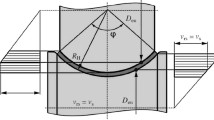

The advantages and disadvantages of single-radius roll-pass design for the production of longitudinally welded pipes of small (5–114 mm) and medium (114–480 mm) diameters in an electric-resistance welding pipe mill are discussed. Double-radius (MISiS) roll-pass design and roll-pass designs for forming the workpiece periphery with constant parameters in all the stands of the forming mill are presented. For these roll-pass designs, forming “flowers” are drawn, and the trajectories for fixed fibers of the workpiece and the longitudinal-strain fields are determined for a Dt × St ∅ 50 × 1.5 mm tube. The forming patterns are compared, and the effectiveness of the forming process is assessed. It is established that all the forming patterns produce workpieces of high quality; however, to improve the process, it is advisable to apply forming patterns with a descending middle fiber in the open-pass section of TESA 30-50 electric-resistance welding pipe mill.

Similar content being viewed by others

References

A. S. Budnikov, E. A. Kharitonov, A. S. Aleshchenko, and R. V. Iskhakov, “Effect of plugless deformation in screw rolling threeroll mill on the change of tube wall thickness,” Chernye Metally, No. 12, 41–45 (2019).

V. P. Romanenko, P. P. Stepanov, and S. M. Kriskovich, “Production of hollow railroad axles by screw piercing and radial forging,” Metallurgist, 61, No. 9–10, 873–877 (2018).

B. A. Romantsev, A. V. Goncharuk, A. S. Aleshchenko, A. B. Onuchin, and Y. V. Gamin, “Improving the regimes used for hotrolling tubes on mini tube-production unit 70-270,” Metallurgist, 59, No. 5–6, 386–389 (2015).

A. S. Aleshchenko, Y. V. Gamin, B. K. Chan, and V. Y. Tsyutsyura, “Wear features of working tools during piercing of hightemperature alloys,” Chernye Metally, No. 8, 63–70 (2018).

E. A. Kharitonov, V. P. Romanenko, and A. S. Budnikov, “Pipe behavior in a three-roller screw-rolling mill,” Steel in Transl., 44, No. 10, 769–772 (2014).

A. P. Kolikov and D. Y. Zvonarev, “Expansion of large-diameter welded pipe,” Steel in Transl., 47, No. 3, 210–212 (2017).

M. V. Kadach, A. N. Koshmin, Y. V. Gamin, and B. A. Romantsev, “Obtaining steel tubular items of variable cross-section along their length,” Chernye Metally, No. 4, 37–41 (2019).

V. Y. Osadchii, E. A. Gaas, D. Y. Zvonarev, and A. P. Kolikov, “Shaping of thick sheet in the production of welded large-diameter pipe,” Steel in Transl., 44, No. 5, 374–378 (2014).

A. P. Kolikov, D. Yu. Zvonarev, I. M. Taupek, and T. Yu. Sidorova, “Mathematical simulation of strip plastic deformation process in the whole technological stage of manufacture of large-diameter tubes,” Chernye Metally, 1, No. 7, 41–45 (2017).

S. V. Samusev, A. S. Aleshchenko, and V. A. Fadeev, “Simulation of the process of continuous forming of straight-seam welded pipes on the basis of Tesa 10-50 Trainer,” Izv. Chern. Metallurg., 61, No. 5, 378–384 (2018).

S. V. Samusev and V. A. Fadeev, “Studying the continuous forming of a tubular billet in TESA forming mills of different configurations,” Proizv. Prokata, No. 5, 3–8 (2019).

S. V. Samusev and V. A. Fadeev, “Analyzing the parameters of the bending zones of a strip in TESA 30-50 forming mill,” Kuzn.- Shtamp. Proizv. Obrab. Mater. Davlen., No. 3, 14–18 (2019).

B. Abeyrathna, B. Rolfe, P. Hodgson, and M. Weiss, “Local deformation in roll forming,” Int. J. Adv. Manufact. Technol., 88, No. 9–12, 2405–2415 (2017).

V. A. Rymov, P. I. Polukhin, and I. N. Potapov, Improving the Production of Welded Pipes [in Russian], Metallurgiya, Moscow (1983).

Yu. M. Matveev and Ya. L. Vatkin, Roll-Pass Design for Pipe Mills [in Russian], Metallurgiya, Moscow (1970).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, Vol. 64, No. 7, pp. 55–59, July, 2020.

Rights and permissions

About this article

Cite this article

Samusev, S.V., Fadeev, V.A. & Sidorova, T.Y. Development of Effective Roll-Pass Designs for Production of Longitudinally Welded Pipes of Small and Medium Diameters. Metallurgist 64, 658–664 (2020). https://doi.org/10.1007/s11015-020-01042-4

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-020-01042-4