Abstract

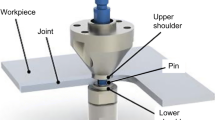

In this paper, we study the effect of welding modes with subsequent isothermal exposure on the quality parameters of the welded joint under laboratory conditions using rail steel samples. Welding of the samples was performed by passing pulses of alternating electric current after welding. Welding was carried out using an MS-2008M resistance butt welding machine with several changes in the control actions. Chromel–alumel thermocouples were used to measure the metal temperature in the heat-affected zone (HAZ). The collection and processing of data from thermocouples was performed using the “Tempol” measuring complex. The temperature of the metal of the welded seam (where it is not possible to install a thermocouple) was measured using a HotFind-D thermal imager. Experimental results and physical and mechanical properties of samples: hardness HB, HAZ length, yield strength, ultimate strength, relative elongation, relative narrowing, and presence of non-metallic inclusions in weld metal are presented. The calculation of hardness deviations (decrease–increase, total deviation) on the surface of the welded joint of the samples was carried out in relation to the requirements established by GOST R 51685–2013. A resistance butt welding method that allows obtaining a welded joint of products from rail steel with a uniform distribution of hardness and a small HAZ is proposed. The dependence of microhardness on the volume fraction of structural components was determined. The effect of the parameters of pulse contact post-weld heating on the decrease in the hardness of the welded joint metal relative to the hardness of the base metal and on the length of the HAZ are modeled. The proposed method allows regulating the metal structure of the welded joint of the rails without resorting to additional local heat treatment.

Similar content being viewed by others

REFERENCES

Protopopov, E.V., Kozyrev, N.A., Shevchenko, R.A., Krat’ko, S.N., and Khomicheva, V.E., RF Patent 2683668, 2019.

Adler, Yu.P., Markova, E.V., and Granovskii, Yu.V., Planirovanie eksperimenta pri poiske optimal’nykh uslovii (Planning an Experiment to Find Optimal Conditions), Moscow: Nauka, 1976.

Gmurman, V.E., Teoriya veroyatnostei i matematicheskaya statistika (Theory of Probability and Mathematical Statistics), Moscow: Vysshaya Shkola, 2003.

Gmurman, V.E., Rukovodstvo k resheniyu zadach po teorii veroyatnostei i matematicheskoi statistike (Manual on Problem Solving in Probability Theory and Mathematical Statistics), Moscow: Vysshaya Shkola, 1979.

Venttsel’, E.S., Teoriya veroyatnostei (Probability Theory), Moscow: Vysshaya Shkola, 1999.

Venttsel’, E.S. and Ovcharov, L.A., Teoriya veroyatnostei i ee inzhenernye prilozheniya (Probability Theory and Its Engineering Applications), Moscow: Akademiya, 2003.

Kostin, V.N. and Tishina, N.A., Statisticheskie metody i modeli: uchebnoe posobie (Statistical Methods and Models: Manual), Orenburg: Orenb. Gos. Univ., 2004.

Myers, J., Geiger, G.H., and Poirier, D.R., Structure and properties of thermite welds in rails, Weld. J., 1982, vol. 61, no. 8, pp. 258–268.

Volchenko, V.N., Yampol’skii, V.M., Vinokurov, V.A., et al., Teoriya svarochnykh protsessov: uchebnik dlya vuzov (Theory of Welding Processes: Manual for Higher Education Institutions), Frolov, V.V., Ed., Moscow: Vysshaya Shkola, 1988.

Nerovnyi, V.M., Konovalov, A.V., Yakushin, B.F., et al., Teoriya svarochnykh protsessov: uchebnik (Theory of Welding Processes: Manual), Nerovnyi, V.M., Ed., Moscow: Mosk. Gos. Tekh. Univ. im. N.E. Baumana, 2016.

Weingrill, L., Krutzler, J., and Enzinger, N., Temperature field evolution during flash-butt welding of railway rails, Mater. Sci. Forum, 2017, vol. 879, pp. 2088–2093.

Yamamoto, R., Komizu, Y., and Fukada, Y., Experimental examination for understanding of transition behavior of oxide inclusions on gas pressure weld interface: joining phenomena of gas pressure welding, Weld. Int., 2014, vol. 28, no. 7, pp. 510–520.

Mitsuru, F., Hiroaki, N., and Kiyoshi, N., Rail flash-butt welding technology, JFE Tech. Rep., 2015, no. 20, pp. 159–163.

Saita, K., Karimine, K., Ueda, M., Iwano, K., Yamamoto, T., and Hiroguchi, K., Trends in rail welding technologies and our future approach, Nippon Steel Sumitomo Met. Tech. Rep., 2013, no. 105, pp. 84–92.

Dahl, B., Mogard, B., Gretoft, B., and Ulander, B., Repair of rails on-site by welding, Svetsaren, 1995, vol. 50, no. 2, pp. 10–14.

Takimoto, T., Latest welding technology for long rail and its reliability, Tetsu-to-Hagane, 1984, vol. 70, no. 10, pp. 40–45.

Tachikawa, H., Uneta, T., and Nishimoto, H., Steel welding technologies for civil construction applications, Nippon Steel Tech. Rep., 2000, vol. 82, no. 7, pp. 35–41.

Okumura, M., Karimine, K., Uchino, K., and Yurioka, N., Development of field fusion welding technology for railroad rails, Nippon Steel Tech. Rep., 1995, vol. 65, no. 4, pp. 41–49.

Altemühl, B., Welding tramway rails in Bucharest, Svetsaren, 2002, vol. 52, no. 2, pp. 32–35.

Kozyrev, N.A., Shevchenko, R.A., Usol’tsev, A.A., Prudnikov, A.N., and Bashchenko, L.P., Development and modeling of differentially heat-strengthened rail welding: welding and local heat treatment modeling, Steel Transl., 2020, vol. 50, no. 3, pp. 139–145.

Funding

This study was supported by the Russian Foundation for Basic Research and the Kemerovo oblast, project no. 20-48-420003 r_a, “Development of Physicochemical and Technological Foundations for Creating a Fundamentally New Method of Welding Differentially Heat-Strengthened Railroad Rails.”

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated by A. Ivanov

About this article

Cite this article

Kozyrev, N.A., Shevchenko, R.A., Usol’tsev, A.A. et al. Development and Modeling of Welding Differentially Heat-Strengthened Railway Rails. Laboratory Studies. Steel Transl. 50, 438–444 (2020). https://doi.org/10.3103/S0967091220070086

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0967091220070086