Abstract

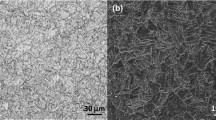

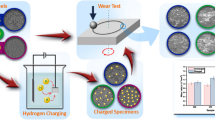

The CO2 corrosion behavior of V140 steel for oil country tubular goods exposed to high-temperature and pressure environment was studied by immersion corrosion experiments. The morphology, composition and elemental analysis of corrosion products were conducted by scanning electron microscope, x-ray diffractometer and electron probe micro-analyzer, respectively. The results showed that the corrosion rate gradually decreased and tended to be stable with the extension of corrosion time. The corrosion products in the initial stage were FeOOH and Fe2O3, and the final corrosion product was FeCO3. With the extension of corrosion time, corrosion products gradually became thick and dense from sparse. The fine and dense FeCO3 layer effectively improved the CO2 corrosion resistance of V140 steel.

Similar content being viewed by others

References

H. Li, Y. Zhang, and L. Han, Development Situation of OCTG and Production Localization of Hi-grade OCTG, Steel Pipe, 2008, 37(1), p 1–6

Z. Liu, Y. Chen, H. Hu, and L. Niu, The Domestic and Foreign Research Status of High Strength and High Toughness of OCTG, Petrol. Tubul. Goods Instrum., 2017, 3(6), p 5–8

M. Luo, M. Liu, X.T. Wang, M.C. Li, X. Li, Z.M. Ren, G.H. Cao, and Z.H. Zhang, Effect of Tempering Temperature at High Temperature Zone on Sulfide Stress Cracking Behavior for Casing Steel, Eng. Fail. Anal., 2019, 105, p 227–236

R.H. Huasler and D.E. Stenglnan, CO2 Corrosion and Its Prevention by Chemical Inhibition Oil and Gas Production, Corrosion, 1988, 44(1), p 5–9

M. Lu, Z. Bai, X. Zhao, G. Zhao, J. Luo, and C. Chen, Actuality and Typical Cases for Corrosion in the Process of Extraction, Gathering, Storage and Transmission for Oil and Gas, Corros. Prot., 2003, 23(3), p 105–112

Y. Li and J. Han, Research Progress and Prospect of the Application Technology of Tubing and Casings, Baosteel Technol., 2009, 6, p 27–31

B. Li, M. Luo, Z. Yang, F. Yang, H. Liu, H. Tang, Z. Zhang, and J. Zhang, Microstructure Evolution of the Semi-macro Segregation Induced Banded Structure in High Strength Oil Tubes During Quenching and Tempering Treatments, Materials, 2019, 12(20), p 3310

K. Deng, Y. Lin, J. Wang, W. Liu, and Y. Wei, Study on the Minimum Transverse Impact Toughness Required to Resist Cracking of Non-API, High Grade Steel Casing, Thin Wall. Struct., 2019, https://doi.org/10.1016/j.tws.2019.106368

J. Wang, K. Deng, Z. Yin, B. Liu, Y. Lin, and Y. Feng, Study of Technical Specifications for Non-API, 140 Casing in Ultra-Deep Well, Eng. Fail. Anal., 2019, 97, p 115–127

H.K. Abadeh and M. Javidi, Assessment and Influence of Temperature, NaCl and H2S on CO2 Corrosion Behavior of Different Microstructures of API, 5L X52 Carbon Steel in Aqueous Environments, J. Nat. Gas Sci. Eng., 2019, 67, p 93–107

L. Wei, X. Pang, C. Liu, and K. Gao, Formation Mechanism and Protective Property of Corrosion Product Scale on X70 Steel Under Supercritical CO2 Environment, Corros. Sci., 2015, 100, p 404–420

A. Kahyarian, M. Singer, and S. Nesic, Modeling of Uniform CO2 Corrosion of Mild Steel in Gas Transportation Systems: A Review, J. Nat. Gas Sci. Eng., 2016, 29, p 530–549

Z. Liu, X. Gao, L. Du, J. Li, X. Zhou, X. Wang, Y. Wang, C. Liu, G. Xu, and R.D.K. Misra, Hydrogen Assisted Cracking and CO2 Corrosion Behaviors of Low-Alloy Steel with High Strength Used for Armor Layer of Flexible Pipe, Appl. Surf. Sci., 2018, 440, p 974–991

T.C. Almeida, M.C.E. Bandeira, R.M. Moreira, and O.R. Mattos, New Insights on the Role of CO2 in the Mechanism of Carbon Steel Corrosion, Corros. Sci., 2017, 120, p 239–250

L. Wei, K. Gao, and Q. Li, Corrosion of Low Alloy Steel Containing 0.5% Chromium in Supercritical CO2-Saturated Brine and Water-Saturated Supercritical CO2 Environments, Appl. Surf. Sci., 2018, 440, p 524–534

R. Barker, D. Burkle, T. Charpentier, H. Thompson, and A. Neville, A Review of Iron Carbonate (FeCO3) Formation in the Oil and Gas Industry, Corros. Sci., 2018, 142, p 312–341

W. Li, L. Xu, L. Qiao, and J. Li, Effect of Free Cr Content on Corrosion Behavior of 3Cr Steels in a CO2 Environment, Appl. Surf. Sci., 2017, 425, p 32–45

P.A. Alaba, S.A. Adedigba, S.F. Olupinla, O. Agboola, and S.E. Sanni, Unveiling Corrosion Behavior of Pipeline Steels in CO2-Containing Oilfield Produced Water: Towards Combating the Corrosion Curse, Crit. Rev. Solid State Mater. Sci., 2020, 45(3), p 239–260

R.D. Motte, E. Basilico, R. Mingant, J. Kittel, F. Ropital, P. Combrade, S. Necib, V. Deydier, D. Crusset, and S. Marcelin, A Study by Electrochemical Impedance Spectroscopy and Surface Analysis of Corrosion Product Layers Formed During CO2 Corrosion of Low Alloy Steel, Corros. Sci., 2020, https://doi.org/10.1016/j.corsci.2020.108666

G.A. Zhang, D. Liu, Y.Z. Li, and X.P. Guo, Corrosion Behaviour of N80 Carbon Steel in Formation Water under Dynamic Supercritical CO2 Condition, Corros. Sci., 2017, 120, p 107–120

S.D. Zhu, A.Q. Fu, J. Miao, Z.F. Yin, G.S. Zhou, and J.F. Wei, Corrosion of N80 Carbon Steel in Oil Field Formation Water Containing CO2 in the Absence and Presence of Acetic Acid, Corros. Sci., 2011, 53, p 3156–3165

G.X. Zhao, X.H. Lu, J.M. Xiang, and Y. Han, Formation Characteristic of CO2 Corrosion Product Layer of P110 Steel Investigated by SEM and Electrochemical Techniques, J. Iron. Steel Res. Int., 2009, 16, p 89–94

D. Zhang, X. Gao, G. Su, Z. Liu, N. Yang, L. Du, and R.D.K. Misra, Effect of Tempered Martensite and Ferrite/Bainite on Corrosion Behavior of Low Alloy Steel Used for Flexible Pipe Exposed to High-Temperature Brine Environment, J. Mater. Eng. and Perform., 2018, 27(9), p 4911–4920

H. Antony, L. Legrand, L. Maréchal, S. Perrin, Ph Dillmann, and A. Chaussé, Study of Lepidocrocite γ-FeOOH Electrochemical Reduction in Neutral and Slightly Alkaline Solutions at 25 & #xB0;C, Electrochim. Acta, 2005, 51, p 745–753

D. de la Fuente, J. Alcántara, B. Chico, I. Díaz, J.A. Jiménez, and M. Morcillo, Characterisation of Rust Surfaces Formed on Mild Steel Exposed to Marine Atmospheres Using XRD and SEM/Micro-Raman Techniques, Corros. Sci., 2016, 110, p 253–264

M. Gao, X. Pang, and K. Gao, The Growth Mechanism of CO2 Corrosion Product Film, Corros. Sci., 2011, 53(2), p 557–568

F. Rouillard and T. Furukawa, Corrosion of 9-12Cr Ferritic-Martensitic Steels in High-Temperature CO2, Corros. Sci., 2016, 105, p 120–132

R.A. De Motte, R. Barker, D. Burkle, S.M. Vargas, and A. Neville, The Early Stages of FeCO3 Scale Formation Kinetics in CO2 Corrosion, Mater. Chem. Phys., 2018, 216, p 102–111

S. Guo, L. Xu, L. Zhang, W. Chang, and M. Lu, Characterization of Corrosion Scale Formed on 3Cr Steel in CO2-Saturated Formation Water, Corros. Sci., 2016, 110, p 123–133

T. Kamimura, S. Hara, H. Miyuki, M. Yamashita, and H. Uchida, Composition and Protective Ability of Rust Layer Formed on Weathering Steel Exposed to Various Environments, Corros. Sci., 2006, 48(9), p 2799–2812

Q.X. Li, Z.Y. Wang, W. Han, and E.H. Han, Characterization of the Rust Formed on Weathering Steel Exposed to Qinghai Salt Lake Atmosphere, Corros. Sci., 2008, 50(2), p 365–371

N. Zhang, D. Zeng, G. Xiao, J. Shang, Y. Liu, D. Long, Q. He, and A. Singh, Effect of Cl− Accumulation on Corrosion Behavior of Steels in H2S/CO2 Methyldiethanolamine (MDEA) Gas Sweetening Aqueous Solution, J. Nat. Gas Sci. Eng., 2016, 30, p 444–454

Q.Y. Liu, L.J. Mao, and S.W. Zhou, Effects of Chloride Content on CO2 Corrosion of Carbon Steel in Simulated Oil and Gas Well Environments, Corros. Sci., 2014, 84, p 165–171

Y. Hua, S. Xu, Y. Wang, W. Taleb, J. Sun, L. Zhang, R. Barker, and A. Neville, The Formation of FeCO3 and Fe3O4 on Carbon Steel and Their Protective Capabilities Against CO2 Corrosion at Elevated Temperature and Pressure, Corros. Sci., 2019, 157, p 392–405

D.Z. Zhang, X.H. Gao, L.X. Du, H.X. Wang, Z.G. Liu, N.N. Yang, and R.D.K. Misra, Corrosion Behavior of High-Strength Steel for Flexible Riser Exposed to CO2-Saturated Saline Solution and CO2-Saturated Vapor Environments, Acta Metall. Sin. Engl. Lett., 2019, 32(5), p 607–617

D.G. Li, Y.R. Feng, Z.Q. Bai, and M.S. Zheng, Characteristics of CO2 Corrosion Scale Formed on N80 Steel in Stratum Water with Saturated CO2, Appl. Surf. Sci., 2007, 253(3), p 8371–8376

L. Xu, B. Wang, J. Zhu, W. Li, and Z. Zheng, Effect of Cr Content on the Corrosion Performance of Low-Cr Alloy Steel in a CO2 Environment, Appl. Surf. Sci., 2016, 379, p 39–46

X.M. Xiao, Y. Peng, C.Y. Ma, and Z.L. Tian, Effects of Alloy Element and Microstructure on Corrosion Resistant Property of Deposited Metals of Weathering Steel, J. Iron. Steel Res. Int., 2016, 23, p 171–177

S. Jiang, F. Chai, H. Su, and C. Yang, Influence of Chromium on the Flow-Accelerated Corrosion Behavior of Low Alloy Steels in 3.5% NaCl Solution, Corros. Sci., 2017, 123, p 217–227

Y. Zhou, J. Chen, Y. Xu, and Z. Liu, Effects of Cr, Ni and Cu on the Corrosion Behavior of Low Carbon Microalloying Steel in a Cl− Containing Environment, J. Mater. Sci. Technol., 2013, 29(2), p 168–174

Acknowledgments

This work was supported by National High Technology Research and Development Program of China (Grant No. 2015AA03A501).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Gao, X., Zhang, D., Lu, Y. et al. CO2 Corrosion Behavior of High-Strength and Toughness V140 Steel for Oil Country Tubular Goods. J. of Materi Eng and Perform 29, 8451–8460 (2020). https://doi.org/10.1007/s11665-020-05306-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-05306-7