Abstract

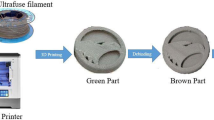

In view of the rough and sunken bottom of blind hole during the laser processing on carbon fiber-reinforced plastics (CFRP), a processing experiment with different hatch distance is conducted by picosecond laser, and the numerical simulation is carried out by COMSOL. The effects of scanning path distribution of hatch distance with equal and variable hatch distance in the processing depth, heat-affected zone and bottom micro-morphology of blind holes are studied. The results show that the variable hatch distance machining path can make heat more uniform on the material, so that the concave effect of the inner ring bottom is weakened. Moreover, the variable hatch distance path can reduce the fiber breakage and resin residue of blind holes, and enhance the physical performance of the structure. When the processing path is three sets of concentric circles with 70 µm innermost hatch distance and 100 µm outermost hatch distance, the machining depth can be achieved, and high-quality blind hole can be obtained under the premise of smaller heat-affected zone and borehole taper.

Similar content being viewed by others

References

D.M. Che, I. Saxena, P.D. Han, P. Guo, K.F. Ehmann, Machining of carbon fiber reinforced plastics/polymers: a literature review. J Manuf Sci Eng Asme 136(3), 034001 (2014)

M. Hasan, J. Zhao, Z. Jiang, Micromanufacturing of composite materials: a review. Int J Extreme Manuf 1(1), 012004 (2019)

P. Mucha, N. Speker, R. Weber, T. Graf, Momentum and velocity of the ablated material in laser machining of carbon fiber preforms. Appl Phys A Mater 113(2), 361–366 (2013)

A. Riveiro, F. Quintero, F. Lusquinos, J. del Val, R. Comesana, M. Boutinguiza, J. Pou, Experimental study on the CO2 laser cutting of carbon fiber reinforced plastic composite. Compos Part A Appl Sci 43(8), 1400–1409 (2012)

B. Rethfeld, D.S. Ivanov, M.E. Garcia, S.I. Anisimov, Modelling ultrafast laser ablation. J Phys D Appl Phys 50(19), 193001 (2017)

H. Dhieb, J.G. Buijnsters, F. Eddoumy, J.P. Celis, Surface damage of unidirectional carbon fiber reinforced epoxy composites under reciprocating sliding in ambient air. Compos Sci Technol 71(15), 1769–1776 (2011)

C. Freitag, V. Onuseit, R. Weber, T. Graf, High-speed observation of the heat flow in CFRP during laser processing. Phys Proc 39, 171–178 (2012)

L. Romoli, F. Fischer, R. Kling, A study on UV laser drilling of PEEK reinforced with carbon fibers. Opt Lasers Eng 50(3), 449–457 (2012)

R. Staehr, S. Bastick, S. Bluemel, P. Jaeschke, O. Suttmann, J.P. Negel, V. Angrick, C. Stolzenburg, S. Kaierle, L. Overmeyer, High precision laser macrodrilling of carbon fiber reinforced plastics with a new nanosecond pulsed laser—optimized toward industrial needs. J Laser Appl 31(2), 022207 (2019)

Z.L. Li, H.Y. Zheng, G.C. Lim, P.L. Chu, L. Li, Study on UV laser machining quality of carbon fibre reinforced composites. Compos Part A Appl S 41(10), 1403–1408 (2010)

M.J. Li, S. Li, X.J. Yang, Y. Zhang, Z.C. Liang, Fiber laser cutting of CFRP laminates with single- and multi-pass strategy: a feasibility study. Opt Laser Technol 107, 443–453 (2018)

K. Takahashi, M. Tsukamoto, S. Masuno, Y. Sato, H. Yoshida, K. Tsubakimoto, H. Fujita, N. Miyanaga, M. Fujita, H. Ogata, Influence of laser scanning conditions on CFRP processing with a pulsed fiber laser. Int J Adv Manuf Tech 222, 110–121 (2015)

A. Salama, L. Li, P. Mativenga, A. Sabli, High-power picosecond laser drilling/machining of carbon fibre-reinforced polymer (CFRP) composites. Appl Phys A Mater 122(2), 73 (2016)

P. Sheng, G. Chryssolouris, Theoretical-model of laser grooving for composite-materials. J Compos Mater 29(1), 96–112 (1995)

R. Weber, C. Freitag, T.V. Kononenko, M. Hafner, V. Onuseit, P. Berger, T. Graf, Short-pulse laser processing of CFRP. Laser Assist Net Shape Eng 7(39), 137–146 (2012)

C.F. Cheng, Y.C. Tsui, T.W. Clyne, Application of a three-dimensional heat flow model to treat laser drilling of carbon fibre composites. Acta Mater 46(12), 4273–4285 (1998)

J.E.J. Staggs, Short communication: approximate solutions for the pyrolysis of char forming and filled polymers under thermally thick conditions. Fire Mater 24(6), 305–308 (2000)

C.T. Pan, H. Hocheng, The anisotropic heat-affected zone in the laser grooving of fiber-reinforced composite material. Int J Adv Manuf Tech 62(1–3), 54–60 (1996)

H.B. Xu, J. Hu, Z. Yu, Absorption behavior analysis of carbon fiber reinforced polymer in laser processing. Opt Mater Exp 5(10), 2330–2336 (2015)

J.M. Li, C.H. Lu, J.Q. Zhang, Y.S. Wu, Computational and experimental investigations of laser marking on 6061 aluminium alloy. Lasers Eng 33(1–3), 17–29 (2016)

C. Leone, I. Papa, F. Tagliaferri, V. Lopresto, Investigation of CFRP laser milling using a 30W Q-switched Yb:YAG fiber laser: Effect of process parameters on removal mechanisms and HAZ formation. Compos Part A Appl Sci Manuf 55, 129–142 (2013)

W. Johannes, F. Michael and P. Justinian, Remote laser cutting of CFRP: influence of the edge quality on fatigue strength, in Proceedings of SPIE—The International Society for Optical Engineering (2014)

Acknowledgements

This project is supported by the Fundamental Research Funds for the Central Universities (Grant No. 2232020D-28 and No. 2232018A3-08). It is also supported by Initial Research Funds for Young Teachers of Donghua University.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yu, Z., Xu, L., Cao, W. et al. Study on picosecond laser processing of blind holes in carbon fiber-reinforced plastics. Appl. Phys. A 126, 944 (2020). https://doi.org/10.1007/s00339-020-04020-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-020-04020-4