Abstract

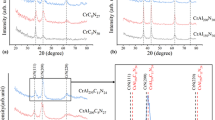

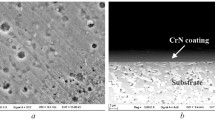

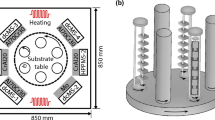

The cutting tool is prone to wear and failure during turning process, which affects the quality of the machined surface. In order to increase the hardness, wear resistance, and extend lifespan of the cutting tool, this work proposed a CrCN super-hard coating and optimized its parameters of preparation process. The CrCN super-hard coating was deposited on cemented carbides by radio frequency reactive magnetron sputtering. Cr3C2 (99.9%) was selected as the target, N2 and Ar as the reaction gas. The effects of power, N2/Ar flow ratio, deposition temperature, and deposition pressure on the properties of deposited CrCN super-hard coatings were investigated. The deposition rate, Vickers hardness, crystal degree, and surface morphology of the coating were comprehensive analyzed, and then, the optimal parameters for preparing CrCN super-hard coating were obtained: sputtering power of 300 W, N2/Ar gas flow ratio of 4/46 sccm, deposition temperature of 200 °C, and deposition pressure of 0.8 Pa. After measurement, the physical and mechanical properties of the CrCN super-hard coating were: the thickness of 1.8 μm, the hardness of 2700 HV, and the bonding force of 52 N.

Similar content being viewed by others

References

J. Kümmel, D. Braun, J. Gibmeier, J. Schneider, C. Greiner, V. Schulze, and A. Wanner, Study on Micro Texturing of Uncoated Cemented Carbide Cutting Tools for Wear Improvement and Built-Up Edge Stabilization, J. Mater. Process. Tech., 2015, 215, p 62–70

Y. Lian, C. Xie, C. Mu, S. Yang, and B. Yao, Preparation Technology of Micro-Textured Tools Fabricated by Inductively Coupled Plasma Etching, Surf. Coat. Technol., 2019, 370, p 177–186

Y. Xing, J. Deng, X. Wang, K. Ehmann, and J. Cao, Experimental Assessment of Laser Textured Cutting Tools in Dry Cutting of Aluminum Alloys, J. Manuf. Sci. E.-T. Asme, 2016, 138(7), p 071006

D.M. Kim, I. Lee, S.K. Kim, B.H. Kim, and H.W. Park, Influence of a Micropatterned Insert on Characteristics of the Tool-Workpiece Interface in a Hard Turning Process, J. Mater. Process. Tech., 2016, 229, p 160–171

W. Zhang, M. Yi, G. Xiao, J. Ma, G. Wu, and C. Xu, Al2O3-Coated h-BN Composite Powders and As-Prepared Si3N4-Based Self-Lubricating Ceramic Cutting Tool Material, Int. J. Refract. Met. H., 2018, 71, p 1–7

Y. Feng, J. Zhang, and L. Wang, Fabrication Techniques and Cutting Performance of Micro-Textured Self-Lubricating Ceramic Cutting Tools by In-Situ Forming of Al2O3-TiC, Int. J. Refract. Met. H., 2017, 68, p 121–129

J. Zuo, Y. Lin, J. Zheng, P. Zhong, and M. He, An investigation of Thermal-Mechanical Interaction Effect on PVD Coated Tool Wear for Milling Be/Cu Alloy, Vacuum, 2019, 167, p 271–279

G. Krolczyk, P. Nieslony, and S. Legutko, Microhardness And Surface Integrity in Turning Process of Duplex Stainless Steel (DSS) for Different Cutting Conditions, J. Mater. Eng. Perform., 2013, 23(3), p 859–866

A. Singh, S. Ghosh, and S. Aravindan, Flank wEar And Rake Wear Studies for arc Enhanced HiPIMS Coated AlTiN Tools During High Speed Machining of Nickel-Based Superalloy, Surf. Coat. Technol., 2019, 381, p 125190

K. Bobzin, High-Performance Coatings for Cutting Tools, CIRP J. Manuf. Sci. Tec., 2017, 18, p 1–9

M. Günay, M.E. Korkmaz, and N. Yaşar, Performance Analysis of Coated Carbide Tool in Turning of Nimonic 80A Superalloy Under Different Cutting Environments, J. Manuf. Process., 2020, 56, p 678–687

K.-D. Bouzakis, N. Michailidis, G. Skordaris, E. Bouzakis, D. Biermann, and R. M’Saoubi, Cutting with Coated Tools: Coating Technologies, Characterization Methods and Performance Optimization, CIRP Ann. Manuf. Technol., 2012, 61(2), p 703–723

P. Yan, J.X. Deng, Y.S. Lian, J. Zhao, Z. Chen, and X. Ai, Effect of Depositing Parameters on Microstructures and Properties of Multi Arc Ion Plating ZrTiN films, Surf. Eng., 2012, 28(1), p 17–23

Y.Y. Chang, Y.J. Yang, and S.Y. Weng, Effect of Interlayer Design on the Mechanical Properties of AlTiCrN and Multilayered AlTiCrN/TiSiN Hard Coatings, Surf. Coat. Technol., 2020, 389, p 125637

J. Jin, H. Duan, and X. Li, The Influence of Plasma Nitriding on Microstructure and Properties of CrN and CrNiN Coatings on Ti6Al4V by Magnetron Sputtering, Vacuum, 2017, 136, p 112–120

K. Dejun and Z. Shouyu, Atomic Force Microscopy Analysis of Cathodic Arc Ion-Plated CrN and CrC Coatings, J. Coat. Technol. Res., 2018, 15(4), p 781–787

B. Warcholiński, A. Gilewicz, Z. Kukliński, and P. Myśliński, Arc-Evaporated CrN, CrN and CrCN Coatings, Vacuum, 2008, 83(4), p 715–718

A. Gilewicz, P. Chmielewska, D. Murzynski, E. Dobruchowska, and B. Warcholinski, Corrosion Resistance of CrN and CrCN/CrN Coatings Deposited Using Cathodic Arc Evaporation in Ringer’s and Hank’s Solutions, Surf. Coat. Technol., 2016, 299, p 7–14

L. Jiang, X. Tan, T. Xiao, and P. Xiang, The Influence of Methane Flow Rate on Microstructure and Surface Morphology of a-SiC: H Thin Films Prepared by Plasma Enhanced Chemical Vapor Deposition Technique, Thin Solid Films, 2017, 622, p 71–77

Z. Liu and Z. Wang, Effect of Substrate Preset Temperature on Crystal Growth and Microstructure Formation in Laser Powder Deposition of Single-Crystal Superalloy, J. Mater. Sci. Technol., 2018, 34(11), p 2116–2124

Z. Zhang, C. Bao, W. Yao, S. Ma, L. Zhang, and S. Hou, Influence of Deposition Temperature on the Crystallinity of Al-doped ZnO Thin Films at Glass Substrates Prepared by RF Magnetron Sputtering Method, Superlattice. Microst., 2011, 49(6), p 644–653

Acknowledgments

This work was supported by the National Natural Science Foundation of China (Grant Nos. 51505399 and 51975496), the Natural Science Foundation of Fujian Province of China (Grant No. 2017J05088) and Jiangsu Key Laboratory of Precision and Micro-Manufacturing Technology.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, T., Mu, C., Zhao, G. et al. Preparation of CrCN Super-Hard Coating. J. of Materi Eng and Perform 29, 7872–7882 (2020). https://doi.org/10.1007/s11665-020-05304-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-05304-9