Abstract

Waste selective catalytic reduction (SCR) catalysts are potential environmental hazards. In this study, the recovery of vanadium and tungsten from waste SCR catalysts by K2CO3 roasting and water leaching was investigated. The roasting and leaching conditions were optimized: the leaching efficiencies of vanadium and tungsten were 91.19% and 85.36%, respectively, when 18 equivalents of K2CO3 were added to perform the roasting at 900 °C for 2 h, followed by leaching at 90 °C for 1 h. Notably, in the described conditions, the leaching rate of silicon was only 28.55%. Titanates, including K2Ti6O13 and KTi8O17, were also produced. Si removal was achieved in 85% efficiency adjusting the pH to 9.5, and the Si impurity thus isolated was composed of amorphous Si. Tungsten and vanadium were precipitated using CaCl2. At pH 10 and following the addition of 0.10 mol of H2O2 and 16 equivalents of CaCl2, the precipitating efficiencies of tungsten and vanadium were 96.89% and 99.65%, respectively. The overall yield of tungsten and vanadium was 82.71% and 90.87%, respectively.

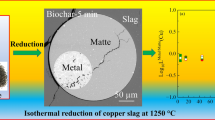

Graphic abstract

Similar content being viewed by others

1 Introduction

Nitrogen oxide (NOx) emissions can trigger environmentally hazardous phenomena like photochemical smog and haze (Du et al. 2011; Thomas 1997). Therefore, in recent years environmental laws on NOx emissions have become increasingly strict in China. Due to its high efficiency and selectivity, the selective catalytic reduction (SCR) of NOx by ammonia to produce water and molecular nitrogen is the most popular approach to cutting NOx emissions (Forzatti 2001). The key component of SCR systems is the catalyst, which plays a fundamental role in the conversion of NOx to N2. The V2O5–WO3/TiO2 catalyst in NH3-SCR is widespread used in coal-fired power plants, as a result of the high activity of this catalyst and its tolerance to SO2 (Baiker et al. 1992; Wang et al. 2019).

However, the lifespan of V2O5–WO3/TiO2 catalyst is limited by the activity of toxic substances present in flue gas, such as SO2, K2O, CaO, As2O3, and HgO (Kong et al. 2015; Li et al. 2016a, b; Li et al. 2018; Nicosia et al. 2007; Qi et al. 2017; Xu et al. 2017; Zhang et al. 2014). After several regenerations, these catalysts have been observed to become unable to catalyze NOx SCR (Huo et al. 2015; Wu et al. 2016). Notably, waste catalysts contain leachable hazardous metals, a trait that contributes to environmental concerns associated with their storage and disposal (Imtiaz et al. 2015). The hazardous metal-based species present in SCR catalysts, such as WO3, V2O5, As2O3, and HgO, are known to be harmful to the environment and human health. On the other hand, the metals in waste catalysts are valuable (Wu et al. 2018), so recovery of such metals from the spent catalysts is a prime environmental and economic objective.

The recovery of vanadium (V) and tungsten (W) from waste catalysts has been studied by several methods, including acid leaching, sodium hydroxide leaching, and salt roasting followed by leaching with water. Some researchers have used a range of acids to separate V from waste catalysts (Li et al. 2014). Li et al. (2016a) compared the separation efficiency of V afforded by several acids. Results from this study indicated the order of leaching ability of the various acids to be hydrochloric acid > oxalic acid > sulfuric acid > nitric acid. However, the leaching efficiency of V as made possible by acids is limited, and, applying the relevant approach, V is found in solution as a complex mixture of species. Therefore, investigating V recovery from solution is a very difficult undertaking and no further research on precipitating vanadium-containing species from acid solutions was conducted. Many researchers have shown interest in sodium hydroxide leaching. Kim et al. (2015) found that the leaching efficiency of W and V can reach values of 99.9% and 86.6%, respectively, at high temperature and pressure. Other researchers obtained similar results at atmospheric pressure (Huo et al. 2015; Wu et al. 2016). However, large amounts of hydroxides were observed to be needed in these studies. Unfortunately, excessive concentrations of sodium hydroxide in solution proved harmful to the reaction equipment and to further research about purify valuable metals.

Salt roasting followed by water leaching is another approach to W and V recovery from SCR catalysts. Na2CO3 and NaCl used to be widely employed as leaching agents in metallurgy (Shi et al. 2011; Zhao et al. 2016). Since NaCl roasting causes the release of harmful gas, researchers prefer to use Na2CO3 as leaching agent in the extraction of W and V from waste SCR catalysts. The leaching efficiency of W and V by Na2CO3 roasting and water leaching has been found to be considerable (Choi et al. 2018a). However, the leaching efficiency of silicon (Si) in waste catalyst was neglected, and few researchers pay attention to the leaching efficiency of Si in the roasting and leaching process. Importantly, the presence of Si in solution was found to negatively influence the efficacy of the subsequent steps, such as precipitation valuable metals W or V.

K2CO3 has been observed to easily react with W, V, and Si and other elements (Al, Ca and so on)and some of silicates (like CaSiO3, KAlSiO8) were insoluble (Eliasson et al. 2007; Mu and Su 2009). As a result of the fact that the amount of Si and a bit of Alin waste catalyst were substantial, and it was larger than that of valuable metals(Choi et al. 2018a), the K2CO3 roasting method was put forward to reduce the amount of leached Si. And the more insoluble aluminosilicate was expected. In fact, the potassium titanate obtained following K2CO3 roasting is widely used, for instance, as insulation and electrical insulation material (Cao et al. 2019; Li et al. 2019), rendering it more valuable than sodium titanate. In the present study the conditions for the recovery of vanadium and tungsten from waste SCR catalysts by way of K2CO3 roasting and water leachingwere investigated. Notably, some soluble Si compounds were inevitably generated as part of the said recovery process; therefore, a procedure to remove Si from solution was also needed. Since the silicic acid precipitation or silicic acid gelatine were generated with acid added, the pH of the solution was adjusted with acid to cause these Si compounds to precipitate. Subsequently, in order to maximize the amount of recovered metals, CaCl2 was added to the filtered solution to prompt the precipitation of the desired W and V compounds.

2 Materials and methods

2.1 Materials and analytical instrumentation

2.1.1 Waste SCR catalyst

The spent commercial honeycomb monolith catalyst was collected from a coal-fired power plant in China. The catalyst was purged to remove the fly ash present on its surface. The catalyst was then mashed to under 149 μm in size in advance of the experiments described below. The powders were dried in an oven at 95 °C for 24 h. A 0.1 g sample of waste catalyst was digested using a mixture consisting of 10 mL of HNO3, 2 mL of HF, and 2 mL of H2O2; the digested material was then analyzed by inductively coupled plasma-atomic emission spectroscopy. The waste catalyst investigated in this study includes elements Ti, V, Si, and W, each present in a weight ratio of 46.97%, 0.58%, 4.23%, and 3.21%, respectively. The X-ray diffraction (XRD) pattern of the waste catalyst is reported in Fig. 1. The main phase of the waste catalyst was anatase TiO2, with no obvious phases of other ingredients, due to their low contents (Choi et al. 2018a).

2.1.2 Chemicals and analytical instrumentation

K2CO3, CaCl2, and hydrogen peroxide were of analytical reagent grade and were provided by Beijing Chemical Industry. Hydrochloric acid, nitric acid, hydrofluoric acid of analytical reagent grade were provided by Sinopharm Chemical Reagent Co., Ltd. Structural investigations of crystalline phases were conducted by XRD (X’Pert Pro, Holland). The concentrations of V, W, and Si in solution were determined using an inductively coupled plasma-atomic emission spectrometer (Prodigy 7, USA). The particle morphology of the leaching residue was investigated using a scanning electron microscope (SU8020, Japan).

2.2 Experimental procedures

2.2.1 Roasting and leaching experiments

A series of samples prepared pooling together a variable amount of K2CO3 and a fixed amount of waste catalyst were mixed for 0.5 h in a corundum crucible. The obtained mixtures were placed in a muffle furnace and roasted under the desired conditions at ambient atmosphere. The product thus obtained was allowed to cool to room temperature. It was then mixed with a fixed amount of deionized water (300 mL) in a glass beaker after milled under 149 μm. The beaker was then covered, and its contents were stirred with a magnetic stirrer at the certain leaching conditions. The mixture was then filtered, and the residue was washed with deionized water. The filter residue was dried, whereas the filtrate was collected to determine its V, W, and Si contents. After optimizing the roasting and leaching conditions, the filtrate obtained implementing the optimal roasting conditions was collected and used in subsequent experiments. The XRD patterns of the roasted products were collected, and scanning electron microscopy (SEM) images of the TiO2 leaching residue were recorded and inspected.

2.2.2 Si removal

Since the presence of large amounts of Si in solution is not conducive to the precipitation of W and V compounds, the pH of the filtrate was adjusted to a certain value with dilute hydrochloric acid to trigger the precipitation of silicon compounds. In detail, the mixture was kept at room temperature after the pH reached a value of 9.0. Subsequently, the sediment containing the Si-based impurity was filtered, and its XRD pattern was recorded.

2.2.3 Precipitation of W and V compounds

After silicon removal, CaCl2 was added to the solution to afford the recovery of W and V. The solution containing W and V was stirred in a polytetrafluoroethylene beaker. The pH of the solution was adjusted to a certain value with a sodium hydroxide solution. Various amounts of a H2O2 solution (mass ratio: 30%) and solid CaCl2 were added in the beaker. After the mixture was kept in the beaker at 90 °C for 1 h, it was filtered. The filter residue contained precipitates of W and V compounds.

3 Results and discussion

3.1 Roasting and leaching

3.1.1 Effect of the roasting temperature on V, W, and Si leaching efficiency

As a result of the roasting process, V2O5 and WO3 present in the spent catalyst were expected to generate the water-soluble KVO3 and K2WO4. The relevant chemical reactions are reported below. The amount of K2CO3 to be added was calculated based on the stoichiometry of the reactions described by Eqs. (1) and (2), disregarding any reaction between K2CO3 and other catalyst components.

The effect of the roasting temperature was initially investigated adding 14 equivalents of K2CO3 and performing the roasting process over 2 h. Subsequently, water leaching was conducted at 90 °C for 1 h. Data reflecting the leaching efficiency of V, W, and Si are reported in Fig. 2. In the present study, the leaching efficiency of V was higher than that of W, indicating that V extraction from the catalyst was easier to perform. As the calcination temperature increased from 600 to 900 °C, the leaching efficiency of V and W increased by 5% and 29%, respectively. By contrast, as the calcination temperature increased further to 1000 °C, the leaching efficiency of both V and W decreased. This observation may be due to the presence of Ca in the catalyst. In fact, at high roasting temperatures, the water-insoluble CaWOx and CaVOx may be generated (Choi et al. 2018a). Notably, the leaching rate of Si increased with the roasting temperature, with the leaching efficiency of Si displaying the opposite trend to V and W from 900 to 1000 °C. The presence of Si in the form of water-soluble compounds may negatively affect the extraction of W and V. At the roasting temperature of 900 °C, the leaching efficiency of W and V was 78.69% and 83.31%, respectively, whereas the leaching rate of Si was only 28.55%. Hence, at this roasting temperature, most Si remained in the filter residue. Evidence thus suggests that Si underwent complex reactions with other components of the spent catalyst or that a substantial proportion of Si-based compounds did not react with K2CO3. By contrast, most W and V were extracted selectively. Therefore, a roasting temperature 900 °C was utilized in the experiments that followed.

The XRD patterns of the filter residues obtained applying different roasting temperatures were also recorded. As can be evinced from Fig. 3, the intensity of the peak due to anatase TiO2 decreased as the roasting temperature increased. In fact, increasing amounts of titanates, like K2Ti6O13 and KTi8O17, formed as the roasting temperature increased. No obvious peaks attributable to compounds containing W and V were visible, due to their low abundance.

3.1.2 Effect of the relative amount of added K 2 CO 3 on V, W, and Si leaching efficiencies

The leaching process was carried out after varying amounts of K2CO3 had been added to the spent catalyst for sample roasting, which was performed at 900 °C for 2 h. The amount of added K2CO3 ranged from 8 to 20 equivalents, based on Eqs. (1) and (2). The other conditions were those described in Sect. 3.1.1. The data in Fig. 4 indicate that the leaching efficiency of V, W, and Si increased as the amount of added K2CO3 increased from 8 to 18 equivalents. Importantly, sufficiently high amounts of K2CO3 can inhibit the formation of calcium vanadate (Xing et al. 2010). However, the leaching rate of W decreased as the amount of added K2CO3 increased from 18 to 20 equivalents, whereas the leaching efficiency of V remained constant. Notably, increases in the amount of added K2CO3 favored Si leaching from the SCR catalyst, which in turn would make the solution thick and sticky. Considering leaching efficiency and material cost, we decided to add 18 equivalents of K2CO3 to the SCR catalyst in subsequent experiments.

The XRD patterns of the filter residues are reported in Fig. 5. Larger amounts of added K2CO3 favored the formation of titanates. Additionally, Ca(Si2O7)(OH)6 formed when 18 and 20 equivalents of K2CO3 were added, indicating that Ca and Si were activated in the described conditions. The lower leaching efficiency of Si was probably caused by Ca(Si2O7)(OH)6. Additionally, some CaWOx may be generated as Ca gets further activated, which might also negatively affect W leaching efficiency (Choi et al. 2018b). No obvious peaks due to anatase TiO2 were visible when the amount of added K2CO3 was higher than 14 equivalents.

3.1.3 Effect of roasting time on V, W, and Si leaching efficiency

The effect that applying different roasting times, from 1 to 5 h, had on V, W, and Si leaching efficiency was examined; the results of the relevant experiments are reported in Fig. 6. The importance of the roasting time has been evaluated in many studies. Herein, the leaching process was carried out in the following conditions: roasting temperature, 900 °C; leaching temperature, 90 °C; leaching time, 1 h.

The leaching efficiency of V and W increased as the calcination time increased from 1 to 2 h. As the calcination time was extended further, no effect was measured on W and V extraction efficiency. By contrast, the leaching efficiency of Si increased with the calcination time. The XRD patterns of the filter residues isolated after applying different roasting times are reported in Fig. 7, which indicated that the roasting time was helpless to change the crystal form of the filter residue. Therefore, a roasting time of 2 h was applied in the experiments that followed.

3.1.4 Effect of the leaching temperature on V, W, and Si leaching efficiency

Applying a suitable leaching temperature can cause increased amounts of metal ions to dissolve in water. Experiments were conducted whereby the leaching temperature was made to vary from 30 to 120 °C using an oil bath (Fig. 8). The rest of the experimental conditions were those described above. At leaching temperatures below 90 °C, the leaching efficiency of V and W was below 80%. V exists in various forms in aqueous solution which caused V was easily to leach out below 60 °C. However, V combines more easily than W with other elements, such as CaVOx and BaVOx (Cao et al. 2017; Choi et al. 2018b). Therefore, when the leaching temperature was above 60 °C, the leaching efficiency of W was observed to be higher than that of V. The leaching efficiency of V was 85.36% and that of W was 91.19% at a leaching temperature of 90 °C. As the leaching temperature rose above 90 °C, no obvious impact was observed on the leaching efficiency of V and W. Importantly, the leaching temperature also affected the extraction of Si from the catalyst. Considering the leaching efficiency of valuable metals and the cost of the procedure, a leaching temperature of 90 °C was utilized in subsequent experiments.

3.1.5 Effect of leaching time on V, W, and Si leaching efficiency

The effect of the leaching time was also investigated. Leaching experiments were conducted employing 30, 60, 90, 120, and 150 min as the leaching time. As can be evinced from Fig. 9, the leaching percentage of W and V significantly increased as the leaching time was extended from 30 to 90 min. At short leaching times, V leached out more promptly than W, given the multiple V-based species present in solution (Wu et al. 2018). Notably, W and V leaching efficiency did not change as the leaching time was extended over 90 min. By contrast, Si leaching efficiency did not markedly increase with the leaching time. The optimal leaching time for extracting W and V was thus determined to be 90 min.

3.1.6 SEM images of the leaching residue

As can be evinced from Fig. 10a, some rod structures as skeleton were not destroyed by K2CO3 treatment, which was one reason that most Si did not leach out. Si and Ca compounds present in the skeleton did not react with K2CO3, explaining why Ca presence did not negatively affect vanadium leaching efficiency. By contrast, potassium titanate whiskers, appearing as rod and stick structures in Fig. 10b, c, were observed, which may be applied to other fields.

3.2 Si removal

Silicon present in the spent SCR catalyst may not only produce the skeleton structure, but it may also inhibit TiO2 phase transition from the anatase to the rutile form (Hanaor and Sorrell 2011). Considering that Si present in solution may negatively affect W and V recovery, Si removal was performed adjusting the pH of the solution.

The leaching solution obtained after implementing the optimized roasting and leaching conditions was collected, and the W, V, and Si contents were measured. The solution pH was adjusted at this point, before centrifugal filtration. Data on the removal efficiency of W, V, and Si at different values of the solution pH are reported in Fig. 11. Evidence indicates that as the pH increased, the loss rate of W and V decreased.

At pH 9.5, the removal rate of Si was 85.19%, whereas the loss rate of W and V was under 5%. The XRD pattern of the Si impurity indicated that Si was amorphous and that some KCl had separated out (Fig. 12). Notably, Si was present in ions state with the solution at pH > 13, whereas H2SiO3 or H4SiO4 formed at lower pH values.

3.3 Precipitation of W and V

3.3.1 Effect of the pH on W and V precipitation rates

A waste SCR catalyst leaching experiment was conducted implementing the optimized conditions for roasting, leaching, and impurity removal. The solutions containing W and V thus obtained were then pooled together, and the resulting liquid sample was subdivided into several aliquots of equal volume. The W and V concentrations in the pooled solution were 7.13 mg/mL and 1.26 mg/mL, respectively. Notably, at this point W and V are expected to precipitate from solution in the form of CaWO4 and Ca(VO3)2, respectively. The recycled CaWO4 could be the feed material for W-related products (Martins et al. 2007).

The amount of CaCl2 to be added to the solution to prompt W and V precipitation was calculated based on the reactions described by Eqs. (3) and (4). In particular, 10 equivalents of CaCl2 were added on the basis of the theoretical reaction stoichiometries.

The pH of the filtrate after Si removal, a parameter affecting the precipitation rates of W and V, was about 9. The precipitation reaction was conducted in a beaker at 90 °C for 1 h. The effect on W and V precipitation of the pH of the filtrate before precipitation was investigated. The data in Fig. 13 indicate that the proportions of W and V ions that precipitated increased as solution pH increased from 8.0 to 10.0. Moreover, the precipitation efficiency of W and V did not show any obvious changes as the pH increased further above 10. Notably, Ca(OH)2 forms at around pH 11.0, and the presence of this compound is known to have no positive effect on W and V precipitation (Choi et al. 2018a).

3.3.2 Effect of H 2 O 2 addition on the precipitation rate of W and V

CaWO4 is known not to be produced in solution from low-valence W ions, and complex mixtures of Ca–V salts have been observed to be produced from solutions containing V ions of different valence (Wu et al. 2018). Considering that low-valence W and V ions may appear in the solution obtained after Si removal, it was necessary to oxidize low-valence W and V ions to high valence. The addition of H2O2 to the filtrate was investigated for this purpose. Results from the relevant experiments (Fig. 14) indicated that H2O2 addition was necessary to maximize W and V precipitation. The precipitate efficiency of W and V improved by 6.6% and 15.0%, respectively, when 0.10 mol of H2O2 was added to the filtrate. Notably, H2O2 addition may contribute to the transformation of different W and V-based species into a single one.

3.3.3 Effect of adding different amounts of CaCl 2 on the precipitation rate of W and V

The precipitation efficiency of W and V was limited, so the effect of adding varying amounts of CaCl2 to the filtrate obtained after Si removal was also investigated. The results of the relevant experiments indicate that W and V precipitation efficiency improved as the amount of added CaCl2 increased. As can be evinced from Fig. 15, W and V precipitation efficiency reached 96.89% and 99.65%, respectively, when 16 equivalents of CaCl2 were added. The addition of this relative amount of CaCl2 was thus considered optimal for the experiment.

4 Conclusions

A K2CO3 roasting and water leaching protocol for the recovery of V and W from waste SCR catalysts was developed and optimized in the present study. The best conditions for the roasting stage were as follows: roasting time, 2 h; roasting temperature, 900 °C; equivalents of added K2CO3, 18. On the other hand, the optimal conditions for the leaching process consisted of a leaching time of 1 h and a leaching temperature of 90 °C. The leaching efficiency of W and V reached values of 85.36% and 91.19%, respectively, under optimal roasting and leaching conditions; by contrast, the leaching efficiency of Si was below 28.55% in the described conditions. Notably, Si removal efficiency reached 85% as the solution pH was adjusted to 9.5. CaCl2 was used to precipitate W and V from solution after Si removal. The effects on W and V precipitation efficiency of the pH of the solution before precipitation and of adding H2O2 to the said solution were investigated. Precipitation efficiency reached values of 96.89% and 99.65% for W and V, respectively, when the pH of the solution obtained after Si removal was adjusted to 10, before 0.10 mol of H2O2 and 16 equivalents of CaCl2 were added to the said solution. The overall yield of W and V was 82.71% and 90.87%. Finally, XRD and SEM analyses of the residue obtained after carrying out the leaching procedure indicated this residue consists mainly of potassium titanate whiskers.

Data availability

All the data were collected in the experiments.

Code availability

Not applicable.

References

Baiker A, Handy B, Nickl J, Schraml-Marth M, Wokaun A (1992) Selective catalytic reduction of nitric oxide over vanadia grafted on titania. Influence of vanadia loading on structural and catalytic properties of catalysts. Catal Lett 1(14):89–99

Cao ZM, Wang N, Xie W, Qiao ZY, Jung IH (2017) Critical evaluation and thermodynamic assessment of the MgO–V2O5 and CaO–V2O5 systems in air. Calphad 56:72–79

Cao KZ, Liu HQ, Li WY, Xu CX, Han QQ, Zhang Z, Jiao LF (2019) K2Ti6O13 nanorods for potassium-ion battery anodes. J Electroanal Chem 841:51–55

Choi IH, Kim HR, Moon G, Jyothi RK, Lee JY (2018) Spent V2O5–WO3/TiO2 catalyst processing for valuable metals by soda roasting-water leaching. Hydrometallurgy 175:292–299

Choi IH, Moon G, Lee JY, Jyothi RK (2018) Hydrometallurgical processing of spent selective catalytic reduction (SCR) catalyst for recovery of tungsten. Hydrometallurgy 178:137–145

Du HH, Kong LD, Cheng TT, Chen JM, Du JF, Li L, Xia XG, Leng CP, Huang GH (2011) Insights into summertime haze pollution events over Shanghai based on online water-soluble ionic composition of aerosols. Atmos Environ 29(45):5131–5137

Eliasson E, Hooey PL, Annersten H, Lindblom B (2007) Formation of potassium slag in olivine fluxed blast furnace pellets. Ironmak Steelmak 34(5):422–430

Forzatti P (2001) Present status and perspectives in de-NOx SCR catalysis. Appl Catal A-General 1(222):221–236

Hanaor DAH, Sorrell CC (2011) Review of the anatase to rutile phase transformation. J Mater Sci 4(46):855–874

Huo YT, Chang ZD, Li WJ, Liu SX, Dong B (2015) Reuse and valorization of vanadium and tungsten from waste V2O5–WO3/TiO2 SCR catalyst. Waste Biomass Valoriz 2(6):159–165

Imtiaz M, Rizwan MS, Xiong SL, Li HL, Ashraf M, Shahzad SM, Shahzad M, Rizwan M, Tu SX (2015) Vanadium, recent advancements and research prospects: a review. Environ Int 80:79–88

Kim JW, Lee WG, Hwang IS, Lee JY, Han C (2015) Recovery of tungsten from spent selective catalytic reduction catalysts by pressure leaching. J Ind Eng Chem 28:73–77

Kong M, Liu QC, Wang XQ, Ren S, Yang J, Zhao D, Xi WC, Yao L (2015) Performance impact and poisoning mechanism of arsenic over commercial V2O5–WO3/TiO2 SCR catalyst. Catal Commun 72:121–126

Li QC, Liu ZY, Liu QY (2014) Kinetics of vanadium leaching from a spent industrial V2O5/TiO2 Catalyst by sulfuric acid. Ind Eng Chem Res 8(53):2956–2962

Li LC, Wang L, Zhao XJ, Qian Q, Song SS, Li XB (2016a) Comparison of effect of different acid treatments on vanadium extration of waste deNOx catalyst. Chin J Nonferrous Met 10(26):2230–2237

Li X, Li XS, Chen JJ, Li JH, Hao JM (2016b) An efficient novel regeneration method for Ca-poisoning V2O5–WO3/TiO2 catalyst. Catal Commun 87:45–48

Li M, Liu B, Wang XR, Yu XB, Zheng SL, Du H, Dreisinger D, Zhang Y (2018) A promising approach to recover a spent SCR catalyst: deactivation by arsenic and alkaline metals and catalyst regeneration. Chem Eng J 342:1–8

Li JC, Duan B, Li JL, Ruan Z, Gao T, Fang Z, Li GD, Zhai PC, Chen G (2019) Substantial enhancement of mechanical properties for SnSe based composites with potassium titanate whiskers. J Mater Sci-Mater Electron 9(30):8502–8507

Martins JI, Lima JLFC, Moreira A, Costa SC (2007) Tungsten recovery from alkaline leach solutions as synthetic scheelite. Hydrometallurgy 2(85):110–115

Mu ZY, Su J (2009) Study of comprehensive utilization of potassium slate (part B). Light Met 4:11–13

Nicosia D, Elsener M, Kroecher O, Jansohn P (2007) Basic investigation of the chemical deactivation of V2O5–WO3/TiO2 SCR catalysts by potassium, calcium, and phosphate. Top Catal 1–4(42–43):333–336

Qi CP, Bao WJ, Wang LG, Li HQ, Wu WF (2017) Study of the V2O5–WO3/TiO2 catalyst synthesized from waste catalyst on selective catalytic reduction of NOx by NH3. Catalysis 7(4):110–123

Shi LH, Wang XW, Wang MY, Peng J, Xiao CX (2011) Extraction of molybdenum from high-impurity ferromolybdenum by roasting with Na2CO3 and CaO and leaching with water. Hydrometallurgy 3–4(108):214–219

Thomas KM (1997) The release of nitrogen oxides during char combustion. Fuel 6(76):457–473

Wang LL, Su S, Qing MX, Dai ZJ, Sun ZJ, Liu LJ, Wang Y, Hu S, Xu K, Xiang J (2019) Melting solidification and leaching behaviors of V/As during co-combustion of the spent SCR catalyst with coal. Fuel 252:164–171

Wu WC, Tsai TY, Shen HY (2016) Tungsten recovery from spent SCR catalyst using alkaline leaching and ion exchange. Minerals 4(6):107–117

Wu WF, Wang CY, Bao WJ, Li HQ (2018) Selective reduction leaching of vanadium and iron by oxalic acid from spent V2O5–WO3/TiO2 catalyst. Hydrometallurgy 179:52–59

Xing LW, Zhuo Z, Hui SZ, Bin LX (2010) Leaching kinetics of calcium vanadate by Na2CO3 solution. Chin J Process Eng 3(10):548–553

Xu TF, Wu XD, Liu XS, Cao L, Lin QW, Weng D (2017) Effect of barium sulfate modification on the SO2 tolerance of V2O5/TiO2 catalyst for NH3-SCR reaction. J Environ Sci 57:110–117

Zhang L, Wang D, Liu Y, Kamasamudram K, Li JH, Epling W (2014) SO2 poisoning impact on the NH3-SCR reaction over a commercial Cu-SAPO-34 SCR catalyst. Appl Catal B-Environ 156:371–377

Zhao JM, Pan F, Liu HZ (2016) An environmental friendly Na2CO3-roasting decomposition strategy for the mixed rare earth concentrate. Sep Purif Technol 168:161–167

Acknowledgements

The authors gratefully acknowledge financial support from the Fundamental Research Funds for the Central Universities (2010YH14).

Author information

Authors and Affiliations

Contributions

The experiments and data analysis were conducted by Xianghui Liu. The manuscript was written by Xianghui Liu and Qiaowen Yang.

Corresponding author

Ethics declarations

Conflict of interest

No conflicts of interest between authors.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Liu, X., Yang, Q. Recovery of vanadium and tungsten from waste selective catalytic reduction catalysts by K2CO3 roasting and water leaching followed by CaCl2 precipitation. Int J Coal Sci Technol 8, 727–736 (2021). https://doi.org/10.1007/s40789-020-00377-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40789-020-00377-2