Abstract

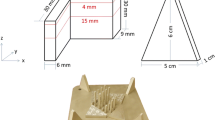

Published literature shows defect formation during laser powder bed fusion additive manufacturing (AM) of nickel base superalloys are sensitive to alloy chemistry, processing conditions, and geometry. In this work, ability to detect spatial distributions of defects is explored using in-situ monitoring of thermal signatures and surfaces. Simple and complex geometrical components were fabricated with CM247-LC® powder in an AM machine outfitted with optical and thermal sensors. The spatial and temporal variations of thermal signatures (peak intensity, decay, and number of gyrations), as well as, layer-by-layer optical images were analyzed. The observed thermal signatures were also verified with an analytical model for layer-wise heat transfer simulation that is sensitive to laser raster scan strategies. The cross-comparison data with reference to defects, obtained by X-ray tomography, were correlated with in-situ observations.

Similar content being viewed by others

Notes

Typical video from a cube geometry can be viewed in the following location: https://youtu.be/0WQTf7_KIBo.

Typical video from a cube geometry can be viewed in the following location: https://youtu.be/TbOMhSdNZlo

Online location for a typical output form SAHTM model for the current geometry https://youtu.be/d3Nx2P9dt2g.

Online movie of the IR data from complex geometries: https://youtu.be/ejCK1V-Sj1w

Online version of the in-situ optical image from the Eye Geometry: https://youtu.be/moylgF_TvBs

References

W. E. Frazier, D. Polakovics, and W. Koegel, JOM, 2001, pp. 16–18

K. Janssens, F. Lambert, S. Vanrostenberghe, and M. Vermeulen, Journal of Materials Processing and Technology, 2001, Vol. 112, pp. 174-184

J. J. Lewandowski and M. Seifi, Annu. Rev. Mater., 2016, Vol. 46, pp. 151-186

A. H. Chern, P. Nandwana, T. Yuan, M. M. Kirka, R. R. Dehoff, P. K. Liaw and C. E. Duty, International Journal of Fatigue, 2019, Vol. 119, pp. 173-184

B. H. Jared, M. A. Aguilo, L. L. Beghini, B. L. Boyce, B. W. Clark, A. Cook, B. J. Kehr, and J. Robbins, Scripta Materialia, 2017, Vol. 135, pp. 141-147

M. Seifi, A. Salem, J. Beuth, O. Harrison and J. J. Lewandowski, JOM, 2016, Vol. 68, pp. 747-764

W. E. Frazier, Journal of Materials Engineering and Performance, 2014, Vol. 23, pp. 1917-1928

Specification for fabrication of metal components using additive manufacturing, 1st Edition, AWS D20.1/D20.1M:2019, American Welding Society, 2019

S. Yoder, P. Nandwana, V. Paquit, M. Kirka, A. Scopel, R. R. Dehoff and S. S. Babu, Additive manufacturing, 2019, Vol. 28, pp. 98-106

S. Yoder, S. Morgan, E. Barnes, C. Kinzy, P. Nandwana, M. Kirka, S. S. Babu, V. Paquit, R. R. Dehoff, Additive Manufacturing, 2018, Vol. 19, pp. 184-196

C. Frederick, M. M. Kirka, M. Haines, A. Staub, E. J. Schwalbach, D. Cullen, and S. S. Babu, Metallurgical and Materials Transaction A, 2018, Vol. 49, pp. 5080-5096

Y. Lee, M. Kirka, S. Kim, N. Sridharan, A. Okello, R. R. Dehoff, and S. S. Babu, Metallurgical and Materials Transaction A, 2018, vol. 49, pp. 5065-5079

S. J. Foster, K. Carver, R. B. Dinwiddie, F. List III, K. A. Unocic, A. Chaudhary and S. S. Babu, Metallurgical and Materials Transactions A, 2018, Vol. 49, pp. 5775-5798

B. Baucher, A. B. Chaudhary, S. S. Babu and S. Chakraborty, Journal of Materials Engineering and Performance, 2019, Vol. 28, pp. 717-721

S. R. Higson, P. Drake, A. Lyons, A. Peyton and B. Lionheart, Ironmaking and Steelmaking, 2006, Vol. 33, pp. 357-361

M. Pliazhuk, C. Reyes, M. Martinez, J. Goldak, H. Nimrouzi and D. K. Aidun, Welding Journal, 2019, Vol. 98, pp. 251s-261s.

L. L. Simon, T. Merz, S. Dubuis, A. Lieb, K. Hungerbuhler, Chemical Engineering Research and Design, 2012, Vol. 90, pp. 1847-1855

S. K. Everton, M. Hirsch, P. Stravroulakis, R. K. Leach and A. T. Clare, Materials and Design, 2016, Vol. 95, pp. 431-445

P. Charalampous, I. Kostavelis and D. Tzovaras, Rapid Prototyping Journal, https://doi.org/10.1108/RPJ-08-2019-0224

A. Gaikwad, R. Yavari, M. Montazeri, K. Cole, L. Bian and P. Rao, IISE Transactions, 2020, https://doi.org/10.1080/24725854.2019.1701753

M. Grasso and M. Colosimo, Meas. Sci. Technol., 2017, Vol. 28, #044005

S. Clijsters, T. Craeghs, S. Buls, K. Kempen, J.-P. Kruth, The International Journal of Advanced Manufacturing Technology, 2014, Vol. 75, pp. 1089-1101

J. Raplee, A. Plotkowski, M.M. Kirka, R. Dinwiddie, A. Okello, R.R. Dehoff, S.S. Babu, Sci. Rep., 2017, Vol. 7, #43554

P. S. Mohanty and J. Mazumder, Metallurgical and Materials Transactions B, 1998, Vol. 29B, pp. 1269-1279

A. C. Hall and C. V. Robino, Science and Technology of Welding and Joining, 2004, Vol. 9, pp. 103-108

S. S. Babu, Welding Journal, 2018 Vol. 97, pp. 1s-16s

M. Grasso, V. Laguzza, Q. Semeraro, and B. M. Colosimo, J. Manuf. Sci. Eng., 2017, Vol. 139, #051001

S. S. Babu, N. Raghavan, J. Raplee, S. J. Foster, C. Frederick, M. Haines, R. Dinwiddie, M. M. Kirka, A. Plotkowski, Y. Lee and R. R. Dehoff, Metall. Mater. Trans. A., 2018, Vol. 49, pp. 3764 - 3780

X. Wang, L. N. Carter, B. Pang, M. M. Attallah and M. Loretto, Acta Materialia, 2017, Vol. 128, pp. 87-95

L. N. Carter, C. Martin, P. J. Withers, and M. M. Attallah, Journal of Alloys and Compounds, 2014, Vol. 615, pp. 338-347

Z. Feng, S. A. David, T. Zacharia, and C. L. Tsai, Science and Technology of Welding and Joining, 1992, Vol. 2, pp. 11-19

T. Zacharia, Welding Journal, 1994, Vol. 73, pp. 164s-172s

Park, J. -W., Vitek, J. M., Babu, S. S., and David, S. A., Science and Technology of Welding and Joining, 2004, 9, 472 – 482

J. Dupont, J. C. Lippold, and S. D. Kiser, “Welding Metallurgy and Weldability of Nickel base alloys,” 2009, John Wiley and Sons Inc., USA

S. Kou, “Welding Metallurgy”, Wiley: Hoboken, 2002

S. Chandrasekar, J. Coble, S. Yoder, P. Nandwana, R. Dehoff, V. Paquit, and S. S. Babu, Addit. Manuf., 2020, Vol. 32, # 100994

H. Schafstall, R. Assaker, and V. Mensing, “Additive Manufacturing 2020,” Hexagon and MSC Software, 2020

Johnson, Gordon R., and William H. Cook, Engineering fracture mechanics 21.1 (1985): 31-48

Deng, Dean, and Hidekazu Murakawa. Computational Materials Science 43.2 (2008): 353-365

Parry, L., I. A. Ashcroft, and R. D. Wildman. Addit. Manuf. 12 (2016): 1–15

O. Grong, “Metallurgical Modeling of Welding,” 2nd Edition, The Institute of Materials, London, 1997

M. G. Chapman, M. D. Uchic, J. M. Scott, M. N. Shah, S. P. Donegan, P. A. Shade, W. D. Musinski, M. Obstalecki, M. A. Groeber, D. Menasche, M. E. Cox, and E. J. Schwalbach, Microsc. Microanal., 2019, pp. 342–43

N. Otsu, IEEE Transactions on Systems, Man, and Cybernetics, 1979, Vol. 9, pp. 62-66

A. Plotkowski, M. M. Kirka, and S. S. Babu, Additive Manufacturing, 2017, Vol. 18, pp. 256-268

Saunders, N., et al., JOM, 55.12 (2003): 60-65

O. Grong, “The Mathematical modeling of welding,” 2nd Edition, The Institute of Materials, London, 1997

K. Masubuchi, “Analyses of welded structures,” Pergamon Press, New York, 1980

L. Scime and J. Beuth, Additive Manufacturing, 2018, Vol. 19, pp. 114-126

P. S. Korinko, J. T. Bobbitt III, M. J. Morgan, M. Reigel, F. A. List III, S. S. Babu, JOM, 2019, Vol. 71, pp. 1095-1104

M. P. Haines, N. J. Peter, S. S. Babu and E. A. Jägle, Addit. Manuf., 2020, Vol. 33, #101178

Acknowledgments

Authors thank Ms. Sujana Chandrasekhar for critical review of the document. This research was sponsored by Honeywell Aerospace and the physical experimentation was completed by support through the Manufacturing Demonstration Facility at Oak Ridge National Research Laboratory. SB also acknowledges partial support from the U.S. Department of Energy, Office of Energy Efficiency and Renewable Energy, Advanced Manufacturing Office, under contract DE-AC05-00OR22725 with UT- Battelle, LLC. This manuscript has been authored by UT-Battelle, LLC under Contract No. DE-AC05- 00OR22725 with the U.S. Department of Energy. The United States Government retains and the publisher, by accepting the article for publication, acknowledges that the United States Government retains a non-exclusive, paid-up, irrevocable, world-wide license to publish or reproduce the published form of this manuscript, or allow others to do so, for United States Government purposes. The Department of Energy will provide public access to these results of federally sponsored research in accordance with the DOE Public Access Plan (https://www.energy.gov/downloads/doe-public-access-plan). SB acknowledges the partial support from the US Department of the Navy, Office of Naval Research under ONR award number N00014-18-1-2794. Any opinions, findings, and conclusions or recommendations expressed in this material are those of the author(s) and do not necessarily reflect the views of the Office of Naval Research. Part of the research supported from the U.S. Department of Energy, Office of Energy Efficiency and Renewable Energy, Advanced Manufacturing Office, under contract DE-AC05-00OR22725 with UT-Battelle, LLC. This manuscript has been authored by UT-Battelle, LLC under Contract No. DE-AC05-00OR22725 with the U.S. Department of Energy. The United States Government retains and the publisher, by accepting the article for publication, acknowledges that the United States Government retains a non-exclusive, paid-up, irrevocable, world-wide license to publish or reproduce the published form of this manuscript, or allow others to do so, for United States Government purposes. The Department of Energy will provide public access to these results of federally sponsored research in accordance with the DOE Public Access Plan (https://www.energy.gov/downloads/doe-public-access-plan)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted May 17, 2020. Accepted September 15, 2020.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

McNeil, J.L., Sisco, K., Frederick, C. et al. In-Situ Monitoring for Defect Identification in Nickel Alloy Complex Geometries Fabricated by L-PBF Additive Manufacturing. Metall Mater Trans A 51, 6528–6545 (2020). https://doi.org/10.1007/s11661-020-06036-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-020-06036-0