Abstract

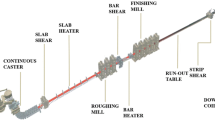

For the production of high-strength reinforcing bars with a diameter of 9.5 mm from C86D steel, cold-formed rebar with a diameter of 9.7 mm was used, made according to the direct drawing scheme from hot-rolled coiled steel with a diameter of 16.0 mm, which was subjected to cold profiling with a dent depth of 0.20 mm in an idle three-roller stand and subsequent stabilization at a temperature of 390 ± 10°C with a specific technological tension of 480 MPa. The power parameters of the application of a periodic profile on the conversion workpiece, the maximum value of the forces acting on the rollers, as well as the values of the required pulling force, have been determined. It has been experimentally shown that a 5.0% decrease in the idle cross-section of a reinforcing bar after deposition of indentations and stabilization is compensated by an increase in σu and σ0.2 by 4.6 and 8.7%, respectively. It has been shown that correction of roll adjustment is necessary during the line riding period and development of process tension. The proposed methodological approach with the use of modeling makes it possible to design equipment for the profiling of rebar integrated into the line of the stabilization section with a pulling device.

Similar content being viewed by others

REFERENCES

Chukin, M.V., Proizvodstvo vysokoprochnoi stal’noi armatury dlya zhelezobetonnykh shpal novogo pokoleniya (Production of High-Strength Steel Armature for New Generation Reinforced Concrete Sleepers), Moscow: Metallurgizdat, 2014.

Zvezdov, A.I., 21st Century as an era of concrete and reinforced concrete, Beton Zhelezobeton, 2001, no. 1, pp. 4–6.

Parusov, E.V., Sychkov, A.B., Chuiko, I.N., et al., Technology of quasi-patenting of large coiled steel in the stream of the Stelmore line, Metall. Gornorudn. Prom-st’, 2016, no. 3, pp. 96–101.

Parusov, E.V., Gubenko, S.I., Klimenko, A.P., et al., Specific kinetics of decomposition of austenite and the structure of C82DCr steel under continuous cooling, Vestn. Pridneprovskoi Gos. Akad. Stroit. Arkhit., 2017, no. 6 (235–236), pp. 27–36.

Parusov, E.V., Gubenko, S.I., Klimenko, A.P., et al., Specific kinetics of decomposition of austenite and the structure of C82DCrV steel under continuous cooling, Vestn. Pridneprovskoi Gos. Akad. Stroit. Arkhit., 2018, no. 1 (237–238), pp. 42–51.

Parusov, E.V., Klimenko, A.P., Lutsenko, V.A., et al., Influence of heating temperature on the kinetics of austenite decomposition of C82DV high-carbon steel, Metalozn. Obrob. Met., 2018, no. 1 (80), pp. 34–42.

Biba, N.V., Lishnii, A.I., and Stebunov, S.A., Calculation of tools and pressing technology of profiles using the QForm software, Tsvetn. Met., 2009, no. 10, pp. 83–87.

Levanov, A.N., Kolmogorov, V.L., Burkin, S.P., et al., Kontaktnoe trenie v protsessakh obrabotki metallov davleniem (Contact Friction during Pressing of Metals), Moscow: Metallurgiya, 1976.

Dolgii, D.K., Korchunov, A.G., and Baryshnikov, M.P., Modeling of the stabilization of high-strength cold-deformed reinforcement, Vestn. Magnitogorsk. Gos. Tekh. Univ. im. G.I. Nosova, 2012, no. 2, pp. 43–45.

Parusov, E.V., Sychkov, A.B., Gubenko, S.I., et al., On addiction the rolled steel to strain aging at drawing process, Probl. Tribol., 2016, no. 4, pp. 31–40.

Vinogradov, V.V., Geomekhanika upravleniya sostoyaniem massiva vblizi gornykh vyrabotok (Geomechanics of Rock Mass Control near Mine Works), Kiev: Naukova Dumka, 1989.

Levchenko, G.V., Vorobei, S.A., Demina, E.G., et al., Quality of reinforced bars for the manufacture of an anchoring tier for mining works, Metall. Gornorudn. Prom-st’, 2005, no. 5, pp. 29–33.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by A. Muravev

About this article

Cite this article

Prikhod’ko, I.Y., Parusov, E.V., Parusov, O.V. et al. Elements of Technology for Producing Cold-Formed Rebar from C86D Steel Using an Idle Stand. Steel Transl. 50, 481–486 (2020). https://doi.org/10.3103/S0967091220070116

Received:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0967091220070116