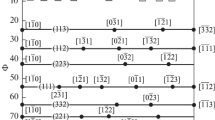

Results are provided for a study of the effect of different microalloying systems (Nb, Nb–V, V–N) on structure formation and mechanical properties of rolled product of strength class K52 produced by combined technology of melting, casting of thin slabs 90 mm thick, and direct rolling with subsequent accelerated cooling and winding on a coil. It is shown that all of the micro-alloying versions selected provide the required strength properties, while metal microalloyed solely with niobium demonstrates the best brittle fracture resistance at low temperature. It is shown that addition of niobium to steel not only refines grain size in the metal matrix, but also changes ferrite morphology increasing the proportion of acicular ferrite, which improves steel cold resistance.

Similar content being viewed by others

References

Yu. I. Matrosov, D. A. Litvinenko, and S. A. Golovanenko, Steel for Main Gas Pipelines [in Russian], Metallurgiya, Moscow (1989).

L. I. Éfron, Materials Science in Large Metallurgy. Pipe Steels [in Russian] Metallurgizdat, Moscow (2012).

Yu. D. Morozov, S. Yu. Nastich, M. Yu. Matrosov, et al., “Provision of an improved set of rolled product properties for large diameter pipes on the basis of forming a steel ferrite-bainite microstructure,” Metallurg, No. 1, 41–46 (2008).

I. P. Shabalov, Yu. D. Morozov, and L. I. Éfron, Steel for Pipes and Building Structures with Increased Operating properties [in Russian], Metallurgizdat, Moscow (2003).

M. I. Gol’dshtein and V. M. Farber, Steel Precipitation Hardening [in Russian], Metallurgiya, Moscow (1979).

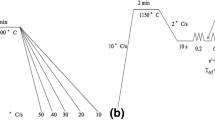

V. V Naumenko, O. A. Bagmet, A. V. Muntin, et al., “Casting and rolling unit; microalloying of pipe steels for producing coldresistant coiled rolled product,” in: Development of Production Technology for Steel Rolled Product and Pipes in the Vyksa Production Area, Coll. works (A. M. Barykov, editor), Metallurgizdat, Moscow (2016).

A. V. Chervonnyi, V. V. Naumenko, A. V. Muntin, et al., “Development of a microalloy system for producing cold-resistant coiled rolled product for pipe purposes under casting and rolling conditions,” Metallurg, No. 10, 38–44 (2016).

L. I. Éfron, V. V. Naumenko, A. V. Muntin, et al., “Effect of microalloying on the microstructure and mechanical properties of cold-rolled product produced under casting and rolling unit conditions,” in: Microalloyed Pipe Steels for the Oil and Gas Industry, Coll. Internat. Conf., Metallurgizdat, Moscow (2018).

A. V. Chervonnyi, V. V. Naumenko, A. V. Muntin, et al., “Microalloying of cold-resistant pipe steels for producing coiled rolled product in a casting an rolling unit,” Stal’, No. 9, 56–61 (2015).

V. V. Naumenko, O. A. Bagmet, and E. S. Mursenkov, “Basis of producing under casting and rolling unit conditions pipe coiled rolled product made from cold-resistant and hydrogen sulfide cracking resistant steels of the V-N microalloying system,” Metallurg, No. 2, 42–52 (2019).

F. Khaisterkamp, K. Khulka, Yu. I. Matrosov, et al., Niobium-Containing Low-Alloy Steels [in Russian], SP INTERMET INZhINIRING, Moscow (1999).

P. S. Mitchell, “Use of vanadium in high-strength steels,” Problems of producing and using steels with vanadium: Proc. Internat. Sci.-Tech. Seminar, URO RAN, Ekaterinburg (2007).

E. A. Goli-Oglu, “Production of thin rolled product up to 150 mm of structural steel microalloyed with vanadium,” Stal’, No. 8, 55–61 (2015).

V. V. Naumenko, “Microalloying with vanadium and nitrogen of low-carbon steels for pipe designation,” Byul. Chern. Met., No. 8, 69–73 (2017).

L. I. Éfron,V. I. Il’inskii, A. V. Golovanov, et al., “Metallurgical bases of obtaining cold-resistant pipe steels by high-temperature controlled rolling,” Stal’, No. 6, 69–72 (2003).

O. A. Bagmet, I. V. Ganoshenko, A. V. Chervonnyi, et al., “Production under casting and rolling unit conditions of coiled rolled product for pipes of strength category X70 without adding niobium,” Metallurg, No. 2, 46–53 (2016).

V. V. Naumenko, O. A Bagmet, O. S. Khlybov, et al., “Precipitation hardening of low-carbon microalloyed steels for pipe purposes with vanadium particles,” Stal’, No. 9, 54–59 (2019).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, Vol. 64, No. 8, pp. 28–35, August, 2020.

Rights and permissions

About this article

Cite this article

Naumenko, V.V., Bagmet, O.A., Matrosov, M.Y. et al. Study of the Effect of Microalloying on Microstructure and Mechanical Property Formation for Rolled Product of Strength Class K52 Produced Under CRU Conditions. Metallurgist 64, 759–769 (2020). https://doi.org/10.1007/s11015-020-01052-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-020-01052-2