Article contents

Influence of load orientations with respect to twin boundaries on the deformation behaviors of high-entropy alloy nanocrystals

Published online by Cambridge University Press: 12 November 2020

Abstract

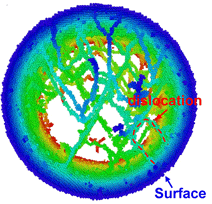

The orientation between twin boundary (TB) and loading direction may play an intriguing role in the deformation behaviors of twinned metallic materials. In this aspect, its essential effect on the high-entropy alloy (HEA) nanocrystals is elusive. Attention herein is focused on the atomic-scaled deformation mechanisms and fracture behaviors of HEA nanocrystals containing twins of even smaller spacings via a combined approach of in situ tensile tests inside a high-resolution transmission electron microscope and molecular dynamics simulations. The results indicate that the deformation mechanisms (especially dislocation activities) of HEA nanocrystals depend on the load orientation with respect to TBs. Because of the low activation energy and uneven local composition of HEA, the surface acts as an effective dislocation source and, together with Schmid factor, dominate the activated dislocation slip system. The load orientation-dependent TB-dislocation interactions may transform the type of fracture from semi-brittle to ductile. Our results indicate that the deformation mechanisms and the types of fracture in HEA nanocrystals can be controlled by changing the orientation.

- Type

- Article

- Information

- Copyright

- Copyright © The Author(s), 2020, published on behalf of Materials Research Society by Cambridge University Press

Footnotes

These authors contributed equally to this work.

The nanotwinned materials attract extensive attention because of their exceptional combination of high strength and ductility. The deep understanding of the role of twin will bring advances to design new strong and ductile materials. The orientation between twin boundary (TB) and loading direction plays an intriguing role in the deformation behaviors. In this work, we use a novel method, in situ transmission electron microscope (TEM) melting, to produce nanotwin with special load/TB orientation. The strong load/TB orientation dependences of deformation mechanisms and fracture modes are revealed via in situ TEM strain and molecular dynamics simulations. The free surface together with Schmid factor dominate the activated dislocation slip system. This work points out an alternative route in designing advanced twin-induced-plasticity materials by controlling load/TB orientations.

References

- 8

- Cited by