Abstract

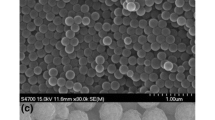

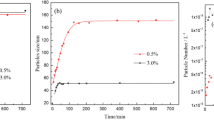

A facile approach to prepare monodisperse polystyrene (PS) particles containing quaternary ammonium salts with long alkyl chain was reported. The PS particles containing quaternary ammonium salts are prepared by two-stage dispersion polymerization in ethanol/water (80/20 w/w) mixture with polyvinylpyrrolidone (PVP) as a steric stabilizer and fatty alcohol polyoxyethylene ether (AEO-9) as a co-stabilizer. Polymerizations are conducted using N′-dimethyl-N-n-dodecyl-N-2-methacryloyloxyethylammonium bromide (QDMDB) as a comonomer added in the second stage. We identify reaction conditions where one can obtain the functional polystyrene microspheres with a size distribution less than 3%. The influence of the initiator concentration, the styrene monomer concentration, the stabilizer concentration, and QDMDB comonomer concentration on the average particle size and the efficient of variation are investigated comprehensively. The novel particles are examined using scanning electron microscopy (SEM), gel permeation chromatography (GPC), zeta potential, and nuclear magnetic resonance (1H NMR). QDMDB comonomer not only functionalized the polystyrene particles but also proved to be effective in controlling the particle size and size distribution. According to these results, we show that two-stage dispersion polymerization is an effective pathway for the structure design of the functional microspheres.

Graphical abstract

Similar content being viewed by others

References

Celebi B, Gokaltun A, Arman E, Evirgen OA, Tuncel A (2017) Polyethylenimine attached-poly(3-chloro-2-hydroxypropyl methacrylate-co-ethylene dimethacrylate) monosized-porous microspheres as a new separation medium for polar compounds. Colloids Surf A Physicochem Eng Asp 441:629f637. https://doi.org/10.1016/j.colsurfa.2013.10.030

Poma A, Guerreiro A, Whitcombe MJ, Piletska EV, Turner APF, Piletsky SA (2013) Solid-phase synthesis of molecularly imprinted polymer nanoparticles with a reusable template–"plastic antibodies". Adv Funct Mater 23:2821–2827. https://doi.org/10.1002/adfm.201202397

Qu JB, Zhou WQ, Wei W, Su ZG, Ma GH (2008) An effective way to hydrophilize gigaporous polystyrene microspheres as rapid chromatographic separation Media for Proteins. Langmuir 24:13646–13652. https://doi.org/10.1021/la801486t

Anderson JM, Shive MA (1997) Biodegradation and biocompatibility of PLA and PLGA microspheres. Adv Drug Deliv Rev 28:5–24. https://doi.org/10.1016/S0169-409X(97)00048-3

Cheng J, Teply BA, Sherifi I et al (2007) Formulation of functionalized PLGA-PEG nanoparticles for in vivo targeted drug delivery. Biomaterials 28:869–876. https://doi.org/10.1002/pola.1994.080320611

Tao T, Deng YM, Liang ZH, Liang B, Yao Y, Li P, Lu S, Chen Y (2017) Synthesis of porous polyvinylidene fluoride (PVDF) microspheres and their application in lithium sulfur batteries. Mater Lett 188:180–183. https://doi.org/10.1016/j.matlet.2016.11.023

Kurozuka A, Onishi S, Nagano T, Yamaguchi K, Suzuki T, Minami H (2017) Emulsion polymerization with a biosurfactant. Langmuir 33:5814–5818. https://doi.org/10.1021/acs.langmuir.7b00851

Sajjadi S (2007) Nanoparticle formation by monomer-starved semibatch emulsion polymerization. Langmuir 23:1018–1024. https://doi.org/10.1021/la062397b

Hong J, Hong CK, Shim SE (2007) Synthesis of polystyrene microspheres by dispersion polymerization using poly(vinyl alcohol) as a steric stabilizer in aqueous alcohol media. Colloids Surf A Physicochem Eng Asp 302:225–233. https://doi.org/10.1016/j.colsurfa.2007.02.027

Zhang HT, Huang H, Lv R, Chen M (2005) Micron-size crosslinked microspheres bearing carboxyl groups via dispersion copolymerization. Colloids Surf A Physicochem Eng Asp 253:217–221. https://doi.org/10.1016/j.biomaterials.2006.09.047

Ugelstad J, Kaggerud KH, Hansen FK, Berge A (1979) Absorption of low molecular weight compounds in aqueous dispersions of polymer-oligomer particles, 2. A two step swelling process of polymer particles giving an enormous increase in absorption capacity. Macromo Chem Phys 180:737–744. https://doi.org/10.1002/macp.1979.021800317

Lok KP, Ober CK (1985) Particle size control in dispersion polymerization of polystyrene. Can J Chem 63:209–216. https://doi.org/10.1139/v85-033

Nakano T, Yamane M, Kurozuka A, Suzuki T, Minami H (2020) Preparation of poly(ionic liquid) particles with anionic side chain by dispersion polymerization. Macromol Rapid Commun 2020:2000271. https://doi.org/10.1002/marc.202000271

Peng B, Imhof A (2015) Surface morphology control of cross-linked polymer particles via dispersion polymerization. Soft Matter 11:3589–3598. https://doi.org/10.1039/C5SM00606F

Wang D, Dimonie VL, Sudol ED, el-Aasser MS (2002) Seeded dispersion polymerization. J Appl Polym Sci 84:2710–2720. https://doi.org/10.1002/app.10593

Khakzad F, Alinejad Z, Shirin-Abadi AR et al (2014) Optimization of parameters in preparation of PCM microcapsules based on melamine formaldehyde through dispersion polymerization. Colloid Polym Sci 292:355–368. https://doi.org/10.1016/j.colsurfa.2007.02.027

Tauer K (1998) Comment on the development of particle surface charge density during surfactant-free emulsion polymerization with ionic initiators. Macromolecules 31:9390–9391. https://doi.org/10.1021/ma981413b

Zhang F, Bai Y, Ma Y, Yang WT (2009) Preparing of monodisperse and cation-charged polystyrene particles stabilized with polymerizable quarternary ammonium by dispersion polymerization in a methanol-water medium. J Colloid Interface Sci 334:13–21. https://doi.org/10.1016/j.jcis.2009.02.040

Tseng CM, Lu YY, El-Aasser MS, Vanderhoff JW (1986) Uniform polymer particles by dispersion polymerization in alcohol. J Polym Sci Part A: Polym Chem 24:2995–3007. https://doi.org/10.1002/pola.1986.080241126

Shen S, Sudol ED, El-aasser MS (1994) Dispersion polymerization of methyl methacrylate: mechanism of particle formation. J Polym Sci Part A: Polym Chem 32:1087–1110. https://doi.org/10.1002/pola.1994.080320611

Dong A, Wang T, Xiao L et al (2011) Synthesis of N-halamine-functionalized silica-polymer core-shell nanoparticles and their enhanced antibacterial activity. Nanotechnology 22:295602. https://doi.org/10.1088/0957/4484/22/29/295602

Tuncel A, Kahraman R, Piskin E (1994) Monosize polystyrene latices carrying functional groups on their surfaces. J Appl Polym Sci 51:485–1498. https://doi.org/10.1002/app.1994.070510816

Okubo M, Iwasaki Y, Yamamoto Y (1992) Preparation of micron-size monodisperse polymer microspheres having cationic groups. Colloid Polym Sci 270:733–737. https://doi.org/10.1007/BF00776143

Lü SS, Jiang WW, Li JJ (2019) Preparation of surface-modified monodisperse polystyrene microspheres with cationic functional comonomer. Colloid Polym Sci 297:165–175. https://doi.org/10.1007/s00396-018-4452-2

Lee JW, Ha JU, Choe S, Lee CS, Shim SE (2006) Synthesis of highly monodisperse polystyrene microspheres via dispersion polymerization using an amphoteric initiator. J Colloid Interface Sci 298:663–671. https://doi.org/10.1016/j.jcis.2006.01.001

Paine AJ. Dispersion polymerization of styrene in polar solvents 7. A simple mechanistic model to predict particle size. Macromolecules 23:3109–3117. https://doi.org/10.1021/ma00214a013

Li K, Stöver HDH (1993) Highly crosslinked micron-range polymer microspheres by dispersion polymerization of divinylbenzene. J Polym Sci A Polym Chem 31:2473–2479. https://doi.org/10.1002/pola.1993.080311007

Acknowledgments

The authors are grateful to the Sichuan University, Analytical & Testing Center. We thank them for all the characterization work in this paper. Thanks Ruili Xiang for helping obtain SEM images.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Lü, S., Jiang, W. & Li, J. Monodisperse polystyrene microspheres containing quaternary ammonium salt groups by two-stage dispersion polymerization: effect of reaction parameters on particle size and size distribution. Colloid Polym Sci 299, 611–622 (2021). https://doi.org/10.1007/s00396-020-04785-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00396-020-04785-3