Abstract

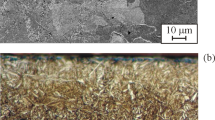

The method of magnetron sputtering of a ZrB2–20% Si target was used to obtain coatings on substrates of molybdenum, chromium, and hard alloy. The composition, structure and tribological properties of the coatings have been studied. The influence of physical and mechanical properties of substrates on the behavior of coatings under friction sliding and impact of impact dynamic loading is established. The coating had a low-defect structure and contained a hexagonal ZrB2 phase with a crystallite size of 15–30 nm. Tribological tests of the substrates showed that, at a load of 1 N, the friction coefficient was in the range of 0.6–0.8. After coating, this value was 0.7–0.75. When using a hard alloy as a substrate in the tribocontact zone, brittle destruction of the coating was observed at the lowest penetration depth of the counterbody. In the case of coatings on substrates with low hardness and modulus of elasticity, the maximum wear depth was reached, there was a pronounced deformation, and the portion of the plastic component was reduced after coating. The resistance of substrates to impact dynamic loading at 100, 300, and 500 N regularly increased with an increase in their hardness and plasticity index. The coating obtained on a carbide substrate with a hardness of 19 GPa and a plasticity index of 0.03 showed a crater depth of 0.45 μm, which is 16 and 5 times less than for coatings on molybdenum and chromium alloys.

Similar content being viewed by others

REFERENCES

Broitman, E., Tengdelius, L., Hangen, U.D., et al., Scr. Mater., 2016, vol. 124, p. 117.

Tengdelius, L., Broitman, E., Lu, J., et al., Acta Mater., 2016, vol. 111, p. 166.

Tay, C.Y., Harris, I.R., and Wright, S.J., J. Electron. Mater., 1989, vol. 18, p. 511.

Choi, H., Jang, J., Zhang, T., et al., Surf. Coat. Technol., 2014, vol. 259, p. 707.

Ren, X., Shi, H., Wang, W., et al., J. Eur. Ceram. Soc., 2020, vol. 40, p. 203.

Kiryukhantsev-Korneev, Ph.V., Iatsyuk, I.V., Shvindina, N.V., et al., Corros. Sci., 2017, vol. 123, p. 319.

Ren, X., Sun, X., Wang, W., et al., J. Alloys Compd., 2018, vol. 769, p. 387.

Aliasgarian, R., Naderi, M., Mirsalehi, S.E., et al., J. Alloys Compd., 2018, vol. 742, p. 797.

Yao, X., Li, H., Zhang, Y., et al., Ceram. Int., 2012, vol. 38, p. 2095.

Jinyuan, M., Min, L., Chunming, D., et al., Rare Met. Mater. Eng., 2016, vol. 45, p. 1386.

Dou, H., Qiangang, F., Tianyu, L., and Mingde, T., J. Eur. Ceram. Soc., 2020, vol. 40, p. 212.

Yanjiao, Y., Mingjiang, D., Chunbei, W., et al., Rare Met. Mater. Eng., 2017, vol. 46, p. 3663.

Li, J., Zhang, Y., Wang, H., et al., J. Alloys Compd., 2020, vol. 824, p. 153934.

Ren, Y., Qian, Y., Xu, J., et al., Ceram. Int., 2019, vol. 45, no. 12, p. 15366.

Wang, Z., Niu, Y., Hu, C., et al., Ceram. Int., 2015, vol. 41, p. 14868.

Kudryashov, A.E., Kiryukhantsev-Korneev, Ph.V., Petrzhik, M.I., et al., CIS Iron Steel Rev., 2019, vol. 18, p. 46.

Iatsyuk, I.V., Lemesheva, M.V., Kiryukhantsev-Korneev, Ph.V., et al., IOP Conf. Ser.: Mater. Sci. Eng., 2018, vol. 347, p. 012028.

Kiryukhantsev-Korneev, F.V., Lemesheva, M.V., Shvindina, N.V., et al., Prot. Met. Phys. Chem. Surf., 2018, vol. 54, no. 6, p. 1147.

Kiryukhantsev-Korneev, F.V. and Yatsyuk, I.V., Phys. At. Nucl., 2019, vol. 82, no. 11, p. 1437.

Shtansky, D.V., Petrzhik, M.I., Bashkova, I.A., et al., Phys. Solid State, 2006, vol. 48, no. 7, p. 1301.

Levashov, E.A., Petrzhik, M.I., Shtansky, D.V., et al., Mater. Sci. Eng., A, 2013, vol. 570, p. 51.

Shtansky, D.V., Kulinich, S.A., Levashov, E.A., et al., Thin Solid Films, 2012, vols. 420–421, p. 330.

Saha, R. and Nix, W.D., Acta Mater., 2002, vol. 50, p. 23.

Kiryukhantsev-Korneev, F.V. and Petrzhik, M.I., Nanotekhnol.:Nauka Proizvod., 2018, vol. 1, p. 3.

Kiryukhantsev-Korneev, F.V., Sheveiko, A.N., Komarov, V.A., et al., Russ. J. Non-Ferrous Met., 2011, vol. 52, p. 311.

Kiryukhantsev-Korneev, Ph.V., Pierson, J.F., Kuptsov, K.A., et al., Appl. Surf. Sci., 2014, vol. 314, p. 104.

Metotechnics. https://www.metotech.ru/molibden-opisanie.htm.

Kashirtsev, V.V., Cand. Sci. (Eng.) Dissertation, Moscow, 2014.

Kuksenova, L.I., Iznosostoikost’ konstruktsionnykh materialov. Uchebnoe posobie (Wear-Resistance of Structure Materials), Moscow: Bauman Moscow State Technical Univ., 2011.

Kiryukhantsev-Korneev, Ph.V. and Sheveiko, A.N., Prot. Met. Phys. Chem. Surf., 2018, vol. 54, p. 963.

Xi, H.-H., He, P.-F., Wang, H.-D., et al., Int. J. Refract. Met. Hard Mater., 2020, vol. 86, p. 05095.

Kumar, D.D., Kumar, N., Kalaiselvam, S., et al., Ceram. Int. 2015, vol. 41, p. 9849.

Picas, J.A., Forn, A., Baile, M.T., and Martín, E., Int. J. Refract. Met. Hard Mater., 2005, vol. 23, p. 330.

Leyland, A. and Matthews, A., Wear, 2000, vol. 246, p. 1.

ACKNOWLEDGMENTS

The authors are grateful to P. Loginov and D. Sidorenko for their help in conducting the TEM studies.

Funding

This work was financially supported by the Russian Foundation for Basic Research within the framework of project no. 19-08-00187.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by V. Selikhanovich

Rights and permissions

About this article

Cite this article

Kiryukhantsev-Korneev, P.V., Sytchenko, A.D. Influence of Physical and Mechanical Properties of the Substrate on the Behavior of Zr–Si–B Coatings under Sliding Friction and Cyclic Impact-Dynamic Loading. Prot Met Phys Chem Surf 56, 981–989 (2020). https://doi.org/10.1134/S2070205120050160

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S2070205120050160