Abstract

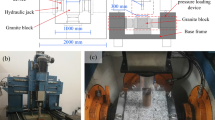

The core-disk phenomenon has been observed generally in the drilling process under high-stress conditions. This paper presents the in-situ experimental study of the coring-disking failure mechanism of marble in an underground cavens with 2400 m depth. Based on the disk samples in several boreholes with different diameters, both macro- and micro-morphological characteristics of core-disks’ break surface were analysis, using 3D optical scanning and electron microscope scanning. Moreover, the numerical back analysis was also used to simulate the drilling process for demonstrating the development of core disking. The in-situ experiment results showed that the failure types of core disking consisted of tensile break and shear break, i.e., the shear break usually appears in the edge part of break surface, and tensile break appears in the central part. What’s more, the ration of core-disks thickness to borehole diameter is in a relatively stable range. Numerical back analysis indicated this micro asynchronous break of hard marble is induced by high geostress and unloading drill.

摘要

高应力条件下钻孔过程中, 岩芯饼化体现了深部岩体一种典型的破裂模式. 本文依托埋设达 2400m 的中国锦屏深部地下实验室, 通过现场试验揭示了锦屏大理岩饼化的原位规律和破裂机制. 首先基于现场不同孔径钻孔的饼化岩芯, 通过宏观饼厚统计、细观 3D 激光扫描和微观电镜观察, 揭示了饼化岩芯破坏面的多尺度宏细观形貌特征; 进而通过数值方法模拟钻进过程中岩芯的局部应力应变演化特征和饼化动态发展过程. 分析揭示岩芯饼化破裂同时包含了张拉破裂和剪切破裂,剪切破裂多出现于岩饼的边缘部位而张拉破裂多出现于岩饼的中心部位; 而且不同直径钻孔岩饼统计表明饼化岩芯厚度与直径的比值基本不变. 综合研究表明外部高应力环境和钻进过程中岩芯自身局部卸荷与应力 集中是导致大理岩微观上异步饼化破裂的关键驱动因素.

Similar content being viewed by others

References

FAIRHURST C, COOK N G W. The phenomenon of rock Splitting parallel to the direction of maximum compression in the neighbourhood of a surface [C]// 1st ISRM Congress 1966. Lishon: ISRM, 1966.

ORTLEPP W D, STACEY T R. Rockburst mechanisms in tunnels and shafts [J]. Tunnelling and Underground Space Technology, 1994, 9(1): 59–65. DOI: https://doi.org/10.1016/0886-7798(94)90010-8.

JIANG Q, FENG X T, LI S J, SU G S, XIAO Y X. Cracking-restraint design method for large underground caverns with hard rock under high geostress condition and its practical application [J]. Chinese Journal of Rock Mechanics and Engineering, 2019, 38(6): 1081–1100. DOI: https://doi.org/10.13722/j.cnki.jrme.2018.1147. (in Chinese)

LUO Yong, GONG Feng-qiang, LI Xi-bing, WANG Shan-yong. Experimental simulation investigation of influence of depth on spalling characteristics in circular hard rock tunnel [J]. Journal of Central South University, 2020, 27(3): 891–910. DOI: https://doi.org/10.1007/s11771-020-4339-5

BRADY B H G, BROWN E T. Monitoring rock mass performance [M]// Rock Mechanics. Dordrecht: Springer Netherlands, 1999: 491–517.

MATSUKI K, KAGA N, YOKOYAMA T, TSUDA N. Determination of three dimensional in situ stress from core discing based on analysis of principal tensile stress [J]. International Journal of Rock Mechanics and Mining Sciences, 2004, 41(7): 1167–1190. DOI: https://doi.org/10.1016/j.ijrmms.2004.05.002.

FENG Guang-liang, FENG Xia-ting, CHEN Bing-rui, XIAO Ya-xun, ZHAO Zhou-neng. Effects of structural planes on the microseismicity associated with rockburst development processes in deep tunnels of the Jinping-II Hydropower Station, China [J]. Tunnelling and Underground Space Technology, 2019, 84: 273–280. DOI: https://doi.org/10.1016/j.tust.2018.11.008.

JIANG Quan, SU Guo-shao, FENG Xia-ting, CHEN Guo-qing, ZHANG Mei-zhu, LIU Chang. Excavation optimization and stability analysis for large underground Caverns under high geostress: A case study of the Chinese laxiwa project [J]. Rock Mechanics and Rock Engineering, 2019, 52(3): 895–915. DOI: https://doi.org/10.1007/s00603-018-1605-z.

ZHAO Guo-qing, YANG Yu-you, MENG Su-yun. Failure of circular shaft subjected to hydraulic uplift: Field and numerical investigation [J]. Journal of Central South University, 2020, 27(1): 256–266. DOI: https://doi.org/10.1007/s11771-020-4293-2.

JIANG Quan, YANG Bing, YAN Fei, LIU Chang, SHI Yin-gen, LI Li-fu. New method for characterizing the shear damage of natural rock joint based on 3D engraving and 3D scanning [J]. International Journal of Geomechanics, 2020, 20(2): 06019022. DOI: https://doi.org/10.1061/(ASCE)GM.1943-5622.0001575.

CUNDALL P, POTYONDY D, LEE C. Micromechanics-based models for fracture and breakout around the mine-by tunnel [C]// Proceedings, International Conference on Deep Geological Disposal of Radioactive Waste, Winnipeg. Edited by MARTINO J B and MARTIN C D. Toronto: Canadian Nuclear Society, 1996: 113–122.

MARTINI C D, READ R S, MARTINO J B. Observations of brittle failure around a circular test tunnel [J]. International Journal of Rock Mechanics and Mining Sciences, 1997, 34(7): 1065–1073. DOI: https://doi.org/10.1016/S1365-1609(97)90200-8.

JIANG Quan, LIU Xiao-pei, YAN Fei, YANG Yao, XU Ding-ping, FENG Guang-liang. Failure performance of 3DP physical twin-tunnel model and corresponding safety factor evaluation [J]. Rock Mechanics and Rock Engineering, 2020 (Online). DOI:https://doi.org/10.1007/s00603-020-02244-7.

GONG Feng-qiang. Experimental simulation and investigation of spalling failure of rectangular tunnel under different three-dimensional stress states [J]. International Journal of Rock Mechanics and Mining Sciences, 2019, 122: 104081. DOI: https://doi.org/10.1016/j.ijrmms.2019.104081.

LEMPP C H, MUHLHAUS H B. Splitting and core disking in deep boreholes [C]// 2nd Int Symp on Observation of the Continental Crust through Drilling. 1985: 94.

LI Yong-yi, SCHMITT D R. Drilling-induced core fractures and in situ stress [J]. Journal of Geophysical Research: Solid Earth, 1998, 103(B3): 5225–5239. DOI: https://doi.org/10.1029/97JB02333.

BAUCH E, LEMPP C. Rock splitting in the surrounds of underground openings: An experimental approach using triaxial extension tests [M]. Engineering Geology for Infrastructure Planning in Europe, 2004: 244–254. DOI: https://doi.org/10.1007/978-3-540-39918-629.

CORTHÉSY R, LEITE M H. A strain-softening numerical model of core discing and damage [J]. International Journal of Rock Mechanics and Mining Sciences, 2008, 45(3): 329–350. DOI: https://doi.org/10.1016/j.ijrmms.2007.05.005.

JAEGER J C, COOK N G W. Pinching-off and disking of rocks [J]. Journal of Geophysical Research Atmospheres, 1963, 68(6): 1759–1765. DOI: https://doi.org/10.1029/JZ068i006p01759.

OBERT L, STEPHENSON D. Stress condition under which core discing occurs [J]. Society of Mining Engineers of AIME Transactions, 1965, 232(3): 227–235.

LIM S S, MARTIN C D. Core disking and its relationship with stress magnitude for Lac du Bonnet granite [J]. International Journal of Rock Mechanics and Mining Sciences, 2010, 47(2): 254–264. DOI: https://doi.org/10.1016/j.ijrmms.2009.11.007.

KAGA N, MATSUKI K, SAKAGUCHI K. The in situ stress states associated with core discing estimated by analysis of principal tensile stress [J]. International Journal of Rock Mechanics and Mining Sciences, 2003, 40(5): 653–665. DOI: https://doi.org/10.1016/S1365-1609(03)00057-1.

LI Z H, FENG X T, LI S J, ZHOU H, CHEN B D, ZHANG C Q. Characteristics and formation mechanism of core discing in deep rock mass [J]. Chinese Journal of Rock Mechanics & Engineering, 2011, 30(11): 2254–2266. http://www.rockmech.org/CN/Y2011/V30/I11/2254. (in Chinese)

YAN Peng, LU Wen-bo, HE Yan-li, ZHOU Wei, CHEN Ming, WANG Gao-hui. Coring damage mechanism of the Yan-Tang group marble: combined effect of stress redistribution and rock structure [J]. Bulletin of Engineering Geology and the Environment, 2016, 75(4): 1701–1716. DOI: https://doi.org/10.1007/s10064-015-0842-6.

FAKHIMI A, TAROKH A. Process zone and size effect in fracture testing of rock [J]. International Journal of Rock Mechanics and Mining Sciences, 2013, 60: 95–102. DOI: https://doi.org/10.1016/j.ijrmms.2012.12.044.

DARLINGTON W J, RANJITH P G, CHOI S K. The effect of specimen size on strength and other properties in laboratory testing of rock and rock-like cementitious brittle materials [J]. Rock Mechanics and Rock Engineering, 2011, 44(5): 513–529. DOI: https://doi.org/10.1007/s00603-011-0161-6.

CUNDALL P, PIERCE M, MAS IVARS D. Quantifying the size effect of rock mass strength [C]// Proceedings of the First Southern Hemisphere International Rock Mechanics Symposium. Australian Centre for Geomechanics, Perth, 2008: 16–19. DOI: https://doi.org/10.36487/ACG_repo/808_31.

FENG X J, WU S Y, LI S J, QIU S L, XIAO Y X, FENG G L, SHENG M B, ZENG X H. Comprehensive field monitoring of deep tunnels at Jinping underground laboratory (CJPL-II) in China [J]. Chinese Journal of Rock Mechanics and Engineering, 2016, 35(4): 649–657. DOI: https://doi.org/10.13722/j.cnki.jrme.2016.0048. (in Chinese)

ZHONG S, JIANG Q, FENG X T, LIU J G, LI S J, QIU S L, WU S Y. A case of in-situ stress measurement in Chinese Jinping underground laboratory [J]. Rock Soil Mech, 2018, 39: 356–366. DOI: https://doi.org/10.16285/j.rsm.2017.0336. (in Chinese)

LU Tong, GAO Ming-zhong, ZHANG Ru, XIE Jing, TAN Qiang, LU Yi-qiang, HE Zhi-qiang, WANG Wen-yong, PENG Gao-you. Exploration on stress mechanism of deep disked core [J]. Advanced Engineering Sciences, 2018, 50(5): 47–54. DOI: https://doi.org/10.15961/j.jsuese.201800445. (in Chinese)

JIANG Quan, FENG Xia-ting, XIANG Tian-bing, SU Guo-shao. Rockburst characteristics and numerical simulation based on a new energy index: a case study of a tunnel at 2500 m depth [J]. Bulletin of Engineering Geology and the Environment, 2010, 69(3): 381–388. DOI: https://doi.org/10.1007/s10064-010-0275-1.

Author information

Authors and Affiliations

Contributions

ZHONG Shan carried out the onsite experiment and wrote the content. JIANG Quan designed and organized the study and modified the content. LIU Chang, LI Shao-jun and QIN Wei-min took part in the experiment study. ZHOU Ji-fang and SUN Wen-liang provided the experimental site and equipment. All authors have read and approved the final manuscript.

Corresponding author

Additional information

Conflict of interest

ZHONG Shan, JIANG Quan, LIU Chang, LI Shao-jun, QIN Wei-min, ZHOU Ji-fang, and SUN Wen-liang declared that they have no conflicts of interest to this work.

Foundation item: Projects(U1965205, 51779251, 41672314) supported by the National Natural Science Foundation of China

Rights and permissions

About this article

Cite this article

Zhong, S., Jiang, Q., Liu, C. et al. In-site core disking phenomenon and break mechanism of hard marble: Investigation in 2400 m deep-buried underground laboratory. J. Cent. South Univ. Technol. 27, 2959–2970 (2020). https://doi.org/10.1007/s11771-020-4521-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-020-4521-9