Abstract

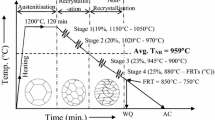

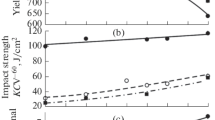

The concurrent use of micro-alloying additions and thermomechanical treatment is a common practice for obtaining high-quality grades of forged steels. Judicious use of chemistry, heat treatment schedule, and controlled processing can lead to a wide range of microstructure and thus final properties suitable for the production of different parts for the automobile industry. In this paper, thermomechanical treatment of Ni-added micro-alloyed steel containing Nb, V, Ti has been carried out with different deformation schedules (50-70%) at high temperatures followed by the varying cooling rate (i.e., forced air cooling, oil quenching, and water quenching). The cooling rates for three conditions were measured as 5 °C/s for forced air cooling, 40 °C/s for oil quenched, and 110 °C/s for water quenched samples. Thermomechanical and post-tempering treatment cycles were employed for the steel with 1150 and 900 °C as upper and lower forging temperatures. The best combination of properties viz; YS: 1044 MPa, UTS: 1308 MPa, % El: 16.7, %RA: 57 and Impact Toughness: 50 J/cm2 could be achieved for 70% deformed samples, followed by forced air cooling. The reasons have been attributed to the segregation of Ti & Nb carbides at grain boundaries as revealed by microstructural analysis. This has led to restriction of grain boundary coarsening at high temperatures. Further, fine vanadium carbide and the presence of retained austenite have contributed to improving the elongation and toughness values.

Similar content being viewed by others

References

N.J. Kim, The physical metallurgy of HSLA linepipe steels-a review, J. Met., 1983, 35, p 21–27

L.F. Porter and P.E. Repas, The evolution of HSLA steels, J. Met., 1983, 34, p 14–21

W. Roberts, “Recent innovations in alloy design and processing of micro-alloyed steels. in Conference Proceedings of International Conference on Technology and Applications of HSLA Steels, Philadelphia, Pennsylvania, ASM, October 1983, pp. 3–6.

J.H. Woodhead, “Review of principles of micro-alloyed bar & forging steels. in Proceedings of an International Symposium Sponsored by the Ferrous Metallurgy Committee of The Metallurgical Society held in Golden, Colorado, July 8–10, pp. 3–18 (1986).

C.J. Van Tyne, G. Krauss, and D.K. Matlock, Fundamentals & Applications of Micro-alloying Forging Steels, TMS, Warrendale, PA, 1996

G. Krauss and S.K. Banerjee, Fundamentals of Micro-alloying Forging Steels, Metallurgical Society, INC Colorado, Denver, 1986

F. Fazeli, B.S. Amirkhiz, C. Scott, M. Arafin, and L. Collins, Kinetics and microstructural change of low-carbon bainite due to vanadium micro-alloying, Mater. Sci. Eng. A, 2018, 720, p 248–256

P. Gong, E.J. Palmiere, and W.M. Rainforth, Thermo-mechanical processing route to achieve ultrafine grains in low carbon micro-alloyed steels, Acta Mater., 2016, 119, p 43–54

H. Xiang-dong, L. Lie-jun, P. Zheng-wu, and C. Song-jun, Effects of TMCP schedule onprecipitation, microstructure and properties of Ti-micro-alloyed high strength steel, J. Iron. Steel Res. Int., 2016, 23, p 593–601

W.B. Morrison, Microalloy steels—the beginning, Mater. Sci. Technol., 2009, 25, p 1066–1073

P. Wang, Z. Li, G. Lin, S. Zhou, C. Yang, and Q. Yong, Influence of vanadium on themicrostructure and mechanical properties of medium-carbon steels for wheels, Metals, 2018, 8, p 978

D. Stalheim, “The use of high temperature processing (HTP) for high strength oil and gas transmission pipeline applications”. in Proceedings of the 5th HSLA Steels Conference, Iron and Steel Supplement, vol. 40, pp. 699–704 (2005).

S. Jansto, The integration of process and product metallurgy in niobium bearing steels, Metals, 2018, 8, p 671

Y. Chen, D.T. Zhang, Y.C. Liu, H.J. Li, and D.K. Xu, Effect of dissolution andprecipitation of Nb on the formation of acicular ferrite/bainite ferrite in low-carbon HSLA steels, Mater. Charact., 2013, 84, p 232–239

J.M. Gray ‘Metallurgy of high-strength low-alloy pipeline steels: present and future possibilities’. Tech. Rep. 7201, Molycorp (1972).

T. Tanaka, Controlled rolling of steel plate and strip, Int. Met. Rev., 1981, 4, p 185–212

G.T. Eldis, W.C. Hagel, Effects of microalloying on the hardenability of steels. in Hardenability concepts with applications to steels ed. by D.V. Doane, J.S. Krikaldy (TMS-AIME, Warrendale, Pennsylvania, USA, 1977), pp. 397–415.

C.J. Van Tyne, D.K. Matlock, J.G. Speer, Microalloyed forging steels for automotive applications. in International Conference: Automotive Materials & Manufacturing—2010, pp. 51–56.

W.E. Heitman, P.B. Babu, Influence of bainite in the microstructure on tensile and toughness properties of microalloyed steels, bars & forgings. in Proceedings of an International Symposium Sponsored by the Ferrous Metallurgy Committee of The Metallurgical Society held in Golden, Colorado, July 8–10, pp. 55–72 (1986).

L. Sanz, B. Pereda, and B. López, Effect of thermo-mechanical treatment and coiling temperature on the strengthening mechanisms of low carbon steels micro alloyed with Nb, Mater. Sci. Eng. A, 2017, 685, p 377–390

H.K.D.H. Bhadeshia, R. Honeycombe, Steels microstructures and properties, fourth edition. Elsevier, ISBN: 978-0-08-100270-4. https://www.elsevier.com.

V.S.A. Challa, W.H. Zhou, R.D.K. Misra, R. O’Malley, and S.G. Jansto, The effect ofcoiling temperature on the microstructure and mechanical properties of a niobium–titanium microalloyed steel processed via thin slab casting, Mater. Sci. Eng. A, 2014, 595, p 143–153

T.N. Baker, Microalloyed steels, Ironmak. Steelmak., 2016, 4, p 264–307

ASTM International, Alloying in high-strength low-alloy steels: understanding the basics. Link: www.asminternational.org/bookstore,productcode:#06117G.

A.A. Gorni, Steel forming and heat treating handbook. São Vicente, Brazil, agorni@iron.com.br, www.gorni.eng.br. Version: 25 January 2012.

X.L. Li, C.S. Lei, X.T. Deng, Z.D. Wang, Y.G. Yu, G.D. Wang, and R.D.K. Misra, Precipitation strengthening in titanium microalloyed high-strength steel plates with newgeneration-thermo-mechanical controlled processing (NG-TMCP), J. Alloys Compd., 2016, 689, p 542–553

H.-J. Schüller, L. Hagn, and A. Woitschek, Der Maschinenschaden, 1974, 47, p 1–13

H. Kreye, I. Olefjord, and J. Löttgers, Arch. Eisenhüttenwesen, 1977, 48, p 291–295

M. Möser, V. Schmidt, Proc. 6th Int. Conf. Fracture, New Delhi 1984, Vol. 4, p. 24.

Fractography and Atlas of Fractographs. Metals Handbook, Vol. 9, 8th Edition. – Ohio: ASM 1974

F. Siciliano, High-strength linepipe steels and physical simulation of production processes. in Advanced High Strength Steel. Springer, Singapore, pp. 71–78 (2018).

L. Dongsheng, C. Binggui, and C. Yuanyan, Strengthening and toughening of a heavyplate steel for shipbuilding with yield strength of approximately 690 MPa, Metall. Mater. Trans. A, 2013, 44, p 440–445

S. Vervynckt, K. Verbeken, B. Lopez, and J.J. Jonas, Modern HSLA steels and role of non-recrystallisation temperature, Int. Mater. Rev., 2012, 57, p 187–207

D. Rasouli, Sh Khameneh Asl, A. Akbarzadeh, and G.H. Daneshi, Effect of cooling rate on the microstructure and mechanical properties of Microalloyed forging steel, J. Mater. Process. Technol., 2008, 206, p 92–98

A.D. Wilson, E.G. Hamburg, D.J. Colvin, S.W. Thompson, G. Krauss. in Proceedings of International Conference on Microalloyed HSLA Steel, Microalloying ’88. ASM INTERNATIONAL, Metals Park, OH, pp. 259–75 (1988).

S.W. Thompson, D.J. Kolvin, and G. Krauss, Metall. Mater. Trans. A, 1996, 27A, p 1554–1568

G.J.P. Buchi, J.H.R. Page, and M.P. Sidey, J. Iron Steel Inst., 1965, 203, p 291–299

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Roy, D., Gupta, A.K., Alam, M.S. et al. Enhancement of Properties of Micro-alloyed Low-Carbon Ni-Added Steel by Thermomechanical Treatment. J. of Materi Eng and Perform 29, 7952–7963 (2020). https://doi.org/10.1007/s11665-020-05311-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-05311-w